SM321009D Page 9 of 9 ©Aero-Motive Nov-03

35 H22110388

H22110390

H22110391

1

1

1

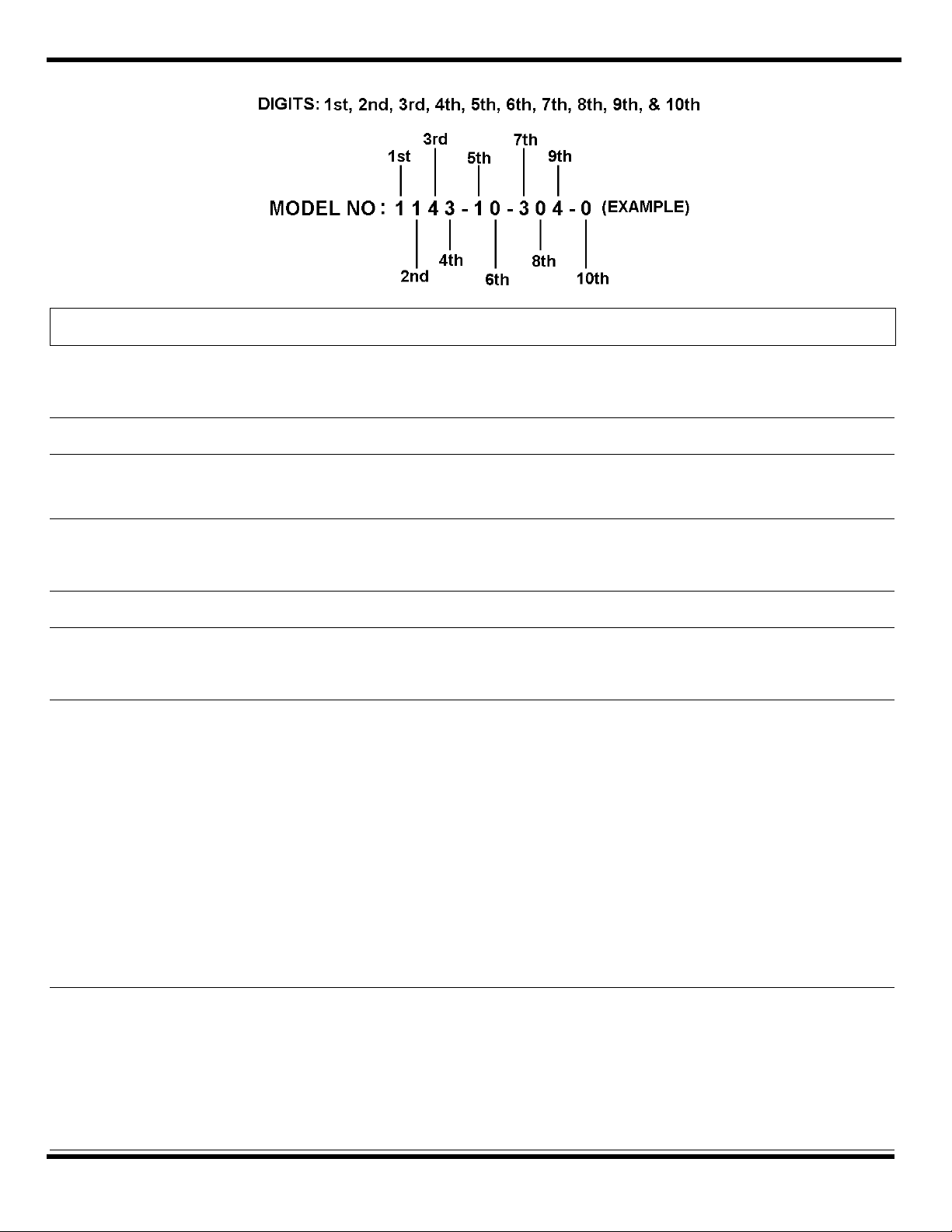

Stand; Weldment (Digit 1 & 2 = 11)

Stand; Weldment (12, 13)

Stand; Weldment (14, 15)

36 C01190116 17 Washer; Spring Lock M6

37 C22180116 4 Nut; hex M6

38 01151P0019

01151P0020

01151P0014

01151P0015

01151P0016

01151P0024

01151P0025

A/R

A/R

A/R

A/R

A/R

A/R

A/R

Connector; Cable (.375-.499 OD)

Connector; Cable (.500-.624 OD)

Connector; Cable (.625-.750 OD)

Connector; Cable (.751-.880 OD)

Connector; Cable (.930-1.065 OD)

Connector; Cable (.1.066-1.187 OD)

Connector; Cable (.1.188-1.625 OD)

39 00669P0045 A/R Bushing 2-1-¼

40 5491000001

5491000002

1

1

Fitting; Goose Neck (.375-.929 OD)

Fitting ; Goose Neck (.930-1.625 OD)

41 C71180001 1 Cover; Conduit

42 C22180210 1 Nut; Hex Head Jam (M10x1.5)

43 M25060011 1 Stud; Drive

45 C01190115 A/R Washer; Lock M5

46 M14210027 1 Gasket

47 H82630032

H82630033

H82630034

H82630035

H82630036

H82630037

H82630039

H82630040

1

1

1

1

1

1

1

1

Cover; Collector Ring 3.25” length (For digits 7,8,9 = 303, 304)

Cover; Collector Ring 5.25” length ( = 308, 402, 403, 404)

Cover; Collector Ring 7.25” length ( = 312, 405, 406, 902, 903)

Cover; Collector Ring 9.25” length ( = 314, 316, 407, 408, 409, 904, 905)

Cover; Collector Ring 11.25” length ( = 318, 320, 410, 411)

Cover; Collector Ring 13.25” length ( = 324, 906)

Cover; Collector Ring 15.25” length ( = 328, 330)

Cover; Collector Ring 17.25” length ( = 336)

48 C11080531 1 Screw; Hex Head Cap (GROUND) M5x10

49 00903P0001

00904P0001

4027900002

A/R

A/R

A/R

Cap, 7th Digit = (3)

Insulator 7th Digit = (3)

Connector; Wire 7th Digit = (4)

50 SRXXX

AGXXX

1 Assembly; Collector Ring (Digits 7,8,9 = XXX).

If Silver Slip Ring, 10th digit = S, then use this model.

51 00580P0137 1 Ring ;Retaining (1.500)

52 5629100000 1 Ring; Thrust

53 M53800005 3 Clamp; Cover

54 M26740141

M26740142

M26740143

M26740134

M26740137

M26740132

6

6

6

6

6

6

Tie Bolt, cable drum Digits 1-4 = (1165,1255,1445)

Tie Bolt, cable drum (1356, 1446, 1476, 1546, 1576)

Tie Bolt, cable drum (1257)

Tie Bolt, cable drum (1143, 1163, 1443, 1253)

Tie Bolt, cable drum (1164)

Tie Bolt, cable drum ( 1142)

55 M64560017 1 Ring; Entrance

57 5491200000 1 Gasket

63 00580P0030 AR Ring; Retaining (for .375 shaft) (1200M, 1400M)

64 6110500000 2 Spacer

KIT H25460024 AR Entrance Ring Kit (Includes 55, 53, 22 & 13)

Aero-Motive Company AKAPP Electro Industrie Woodhead Connectivity LTD. Woodhead Asia PTE LTD. Woodhead Canada LTD.

WA Woodhead Industries Inc. Subsidiary WA Woodhead Industries Inc. Subsidiary WA Woodhead Industries Inc. Subsidiary WA Woodhead Industries Inc. Subsidiary WA Woodhead Industries Inc. Subsidiary

PO Box 2678

Kalamazoo, MI 49003-2678

(616) 337 7700

(800) 999 8559

FAX: (800) 333 6119

www.aeromotive.com

Nijverheidsweg 14 Box 54

NL-3771 ME Barneveld

NL-3771 AB Barneveld

Holland

(31) 34 241 4022

FAX: (31) 34 249 2384

www.akapp.com

Factory No. 9

Rassau Industrial Estate

Ebbw Vale Gwent NP3 5SD

United Kingdom

(0495) 35 0436

FAX: (0495) 35 0877

401 Commonwealth Drive #04-04

Haw Par Technocentre

Singapore 0314

(65) 261 6533

FAX: (65) 479 3588

1090 Brevik Place

Mississauga Ontario

L4W 3Y5 Canada

(905) 624-6518

FAX: (905) 624-9151

www.woodhead.ca