AeroFlash CanopyFlasher LITE User manual

A e r o F L A S H

PowerBox (PRO)

“See and Avoid” starts with being SEEN…

CanopyFlasher LITE, AeroFlash BASIC,

PowerBox, PowerBox PRO.

Installation and Operating Manual

Revision 3 - August 2021

1

www.AeroFLASH.de “See and Avoid” starts with being SEEN Rev 3 - AUG 2021

1. Important notices and limited warranty

2. Introduction

2.1 Terminology

3. System overview and installation planning

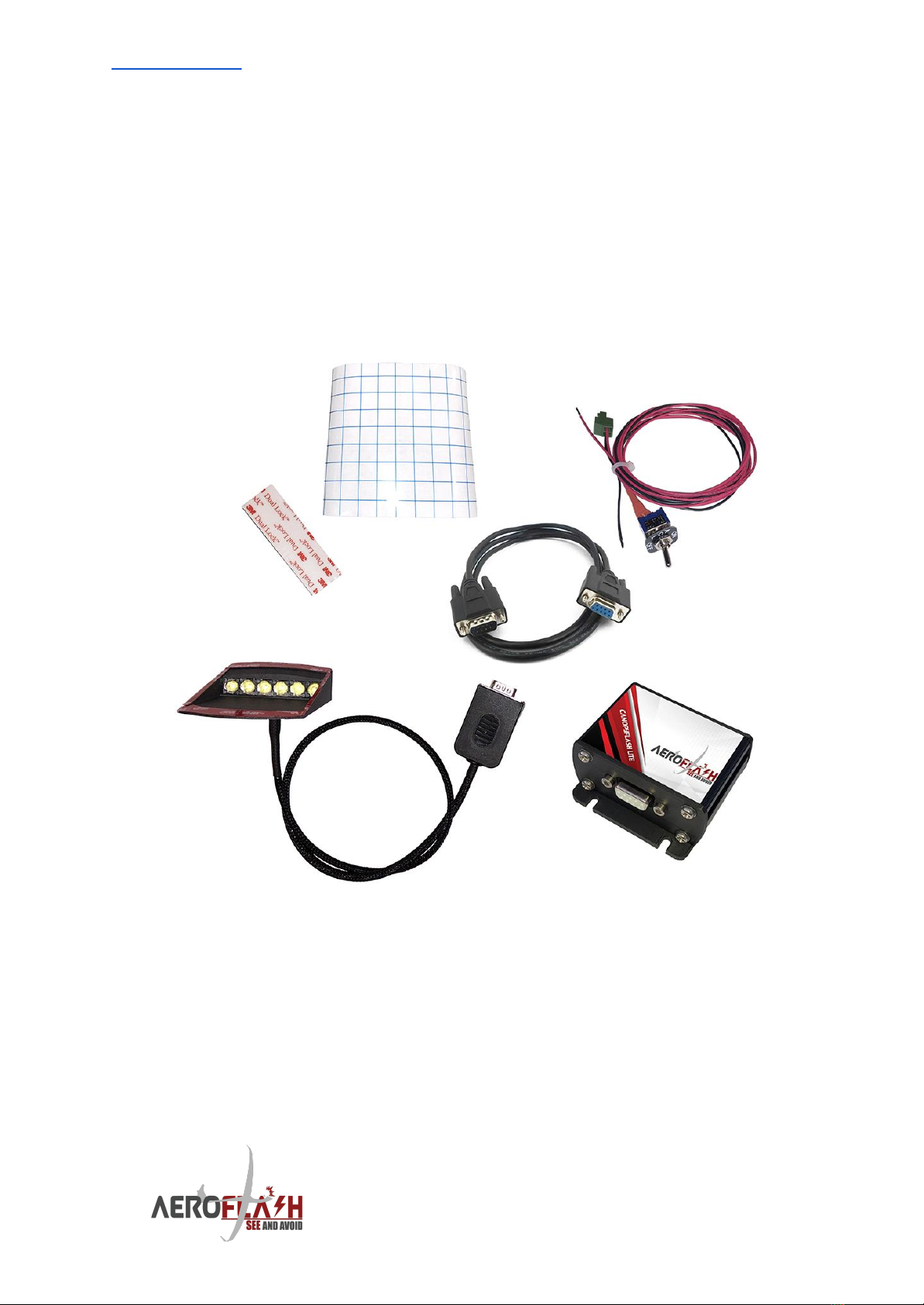

3.1 Scope of delivery

3.2 Status LEDs

3.3 Flashing logic

3.4 Power consumption

3.5 Power supply

3.6 Dimensions and weights

3.7 Temperature specifications and cooling requirements

3.8 Humidity

3.9 Mounting requirements

4. Installation instructions and examples

4.1 Installation and connection of PowerBox (PRO)

4.2 Mounting the CanopyFlasher

4.3 Vertical-opening canopy installations

4.4 Side-opening canopy installations - general

4.5 Side-opening canopy installations - Schempp Hirth

4.6 Installation of the FuselageFlasher and PowerBox PRO

4.7 Installation of the OFF/ON switch

4.8 Post-installation system check

5. Troubleshooting

6. Revision history

7. Appendix

7.1 AeroFlash product comparison

2

www.AeroFLASH.de “See and Avoid” starts with being SEEN Rev 3 - AUG 2021

1. Important notices and limited warranty

The AeroFlash system is designed for VFR use only, as an aid to collision

avoidance. AeroFlash is in no way designed for operation in IFR or IMC conditions.

Installing AeroFlash does not refrain from exercising the regular See and Avoid

procedures.

The pilot is always responsible for this action and may NEVER fully rely on being

seen by the other traffic. AeroFlash is only an aid to enhance visibility of your

aircraft.

The installation of an AeroFlash system must comply with EASA regulations as

per Standard Change CS-SC036a “INSTALLATION OF VISUAL AWARENESS

LIGHTS”:click here for the link to the EASA document.

Information in this document is subject to change without notice. AeroFlash

reserves the right to change or improve their products and to make changes in

the content of this material without obligation to notify any person or

organisation of such changes or improvements.

A yellow triangle is shown for parts of the manual which should be read

very carefully and are important for operating the system.

Notes with a red triangle describe procedures which are critical and may

result in serious damage or any other critical situation.

A bulb icon is shown when a useful hint is provided to the reader.

This AeroFlash product is warranted to be free from defects in materials or

workmanship for two years from the date of purchase. Within this period,

AeroFlash will, at its sole discretion, repair or replace any components that fail in

normal use. Such repairs or replacement will be made at no charge to the

customer for parts and labour, provided that the customer shall be responsible for

any transportation cost. This warranty does not cover failures due to abuse,

misuse, accident, or unauthorised alterations or repairs.

THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE EXCLUSIVE AND IN

LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED OR STATUTORY,

INCLUDING ANY LIABILITY ARISING UNDER ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, STATUTORY OR

OTHERWISE. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, WHICH MAY

VARY FROM STATE TO STATE. IN NO EVENT SHALL AEROFLASH BE LIABLE FOR

ANY INCIDENTAL, SPECIAL, INDIRECT OR CONSEQUENTIAL DAMAGES,

WHETHER RESULTING FROM THE USE, MISUSE, OR INABILITY TO USE THIS

PRODUCT OR FROM DEFECTS IN THE PRODUCT. Some states do not allow the

3

www.AeroFLASH.de “See and Avoid” starts with being SEEN Rev 3 - AUG 2021

exclusion of incidental or consequential damages, so the above limitations may

not apply to you. AeroFlash retains the exclusive right to repair or replace the unit

or firmware, or to offer a full refund of the purchase price, at its sole discretion.

SUCH REMEDY SHALL BE YOUR SOLE AND EXCLUSIVE REMEDY FOR ANY

BREACH OF WARRANTY.

To obtain warranty service, contact your local AeroFlash dealer or contact

AeroFlash directly.

2. Introduction

A printed version of this installation manual may be in grayscale. Some figures

and diagrams are coloured, like coding of power- and data wires. Please refer to

the electronic version to see the correct colours. Confusion of color coded wires

may cause serious system damage and is not covered by the limited warranty.

The latest electronic version of this manual can be downloaded from

www.AeroFLASH.de, section downloads - manuals. Please refer to your hardware

version if certain items apply to your device.

This manual will guide you through the installation process of all systems,

components, basic setup and check of the system.

If in any case confusion exists, please contact us for a clarification.

Before using any part of the system, please read and understand this

Installation and Operating manual.

There are no serviceable parts within the unit, hence the unit must be

taken to the dealer or factory for service.

Opening of any AeroFlash product by the user will void all warranty!

Never plug any unauthorized devices into the DB9 connectors! These

will certainly cause serious damage to the PowerBox, CanopyFlasher

and/or your computer. PowerBox cannot be connected to your

computer!

2.1 Terminology

PowerBox: stand-alone power supply and Flasher activator for

CanopyFlasher LITE only.

PowerBox PRO: all-in-one, stand-alone power supply and synchronised

flashing sequencing for one CanopyFlasher LITE and one FuselageFlasher.

CanopyFlasher: canopy mounted forward flashing device.

4

www.AeroFLASH.de “See and Avoid” starts with being SEEN Rev 3 - AUG 2021

FuselageFlasher: top or bottom fuselage external mounted, 360º by 180º

flashing device. This may also be an “external flasher” - not necessarily

supplied by AeroFlash (read further for compatibility).

CanopyConnector: the opposite 7-pin connector that is fitted to the

CanopyFlasher, and is mounted on the canopy or canopy frame, supplying

power and data between Nexus/PowerBox and the CanopyFlasher.

SidewallContact: a 7-pin contact fitted to the Nexus/PowerBox cable set,

which is to be mounted on the interior sidewall. It is universal for every

glider with a side opening canopy. It connects to the CanopyFlasher.

CanopyContact: a 7-pin contact fitted to the Nexus/PowerBox cable set,

which is to be mounted on the instrument panel cover, specially made for

Schempp-Hirth gliders, which connects to the CanopyFlasher. SH-glider

owners may also choose the SidewallContact if they prefer not to drill a

hole in the instrument panel cover.

3. System overview and installation planning

The CanopyFlasher LITE and AeroFlash BASIC Visual Awareness Light

system features multiple parts:

The system is designed to be

plug-and-fly. It comes complete

with everything you need. No

additional wiring, splitters or

soldering is required, other than connecting it to your aircraft’s power

supply. Typical installations can be done in 60 to 120 minutes. For an

overview of the scope of delivery please refer to chapter 3.1.

5

www.AeroFLASH.de “See and Avoid” starts with being SEEN Rev 3 - AUG 2021

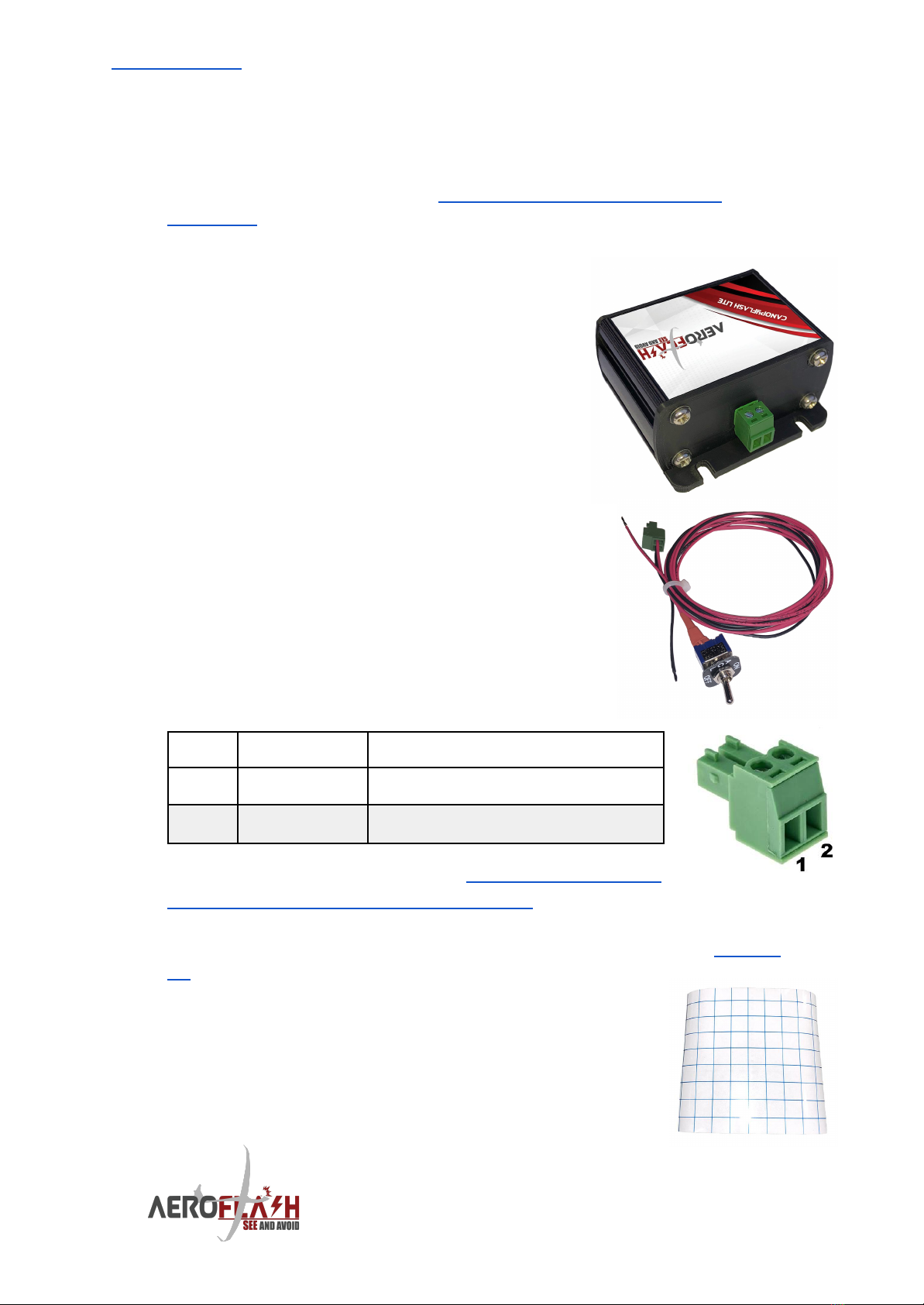

PowerBox (PRO)

PowerBox (PRO) is fully stand-alone.

PowerBox powers the CanopyFlasher

LEDs and provides flashing timing.

PowerBox (PRO) is not connectable

to Flarm and does not have

Bluetooth features. It’s a simple,

cost-effective solution for those who

do not need all the “luxury” features.

PowerBox PRO as part of AeroFlash

BASIC kit can also supply power to

one FuselageFlasher and provides

optimised synchronised flashing

sequencing.

PowerBox (PRO) continuously monitors the temperature of the

CanopyFlasher system. If an overheat situation is present, it automatically

shuts down the system to prevent damage to the system and to your

expensive canopy. After a short cooling the system will restart

automatically if conditions permit. Don’t worry, the system generally

doesn’t get very warm in flight, but in summer conditions on ground

without air flow your glider is well protected.

A neat removable screw-terminal system allows a quick connection of the

power wires, and easy removal when needed. No need for soldering;

everything is plug-and-fly.

CanopyFlasher - canopy mounted, forward-facing flasher

CanopyFlasher is made from a high strength, UV-resistant ABS based

polymer. The unit is delivered as standard painted in a high quality, matte

“Space Grey” (Nextel like) finish.

Optionally it can be delivered in

different colors.

The heart of the CanopyFlasher

is the array of 6 extremely

bright CREE LEDs emitting

approximately 4000-4500

(red/white) Lumens, with

powerful, oval lenses; 2 beams

orientated vertically, and 4

beams orientated horizontally.

This makes the Flasher well visible at distances of even up to 3500m, ±30

degrees above and below- and up to ±45 degrees left and right of the nose.

6

www.AeroFLASH.de “See and Avoid” starts with being SEEN Rev 3 - AUG 2021

The CanopyFlasher system incorporated many safety features, like heat

sinks, a temperature sensor to prevent overheat conditions and two status

LEDs for indication of the operating modes.

Never look straight into the illuminated CREE LEDs as this will

certainly result in temporary blindness, with risk of permanent

damage to the eye sight! It is your responsibility to inform

anyone who is not familiar with this system.

FuselageFlasher - 360º external, top/bottom fuselage mounted flasher

The PowerBox system features an additional flasher data port for

connection to our Fusion/FuselageFlasher system. The FuselageFlasher is

made out of a very strong, super clear UV resistant epoxy and features 16

extremely bright CREE LEDs, emitting approximately 7500-8500

(red/white) Lumens. It can be installed on the top or bottom of the

fuselage, flashing in a 360 degrees view. The FuselageFlasher is extremely

sleek and aerodynamic, measured at only 110mm long x 15mm wide x

11mm high. Only one small hole of 5mm is required for the three power

wires. Mounting of the flasher can be done simply with the (included)

super strong 3M double sided adhesive foam tape, sealed off with some

silicone mounting kit for weather-proofing. A simple and sturdy mounting,

but less “permanent” than other solutions.

Install the FuselageFlasher on one of the wheel- or engine bay

doors (close to the center-line of the fuselage) to avoid drilling

in the fuselage. This is the quickest and easiest installation

with the least amount of impact on the airframe.

7

www.AeroFLASH.de “See and Avoid” starts with being SEEN Rev 3 - AUG 2021

3.1 Scope of delivery

CanopyFlasher LITE system:

1x PowerBox device.

1x CanopyFlasher with 3M double sided adhesive foam tape pre-applied

and cable set***.

1x DB9 - DB9 extension cable (1 meter).

1x Dual Lock adhesive tape for mounting of the PowerBox.

1x Vinyl sticker template for aligning the CanopyFlasher during installation.

1x 1 meter power cable with ON/OFF switch and marking/label.

*** The cable set version and length depends on the canopy opening

direction:

- Vertical opening canopies receive a DB9 connector set.

- Other glareshield/panel mounted DB9-connection solutions for

side-opening canopies on special request.

8

www.AeroFLASH.de “See and Avoid” starts with being SEEN Rev 3 - AUG 2021

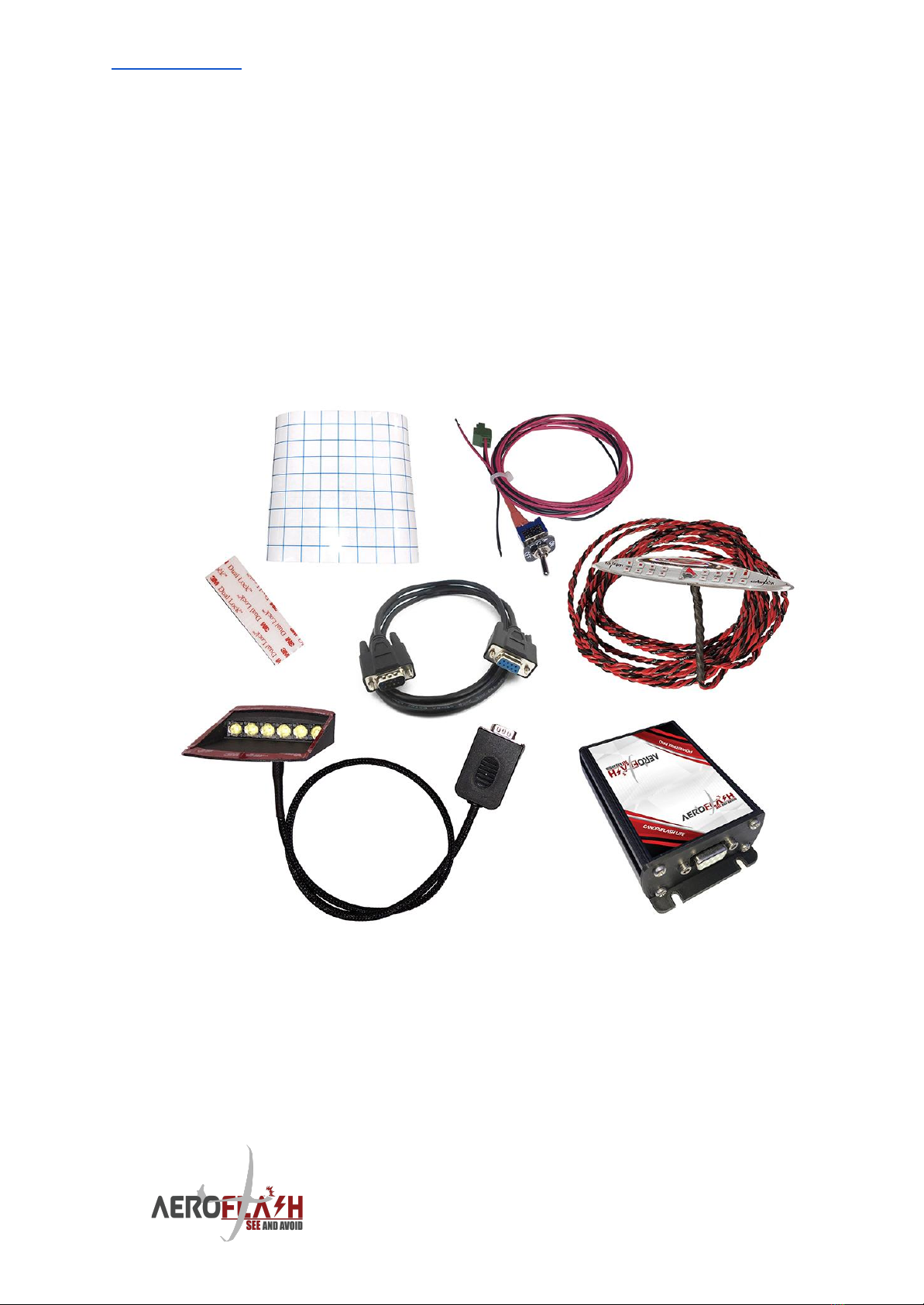

AeroFlash BASIC system:

1x PowerBox PRO device.

1x FuselageFlasher, with 3M double sided adhesive foam tape pre-applied,

with 4 meter pre-attached AWG20 wiring (3 wires: red, red, black) - other

lengths available on request.

1x CanopyFlasher with 3M double sided adhesive foam tape pre-applied

and cable set***.

1x DB9 - DB9 extension cable (1 meter).

1x Dual Lock adhesive tape for mounting of the PowerBox PRO.

1x Vinyl sticker template for aligning the CanopyFlasher during installation.

1x 1 meter power cable with ON/OFF switch and marking/label.

*** The cable set version and length depends on the canopy opening

direction:

- Vertical opening canopies receive a DB9 connector set.

- Other glareshield/panel mounted DB9-connection solutions for

side-opening canopies on special request.

9

www.AeroFLASH.de “See and Avoid” starts with being SEEN Rev 3 - AUG 2021

NOT included, optionally available and may be required for the

installation:

Fuse/circuit breaker, 2A or 3A - available from us separately.

Silicone sealant/kit (for weather-proofing the FuselageFlasher).

Additional power cable. Crimp or soldering tools. Cable ties, cable clips.

3.2 Status LEDs

The CanopyFlasher LITE features two different colored status LEDs

indicating the following:

Green status LED:

Off

System switched off.

Steady

System operating normally (flashing).

Blinking (1 Hz)

Flasher temperature high, overheat protection active.

Red status LED:

Off

Flasher temperature normal

Blinking (1 Hz)

Flasher temperature high, overheat protection active.

GREEN and RED status LEDs blinking rapidly (2Hz) at the

same time indicate that an overheat condition is detected.

Subsequently, the CanopyFlasher is deactivated until the

overheat condition disappears.

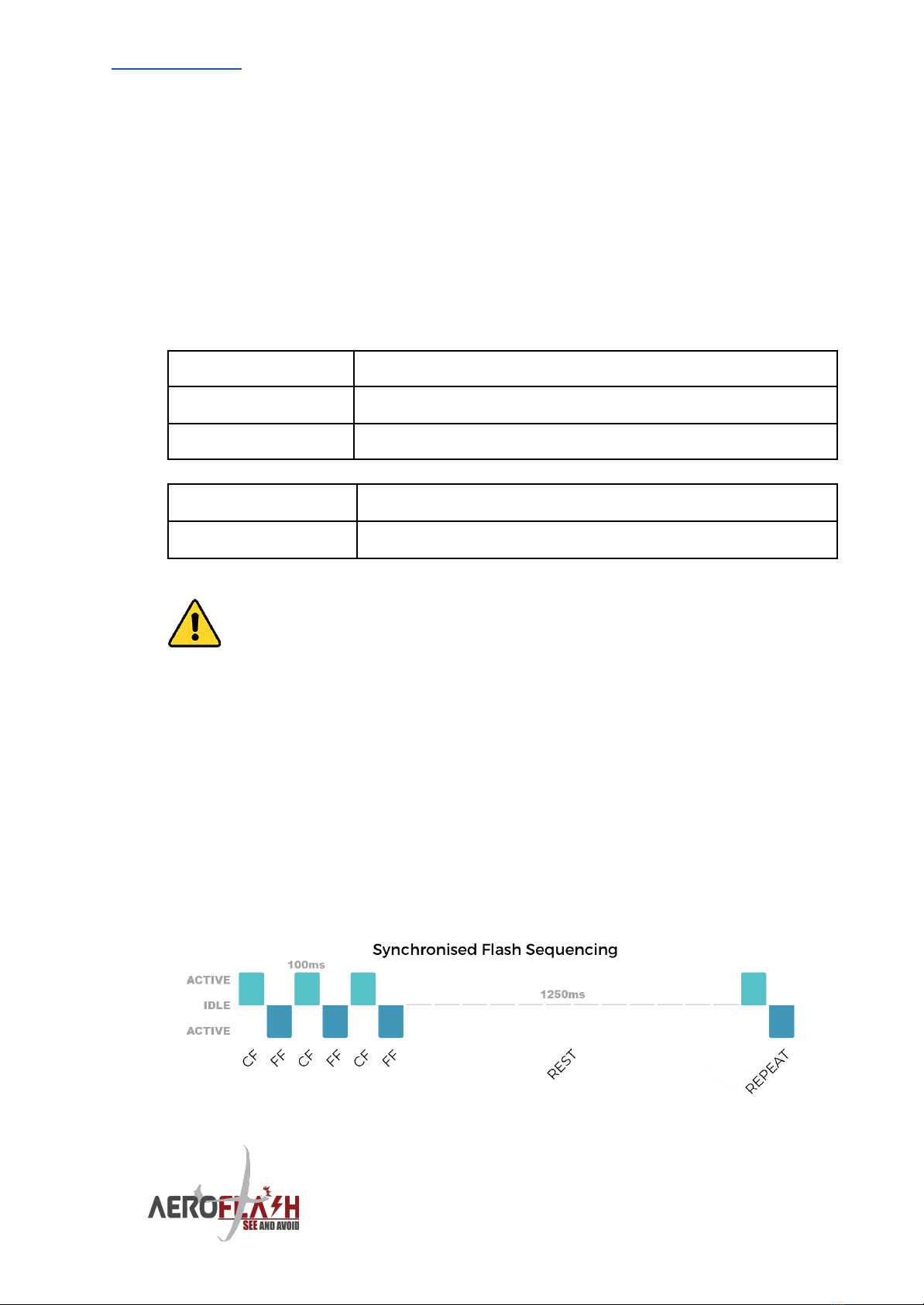

3.3 Flashing logic

PowerBox (PRO) automatically starts flashing once switched on. The

CanopyFlasher and FuselageFlasher never flash at the same time. They

each alternate every pulse, meaning only one flasher is draining power at

the same time, resulting in lower peak currents and less stress on your

battery.

PowerBox (PRO) flashes at 3 flash-cycles followed by a rest/cooling cycle of

1250 milliseconds, continuously until switched off. The flashing sequencing

or timing cannot be changed.

10

www.AeroFLASH.de “See and Avoid” starts with being SEEN Rev 3 - AUG 2021

3.4 Power consumption

Due to the efficient technology and smart synchronised flash-sequencing

we incorporated in PowerBox (PRO) and all AeroFlash products, power

consumption is very reasonable and should not be an obstacle to installing

AeroFlash systems. Typical power consumption will result in an average

power consumption of only 210-720mAh (milliamps per hour).

System situation & setup

Power usage per hour

CanopyFlasher LITE

(PowerBox + CanopyFlasher.

3-Flashes per 1250 milliseconds).

±210mAh

AeroFlash BASIC

(PowerBox PRO + CanopyFlasher + FuselageFlasher.

2 x 3-Synchronised flashes per 1250 milliseconds).

±720mAh

AeroFlash can strongly recommend special AIRNERGY high

capacity LiNiMnCoO2 (NMC) batteries, which double capacity

versus LiFePO4 (LFP) for the same size and even lower weight!

3.5 Power supply

PowerBox (PRO) systems accept a power input of 10V to 20V DC.

There is NO fuse inside, nor included with the system. Suitable fuses or

circuit breakers are available from our dealers, or from AeroFlash directly.

PowerBox (PRO) requires a minimum thickness of 20AWG wire (standard

supplied), and a circuit breaker rated at 2 or 3A:

System setup

Circuit breaker requirement

CanopyFlash LITE + PowerBox

2A

CanopyFlash LITE +

FuselageFlasher + PowerBox

PRO(basic)

3A

We strongly advise to install an automatic circuit breaker that

can be tripped manually, rather than a fast blowing glass-fuse.

These automatic circuit breakers are available from AeroFlash

webshop or our dealers. Contact us for more information.

11

www.AeroFLASH.de “See and Avoid” starts with being SEEN Rev 3 - AUG 2021

3.6 Dimensions and weights

PowerBox:

Dimensions LWH: 100 x 63 x 31mm (including mounting flanges).

Weight: ±100 grams.

PowerBox PRO:

Dimensions LWH: 100 x 63 x 31mm (including mounting flanges).

Weight: ±190 grams.

CanopyFlasher:

Dimensions LWH: 90 x 64 x 23mm (±10%, length/height varies per glider

type).

Weight: ±100 grams with 100cm cable.

FuselageFlasher:

Dimensions LWH: 110 x 15 x 11mm (including mounting-foam tape).

Weight: ±15 grams without cable / ±95 grams with 4m cable.

3.7 Temperature specifications and cooling requirements

All AeroFlash components are designed to operate in temperatures

ranging from -30 to +60ºC. These temperature limitations depend on the

actual ambient conditions. Generally with high-summer (>30°C)

temperatures some precautions must be observed.

Maximum operating times at high ambient temperatures:

CanopyFlasher

FuselageFlasher

On ground

In flight

On ground

In flight

Max 10 minutes

50ºC OAT

Max 5 minutes!

50ºC OAT

(temperature

sensor prevents

overheating in

normal conditions)

(with

forward

canopy

airflow open)

(limited*

temperature

protection installed!)

(no additional

cooling

requirements)

*Temperature protection linked to CanopyFlasher

temperature.

In flight there are no special precautions that must be made for cooling of

the system. Multiple heat sinks, cooling slots and a temperature sensor are

built-in the CanopyFlasher to monitor the system and automatically shut it

down when an overheat condition is experienced (LED temperature of

70ºC). Ensure to never block the cooling slots.

12

www.AeroFLASH.de “See and Avoid” starts with being SEEN Rev 3 - AUG 2021

Generally even in hot summer conditions, the airflow from the front of the

canopy is more than sufficient to cool the system and the system will not

even come close to the maximum operating temperature of 70ºC. These

protections are built-in solely to prevent aircraft- and system damage in

case of a failure of the electronics.

In high ambient temperatures (and strong sunlight), the

CanopyFlasher and FuselageFlasher LEDs may become quite

warm when operated continuously on the ground, without

cooling from the (canopy) airflow ventilation. Do not rely on

the temperature sensor and avoid activating the system on

the ground for prolonged times. Serious damage to the

flasher, as well as to the fuselage (overheating) may occur due

to the lack of air-cooling, especially in strong sunlight and

high ambient temperatures!

Please always use a canopy cover whenever the glider is not

in use, and switch off the power supply to the system. This will

benefit the life-time of all the components due to less

exposure to heat and UV light.

3.8 Humidity

PowerBox (PRO), CanopyFlasher and FuselageFlashers are designed to

operate in humidity ranging from 0 to 95%.

The FuselageFlasher is waterproof. Please refer to the specific installation

instructions in chapter 4.8 for more details.

3.9 Mounting requirements

PowerBox (PRO) may be mounted with up to 4 screws, or by using the

supplied 3M “Dual Lock” super strong double sided adhesive tape and

some cable ties.

In any case AeroFlash should be mounted in accordance with the

installation requirements as per (a.o.) CS-SC036a and CS-SC402b.

The CanopyFlasher comes prepared with super strong black 3M double

sided adhesive foam tape. It is strongly recommended to use this black

tape as it blocks out any reflections that may appear in the canopy when

the flasher is activated. This 3M tape is safe to use on plexiglass.

13

www.AeroFLASH.de “See and Avoid” starts with being SEEN Rev 3 - AUG 2021

4. Installation instructions and examples

The installation of an AeroFlash system must comply with EASA

regulations as per Standard Change CS-SC036a “INSTALLATION OF

VISUAL AWARENESS LIGHTS”:click here for the link to the EASA

document.

4.1 Installation and connection of

PowerBox (PRO)

Find a suitable location for the PowerBox (PRO)

unit. It may be required to make some brackets

and use the mounting flanges to mount it with

two or four screws. Avoid over-tightening of

screws on the plastic flanges, as the plastic may

break! It may also be possible to use some cable

ties to mount the PowerBox (PRO) to another

device, or use a piece of the 3M Dual Lock

adhesive tape that we included.

Wiring up the PowerBox

The cable set comes already prepared with a

pluggable 2-pin Camdenboss CTB922HE/2 power

connector. In case you wish to shorten the wires; it

uses the following pinout which must be carefully

observed. Wrong connection will permanently

damage the device.

Pin

Color

Description

1

Black

Ground INPUT (GND, negative) (AWG20)

2

Red

+10 to 20V INPUT (VCC, positive) (AWG20)

For PowerBox PRO pinout refer to chapter 4.6 Installation

of the FuselageFlasher and PowerBox PRO.

Install a fuse/circuit breaker. Observe the tripping current as per chapter

3.5, and connect these to the glider’s power network.

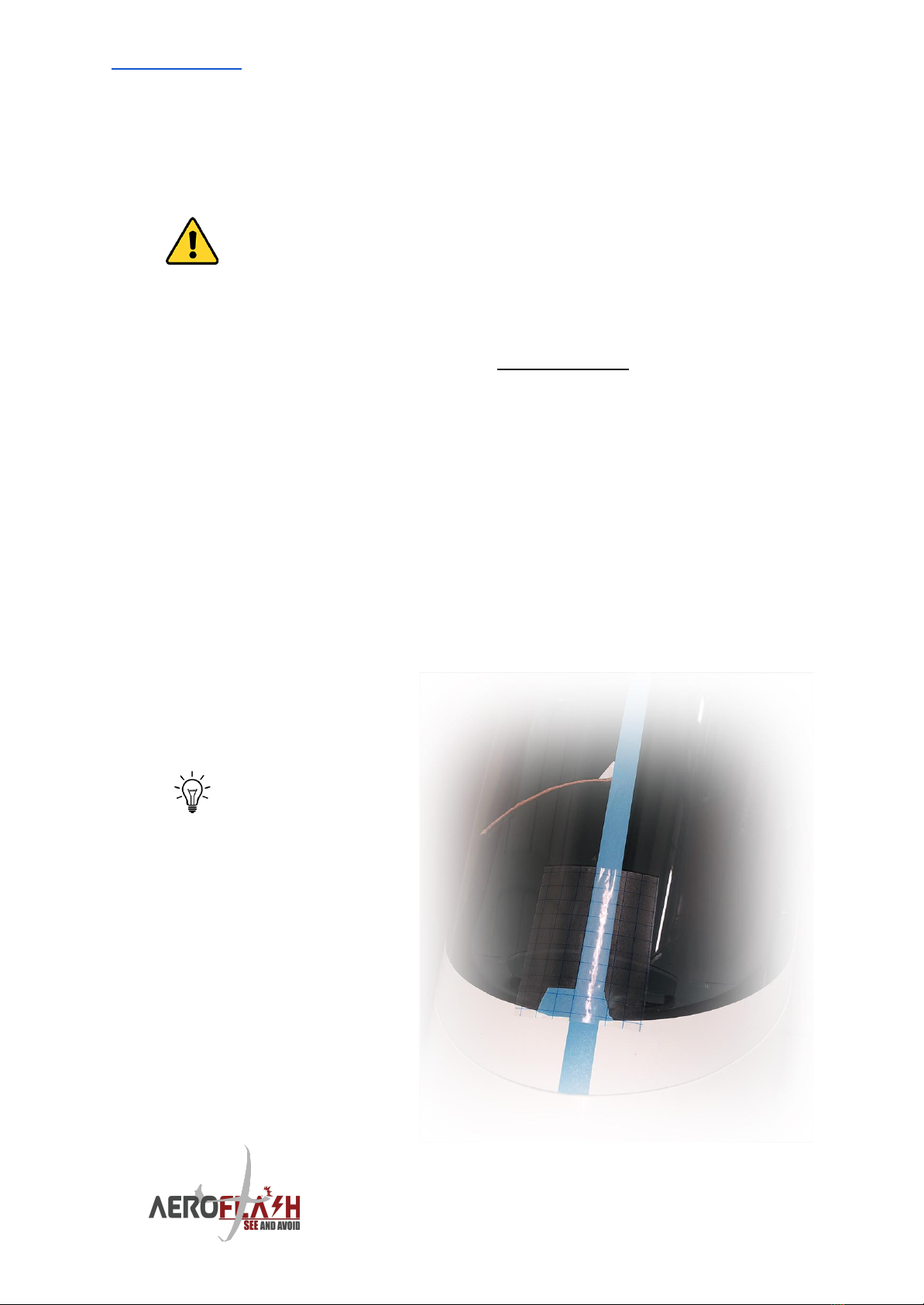

4.2 Mounting the CanopyFlasher

Mark the centerline of the canopy with a piece of white

PVC tape. Please be cautious to use the yaw string as

centerline reference, as often these are not placed in the

exact center!

14

www.AeroFLASH.de “See and Avoid” starts with being SEEN Rev 3 - AUG 2021

Using the supplied vinyl grid sticker may make it easier to align the

CanopyFlasher so it’s perfectly straight. It may be very difficult to see the

alignment once you try to stick it to the canopy from the inside.

Before permanently mounting the CanopyFlasher, check if

the selected location does not intervene with the canopy

ventilation mechanism!

After marking the correct position, it may be easiest to remove the canopy

and place it upside down on a soft/safe location.

Clean the surface of the canopy with a non-aggressive cleaning agent to

remove dirt and grease, to ensure the adhesive tape sticks well. Normally

water and a bit of soap is fine.

The CanopyFlasher is pre-applied with black 3M VHB double sided

adhesive foam tape. It is strongly recommended to use this black tape as it

blocks out any reflections that may appear in the canopy when the flasher

is activated. This 3M tape is safe to use on plexiglass canopies.

Remove the film and carefully stick the CanopyFlasher against the canopy.

Be careful not to apply too much force to the canopy, but make sure the

tape is attached well in all corners. If there is a small air bubble between

the canopy and the tape, don’t attempt to remove the CanopyFlasher. Most

likely the bubble will disappear in a couple of days or with some warmth

from the sun.

The 3M VHB

double sided

adhesive foam

tape is best

applied at

temperatures

above 15ºC.

15

www.AeroFLASH.de “See and Avoid” starts with being SEEN Rev 3 - AUG 2021

4.3 Vertical-opening canopy installations

This section mostly applies to JS, Schleicher, HPH,

Rolladen Schneider (LS) and Glaser Dirks (DG)

gliders. In some side-opening canopy installations it

may be preferential to use the vertical-opening

cable set solution. This applies to for example

DG500/DG1000, (Twin) Astir and Standard Cirrus, and

perhaps other gliders.

Vertically opening canopies need an easy to attach, but most

importantly, easy to DETACH connector. When jettisoning the

canopy in case of an emergency, our connectors are designed

to easily separate. Do not modify these connectors, or install a

different type.

Now that you have mounted the CanopyFlasher, it’s time to take care of the

cable set.

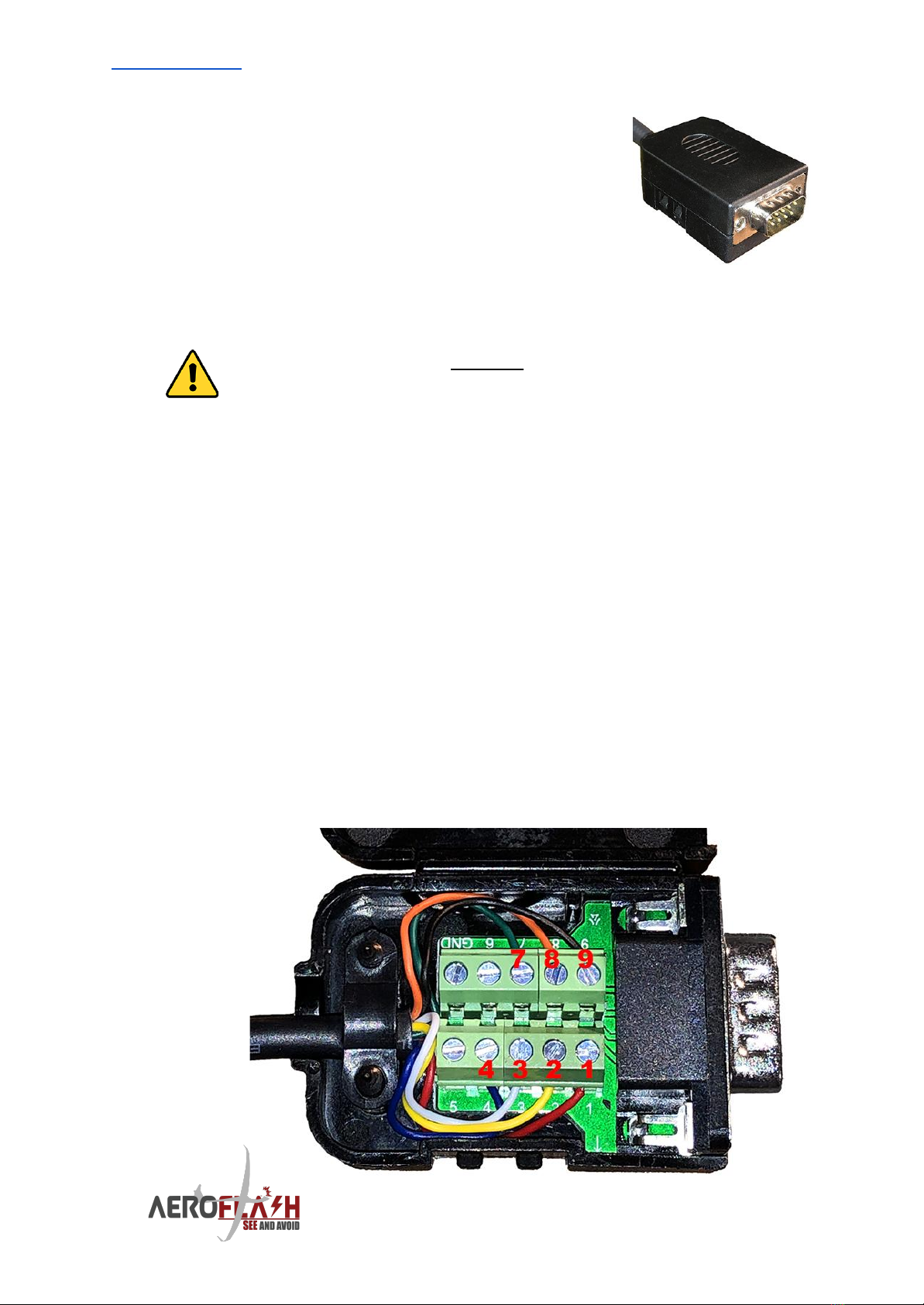

The AeroFlash installation consists of commonly seen male and female

DB9 (D SUB 9) type connectors for the data cables (status LEDs and

temperature sensor), and for the power supply of the CanopyFlasher. It is

sturdy, easy to attach, separate, and highly suited for the currents.

Step 1

The DB9 connector comes pre-attached to the CanopyFlasher. In certain

installations there may be required to make a hole through the instrument

panel cover to feed the cable through. Of course it’s highly desirable to

keep this hole as small as possible. Our DB9 connector is fitted with certain

easy to install screw-type terminals (no soldering required!). Open the

connector cover by loosening the clip on the side with a screwdriver and

take note of the color coding and pinout of the connector:

16

www.AeroFLASH.de “See and Avoid” starts with being SEEN Rev 3 - AUG 2021

Pin

Wire color

Wire description

1

RED

Flasher +9-20V VCC/Positive (internally connected with pin 6)

2

YELLOW

Temperature sensor +5V

3

WHITE

Temperature sensor signal

4

BLUE

Common signal GND (ISOLATE FROM PIN 9!)

5

-

Flasher GND/Negative (internally connected with pin 9)

6

-

Flasher +9-20V VCC/Positive (internally connected with pin 1)

7

GREEN

Status LED 1 (green LED)

8

ORANGE

Status LED 2 (red LED)

9

BLACK

Flasher GND/Negative (internally connected with pin 5)

Loosen the screws on the DB9 terminals to temporarily remove the wires. It

is now possible to feed the data cable through a hole of approximately

5mm.

Carefully replace the wires in the original pinout and tighten the screw

terminals. Do not overtighten the screws to avoid damage to the threads.

Replace the connector cover.

You may use the supplied DB9 female - DB9 male extension cable (1 meter)

to more optimally route the cables underneath the instrument panel cover.

In case you need a different length, any 1:1 DB9 or RS232 extension cable

will work.

If using the supplied extension cable, it’s recommended to

secure both sides of the cable to a sturdy point on the frame

of the instrument panel or canopy with a cable tie. In case

someone forgets to manually separate the connectors during

regular maintenance/removal of the canopy, no chance exists

to accidentally damage the CanopyFlasher cable.

Step 2

In case of a PowerBox PRO installation, continue with chapter 4.6

Installation of the FuselageFlasher and PowerBox PRO, or continue to 4.7

Installation of the OFF/ON switch.

Depending on the glider type, you may have removed the canopy. You can

now reinstall the canopy as the installation is nearly complete and we need

to correctly orientate the OFF/ON switch and test its function. Make sure

not to forget to attach the system’s cables.

17

www.AeroFLASH.de “See and Avoid” starts with being SEEN Rev 3 - AUG 2021

4.4 Side-opening canopy installations - general

Each glider type requires a

specially designed connector

solution. This is unique to every

different glider type. A brief

installation instruction manual

together with installation example

pictures will be delivered together

with these orders.

Below / on the side are a few

examples suitable for Grob G102

Club/Standard Astir and G103 Twin

Astir gliders.

If your glider is not yet supported,

please contact us to develop a

solution together.

18

www.AeroFLASH.de “See and Avoid” starts with being SEEN Rev 3 - AUG 2021

4.5 Side-opening canopy installations - Schempp-Hirth

This section mostly applies

(but is not limited to, or

possible for all) to

Schempp-Hirth gliders.

For example Cirrus gliders

require a vertical-opening

canopy connector solution.

Schempp-Hirth glider owners

may also choose to install a

panel mounted DB9

connector option when the

instrument panel cover has a

lot of play. It must be fairly

sturdy in order to work

well/reliable.

For safety reasons, we require

a connector that is easily

DETACHED in case of an

emergency. We designed a

special 7-pin spring loaded

connector to be mounted on

the glareshield/panel cover

and the canopy edge, which

requires absolutely no force to

separate. There is no need to

solder any wiring, however you

will need to install the

connector in a suitable

location and drill some holes.

19

www.AeroFLASH.de “See and Avoid” starts with being SEEN Rev 3 - AUG 2021

Find a suitable place to install the 7-pin CanopyConnector that is attached

to the CanopyFlasher. You need to install this CanopyConnector to the

canopy frame using one of the supplied mountings at a location where

when the canopy is closed, it can make good contact with the opposite

part. This should be done on the

right side of the instrument panel

cover. Ideally there should be no or

limited movement of the panel

cover. A good place is close to the

instrument panel, and near the

canopy hinge.

The opposite connector part (called

PanelContact) is already attached

to the PowerBox’s cable set and is

ideally mounted through a small

hole (approximately 25 x 10mm) in

the instrument panel top cover,

using the supplied stainless steel

M3 cylinder head bolts. These bolts

are designed to align correctly with

the CanopyConnector.

Please note that certain

glider types may use or

require a “vertical-opening

canopy installation”, even

though they have

side-opening canopies.

This applies to for example:

DG500/DG1000, Standard

Cirrus, etc, and is due to

the difficulty finding a

suitable location for

installing this

CanopyConnector.

20

This manual suits for next models

3

Table of contents

Other AeroFlash Lighting Equipment manuals