AEREX Reco-Boxx 750 ZXR Troubleshooting guide

www.aerex.de© AEREX March – 2021

Operation and maintenance instructions

Operation and maintenance instructions

Reco-Boxx ZXR / ZXA / Flat

2www.aerex.de

Reco-Boxx ZXR / ZXA / Flat – Operation and maintenance instructions [03/

2021

]

Table of content

1.0 Operation and maintenance instructions ..................................................................................................... 3

2.0 Basic safety instructions .............................................................................................................................. 4

2.1 Intended use ........................................................................................................................................ 4

2.2 Specialist installer qualifications .......................................................................................................... 4

2.3 Non-intended use ................................................................................................................................ 4

2.4 Safety instructions ............................................................................................................................... 5

3.0 Symbols and abbreviations .......................................................................................................................... 8

4.0 Product overview ......................................................................................................................................... 9

4.1 General overview .................................................................................................................................. 9

4.2 Air volumes and dimensions Reco-Boxx ZXR / Flat-H ........................................................................ 11

5.0 Wiring overview ............................................................................................................................................ 12

5.1 Main control board TAC5 DG ............................................................................................................... 12

5.1.1 Reco-Boxx with counterflow ZXR / ZXA and Flat ..................................................................... 12

5.2 Circuit board SAT3 ............................................................................................................................... 14

5.3 Circuit board SAT BA/KW .................................................................................................................... 13

6.0 Functions ................................................................................................................................................... 14

6.1 Operating mode ................................................................................................................................... 14

6.2 Temperature control ............................................................................................................................. 15

6.3 Free cooling .......................................................................................................................................... 15

6.4 Change over function ........................................................................................................................... 16

6.5 Frost protection .................................................................................................................................... 17

6.6 Time schedule ...................................................................................................................................... 18

7.0 Commissioning ............................................................................................................................................. 19

7.1 Commissioning with Touchscreen TP-Touch ........................................................................................ 20

7.1.1 Home screen ............................................................................................................................. 21

7.1.2 Main menu ................................................................................................................................ 22

7.1.3 Basic Setup ............................................................................................................................... 24

7.1.4 Advanced setup ........................................................................................................................ 27

8.0 Preventive maintenance ................................................................................................................................ 34

8.1 Once the unit operates in normal condition ......................................................................................... 34

8.2 Every 3 months ..................................................................................................................................... 34

8.3 Every 12 months ................................................................................................................................... 35

9.0 Troubleshooting ............................................................................................................................................ 36

9.1 Troubleshooting .................................................................................................................................... 36

…

9.22 Troubleshooting .................................................................................................................................... 50

10.0 Parameters/Commissioning Sheet ............................................................................................................... 51

10.1 Main parameters after commissioning ................................................................................................. 51

10.2 Track changes ....................................................................................................................................... 52

3www.aerex.de

Reco-Boxx ZXR / ZXA / Flat – Operation and maintenance instructions [03/

2021

]

1.0 Operation and maintenance instructions

Applicable for the following units

Exchanger Sizes Integrated

pre-heating

Integrated

post-heating Handing Fan

Reco-Boxx ZXR

Counterflow

1000/1600/1800/2300/

2700/2900/3200/4200/

4700/6200/7000

Yes, electrical Yes, electrical

or water Left / Right Backward

(BW)

Reco-Boxx ZXA

Counterflow

900/1500/1900/

2500/2800/3700 Yes, electrical Yes, electrical

or water Left / Right Backward

(BW)

Reco-Boxx Flat-H

Counterflow

550/650/1000/1400/1700/

2100/2500/2700/3300/3700 Yes, electrical Yes, electrical

or water Left / Right Backward

(BW)

Reco-Boxx Flat

Counterflow

450/600/1000/

1300/1600/2000 Yes, electrical No Left / Right Forward

(FW)

4www.aerex.de

Reco-Boxx ZXR / ZXA / Flat – Operation and maintenance instructions [03/

2021

]

2.0 Basic safety instructions

2.1 Intended use

This ventilation unit with heat recovery is used in

centralised or decentralised ventilation systems.

The unit provides controlled ventilation and air

extraction in, for example, oces, school class-

rooms and other similar spaces. The units are

intended for ceiling-mounted installation because

they have outside air/outgoing air sockets on

the sides and/or discharging upwards. Please

note that the unit is very heavy, weighing approx.

210kg. The unit may only be used if installed

permanently, in dry indoor spaces and with

connected ventilation ducts. DN 250 connection

for geniovent.x 600 H and DN 315 connection

for geniovent.x 900 H. The units do not have unit

switches. Scope for completely disconnecting

the unit from the power supply should be pro-

vided by the customer. These ventilation units

are only intended for domestic use and similar

purposes. No other or additional use is intended.

2.2 Specialist installer qualifications

The ventilation unit may only be installed, set up,

retrofitted, started up, cleaned and maintained

by a trained specialist in accordance with these

instructions. You are deemed a trained spe-

cialist if your education, training or experience

in ventilation technology mean that you can

competently and safely undertake installation in

accordance with the planning requirements and

these instructions and are able to recognise and

avoid risks resulting from incorrect installations

and settings and the dangers resulting from

them. Only a qualified electrician is permitted to

work on the electrics. You are deemed a qualified

electrician if you are familiar with the relevant

standards and guidelines, can competently and

safely create electrical connections in line with

the attached wiring diagram and are able to

recognise and avoid risks and dangers associat-

ed with electricity on the basis of your technical

training and experience. Repair work may only be

undertaken by an authorised AEREX specialist.

After successful installation and commissioning,

instruct users in the ventilation unit and associat-

ed control unit.

2.3 Non-intended use

The ventilation unit must not be used in the fol-

lowing situations under any circumstances. Read

all the safety instructions.

Risk of combustion/fire from flammable ma-

terials, liquids or gases in the vicinity of the

ventilation unit. Do not place any flammable ma-

terials, liquids or gases near the ventilation unit,

which may ignite in the event of heat or sparks

and catch fire.

Risk of death if an air-ventilated fireplace is

connected to an exhaust gas system, which

itself has multiple connections. The air-venti-

lated fireplace may result in exhaust fumes being

transferred to other living units. Risk of death, for

example from carbon monoxide. Never use the

ventilation unit if there are air-ventilated fireplaces

in the living unit that are connected to exhaust

gas systems, which themselves have multiple

connections.

Explosion hazard. Explosive gases and dust

may ignite and cause serious explosions or fire.

Never use ventilation unit in an explosive atmos-

phere.

Explosion hazard. Explosive substances in lab

extraction units may ignite and cause serious

explosions or fire. Aggressive substances may

damage the ventilation unit. Never use ventilation

unit in combination with a lab extraction unit.

Risk to health from chemicals or aggressive

gases/vapours. Chemicals or aggressive gases/

vapours may present a risk to health, especially

if the ventilation unit distributes them into rooms.

Never use the ventilation unit to convey chemi-

cals or aggressive gases/vapours.

Damage to the unit.

• If operated during the build phase, potential

damage to unit caused by contamination of

the ventilation unit and ventilation ducts. Venti-

lation unit operation is not permitted during the

build phase

• Grease and oil vapours from range hoods may

contaminate the unit and ventilation ducts

and reduce eciency. Never use ventilation

unit in combination with range hoods, that are

connected directly to the controlled domestic

ventilation exhaust air channel. In rooms with

5www.aerex.de

Reco-Boxx ZXR / ZXA / Flat – Operation and maintenance instructions [03/

2021

]

greasy exhaust air, e.g. kitchens, only use

ventilation valves with a grease filter. Recom-

mendation: In terms of energy consumption,

use range hoods in circulating air mode.

• Corrosion of metal parts inside the ventilation

unit by additional components in the exhaust

duct. Do not use components which aect

temperature, humidity or air volumes on the

exhaust duct, for example if a drying cabinet is

connected to the exhaust duct.

2.4 Safety instructions

Read and observe all the safety instructions.

Risks for those who are not trained spe-

cialists, children and persons with reduced

physical, sensory or mental capabilities or a

lack of knowledge. Ventilation unit may only be

installed, commissioned, cleaned and maintained

by persons who can safely recognise and avoid

the risks associated with this work.

Risk to health if filters are not replaced or if

there are no air filters. Heavily soiled or moist

air filters can accumulate harmful substances

(mould, germs, etc.). This may also happen if the

ventilation unit is shut down for an extended pe-

riod. If there are no air filters, the ventilation unit

and ventilation ducts become dirty. Unfiltered

substances may enter the rooms.

• Never operate ventilation unit without air filters.

• Only use original filters.

• Recommendation: continuous operation.

• Observe filter change display. Change the air

filter every 6 months.

• If the ventilation unit has not been used for a

long time, always replace the air filters.

Risk to health if ventilation unit is not correct-

ly cleaned/maintained.

Clean/service the ventilation unit regularly, at

least every 2 years. This is the only way of ensur-

ing that the ventilation unit is running hygienically.

Risk of death from toxic air and air containing

pollutants (smoke, vapours) in the surround-

ing area – in the event of a fire or chemicals

accident etc. Switch the entire ventilation sys-

tem o immediately until the outside air is safe

again.

Risk during transport from heavy or falling

loads.

• Observe applicable safety and accident pre-

vention requirements.

• Note permissible maximum loading capacity of

lifting gear.

• Do not stand under a suspended load.

• Exercise caution when lifting. Note transport

weight (ventilation unit 210 kg) and centre of

gravity of ventilation unit (centre).

• Only transport ventilation unit to installation

site using suitable means of transport (e.g.

a lifting fixture) and with the help of several

people.

• Check unit for transport damage. Do not com-

mission a damaged unit.

Risk from inadequate load-bearing capacity of

the base/ceiling construction. Only install ven-

tilation unit on a base/ceiling construction with an

installation/attachment surface with an adequate

load-bearing capacity (at least 300 kg/m²).

Risk of injury from handling pointed housing

parts or those with sharp edges, e.g. on hous-

ing panels, railings, mounting feet or pointed

parts of front doors. Wear protective gloves.

Risk of injury if work is carried out by unquali-

fied sta. Specialist knowledge is needed for the

safe transport, installation, electrical connection

and commissioning of the ventilation unit. Only

have this work carried out by a specialist installer

or qualified electrician.

Risk of injury when working at heights.

Risk of injury when working at heights. Use ap-

propriate climbing aids (ladders). Stability should

be ensured, if necessary have the ladders stead-

ied by a 2nd person. Ensure that you are stand-

ing securely and cannot lose your balance and

that there is no one under the ventilation unit.

Danger of injury from damaged ventilation

unit. Switch the ventilation unit o immediately if

you discover damage or faults that could endan-

ger persons or property. Prevent further use until

the issue has been fully rectified.

Intended operation not ensured if installed in-

correctly. A ventilation unit not installed correctly

may result in operation not as intended.

6www.aerex.de

Reco-Boxx ZXR / ZXA / Flat – Operation and maintenance instructions [03/

2021

]

• Only install ventilation unit in accordance with

the planning documents.

• In particular, note the information on insulating

ventilation channels and sound deadening.

Recommendation: Use tubular sound absorber

for sound-deadened installation of ventilation

unit.

Risks from parts which may aect the ventila-

tion system which are added or modified at a

later date.

• Parts (range hood, air-ventilated fireplace etc.)

which are added or modified at a later date

may result in health risks and operation which

is not permitted.

• Parts may only be added or modified at a later

date if system compatibility is established/en-

sured by a planning oce. If using an exhaust

air range hood or air-ventilated fireplace, this

must be accepted by a regional master chim-

ney sweep.

Risk from operating with ventilation unit not

fully installed (open unit / without ventilation

ducts).

• Running fans can be touched. Electric compo-

nents are a potential source of electric shock.

Danger of burning on units with a heat register.

• If the ventilation unit is open, all the supply

circuits must be switched o (mains fuse o),

secured against being accidentally switched

back on and a visible warning sign must be

attached.

• Only operate ventilation unit if fully installed, if

all ventilation ducts are attached and the front

doors are closed.

• Do not reach into running fans.

• The heat register and/or protective grilles

of the heat register may be very hot. Before

touching, check whether heat registers and/or

protective grilles are still hot. Do not touch hot

surfaces.

Risk of injury if unit components (heat reg-

ister, heat exchanger etc.) fall down during

removal. Sometimes these can be hard to pull

out/slide in.

• Ensure that you are standing securely and

cannot lose your balance and that there is no

one under the unit.

• When removing and installing the components,

support them from below with a hand.

Risk of injury and health risk when using

accessory elements which have not been

approved.

The ventilation unit is tested with original ac-

cessories and components (e.g. air filter, heat

register, heat exchanger).

• The unit may only be operated with original

components.

• Modifications and alterations to units are not

permitted and release the manufacturer from

any guarantee obligations and liability.

Danger of electric shock.

Before opening the front doors and installing

the electrics, switch o all supply circuits and

secure them against being accidentally switched

back on again. Attach a warning sign in a clearly

visible place.

Danger if the relevant regulations for electri-

cal installations are not observed.

• Before removing the electronics cover and

installing the electrics, switch o all supply cir-

cuits and secure them against being acciden-

tally switched back on again. Attach a warning

sign in a clearly visible place.

• Be sure to observe the relevant regulations for

electrical installation; e.g. DIN EN 50110-1. In

Germany, particularly observe VDE 0100, with

the corresponding sections.

• A mains isolation device with contact openings

of at least 3 mm at each pole is mandatory.

• Only connect the ventilation unit to a perma-

nent electrical installation.

• Units may only be operated using the voltage

and frequency shown on the rating plate.

Damage to unit in the event of moisture in-

gress.

The ventilation unit has IP 40 degree of protec-

tion.

• Do not install ventilation unit outdoors.

• Protect ventilation unit from moisture and

wetness

Exercise caution when handling packaging

materials.

Store packaging material out of the reach of

children.

7www.aerex.de

Reco-Boxx ZXR / ZXA / Flat – Operation and maintenance instructions [03/

2021

]

Risk of death when operating with air-ventilat-

ed fireplaces. Ensure sucient supply air intake

during operation with air-ventilated fireplaces.

Note maximum permissible pressure dierence

per residential unit. The consent of a professional

chimney sweep is needed in all cases. Ventilation

units may only be installed in rooms, apartments

or housing units of a comparable size, in which

air-ventilated fireplaces are installed if:

• a parallel operation of air-ventilated fireplaces

for liquid or gaseous fuels and the air-extract-

ing equipment can be prevented via safety

devices, or

• the extraction of exhaust gas from the air-ven-

tilated fireplaces is monitored by a special

safety device. In the case of air-ventilated fire-

places for liquid or gaseous fuels, the fireplace

or the ventilation system must be switched

o if the safety device is triggered. In the case

of air-ventilated fireplaces for solid fuels, the

ventilation system must be switched o if the

safety device is triggered. In order to permit

the intended operation of ventilation systems

equipped with the central ventilation units with

heat recovery, it must be possible to shut o

any combustion air ducts or exhaust gas ducts

from air-ventilated fireplaces. For exhaust gas

ducts of fireplaces for solid fuels, the shut-o

device may only be operated by hand. It must

be possible to identify the position of the shut-

o device from the setting of the operating

handle. This is considered to be fulfilled if a

soot blocking device is deployed.

8www.aerex.de

Reco-Boxx ZXR / ZXA / Flat – Operation and maintenance instructions [03/

2021

]

3.0 Symbols and abbreviations

BW BACKWARD

CURVED FAN FW FORWARD

CURVED FAN

BF BAG FILTER PF PLEATED FILTER

RX REDARY HEAT

EXCHANGER PX PLATE HEAT

EXCHANGER

WARNING

Must be connected by a qualified Electrician.

Warning! Hazardous voltage.

OUTDOOR AIR Air from outdoor to the AHU

SUPPLY AIR Air from the AHU to the building

EXTRACT AIR Air from the building to the AHU

EXHAUST AIR Air from the AHU to outdoor

COOLING COIL BA-

NV / KW HEATING COIL

(WATER/ELECTRICAL)

SILENCER GD CTm MOTORISED

DAMPER

PRESSURE SENSOR P Tx TEMPERATURE SENSOR

No = x (1,2,3…)

SLIP CLAMP SC MS FLEXIBLE

CONNECTION

CIRCULAR DUCT CONNECTION ER For inlet SR For outlet

9www.aerex.de

Reco-Boxx ZXR / ZXA / Flat – Operation and maintenance instructions [03/

2021

]

4.0 Product overview

4.1 General overview

ATTENTION

Right and left hand units have dierent article numbers and should be ordered accordingly.

Main version described in the manuals is always the hand right version.

Right hand unit (supply air to the right) Left hand unit (supply air to the left)

Reco-Boxx ZXR-R Reco-Boxx ZXR-L

Reco-Boxx Flat-H-R (BOTTOM view) Reco-Boxx Flat-H-L (BOTTOM view)

Außenluft

Abluft

Zuluft

Fortluft Rechtsversion Linksversion

Außenluft

Abluft

Zuluft

Fortluft Rechtsversion Linksversion

Reco-Boxx ZXA-R 900/1500/1900 Reco-Boxx ZXA-L 900/1500/1900

Außenluft

Abluft

Zuluft

Fortluft Rechtsversion Linksversion

Außenluft

Abluft

Zuluft

Fortluft Rechtsversion Linksversion

Reco-Boxx ZXA-R 2500/2800/3700 Reco-Boxx ZXA-L 2500/2800/3700

ATTENTION: The dierence between left and right LP units is the factory placement of the controls box on

opposite sides.

10 www.aerex.de

Reco-Boxx ZXR / ZXA / Flat – Operation and maintenance instructions [03/

2021

]

Reco-Boxx ZXR

Reco-Boxx Flat-H

Reco-Boxx ZXA

Note: internal electrical coils, motorised dampers, internal fan-pressure sensors, flexible connections

and slip-clamps must ordered and are all pre-installed and factory wired. The internal heating

water-coil accessory is pre-installed, but must be connected, hydraulically and electrically, by the

installer.

1. Main switch for power supply AHU

2. Main switch for power supply electrical coils

(both internal pre-hating and post-heating)

3. Electrical cabinet

4. Supply fan

5. Extract fan

6. DDM-Set for CA-airflow measurement (option)

7. Outdoor air filter (bag or pleated)

8. Extract air filter (bag or pleated)

9. Heat exchanger

10. Modulating 100% bypass

11. Drain pan and drain pipe

12. Preheating coil (accessory for

Counterflow-equipments)

13. Internal post-heating water or electrical coil

(accessory)

14. Motorised damper (accessory)

15. Motorised damper (accessory))

16. Access panel (Flat only)

17. Flexible sleeve (accessory)

18. Slip clamp (accessory)

19. Water connection for post-heating (accessory)

11www.aerex.de

Reco-Boxx ZXR / ZXA / Flat – Operation and maintenance instructions [03/

2021

]

4.2 Air volumes and dimensions

Exchanger Volumetric

flow

[m³/h]

Pressure

reserve

[Pa]

Dimensions

(B x H x T)

[mm]

Duct

connection

[mm]

Automatic

Bypass valve

Pre / post

heating

inte-

grable

External,

optional

heating and / or

cooling register

controllable

Reco-Boxx 750 ZXR 200 – 800 800 – 190 1680 x 1465 x 610 DN 315 0 – 100% modulating YES YES

Reco-Boxx 1000 ZXR 200 – 1050 800 – 390 1680 x 1465 x 610 DN 315 0 – 100% modulating YES YES

Reco-Boxx 1300 ZXR 200 – 1380 830 – 420 1680 x 1465 x 815 DN 400 0 – 100% modulating YES YES

Reco-Boxx 1600 ZXR 200 – 1680 830 – 210 1680 x 1465 x 815 DN 400 0 – 100% modulating YES YES

Reco-Boxx 1800 ZXR 250 – 1860 690 – 200 1680 x 1465 x 995 DN 400 0 – 100% modulating YES YES

Reco-Boxx 2300 ZXR 400 – 2300 800 – 420 1680 x 1465 x 1182 1060 x 540 0– 100% modulating YES YES

Reco-Boxx 2700 ZXR 400 – 2800 800 – 240 1680 x 1465 x 1182 1060 x 540 0– 100% modulating YES YES

Reco-Boxx 2900 ZXR 300 – 3000 800 – 230 1680 x 1465 x 1382 1265 x 540 0– 100% modulating YES YES

Reco-Boxx 3200 ZXR 300 – 3230 770 – 200 1680 x 1465 x 1640 1520 x 540 0– 100% modulating YES YES

Reco-Boxx 4200 ZXR 300 – 4200 901 – 290 1880 x 1465 x 2015 1895 x 540 0– 100% modulating YES YES

Reco-Boxx 4700 ZXR 600 – 4700 1000 – 210 2557 x 1825 x 1640 1520 x 670 0– 100% modulating YES YES

Reco-Boxx 6200 ZXR 600 – 6260 890 – 300 2557 x 1825 x 2015 1895 x 670 0– 100% modulating YES YES

Reco-Boxx 7000 ZXR 600 – 7000 880 – 220 2557 x 1825 x 2396 2275 x 670 0– 100% modulating YES YES

Exchanger Volumetric

flow

[m³/h]

Pressure

reserve

[Pa]

Dimensions

(B x H x T)

[mm]

Duct connection

[mm]

Automatic

Bypass valve

Pre / post

heating

inte-

grable

External,

optional

heating and / or

cooling register

controllable

Reco-Boxx 550 Flat-H 100 – 550 1010 – 210 1300 x 350 x 890 DN 200 0 – 100% modulating YES YES

Reco-Boxx 650 Flat-H 100 – 650 1020 – 180 1300 x 350 x 1100 DN 250 0 – 100% modulating YES YES

Reco-Boxx 1000 Flat-H 200 – 1000 800 – 460 2100 x 435 x 1050 DN 315 0 – 100% modulating YES YES

Reco-Boxx 1400 Flat-H 400 – 1400 760 – 320 2100 x 435 x 1300 DN 315 0 – 100% modulating YES YES

Reco-Boxx 1700 Flat-H 400 – 1800 610 – 220 2100 x 435 x 1600

Connection on the suction

side (AU/AB): 800 x 300

Connection on the pressure

side (ZU/FO): 400 x 300

0– 100% modulating YES YES

Reco-Boxx 2100 Flat-H 400 – 2200 610 – 180 2250 x 510 x 1700

Connection on the suction

side (AU/AB): 800 x 400

Connection on the pressure

side (ZU/FO): 500 x 400

0– 100% modulating YES YES

Reco-Boxx 2500 Flat-H 400 – 2550 810 – 270 2250 x 510 x 1700

Connection on the suction

side (AU/AB): 800 x 400

Connection on the pressure

side (ZU/FO): 500 x 400

0– 100% modulating YES YES

Reco-Boxx 2700 Flat-H 400 – 2850 810 – 200 2250 x 510 x 1940

Connection on the suction

side (AU/AB): 1000 x 400

Connection on the pressure

side (ZU/FO): 500 x 400

0– 100% modulating YES YES

Reco-Boxx 3300 Flat-H 400 – 3300 770 – 230 2800 x 660 x 1935 Connection on the suction

side (AU/AB): 700 x 500

Connection on the pressure

side (ZU/FO): 700 x 500

0– 100% modulating YES YES

Reco-Boxx 3700 Flat-H 400 – 3700 1020 – 360 2800 x 660 x 1935 Connection on the suction

side (AU/AB): 700 x 500

Connection on the pressure

side (ZU/FO): 700 x 500

0– 100% modulating YES YES

Exchanger Volumetric

flow

[m³/h]

Pressure

reserve

[Pa]

Dimensions

(B x H x T)

[mm]

Duct

connection

[mm]

Automatic

Bypass valve

Pre / post

heating

inte-

grable

External,

optional

heating and / or

cooling register

controllable

Reco-Boxx 900 ZXA 200 – 940 380 – 790 1680 x 1465 x 610 DN 250 0 – 100% modulating YES YES

Reco-Boxx 1500 ZXA 200 – 1500 300 – 840 1680 x 1465 x 815 DN 315 0 – 100% modulating YES YES

Reco-Boxx 1900 ZXA 300 – 1900 300 – 810 1960 x 1725 x 815 DN 315 0 – 100% modulating YES YES

Reco-Boxx 2500 ZXA 300 – 2550 280 – 800 1960 x 1725 x 995 500 x 300 0 – 100% modulating YES YES

Reco-Boxx 2800 ZXA 300 – 2850 250 – 850 1960 x 1725 x 1182 600 x 300 0 – 100% modulating YES YES

Reco-Boxx 3700 ZXA 400 – 3700 360 – 980 1960 x 1725 x 1382 800 x 300 0 – 100% modulating YES YES

12 www.aerex.de

Reco-Boxx ZXR / ZXA / Flat – Operation and maintenance instructions [03/

2021

]

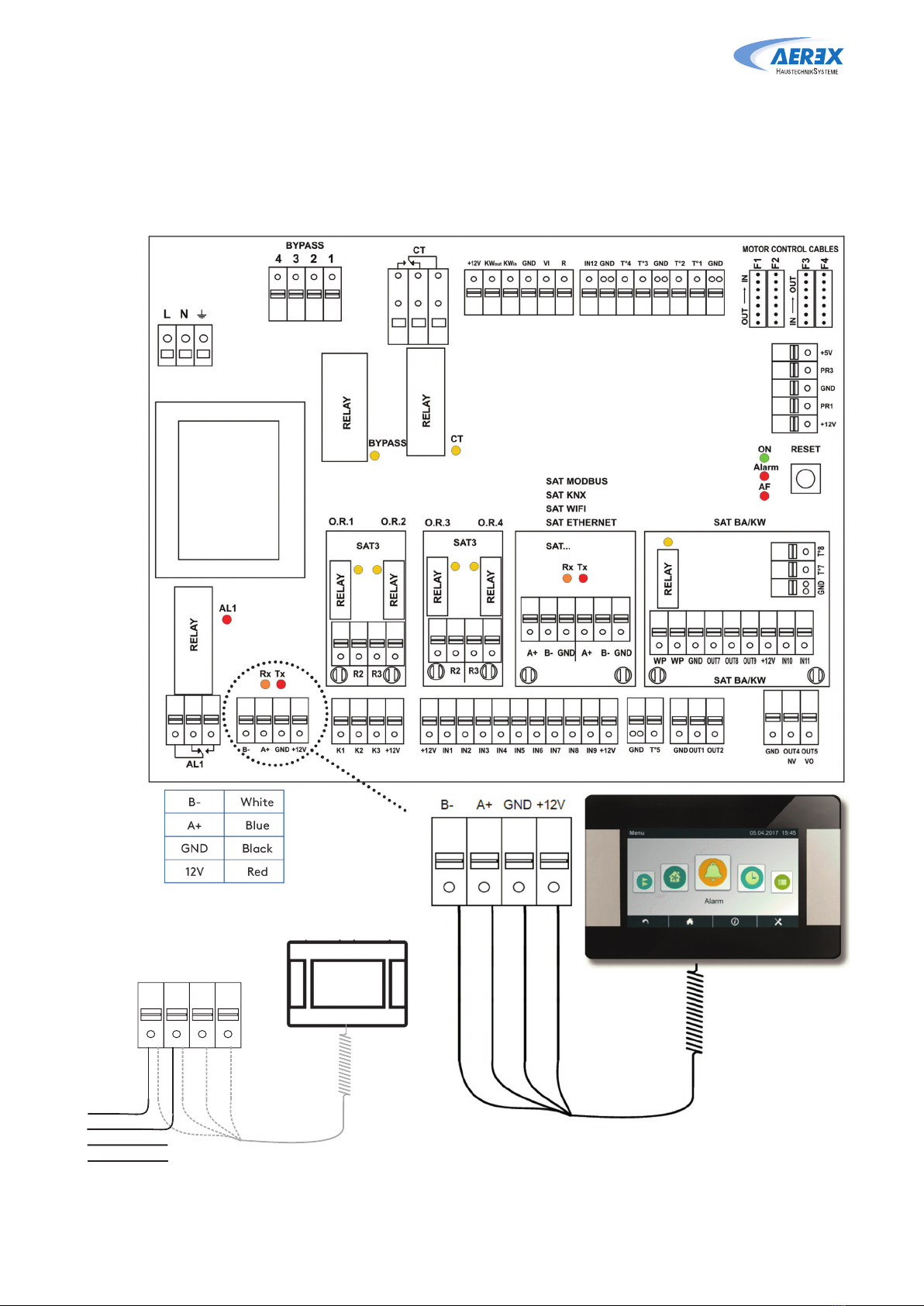

Wiring

The cables used must conform to the RS-485 Standard with twisted pair conductors. The cables must be

shielded. Conductor Area 0.2 mm². The total length must not exceed 100 meters.

Electrical cable: Installers need to foresee extra electrical cable length for easier future maintenance of the AHU.

TAC5 DT

CID 026001

S: 2.8.2

(und höher)

TAC5 DG

CID 026000

S: 2.7.0

(und höher)

LN

F3

F4

F1

F2

MOTORCONTROL CABLES

OUT IN

NITUO

OUT2

OUT1

GND

Alarm

ON

AF

AL1

AL1

RELAY

K1 K2 K3

+12V

IN1+12V IN2 IN3 IN4IN5 +12VIN6 IN7IN8 IN9

BYPASS

RELAY

CT

RELAY

xRxT

B- A+ GND

+12V

GNDT°5

BYPASS

43 21 CT

O.R.1O.R.2 O.R.3O.R.4

GNDOUT4OUT5

NV VO

GNDGNDT°1T°4T°3 GNDT°2

KWout

KW

in

+12V

VIGND

SAT BA/KW

SATMODBUS

+5V

PR3

GND

PR1

+12V

RESET

IN12

R

RELAY

B- A+ GND

+12V

TAC5DT/DG

Red

Black

White

Blue

Blue,Bleu,Blauw,Blau

B-

A+

Black,Noir,Zwart,Schwar

z

GND

Red,Rouge,Rood,Rot 12V

If DDM-Set present: -SiprésenceduDDM-Set:

Wenn das DDM-Setvohanden ist:

White,Blanc,Witte,Weiß

B- A+ GND

+12V

DDM-Set

Green

Red

Black

Yellow

GND

+24V/OUT5

Blue,Bleu,Blauw,Blau

B-

A+

Black,Noir,Zwart,Schwar

z

GND

Red,Rouge,Rood,Rot 12V

White,Blanc,Witte,Weiß

+12V

F2

NITUO

MOTORCONTROL CABLES

LN

R1

RELAY

SATCOM

SAT BA/KW

SAT3

O.R.1 O.R.2

RESET

ON

Alarm

AF

BYPASS

SETUP ENTER

DISPLAY

GND T°1T°2 T°3GNDT°5 GND +12V K1 K2 K3 +12VIN1 IN2 IN3 IN4

PR1 GND PR2 +5V

F1

IN

OUT

R

A+

B-

+12V

TAC5DM

Red

Black

White

Blue

If DDM-Set present: -SiprésenceduDDM-Set:

Wenn das DDM-Setvohanden ist:

DDM-Set

Green

Red

Black

Yellow

GND

+24V/OUT5

GND

A+

B-

+12V

GND

A+

B-

+12V

Touchpanel

Touchpanel

Touchpanel

Touchpanel

5.0 Wiring overview

5.1 Main control board TAC5

5.1.1 Reco-Boxx with counterflow ZXR / ZXA and Flat

13www.aerex.de

Reco-Boxx ZXR / ZXA / Flat – Operation and maintenance instructions [03/

2021

]

5.2 Circuit board SAT3

The SAT3 circuit board is used for extra functions for

which inputs and outputs are not included as standard

in the control unit of the air handling unit. All outputs

are normally open (N.O.). Maximal load: 230VAC – 4A.

The circuit board SAT3 allows for signalling of the

following by means of a potential-free contact: (fig. 2)

• Fan status

• Dierential pressure alarm

• Heating demand

• Bypass status

Installation

SAT3 must be plugged onto the control board circuit

(see fig.1).

Attention: The SAT3 must be plugged in before

the circuit is powered. SAT must be plugged in

correctly, wrong positioning can damage both

circuits permanently.

5.3 Circuit board SAT BA/KW

SAT TAC5 BA/KW is a satellite circuit designed to be fitted

on the main control board. It permits control of external

coils.

Installation

The SAT BA/KW must be plugged onto the control board

circuit (see fig.3).

Attention: The SAT TAC5 BA/KW must be

plugged in before the circuit is powered. SAT

must be plugged in correctly, wrong positioning

can damage both circuits permanently.

Wiring

The terminals of the SAT BA/KW are displayed in fig.4

WP WP = Cooling demand (max. 30 V-2 A)

OUT7 = 0-10 V output to control heating- or change over capacity

OUT8 = 0-10 V output to control cooling capacity

OUT9 = PWM output to control electrical coil

T°7 = Heating coil frost protection sensor (T7)

T°8 = Cooling coil frost protection sensor (T8)

IN10 = Cooling OFF, (to force heating o use IN6)

IN11 = Input cooling/heating (open = heating, closed = cooling)

fig. 1

fig. 2

fig. 3

fig. 4

14 www.aerex.de

Reco-Boxx ZXR / ZXA / Flat – Operation and maintenance instructions [03/

2021

]

6.0 Functions

6.1 Operating mode

There are five main operating modes. The operating mode determines how the airflow or the fan torque is

modulated. The default operating mode is Airflow control. Exceptions are units equipped with backwards

fans without the Constant Air Kit or if Constant Torque mode has been selected in the product setup menu,

in both cases it is the fan torque that will be controlled and modulated.

In all the operating modes, the supply fan(s) will operate as per the assigned mode and parameters. The

exhaust fan(s) will operate according to the chosen percentage of the supply fan (%EXH/SUP ratio). The five

main operating modes are:

• 1 - Airflow control:

Flow control involves operating the air handling unit to keep the pre-set airflow constant. The speed of

the fans is automatically regulated to provide correct airflow even if the filters begin to become clogged,

air terminals are blocked, etc. Airflow control mode is advantageous, since the airflow always is exactly

as it was from the beginning. It should however be noted that everything that increases the pressure drop

in the ventilation system, such as blocking of air terminals and dust accumulating in filters, causes the

fans to run at a higher speed. This results in higher power consumption and may also cause discomfort

in the form of noise. There are three airflow setpoints to be configured by the user (m³h K1, m³h K2, m³h

K3).

• 2 - Torque control:

3 torque setpoints to be configured by the user (%TQ K1, %TQ K2, %TQ K3). The setpoint is configured

in % of the maximal torque. The torque control allows to vary the fan speed automatically, to provide a

variable airflow for demand controlled systems (DCV). This allows for demand controlled fan operation or

fan optimisation by a BMS system, mostly used in multi zone systems. This operation mode can partially

replace the constant pressure control when a duct pressure sensor hasn’t been installed.

• 3 - Demand control 0-10V:

The airflow is controlled by a 0-10 V signal. The control signal is connected to terminals K2&GND. The

assigned supply airflow is set as a percentage of a linear 0-10 V signal. The user defines the link with 4

parameters: Vmin, Vmax, m³h Vmin and m³h Vmax, applied to the following diagram. The demand control

mode is also available for modulating fan torque instead of airflow (relevant for backwards fans units

without Kit CA).

The principle is identical to the demand control mode operation with the dierence that Vmin and Vmax

are connected to a %TQ instead of m³/h.

• 4 - Pressure control:

The airflow automatically varies to provide constant pressure in the ducting system. This type of control is

also called VAV control (Variable Air Volume).

Pressure on supply: the airflow of the supply fan(s) is modulated to maintain a certain pressure Setting

constant. The pressure is measured by a pressure sensor located in the supply air duct.

Pressure on exhaust: the airflow of the exhaust fan(s) is modulated to maintain a certain pressure Setting

constant. The pressure is measured by a pressure sensor located in the extract air duct.

• 5 - MODE OFF:

This stops the AHU.

15www.aerex.de

Reco-Boxx ZXR / ZXA / Flat – Operation and maintenance instructions [03/

2021

]

6.2 Temperature control

There are several options available on Reco-Boxx units to ensure a comfortable temperature.

The options are controlled either via supply or extract air temperature.

Post heating options: Post cooling:

•internal electrical postheating coil EN (KWout) •external water cooling coil (BA-)

•internal water postheating coil WN (NV)

•external electrical postheating coil

•external water postheating coil (BA+)

Supply Air Temperature

Supply temperature control is the default setting. This involves keeping a constant supply air temperature

without consideration to the load in the premises. The supply air temperature is measured on sensor T5.

Extract Air Temperature

The default temperature control can be changed to Extract temperature control via the advanced setup.

The extract air temperature is measured on sensor T2. Extract air control involves keeping a constant

temperature in the extract air duct (premises), by controlling the supply air temperature. This provides a

uniform temperature in the premises regardless of the load. The internal sensor T2 can be replaced with

the optional external room temperature sensor.

Temperature sensor positioning:

Outside Inside

6.3 Free cooling

The free cooling function uses the lower temperature of the outside air to cool the building.

Free cooling is realized by means of the integrated 100% modulating bypass of the heat exchanger (PX)

or the stepless motor control of the rotary heat exchanger (RX). The optional output O.R.4 on the SAT3

relay indicates the position of the bypass. The contact will open if the bypass is fully closed, or close if

the bypass is fully or partially open.

The bypass (PX) or the rotary heat exchanger (RX) can be configured as on/o or modulating. This is con-

figured in ADVANCED SETUP. In modulating mode, the temperature is configured in the base setup and

the position of the bypass/stepless motor will modulate in order to maintain the setpoint. The free cooling

function is activated automatically.

An on/o bypass / stepless motor operates according to the logic below:

Free cooling STARTS if the following

conditions are TRUE:

•The outdoor temperature (sensor T1) is

lower than the extract air temperature

(sensor T2).

•The outdoor temperature (sensor T1) is

higher than 15°C.

•The extract air temperature (sensor T2) is

higher than 22°C.

Free cooling STOPS if one of the following

conditions is TRUE:

•The outdoor temperature (sensor T1) is

higher than the extract air temperature

(sensor T2).

•The outdoor temperature (sensor T1) is

lower than 14°C.

•The extract air temperature (sensor T2) is

lower than 20°C.

These Settings can be configured in ADVANCED SETUP

16 www.aerex.de

Reco-Boxx ZXR / ZXA / Flat – Operation and maintenance instructions [03/

2021

]

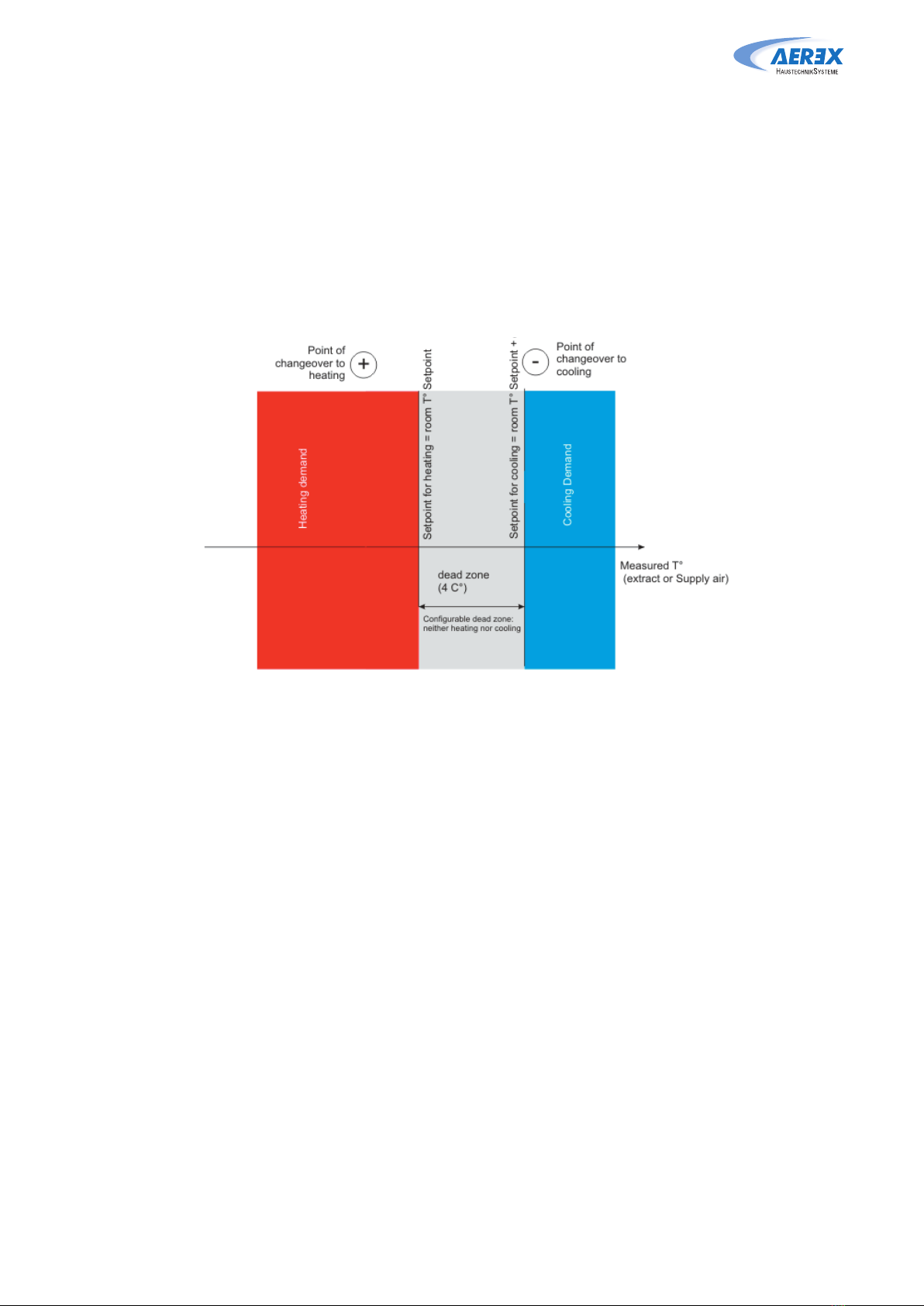

6.4 Change over function

4 PIPE AUTOMATIC CHANGE OVER

The TAC5 controller allows for the control of reversible coil or both cooling and heating coil. The coils are

equipped with their motorised 3-way valves. The oset between the measured temperature (supply air or

extract air, to be configured) and the setpoint will determine if heating or cooling is automatically acti-

vated. When the unit is equipped with reversible coil or with both a cooling and a heating coil, only one

setpoint has to be configured: Comfort temperature. The neutral band prevents the cooling and heating

systems from counteracting each other. The neutral band is added to the comfort setpoint for the activa-

tion of the cooling function. The neutral bands has to be configured in the advanced setup.

17www.aerex.de

Reco-Boxx ZXR / ZXA / Flat – Operation and maintenance instructions [03/

2021

]

6.5 Frost protection

HEATING COIL

The frost protection function is always active if the heating coil has been correctly configured in the

product setup. The monitoring function uses the temperature sensor T4 for the integrated coil (NV) or the

temperature sensor T7 for the external coil (EBA). The function is activated when the surface temperature

of the coil drops below 5°C. Under these conditions the pump output is activated and the three-way

valve output will be 100%. If after 15 minutes the surface temperature has not risen, the unit will shut

down and generate a frost alarm.

PLATE HEAT EXCHANGER (PX)

There are three strategies to protect the plate heat exchanger from freezing:

• 1 - Reduced supply air flow:

The heat exchanger is supplied with a frost protection sensor on the exhaust air (T3). If the exhaust air

temperature (T3) is >1°C and <+5°C:

• In airflow control mode and demand control, the supply air flow will modulate between 100% and

33% (AFlow)of the setpoint (AFn)

• pressure control mode, the supply air pressure will modulate between 100% and 50% (AFlow) of the

setpoint (AFn)

If the exhaust air temperature (T3) is <1°C, the supply air fans will stop until the exhaust air temperature

(T3) is >2°C for 5 minutes.

• 2 - Modulating bypass:

The modulating bypass is controlled by the exhaust temperature sensor (T3). If:

• Exhaust temperature (T3) >+1°C: bypass closed or controlled by free cooling function

• Exhaust temperature (T3) ≤ +1°C: bypass will modulate for the exhaust temperature (T3) to exceed

+1°C.

The corresponding supply air temperature will drop due to a lower airflow through the heat exchanger.

• 3 - Electrical preheating coil (accessory):

If an electrical pre-heating coil EV (KWin) is installed and configured, the pre-heating coil (KWin) will

modulate so the exhaust temperature is +1°C.

• 4 - Dierential pressure measurement (Cold climate option):

For cold climate conditions (≥-20⁰C), the unit is equipped with a dierential pressure sensor mounted

on the heat exchanger. The pressure sensor detects when the pressure drop, due to frost, has become

too high. In critical conditions, the supply air flow will be paused for a short time, to allow for defrost-

ing.

The frost protection strategy (down regulation supply airflow, modulating bypass or electrical pre-

heating) will still be used as a first step. The defrost function will only be active if the frost protection

strategy is not sucient.

These Settings can be configured in ADVANCED SETUP

18 www.aerex.de

Reco-Boxx ZXR / ZXA / Flat – Operation and maintenance instructions [03/

2021

]

6.6 Time schedule

The controller allows 6 time slots (channels) to be configured. For each day of the week, the operation

mode can be either AUTO (operate according to time slots) or OFF.

For each time slot select:

• In airflow control mode: the airflow by selecting m³h K1 / m³h K2 / m³h K3 / OFF (stop)

• In torque control mode: the torque by selecting %TQ K1 / %TQ K2 / %TQ K3 / OFF (stop)

• In demand control mode:

• with only one 0-10 V signal (default) or with 2 signals to control the supply airflow: the link LS

(percentage of the nominal link, cfr m³/h Vmin and m³/h Vmax in setup OR cfr %TQ Vmin and %TQ

Vmax in setup) and the rate of the exhaust airflow by the supply airflow.

• with one 0-10 V signal for supply and one 0-10 V signal for exhaust (via advanced setup): one link

LS (percentage of the nominal link) for supply and one for exhaust.

• In pressure control mode:

• Constant pressure on supply or exhaust: the pressure setpoint (percentage of the nominal setpoint)

and the rate of the exhaust airflow by the supply airflow.

• Constant pressure on supply and exhaust: one pressure setpoint (percentage of the nominal

setpoint) for supply and one for exhaust.

19www.aerex.de

Reco-Boxx ZXR / ZXA / Flat – Operation and maintenance instructions [03/

2021

]

7.0 Commissioning

As a human machine interface (HMI), several options are available. The HMI will enable access to the

control parameters in the integrated controller. The HMI as such does not contain any programming and

therefor is not mandatory.

The possible HMIs are:

Touchpanel TP-Touch

This 4.3” touchscreen display is used when there is

a need for a graphical HMI. The Touchscreen touch-

screen is a complete graphic monitoring system

where the screens are designed to be intuitive and

complete, ensuring a userfriendly experience.

Position switch PCOM4

The most basic interface to control a GLOBAL air

handling unit is the 4 position swich. This swith will

allow to control the unit to its three configured airflow

(low, medium and high) and as a fourth position, the

unit is switched o.

20 www.aerex.de

Reco-Boxx ZXR / ZXA / Flat – Operation and maintenance instructions [03/

2021

]

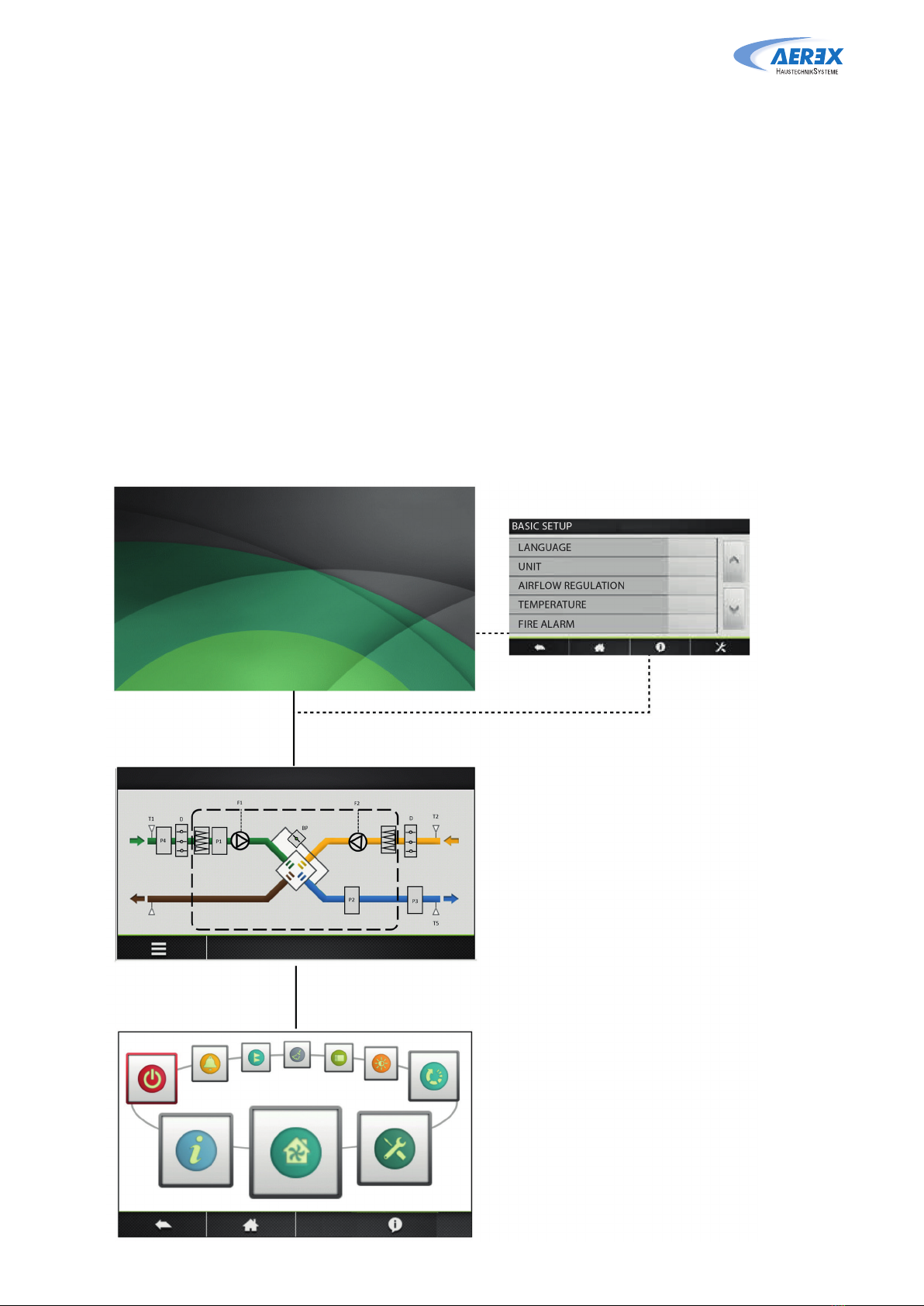

7.1 Commissioning with Touchscreen TP-Touch

The hand-held terminal consists of a 4.3” touch screen with a 1,5 metre long cable for connection to the

air handling unit’s control circuit board.

If the hand-held terminal is not used for 20 minutes, it switches over to the sleep mode.

The Touchscreen controller can be used outdoors, but it must be kept at a weatherproof place.

Data:

Operating temperature: 0... + 50°C

Maximum length of the cable: >100 metres

Protection class: IP20

Dimensions [mm]: 96,8x148,8x14,5

Power consumption: 120mA

Image management

Start-up image

At the first start up, the basic setup menu will be

activated automatically. See section 7.1.3

Home Screen. See Section 7.1.1

By default, the home screen will be shown if no

other menu is opened by the user or if selected

in the main menu.

N.B.! The appearance of the image varies

depending on the type of air handling unit and

functions selected.

Main menu. See Section 7.1.2

The main menu is presented as a rotary menu.

After pressing the “menu”-button at the bottom

left corner of the Home Screen, the rotary menu

will be shown.

This manual suits for next models

48

Table of contents

Other AEREX Fan manuals

Popular Fan manuals by other brands

Emerson

Emerson CF943 owner's manual

Mitsubishi Electric

Mitsubishi Electric VL-100ZSKRT-E operating instructions

Harbor Breeze

Harbor Breeze E-TM52BNK5LED installation guide

Deltafan

Deltafan Ex instruction manual

Sonnenkonig

Sonnenkonig CHROM 16 user manual

Continental Electric

Continental Electric CE29502 instruction manual

RadonAway

RadonAway RP SERIES installation instructions

Vornado

Vornado Zippi owner's guide

Viking Range

Viking Range RDIPR101R manual

Neostar Electronics

Neostar Electronics 3209575 instruction manual

Komfovent

Komfovent DOMEKT ReGO 200VE-B Installation and maintenance manual

Vornado

Vornado OSCR32 user manual