Aeronaut Capri User manual

Other Aeronaut Toy manuals

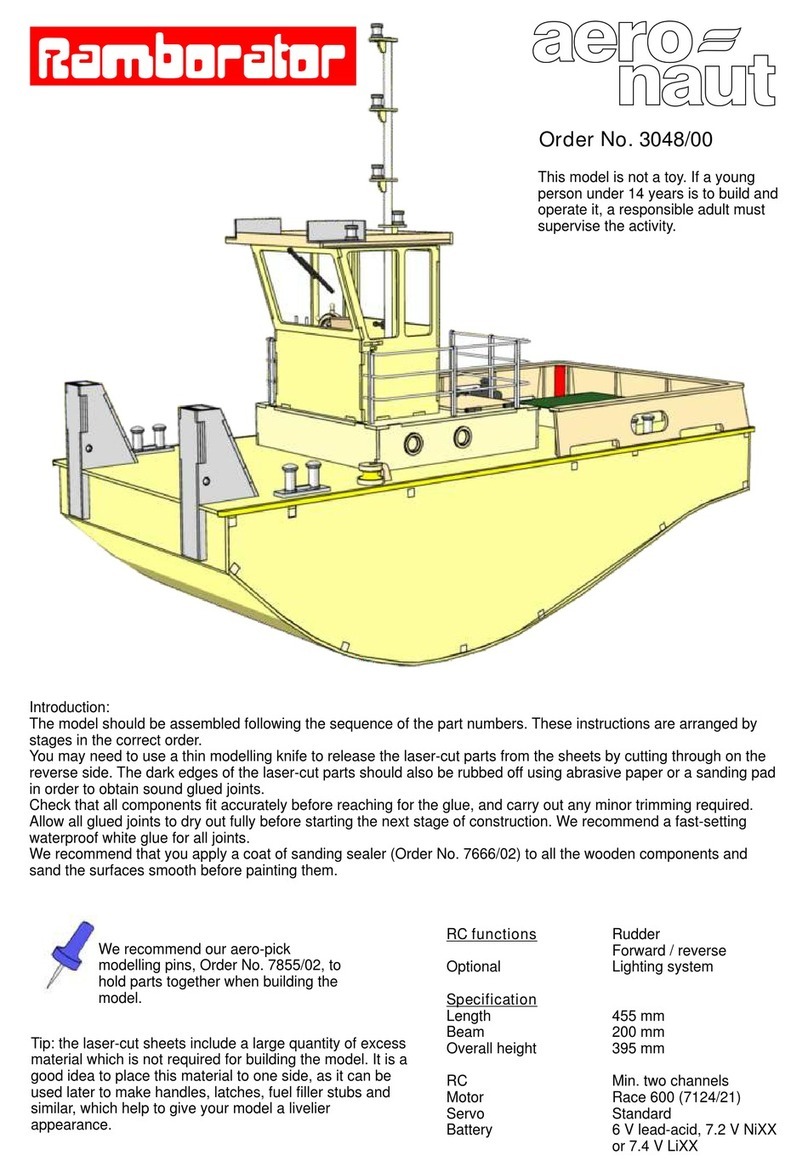

Aeronaut

Aeronaut 3092/00 Instruction Manual

Aeronaut

Aeronaut TRIPLE SPEED R.E.S. THERMIC User manual

Aeronaut

Aeronaut SkyMAXX User manual

Aeronaut

Aeronaut Twinspeedy User manual

Aeronaut

Aeronaut Sukhoi SU 31M Instruction Manual

Aeronaut

Aeronaut Santorini User manual

Aeronaut

Aeronaut Quido User manual

Aeronaut

Aeronaut Airmarine Special User manual

Aeronaut

Aeronaut BLADE 2 Instruction Manual

Aeronaut

Aeronaut Lilienthal 40 R User manual

Aeronaut

Aeronaut Canadair CL-415 Instruction Manual

Aeronaut

Aeronaut The Hansa-Jolle Instruction Manual

Aeronaut

Aeronaut Premiant II Instruction Manual

Aeronaut

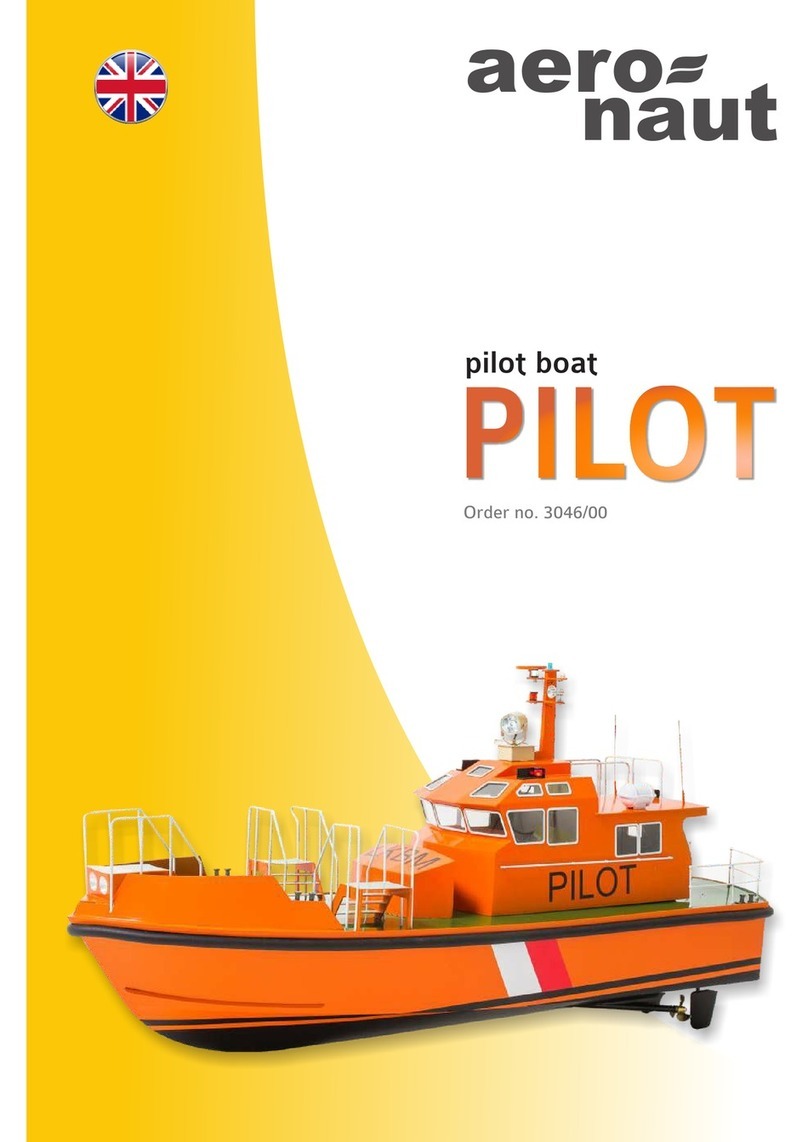

Aeronaut Pilot User manual

Aeronaut

Aeronaut Scarlet Instruction Manual

Aeronaut

Aeronaut Princess User manual

Aeronaut

Aeronaut PEPPER User manual

Aeronaut

Aeronaut Joker RC Instruction Manual

Aeronaut

Aeronaut Turbo-fan 4000 Product information sheet

Aeronaut

Aeronaut Fauvel AV-361 RC glider Instruction Manual

Popular Toy manuals by other brands

Enabling Devices

Enabling Devices Plasma Star with Mounting Arm user guide

Century Helicopter Products

Century Helicopter Products UH-1B Huey Cobra instruction manual

Kyosho

Kyosho EP BLUESTREAK 800 instruction manual

Hobbico

Hobbico Dromida Voyager DIDA0211 manual

Meccano

Meccano 16211 instructions

Seagull Models

Seagull Models Mini Sparrowhawk EP Assembly manual

Eduard

Eduard Tornado ECR interior Assembly instructions

LEGO

LEGO Jurassic World 75916 Assembly guide

Mattel

Mattel Disney Pixar Cars 2 V2996 instructions

Fisher-Price

Fisher-Price 77171 instructions

Ravensburger

Ravensburger Gravitrax Starter-Set manual

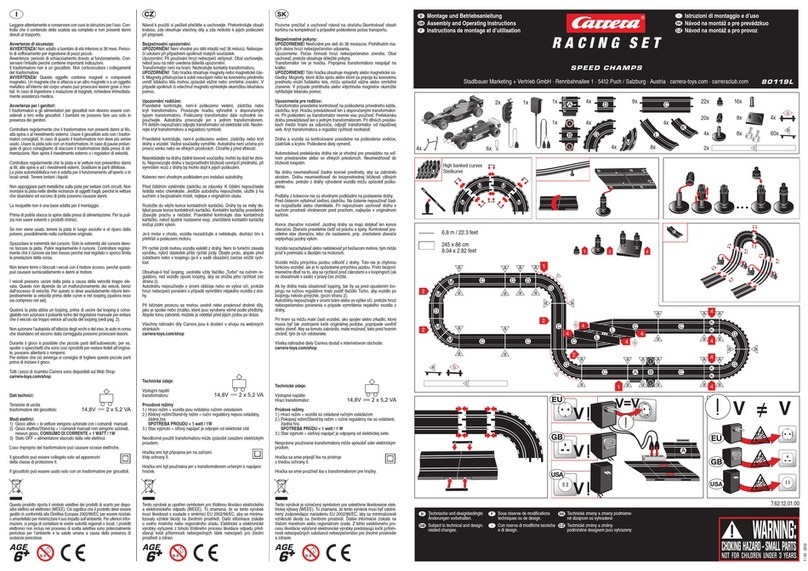

Carrera

Carrera 80119L Assembly and operating instructions