10

English

CRITERIA OF CHOICE

The versions with high cabinet (A, AS,

ACB, ACT and APC) have intake from

below and can be used for vertical wall-

hung or floor installation using the rele-

vant skirting (accessory ZX). The acces-

sory SE (external air damper) where

requested, also allows, to change the

environment air.

The versions with universal cabinet (U

and UE) have front intake and can be

vertically wall-hung or installed hori-

zontally on the ceiling.

The suspended versions (P, PPC, PO and

PE), without cover cabinets and intake

from below, are suitable for vertical or

horizontal installation.

In the case of ducted installations where

the loss of load of the channel is rele-

vant, the PO version (with multi-speed

enhanced motor) allows to obtain the

static pressure necessary to guarantee a

correct air flow rate.

The PO version is available with coils

with 3 and 4 rows.

The AS, U, UE versions require coupling

with a control panel to be applied insi-

de or outside, consult the features and

the compatibility of the control panels

supplied as accessories.

The P, PE and PO require coupling with

a control panel to be applied outside,

consult the features and the compati-

bility of the control panels supplied as

accessories.

The PPC version must be coupled to

panel PXA E.

The other versions of fan coil are sup-

plied with incorporated control panel.

Some control panels can control a net-

work of fan coils if they are combined

with the SIT3 and SIT5 interface board

supplied as an accessory.

In the versions without control

panels, the AERMEC fan coils can all

be coupled to the centralised HSH

AERDOMUS control system with wired

or wireless connection.

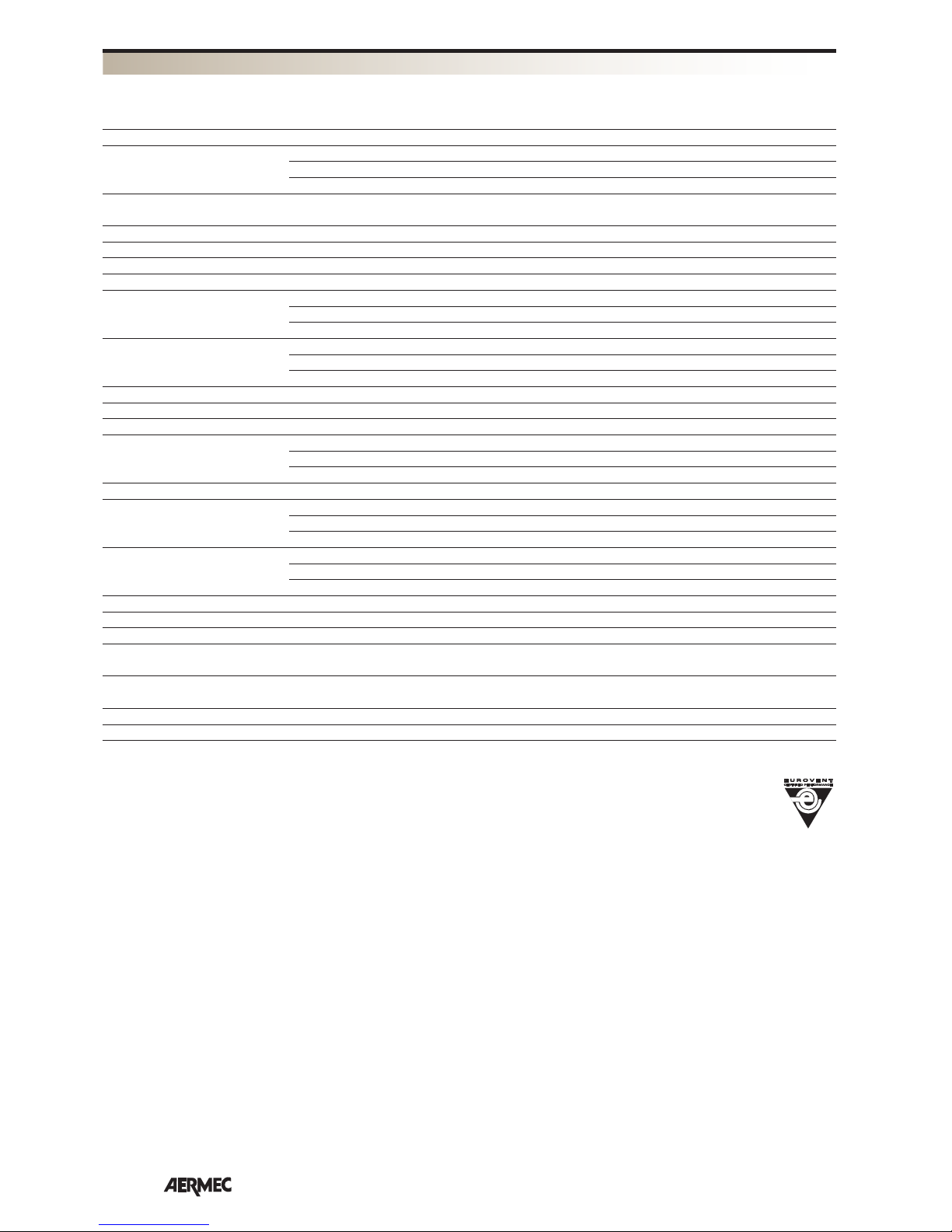

The main technical data of the FCX are

summarised in the tables.

The sensitive and total cooling capa-

city at maximum speed depending on

the temperature of the inlet water, its

heat drop and the dry and wet bulb

temperatures of the air respectively for

sensitive capacity and total capacity for

the versions with coils with 3 rows are

stated in the table. The efficiency at ave-

rage and minimum speed is obtained by

multiplying the table values by the cor-

rective factors indicate. For the versions

with 4 rows, they are obtained by multi-

plying the table values by the corrective

factors indicated for every speed.

The water side pressure drop for the

coils with 3, 1 and 4 rows is respective-

ly stated in the graphics.

The correction factors in functioning

with glycoled water in cooling mode

and in heating mode are stated in the

graphics per percentages of glycol of

10%, 20% and 35%.

The heating capacity of the coils with 3,

4 and 1 row (accessory BV) depending

on the water flow rate and the tempe-

rature difference between inlet water

and inlet air is stated in a graphical

form and is referred at maximum speed.

Performance at average and minimum

speed is obtained by multiplying the

values obtained from the graphics at

maximum speed by the indicated cor-

rective factors.

The sensitive and total cooling capaci-

ties of the direct expansion coils (FCX

PE) depending on the evaporation tem-

perature and the dry and wet bulb tem-

peratures of the air entering are stated in

the graphical form respectively for total

and sensitive capacity and are stated at

maximum speed. Performance at ave-

rage and minimum speed is obtained

by multiplying the values obtained from

the graphics at maximum speed by the

indicated corrective factors.

For the ducted, suspended versions

(P-PE-PO) the performance stated above

must be intended as referring to air flow

rates equal to those of corresponding

models of other versions (A-U) at maxi-

mum speed (nominal flow rate).

The head of the suspended versions,

depending on the air flow rate and fan

speed, are stated in table form. The cur-

ves are indicated for every speed.

For dimensioning of the ducted, suspen-

ded versions, it is recommended to pro-

ceed as follows: select the size which,

in nominal flow rate conditions, have

immediate power that is higher than

that requested; trace the curve of the

channel pressure drop on the flow rate-

static pressure diagram relative to the

machine in question, thus identify the

functioning points of the machine at

the different speeds. On the basis of the

flow rate values corresponding to the

above-mentioned points, the corrective

factors are finally obtained that allow to

calculate the power yielded in real air

flow conditions. The above-mentioned

procedure allows, in the case of multi-

speed versions, to appropriately choose

the speed to be set.

The sound power and sound pressu-

re level of the fan coils at the various

speeds is stated in separate tables for

the versions with 3 rows and versions

with 4 rows. For ducted, suspended ver-

sions, the sound power level is expres-

sed depending on the air flow rate and

static pressure and is represented using

graphics.

A wide range of accessories is avai-

lable for FCX series fan coils, someti-

mes some of them cannot be used at

the same time. The compatibility of the

accessories with the selected fan coil

must be checked. The manual contains

the description, drawing and compatibi-

lity of each accessory.

The information regarding installation

is inserted in the manual supplied with

every fan coil and every accessory. This

manual is limited to general information

in order to perform correct installation.

There are also drawings with dimen-

sions of the fan coils and wiring dia-

grams with connections to the control

panels.