4

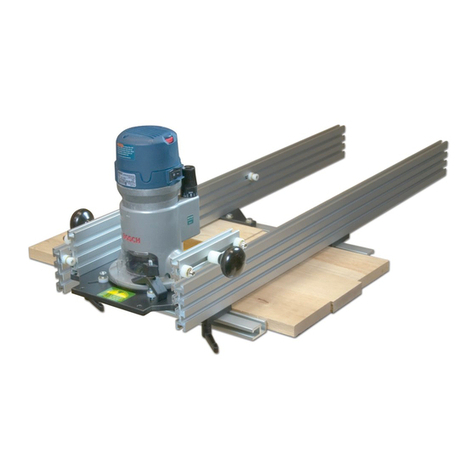

Step 4: Attach the Router Plate to the Vertical Support/Router Block

assembly. Install four 1/2" barrel nuts (5793B) in the holes indicated in

the two Vertical Supports, aligning the slot in the nut with the cross

slot/hole in the Vertical Support. Position the Router Plate over the

assembly, aligning the mounting holes in the Router Plate with the corre-

sponding holes in the Vertical Supports and the Adjuster Assembly. See

fig. 9.Insert the four 1/4-20 x 1" screws (MF015) through the mounting

holes in the Router Plate, into the barrel nuts and loosely tighten. Align

the two holes in the mounting plate of the Adjuster Assembly with the

corresponding holes in the Router Plate. Insert the two 10-24 x 3/4"

screws (MF040) through the Router Plate, into the mounting plate and

tighten securely. Move the Router Plate so it is as centered as possible

(this does not need to be perfect) on the router and tighten the screws

securely. See fig. 10. Tighten the screw attaching the Lift Nut to the

Router Block. See fig. 7.

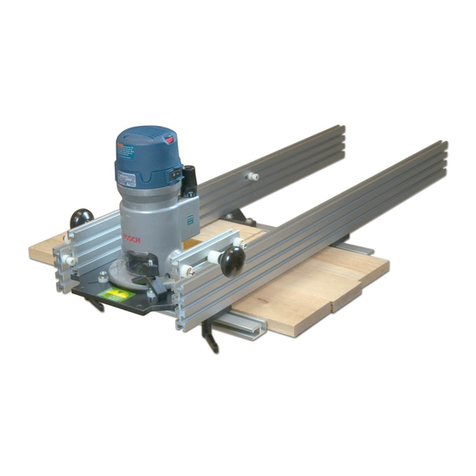

NEVER install the router partially in the Router Block! The

router should ALWAYS be flush, or sticking above, the Router Block

when safely installed. See fig. 11.

USING THE LIFT

Press the Dial Indicator onto the socket so that the end of the sock-

et is protruding approximately 1/4" out the bottom of the Dial Indicator.

The Dial Indicator should fit snugly on your socket, but be able to be

turned (for zeroing-out purposes) on the socket by hand. If the Dial

Indicator is too tight, sand one or several of the four protrusions slightly

with 120 grit sandpaper wrapped around a dowel until a snug fit is

achieved.

The hash marks on the edge of the Dial Indicator represent .0078"

(1/128") per 1/8th turn or .0156" (1/64") per 1/4th turn. There is .0625"

(1/16") of adjustment per one revolution. Turn the Dial Indicator on the

socket to align the desired hash mark with the mark in the router plate to

zero it out. See fig. 12.

When adjusting bit height, lower the bit (turn counter-clockwise) at

least 1/4 turn past the level needed (this compensates for any backlash),

then raise it (turn clockwise) to the desired setting. By varying the

router position in the Router Block, it's possible to raise many routers

above the table for bit changing. As with all routing, the best results are

achieved by making several light passes vs. one heavy pass.

Periodically clean the threads of the Adjuster Assembly and Lift

Nut. Check all screws, especially after initial use, to insure they are

tight. If you are having trouble holding a bit height setting, tighten the

four locknuts a small amount. See fig. 9.

©Copyright WOODHAVEN INC. 8/4/04

(800) 344-6657 or WWW.WOODHAVEN.COM

Fig. 12

Fig. 10

Fig. 9

Install barrel nuts

at four locations

Four locknuts

Fig. 11

Not OK! OK

OK