Aeronaut The Hansa-Jolle Instruction Manual

Other Aeronaut Toy manuals

Aeronaut

Aeronaut Sukhoi SU 31M Instruction Manual

Aeronaut

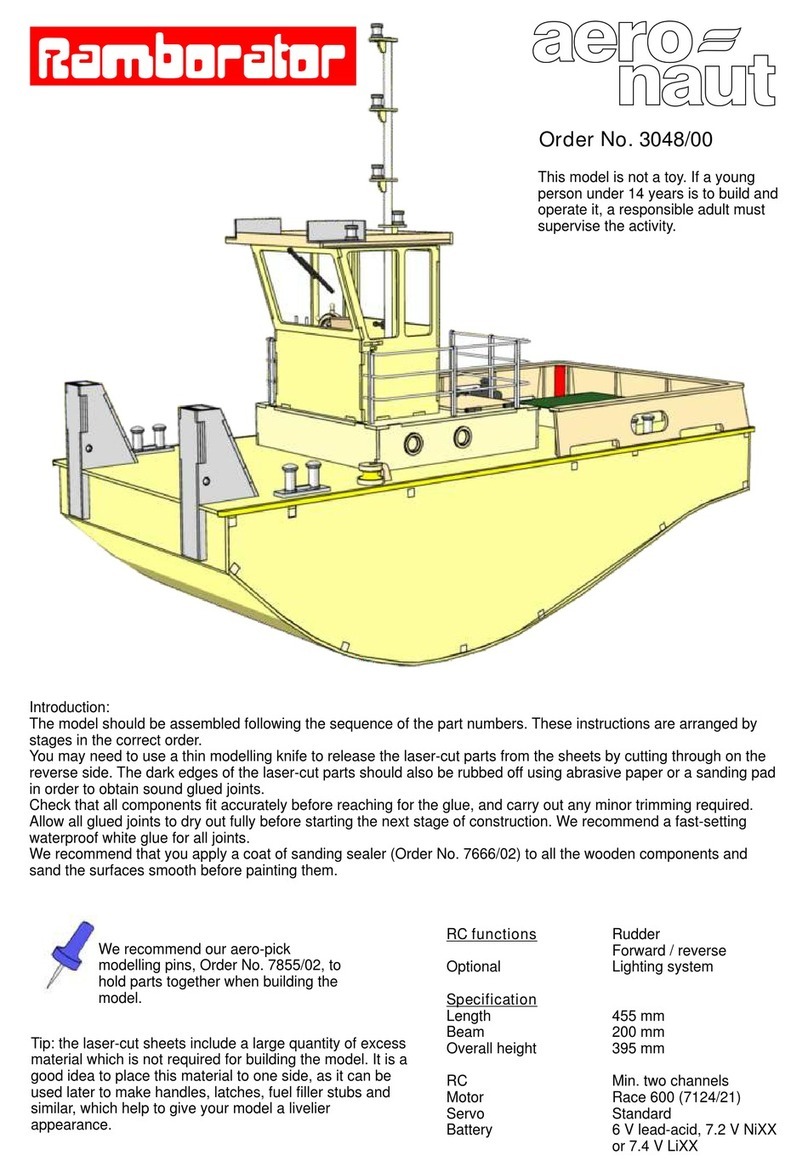

Aeronaut Rambotator User manual

Aeronaut

Aeronaut Triple Neo Series User manual

Aeronaut

Aeronaut Clipper Instruction Manual

Aeronaut

Aeronaut LUXX Instruction Manual

Aeronaut

Aeronaut Luscombe Silvaire 8 User manual

Aeronaut

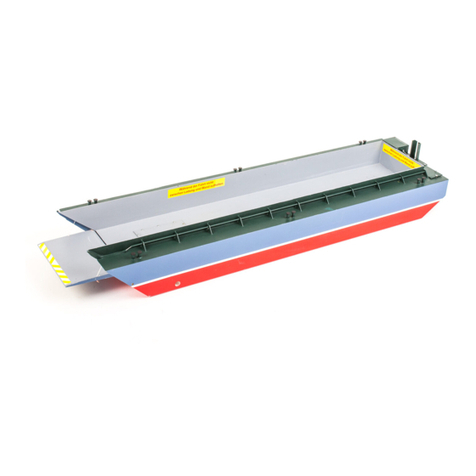

Aeronaut Ramboline User manual

Aeronaut

Aeronaut Dassault Breguet Rafale C 01 Instruction Manual

Aeronaut

Aeronaut Canadair CL-415 Instruction Manual

Aeronaut

Aeronaut Joker RC Instruction Manual

Aeronaut

Aeronaut Lilienthal 40 R User manual

Aeronaut

Aeronaut Manta A 02 User manual

Aeronaut

Aeronaut Galaxy Instruction Manual

Aeronaut

Aeronaut Mowe 2 User manual

Aeronaut

Aeronaut Jonny User manual

Aeronaut

Aeronaut Princess User manual

Aeronaut

Aeronaut Foxx User manual

Aeronaut

Aeronaut Premiant II Instruction Manual

Aeronaut

Aeronaut LT 200 Flex User manual

Aeronaut

Aeronaut Prober Pixie Instruction Manual

Popular Toy manuals by other brands

ROBBE

ROBBE Lightning 46 Assembly instructions

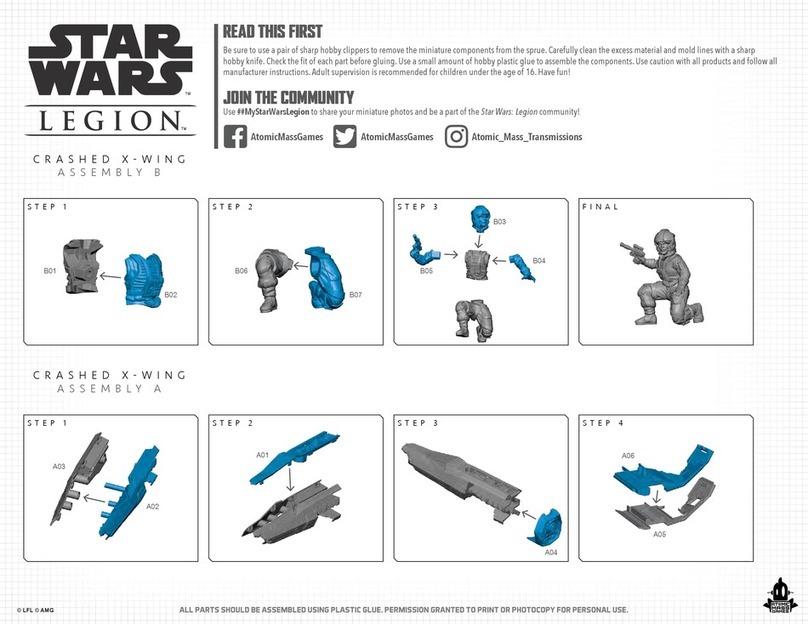

ATOMIC MASS GAMES

ATOMIC MASS GAMES STAR WARS LEGION CRASHED X-WING Assembly

Spirit

Spirit BLACK & RED JUMPING SPIDER Installation and operating instructions

Faller

Faller FLEA MARKET SET 2 manual

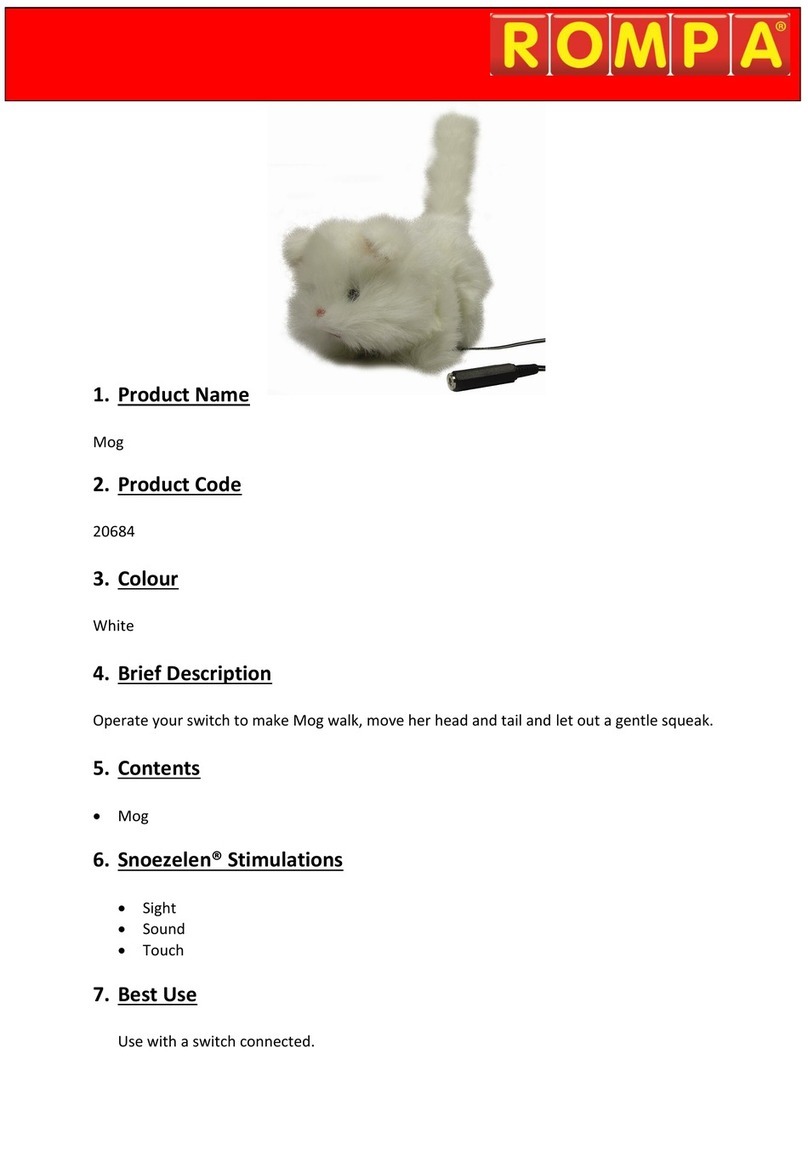

Rompa

Rompa Mog 20684 quick start guide

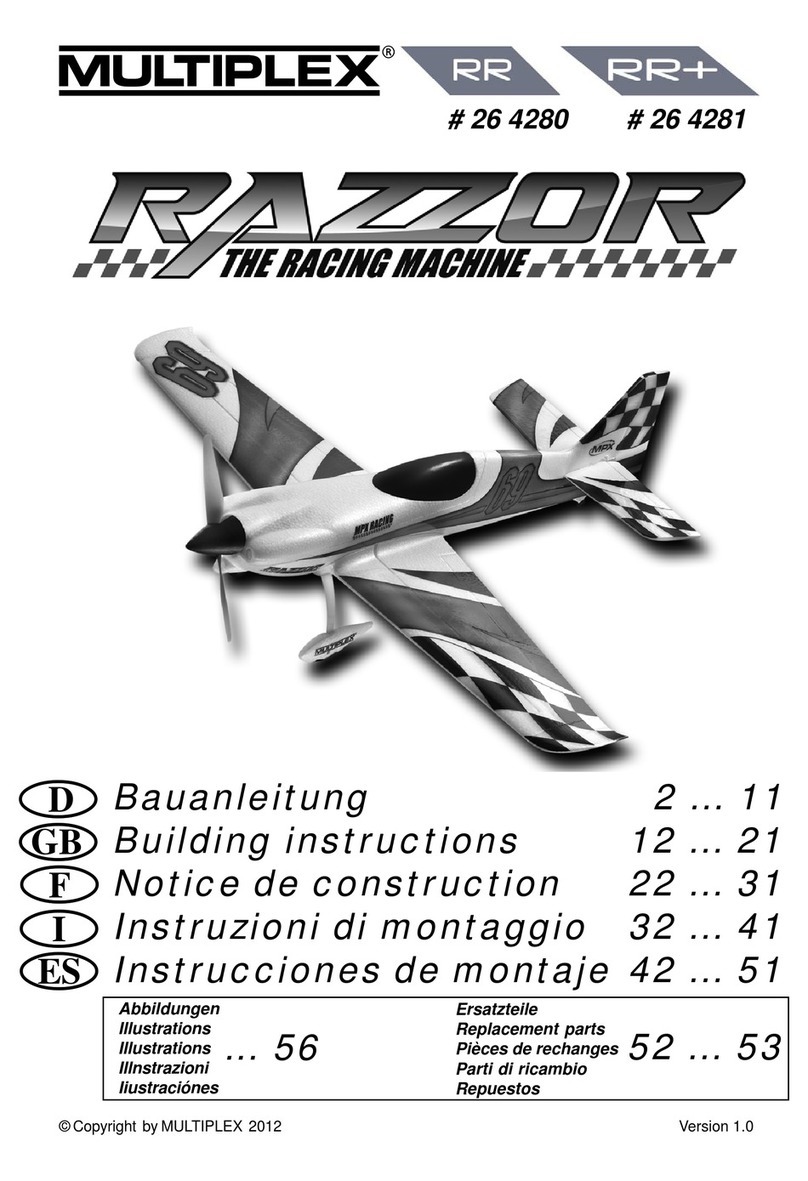

Multiplex

Multiplex Razzor RR+ 26 4281 Building instructions

Enabling Devices

Enabling Devices Plasma Star with Mounting Arm user guide

VBC Racing

VBC Racing FFTwelve instruction manual

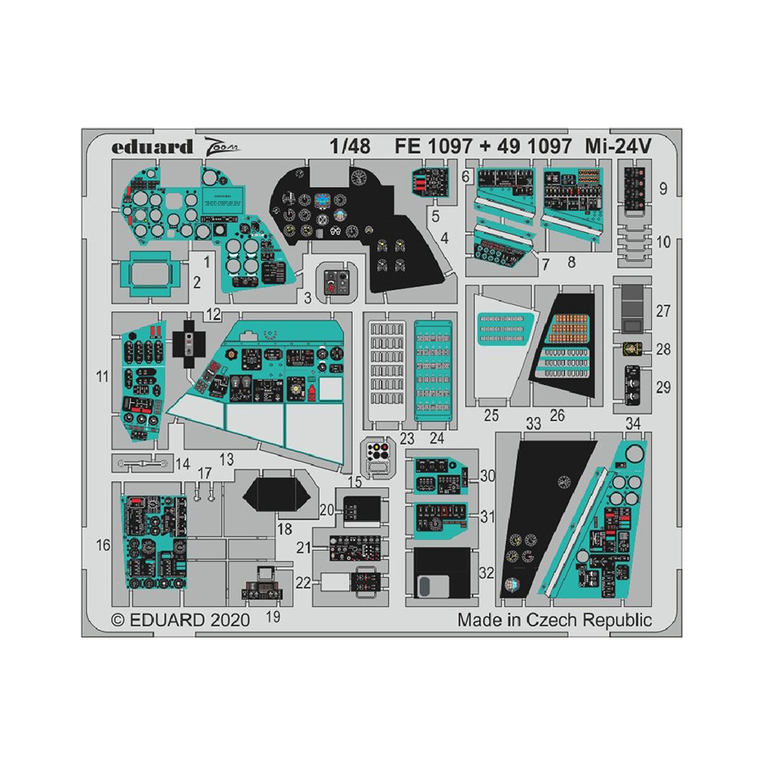

Eduard

Eduard P-51D gun bay manual

Eduard

Eduard P-47D Thunderbolt placards s. adh. manual

ZT Model

ZT Model Global Hawk EP Airplane quick start guide

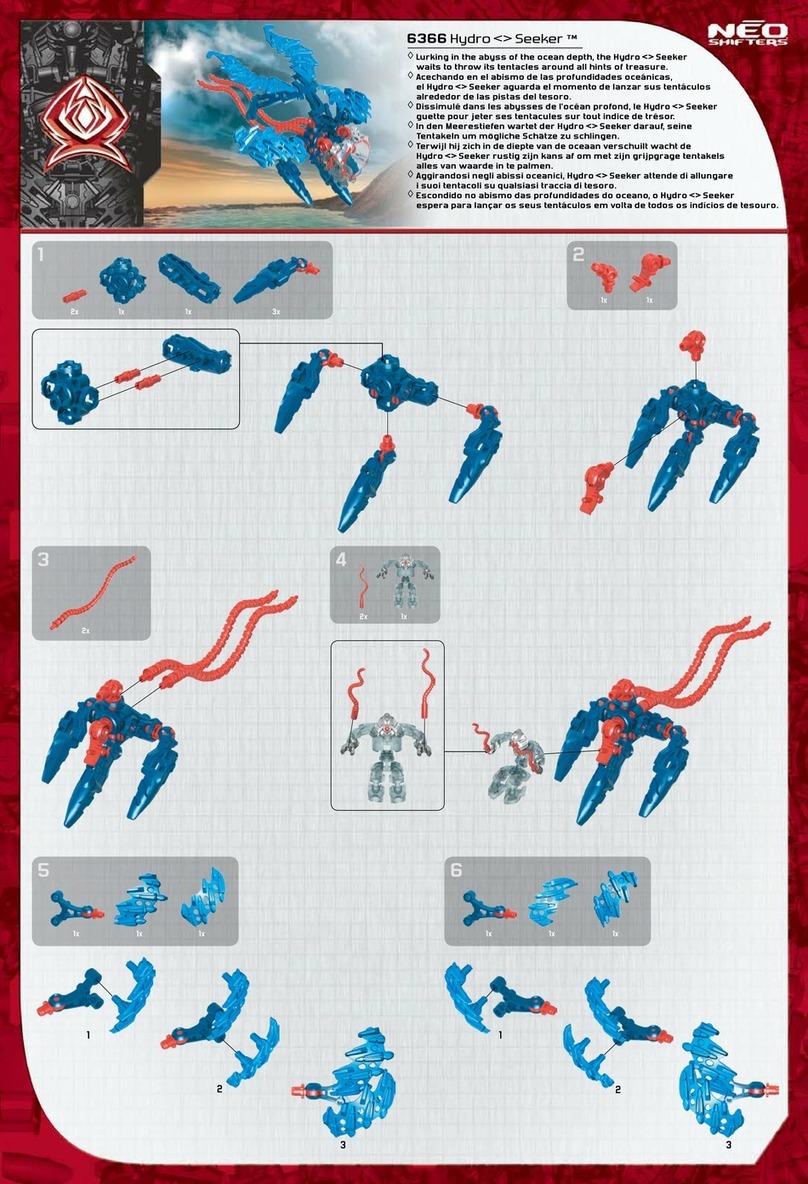

Mega

Mega NEO SHIFTERS Hydro Seeker 6366 quick start guide