AEROPRAKT AEROPRAKT-32 User manual

Aeroprakt Ltd.

24, Polevaya str., Kiev, Ukraine

Tel: 0038 044 496-77-21

Fax: 0038 044 496-77-31

e-mail: [email protected].ua

www.aeroprakt.kiev.ua

1

AEROPRAKT-A32

Airplane Maintenance Manual

A32-002-AMM

Airplane Model: AEROPRAKT-32 (A-32)

Airplane Registration Number:

Airplane Serial Number: 002

Date of issue: 07.04.2015

Approved by: Yuriy Yakovlyev

Position: Chief designer

Date of approval: 07.04.2015

This manual must be carried in the airplane at all times.

This airplane is to be serviced and maintained in compliance with information and instructions

contained herein.

AEROPRAKT-32 Airplane Maintenance Manual A32-002-AMM

2

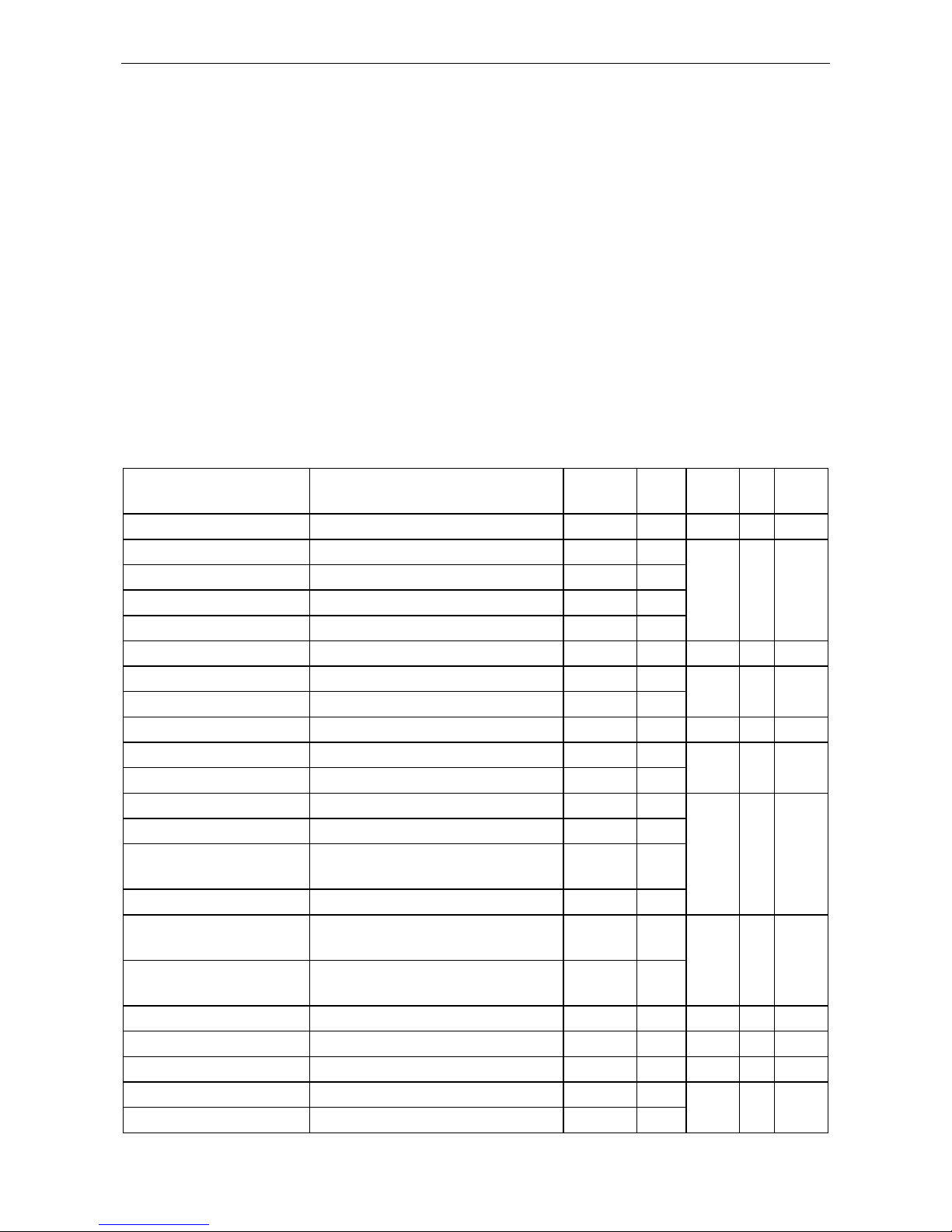

RECORD OF REVISIONS

No part of this manual may be reproduced or changed in any manner without a written

consent of the Manufacturer.

Any revision of the present manual must be recorded by the Manual holder in the following

table according to information from the Manufacturer.

New or amended text in the revised pages must be marked by a black vertical line on the

left hand margin. The Revision No. and the date must be shown on the bottom left hand

side of the page.

Rev. No.

Notice/Bulletin No.

Affected Pages

Date Issued

Date Inserted

Signature

AEROPRAKT-32 Airplane Maintenance Manual A32-002-AMM

3

Contents

1General.........................................................................................................................4

1.1 SOURCES TO PURCHASE PARTS ..............................................................................................................................5

1.2 EQUIPMENT LIST....................................................................................................................................................5

1.3 DISPOSABLE REPLACEMENT PARTS........................................................................................................................5

1.4 ENGINE SPECIFICATIONS........................................................................................................................................6

1.5 WEIGHT AND BALANCE INFORMATION ..................................................................................................................7

1.6 TIRE INFLATION PRESSURE ....................................................................................................................................7

1.7 APPROVED FUEL,OILS AND CAPACITIES ................................................................................................................8

1.8 RECOMMENDED FASTENER TORQUE VALUES.........................................................................................................8

1.9 GENERAL SAFETY INFORMATION...........................................................................................................................9

1.10 REPORTING MAINTENANCE,SERVICE,AND SAFETY DIFFICULTIES .........................................................................9

2Inspections ................................................................................................................10

3Structures ..................................................................................................................13

4Landing gear..............................................................................................................17

5Brake system.............................................................................................................21

6Engine and its control system..................................................................................25

7Cooling system..........................................................................................................29

8Lubrication system....................................................................................................30

9Fuel system................................................................................................................31

10 Exhaust system.........................................................................................................33

11 Propeller.....................................................................................................................34

12 Airplane control system............................................................................................35

13 Electrical system.......................................................................................................40

14 Cockpit heating system ............................................................................................49

15 Instruments and Avionics.........................................................................................50

16 Full and static pressure system...............................................................................52

17 Pilot seats and harness belts...................................................................................54

18 Cockpit doors ............................................................................................................55

19 Recovery system.......................................................................................................56

20 Structural repair.........................................................................................................57

20.1 GENERAL.............................................................................................................................................................57

20.2 FUSELAGE GLAZING REPAIR ................................................................................................................................57

20.3 FABRIC COVERING REPAIR...................................................................................................................................58

20.4 COMPOSITE PARTS’REPAIR .................................................................................................................................59

20.5 RESTORING OF DAMAGED PAINT/COATING ..........................................................................................................61

21 Feedback Form..........................................................................................................62

AEROPRAKT-32 Airplane Maintenance Manual A32-002-AMM

4

1 General

NOTE: This manual is subject to change by the notifications or safety bulletins published

at the official website of Aeroprakt company http://www.aeroprakt.kiev.ua.

This manual describes the procedures of proper aircraft handling and servicing

recommended by the aircraft manufacturer. It also specifies the requirements to inspection

and maintenance that are required for keeping the flight performance and reliability at a

level of a new airplane. It is recommended to adhere to the scheduled periods of

greasing/lubrication and preventive maintenance taking into account the climate and

operating conditions.

Each of the inspection or service/maintenance action outlined in this manual specifies:

recommended special tools (if any) to accomplish the task,

the parts needed to perform the task,

type of maintenance, for example, line, heavy, or overhaul,

the level of certification needed to accomplish the task, for example, owner, A&P,

LSA repairman with inspection (or maintenance) rating, and repair station,

detailed instructions and diagrams as needed to perform the task,

method to test/inspect to verify the task was accomplished properly.

The types of the maintenance (TM) tasks specified in this manual are marked with the

following one-letter abbreviation and are defined as follows:

Line maintenance (L)any repair, maintenance, scheduled checks, servicing,

inspections, or alterations not considered heavy maintenance that is approved by the

manufacturer and is specified in this maintenance manual.

Heavy maintenance (H) any maintenance, inspection, repair, or alteration which

manufacturer has designated that requires specialized training, equipment, or facilities.

Overhaul (O) maintenance, inspection, repair, or alterations that are only to be

accomplished by the manufacturer or a facility approved by the original manufacturer of

the product.

The levels of certification (LC) needed to accomplish the maintenance tasks specified in

this manual are marked with the following three-letter abbreviation and are defined as

follows:

OWN (owner) items that can be expected to be completed by a responsible owner who

holds a pilot certificate but who has not received any specific authorized training.

LRI (LSA repairman inspection) items that can be expected to be completed on an

ELSA by a responsible owner, which holds an FAA repairman certificate (light sport

aircraft), with an inspection rating or equivalent.

LRM (LSA repairman maintenance) items that can be expected to be completed on a

SLSA by a responsible individual, which holds a FAA repairman certificate (light sport

aircraft), with a maintenance rating or equivalent.

A&P (airframe and powerplant mechanic) items that can be expected to be completed

by a responsible individual who holds a mechanic certificate with airframe or powerplant

ratings, or both, or equivalent.

TSP (task specific) items that can be expected to be completed by a responsible

individual who holds either a mechanic certificate or a repairman certificate and has

received task specific training to perform the task.

AEROPRAKT-32 Airplane Maintenance Manual A32-002-AMM

5

1.1 Sources to purchase parts

For purchasing any parts or spares for this airplane contact your local dealer/distributor or

address the aircraft Manufacturer: Aeroprakt Ltd., Polyova str. 24, 03056, Kyiv, UKRAINE,

1.2 Equipment list

This aircraft has the following equipment:

Flight instruments:

oBK-3 airspeed indicator

oBG-3E altimeter

oDynon SkyView system

Engine instruments:

oDynon SkyView system

otwo VAZ-2104 fuel level indicators

Radio equipment:

oDynon radio SV COM 425

oDynon intercom SV 2S

Miscellaneous equipment

oStrobe & navigation lights

oLanding light

1.3 Disposable replacement parts

The manual (see Sections 3 through to 16) contains the check lists with information about

check periods, recommended change out (RCO) times as well as references to inspection

and servicing/maintenance instructions for the airplane components and systems.

Before expiration of the recommended change out time of separate airplane parts or when

it is not specified their operation shall be performed on condition (OC). Such parts must be

inspected and replaced, if necessary, before expiration of the RCO (if specified).

If inspections and checks arouse any issues not covered in this manual contact the

Manufacturer for additional information.

Upon detecting corrosion on airplane structural elements contact the Manufacturer for the

required technical support. In this case further operation of the airplane may be

dangerous!

AEROPRAKT-32 Airplane Maintenance Manual A32-002-AMM

6

1.4 Engine specifications

WARNING! On all issues of engine operation see Rotax engine Operator's Manual.

Follow its instructions to ensure safe and efficient operation of the engine.

Engine data and operational limitations are given in the table below:

Engine manufacturer:

BOMBARDIER-Rotax-GmbH (Austria)

Engine model:

Rotax-912UL

Rotax-912ULS

Engine type:

Flat-four, four-stroke

Maximum takeoff power:

80 h.p.

100 h.p.

Time limit at full power:

5 min (5800 rpm)

Max. revolutions (no time limit)

5500 rpm

Min. revolutions at idle

1400 rpm

Maximum coolant temperature

at pick-up point:

Oil temperature, normal

minimum

maximum

90--

90--

Exhaust gas temperature:

- maximum at takeoff

- maximum

- normal

Oil pressure, normal

minimum

maximum

2,0-5,0 bar (29-73 psi) (above 3500 RPM)

0,8 bar (12 psi) (below 3500 RPM)

7 bar (100 psi) (at cold start, allowed for a short time)

Fuel pressure, normal

maximum

0,15-0,4 bar (2,2-5,8 psi)

0,4 bar (5,8 psi)

Ambient air temperature range

from -

AEROPRAKT-32 Airplane Maintenance Manual A32-002-AMM

7

1.5 Weight and balance information

The airplane CG position must be between 1.53 m and 1.78 m or between 19% and 37%

of the wing MAC (mean aerodynamic chord) see Fig. 1.

Fig. 1 CG location of the empty airplane, pilots, fuel and baggage

Compute the airplane C.G. position using the example in the table below (for the maximum

take-off weight):

Item

Weight, kg

×

Arm, m

=

Moment, kg·m

Empty aircraft

332.5

1.645

=

547.0

180.0

1.663

=

299.3

Baggage

22.7

2.320

=

52.7

Full fuel (90 l, 0.72 kg/l)

64.8

1.960

=

127.0

Total:

600.0

1026.0

XCG = Total moment / Total weight

=

1.710

m

1.6 Tire inflation pressure

Normal inflation pressure for both main and nose wheels is 1.6 kg/cm2(22.8 psi).

AEROPRAKT-32 Airplane Maintenance Manual A32-002-AMM

8

1.7 Approved fuel, oils and capacities

WARNING! On all issues of engine operation see Rotax engine Operator's Manual.

Follow its instructions to ensure safe and efficient operation of the engine.

Fuel

Approved grade: unleaded MOGAS min. RON 95 or AVGAS 100LL

Maximum capacity of the fuel tanks45 = 90 liters

approx. 6 liters per tank

Unusable fuel: approx. 0.5 liter

Oil

Approved grade: any automotive oil of API classification or higher

Oil tank capacity: 3 liters (NOTE: check correct oil level in the tank using the oil probe.)

Coolant

Approved grade: TELKO Polar Premium Long Life Antifreeze

Quantity: 3 liters (NOTE: check the correct level using the overflow bottle marks.)

Braking fluid

Approved grade: Mobil ATF 220

Quantity: 0.2 liter (NOTE: check the correct level using the overflow bottle marks.)

1.8 Recommended fastener torque values

In A-32 all fasteners in front of the firewall and in the electrical system is metric and rear of

the firewall inch. The torque of the screws and nuts (unless specified otherwise) are as

follows:

1. For the static joints joints with spacing inserts (spacers, spherical bearings, etc.)

according to the table:

Metric fasteners

Inch fasteners

Torque,

М5

10-32

6 (4.4)

М6

1/4

10 (7.4)

М8

5/16

15 (11.0)

М10

3/8

25 (18.4)

2. For the movable joints where bolts serve as hinge axle the nuts tightening must be

done only to remove the axial play (gap) while preserving the rotational freedom in

the joint.

WARNING! All bolts, nuts (except for self-locking ones), pins, turnbuckles must be locked

reliably.

AEROPRAKT-32 Airplane Maintenance Manual A32-002-AMM

9

1.9 General safety information

Aircraft owner/operator responsibilities:

Each owner/operator of the Aeroprakt LSA must read and comply with the maintenance

and continued airworthiness information and instructions provided by the Manufacturer.

Each owner/operator of the Aeroprakt LSA is responsible for providing the Manufacturer

with current contact information where the Manufacturer may send the owner/operator

supplemental notification bulletins.

The owner/operator of the Aeroprakt LSA is responsible for notifying the Manufacturer of

any safety of flight issue or significant service difficulty upon discovery.

The owner/operator of the Aeroprakt LSA is responsible for complying with all notices of

corrective action issued by the Manufacturer and for complying with all applicable aviation

authority regulations in regard to maintaining the airworthiness of the LSA.

The owner/operator of the Aeroprakt LSA must ensure that any needed corrective action

be completed as specified in a notice, or by the next scheduled annual inspection.

Should the owner/operator of the Aeroprakt LSA not comply with any mandatory service

requirement, the LSA shall be considered not in compliance with applicable ASTM

standards and may be subject to regulatory action by the presiding aviation authority.

1.10 Reporting maintenance, service, and safety difficulties

In case of encountering any maintenance or service or safety difficulties not covered by

this Manual report about it to the aircraft Manufacturer by e-mail or by fax using the

Feedback Form (see Appendix A). If necessary enclose sketches or photos showing the

problem items in sufficient detail.

AEROPRAKT-32 Airplane Maintenance Manual A32-002-AMM

10

2 Inspections

This section contains the instructions and checklist for inspection and servicing for the

completion of periodic and annual condition/100-h inspections with references to the

sections containing detailed instructions for the inspection/servicing action.

Inspection/Servicing action and its interval in hours

50

100

200

500

1000

2000

Structures (section 3)

Inspect fuselage for damage (fatigue cracks, loose rivets, etc.)

X

Inspect fuselage glazing for damage (silvering, cracks, etc.)

X

Inspect wings for damage (fatigue cracks, loose rivets, torn fabric covering, etc.)

X

Inspect wing attachment points for play

X

Remove the wings and inspect its spherical bearings for play and hinge brackets for

cracks

X

Inspect the wing struts for fatigue cracks, deformation and loose rivets

X

Inspect the sealing fabric tape of the wing strut fairings

X

X

Inspect the all-flying horizontal tail (AFHT) for fatigue cracks, deformation, loose

rivets and play in joints

X

Check the AFHT attachment bolts/nuts torque and locking

X

Inspect the tail wheel for damage and play

X

Check the tail wheel attachment bolt/nut torque and locking

X

Inspect engine cowlings for damage (cracks, ruptures, damaged paint, etc.)

X

Landing gear (section 4)

Inspect the nose leg for fatigue cracks, deformation and play

X

Check the nose leg bellcrank bolt/nut torque and locking

X

Check the shock absorber condition

X

Inspect the MLG springs and attachment beam for fatigue cracks1, deformation and

play

X

Check the MLG spring attachment bolts/nuts torque and locking

X

Inspect the wheel tires for cracks, cuts and wear.

X

Inspect the wheel fairings for cracks, ruptures and damaged paint

X

Check the torque and locking of the fairings attachment bolts/nuts

X

Inspect the mud-screens for fatigue cracks and deformation2

X

Check the torque and locking of the mud-screen attachment bolts/nuts2

X

Inspect the skis for damage3

X

Check the torque and locking of the ski attachment bolts/nuts3

X

Brake system (section 5)

Inspect expansion tank for leaks, cracks, secure attachment. Check fluid level.

X

Inspect the master cylinder for leaks of braking fluid

X

Inspect the parking brake valve for leaks of the braking fluid

X

Inspect the brake unit for the leaks of the braking fluid

X

Measure the brake disks' wear

X

Inspect the brake system tubing and joints for leaks and damage

X

Engine and its control system (section 6)

Inspect the engine mount for fatigue cracks and deformation

X

1

After 5000 landings the MLG springs must be removed and inspected carefully for fatigue cracks

2

For an aircraft version on wheels with mud-screens

3

For an aircraft version on skis

AEROPRAKT-32 Airplane Maintenance Manual A32-002-AMM

11

Inspection/Servicing action and its interval in hours

50

100

200

500

1000

2000

Check the torque of the engine mount attachment bolts

X

Inspect the rubber mounts for damage (deep cracks, etc.)

X

Check the intake airbox function, condition and attachment4

X

Inspect the throttle and choke cables and cable sheath for wear, damage, kinks

X

Check the torque of the throttle lever bolt (axle)

X

Cooling system (section 7)

Check the radiator attachment grommets condition

X

Inspect the overflow tank for leaks of coolant, cracks; check coolant level

X

Inspect lines for leaks, damage (chaffing, cracks), loose joints

X

Lubrication system (section 8)

Inspect the oil tank plug for oil leaks; verify vent line is intact and secured

X

Inspect lines for leaks and damage (chaffing, cracks), loose joints

X

Fuel system (section 9)

Remove fuel tanks and inspect them for fuel leaks and damage

X

Inspect the shut-off and drain fuel valves for leaks of fuel

X

Check condition and replace fuel filter (if necessary)

X

Inspect fuel lines for leaks, damage (chaffing, cracks), loose joints

X

Check condition and replace fuel lines (if necessary)

X

Exhaust system (section 10)

Inspect exhaust pipes and muffler for cracks

X

Verify attachment springs are intact

X

Propeller (section 11)

Inspect propeller hub for fatigue cracks; check pitch angles

X

Check torque and locking of the propeller bolts/nuts

X

Check torque of the spinner bolts

X

Airplane control system (section 12)

Inspect control surfaces for fatigue cracks, deformation, loose rivets, torn fabric

X

Check the play in the hinges of control surfaces/linkages

X

Check tightness/locking of the nuts of control surfaces/linkages

X

Check tightness/locking of the nuts and play in hinges of control rods/shafts

X

Inspect AFHT control cable for wear, check cable tension

X

Inspect flaperons control cable for wear, check cable tension

X

Inspect rudder control cables for wear, check cable tension

X

Extend flaps and inspect flap extension (play in hinges, nuts tightness/locking)

X

Grease the slide bearings of all control surfaces/linkages (where necessary)

X

Inspect rudder pedals for fatigue cracks and deformation

X

Check condition of the control cable pulleys and fairleads

X

Check trim tab attachment bolts/nuts for corrosion, replace if necessary

X

Inspect the trim tab control cables and sheath for damage (wear, kinks, etc.)

X

Electrical system (section 13)

Verify battery charges/discharges properly, otherwise replace

X

Clean starter terminals and starter relay connector of corrosion, if any

X

Verify starter relay and cables are connected and attached reliably

X

Verify power cables have good contact with battery, starter and ground

X

4

For an aircraft version equipped with intake airbox

AEROPRAKT-32 Airplane Maintenance Manual A32-002-AMM

12

Inspection/Servicing action and its interval in hours

50

100

200

500

1000

2000

Clean rectifier-regulator and condenser terminals/connectors of corrosion, if any

X

Check condition of electric switches and warning lights

X

Clean fuse block terminals of corrosion, if any. Check fuses

X

Verify correct function of the fuel level sensors/indicators (check readings)

X

Check landing light function and attaching nut torque

X

Clean engine sensors' terminals and connectors of corrosion, if any

X

Inspect electrical harness for damage (chaffing, broken wires, bad insulation)

X

Cockpit heating system(section 14)

Inspect warm air shutter and its hinges for play/wearing. Repair or replace if

necessary

X

Check condition and operation of the warm air shutter actuator. Replace if necessary

X

Instruments and Avionics (section 15)

Check condition of the switches and lights. Replace defective ones, if any

X

Check operation of the instruments and avionics. Replace defective ones, if any

X

Check condition of the full and static pressure system

X

Pilot seats and harness belts (section 16)

Inspect the seats framework for the fatigue cracks and loose rivets

X

Inspect the seat cushions upholstery for damage

X

properly

X

Cockpit doors (section 17)

Inspect door glass, framework and sealing for damage

X

Verify the gas struts function properly

X

Recovery system (section 19)

Check attachment of the suspension cables to fuselage and parachute lanyard

X

AEROPRAKT-32 Airplane Maintenance Manual A32-002-AMM

13

3 Structures

The airframe of A-32 airplane includes the following parts: fuselage with polycarbonate glass

windscreen, wings, wing struts, all-flying horizontal tail (AFHT), vertical tail unit, wing fillets,

strut fairings and engine cowling. Fuselage with fin and wing struts are made of aluminum

alloys. Wing framework including leading edge section and top skin are all-metal and bottom

skin is fabric. Framework of flaperons, elevator and AFHT is all-metal, their rear skin (aft of

spar) is fabric. The rear fuselage skin panels (top and two side ones) include windows of

PVC glass. The aft wing fillets and engine cowling are made of fiberglass.

When servicing the airplane a special care shall be taken to protect the airframe from

corrosion and to protection of the paint coating. Protection of the airframe parts from

corrosion consists mainly of keeping the protective coatings intact. Care of the fabric skin

consists mainly of care of its paint coating. Correct care of the paint coating is one of the

conditions of preserving the airplane strength and aerodynamic characteristics. To keep

the paint coating of the airplane in good condition the dust and moisture must be removed

in time, the paint must be protected from scratches, and spilling oil products, solvents,

alkalis and acids on paint must be avoided.

INSPECTION CHART

Part No.

Description

Interval

RCO

Instr.

No.

TM

LC

A32-0-530000-00-000

Fuselage

100 h

OC

3.1

L

LRI

A32-0-561000-01-000

Windscreen glass

100 h

OC

3.2

L

OWN

A32-0-530000-12-000

Rear fuselage skin panel, top

100 h

OC

A32-0-530000-08-001

Rear fuselage skin panel, right

100 h

OC

A32-0-530000-08-002

Rear fuselage skin panel, left

100 h

OC

A32-0-572000-00-000

Wing

500 h

OC

3.3

L

OWN

A32-0-531200-00-001

Aft wing fillet, right

200 h

OC

3.10

LRI

A32-0-531200-00-002

Aft wing fillet, left

200 h

OC

COM-5T

Spherical bearings, 4 pcs.

2000 h

OC

3.4

L

LRI

A32-0-579000-00-001

Wing strut, right

500 h

OC

3.5

L

LRI

A32-0-579000-00-002

Wing strut, left

500 h

OC

A32-0-579120-00-001

Wings strut fairing, top, right

200 h

OC

3.6

L

LRI

A32-0-579120-00-002

Wings strut fairing, top, left

200 h

OC

A32-0-579110-00-001

Wings strut fairing, bottom,

right

200 h

OC

A32-0-579110-00-002

Wings strut fairing, bottom, left

200 h

OC

AN 175-16

Wing front attachment bolts, 2

pcs.

100 h

OC

1.8

L

OWN

AN 175-12

Wing aft attachment bolts, 2

pcs.

100 h

OC

-0-530000-63-000

Tail skid

100 h

OC

3.8

L

LRI

AN 3-6

Top tail skid bolt, 2 pcs.

100 h

OC

1.8

L

OWN

AN 4-7

Bottom tail skid bolt, 2 pcs.

100 h

OC

1.8

L

OWN

A32-3-711020-00-000

Engine cowling panel, top

100 h

OC

3.9

L

LRI

A32-3-711010-00-000

Engine cowling panel, bottom

100 h

OC

AEROPRAKT-32 Airplane Maintenance Manual A32-002-AMM

14

Instructions:

1.1 Remove the engine cowling, doors, wing strut fairings (undo the screws fixing the

fairings and 'slide' them along the strut), pilot seats, and rugs. Inspect the fuselage

for cracks and deformation, paying special attention to primary structural elements,

areas of their connection and rivet joints (frames No. 1, 4, 5, 6, longitudinal,

transverse and vertical beams of the cockpit, undercarriage beam, fuselage tubes,

tail boom and fin skin).

Inspection for fatigue cracks. Use torch or any other suitable source of light. When

detecting very thin cracks remove the paint in the area of the suspected crack for a

closer flaw detection. If possible apply load in this area in a manner that will 'open up'

the crack. If the closer inspection confirmed the crack existence contact the

manufacturer for required technical support. If the suspected crack was not detected

repaint this area.

Inspection for loose rivets. When inspecting rivet joints look at the area around

river heads. The paint around the rivet heads must have no cracks or black stains

that indicate on loose and corroded rivet joint. When detecting such flaws contact the

manufacturer for the required technical support.

If no flaws were detected reinstall everything in the reversed order. Apply Loctite 222

on the thread of the attachment screws of the wing strut fairings before reinstalling

them.

Recommended special tools: magnifying glass, electric torch.

Necessary parts/materials: paint, Loctite 222.

1.2 Inspect the glass for 'silvering' (micro cracks) and cracks in the attachment areas.

When detecting a crack shorter than 50 mm (2 in) carefully cut a hole at its end with

a 3 mm (0.12 in) drill to stop the crack propagation. If the crack is longer than

50 mm (2 in) the glass must be replaced. Contact the manufacturer for glass

replacement instructions.

WARNING! The glazing material is not resistant to fuels, oils and solvents. Spilling

those liquids on glazing may cause its dimness and cracking.

Recommended special tools: electric drill, 3 mm drill.

Necessary parts/materials: none.

1.3 Drain fuel from the fuel tanks. Remove the wing strut fairings and fuel tanks. Inspect

the wing for fatigue cracks, deformation and loose rivets as described in 1.1 (2nd and

3rd paragraph). Pay special attention to the strut-to-wing attachment points, rivet

joints of the wing leading edge section and top skin.

Inspect the fabric skin for damage and detachment from the wing framework. It is

allowed to repair small cuts/ruptures (shorter 50 mm or 2 in) covering them with

ORACAL permanent sticking film. Upon detecting bigger damages and delaminating

of the fabric skin from the framework contact manufacturer for the required technical

support.

Verify that there is no play in attachment points of the wing and strut by holding the

wingtip gently and moving it up and down with an amplitude of 300 mm (1 ft). The

movement in the attachment points due to loose joint (play) is not allowed. When

detecting insignificant radial play (less than 0.2 mm or 0.01 in) in the strut attachment

points it must be eliminated by tightening its bolt joint. In case if the play is more than

0.2 mm (0.01 in) contact the manufacturer for the required technical support.

AEROPRAKT-32 Airplane Maintenance Manual A32-002-AMM

15

In case if no defects are found re-assemble everything in the reversed order. Before

re-installing the screws attaching the fuel tanks and strut fairings apply Loctite 222 on

the thread.

Recommended special tools: magnifying glass, electric torch.

Necessary parts/materials: ORACAL permanent sticking film, Loctite 222.

1.4 Detach the wings by doing the following:

- detach the doors;

- drain fuel from the fuel tanks;

- disconnect the fuel lines from the fuel valves, close the valves, plug the fuel lines

and pull them out of cockpit through the rubber sealing rings in fuselage beams;

CAUTION! Be careful while working with the fuel system, the fuel remaining in the

fuel lines is highly fire-hazardous and when spilled on the cockpit glass may cause

glass dimness and cracking.

- disconnect the electric connectors of the navigation lights and fuel level probes at

wing root and take the cables out of fuselage;

- detach the strut fairings (undo the screws attaching the fairings and slide fairings

along the struts);

- detach the Cardan rings from the flaperon shafts by removing the vertical bolts;

- remove the split pins and undo the nuts from wing and strut attachment points;

- while holding the wing by the tip and strut carefully take out the strut attachment

bolts and remove the struts;

- while holding the wing by the tip and at the root take out the wing attachment bolts

and slowly move the wing away from fuselage carefully pulling the navigation light

from the wing fillets;

Inspect the wing and strut attachment fittings for fatigue cracks. Check the spherical

bearing for axial and radial play. When detecting play in bearings, as well as

corrosion and fatigue cracks in the attachment fittings contact the manufacturer for

the required technical support.

If no defects were detected re-assemble everything in the reversed order. Before

reinstalling the screws attaching the fuel tanks and strut fairings apply Loctite 222 on

the thread.

Recommended special tools: magnifying glass, electric torch.

Necessary parts/materials: screw clamps, Loctite 222.

1.5 Remove the strut fairings (undo the screws attaching the fairings and slide fairing

along the strut). Inspect the struts for fatigue cracks, deformation (bend) and loose

rivets as described in 1.1 (2nd and 3rd paragraph).

If no defects were found re-install the fairing applying Loctite 222 on the thread of the

attaching screws.

Recommended special tools: none.

Necessary parts/materials: none.

1.6 Undo the screws attaching the fairings and slide the fairings along the strut. Inspect

the sealing fabric tape in the inner side. If necessary use double-sided sticking tape

to fix the tape.

Re-install the fairings applying Loctite 222 on the thread of the attaching screws.

AEROPRAKT-32 Airplane Maintenance Manual A32-002-AMM

16

1.7 Inspect the tail skid for damage and cracks. When detecting a serious damage

replace the cracks.

Recommended special tools: none.

Necessary parts/materials: none.

1.8 Remove the top and bottom engine cowling and inspect for cracks, ruptures, as well

as damaged paint coating. When detecting damaged paint coating sand the

damaged area with sandpaper and re-paint. When detecting cracks and ruptures

sand the damaged area from inside with sandpaper and cover it with a patch of

fiberglass cloth with epoxy resin. After the resin solidifies properly, sand the damaged

area outside with sandpaper and re-paint.

Recommended special tools: rubber gloves.

Necessary parts/materials: fiberglass cloth, epoxy adhesive, paint.

1.9 Undo the screws attaching the aft wing fillets and remove. Inspect for cracks,

ruptures, as well as damaged paint coating. When detecting damaged paint coating

sand the damaged area with sandpaper and re-paint. When detecting cracks and

ruptures sand the damaged area from inside with sandpaper and cover it with a

patch of fiberglass cloth with epoxy resin. After the resin solidifies properly, sand the

damaged area outside with sandpaper and re-paint. Inspect the sealing fabric tape in

the inner side along outer edge. If necessary use double-sided sticking tape to fix the

tape.

Re-install the the aft wing fillets applying Loctite 222 on the thread of the attaching

screws.

AEROPRAKT-32 Airplane Maintenance Manual A32-002-AMM

17

4 Landing gear

A-32 may have the landing gear (LG) of one of the following three types: wheels, skis or

floats. This manual contains the information for servicing the wheel LG. The float and skis

type LG is not included in this manual. For obtaining additional information contact the

manufacturer.

When put on wheels the airplane is equipped with wheels of Matco mfg.

NOTE! When installing wheels tighten the axle nut as follows: first tighten the nut to

remove the axial play, then turn it back until its slots alight with the hole for the split pin in

the axle. Then lock the nut using the split pin.

The nose LG leg is steerable, telescoping type with spring shock absorber. The leg

structure consists of the strut, trailing link, bellcrank, wheel fork, spring shock absorber,

axle, spacing sleeves, wheel and fairing/mud-screen. The steering is achieved using the

rudder pedals via the rods connected to the bellcrank on the strut. The leg is attached to

the firewall at two points lower and upper supports. The upper support is made of

aluminum alloy plate, the lower support is an assembly. The supports contain bronze

bearings.

Main landing gear (MLG) is of cantilever spring type. The MLG leg consists of the spring, axle,

wheel, brake unit with supporting plate, and fairing (or mud-screen). The MLG spring is made

of aluminum alloy. It is bolted at two points to the lower beam of the frame No.2.

Maintenance of the brake unit with supporting plate is described in "Brake system" section.

INSPECTION CHART

Part No.

Description

Interval

RCO

Instr.

No.

TM

LC

A32-0-321000-00-

000

Nose leg

100 h

OC

4.1

L

LRI

AN 4-22A

Bellcrank bolt

100 h

OC

1.8

L

OWN

165x50 mm

Spring shock absorber

100 h

OC

4.2

L

LRM

A22LS-3-4110-00

Main leg, right

100 h

OC

4.3

H

LRM

A22LS-3-4110-00

Main leg, left

100 h

OC

4.3

AN 6-37

Spring bolts, upper, 2 pcs.

100 h

OC

1.8

L

OWN

AN 7-41

Spring bolts, lower, 2 pcs.

100 h

OC

See Matco P/N

Nose wheel assembly

200 h

OC

4.4

L

LRI

See Matco P/N

Right wheel assembly

200 h

OC

4.4

See Matco P/N

Left wheel assembly

200 h

OC

4.4

A22LS-0-4410-00

Nose wheel fairing

50 h

OC

4.5

L

LRI

A22LS-0-4420-01

Right wheel fairing

50 h

OC

4.5

A22LS-0-4420-02

Left wheel fairing

50 h

OC

4.5

Instructions:

Remove the nose wheel fairing. Inspect the nose leg for fatigue cracks, deformation

and play. When inspecting follow the instructions of 1.1 (2 and 3 paragraph) of

Structuressection. Pay special attention to the areas of the nose leg attachment

near its upper and lower supports as well as weld seams of the nose leg.

AEROPRAKT-32 Airplane Maintenance Manual A32-002-AMM

18

Check the nose leg supports for play. The radial play in the supports may not exceed

1 mm (0.04 in). No axial play is allowed.

If the radial play in the upper support exceeds the above specified value then the

bronze bearing in the support must be replaced. If the radial play in the lower support

exceeds the above specified value then the support with bearing must be replaced.

Contact manufacturer to obtain the instructions on replacement of the bearing and

support.

Upon detecting axial play in the supports tighten the upper support nut until play is

eliminated, if necessary, insert a washer of an appropriate thickness.

WARNING! Tightening the nut must eliminate the play while ensuring free rotation of

the leg in the supports. Do not over-tighten the nut!

Check the torque of all bolted joints with self-locking nuts.

Lubricate all surfaces of the nose leg trailing link subjected to friction depending on

their condition as follows:

- set parking brake to ON;

- disconnect the control rods from the nose leg bellcrank;

- remove the split pin and undo the nut of the upper support of the nose leg;

- undo the nut and take out the bellcrank bolt;

- while holding the nose leg carefully push down the airplane tail near the stabilizer

attachment points till the airplane sets on the tail wheel and hold it in this position

till the nose leg is re-installed back (this operation must be done by two persons);

- carefully take out the nose leg from the supports simultaneously removing the

bellcrank from it;

CAUTION! Do not lower the fuselage nose while the nose leg is removed! This may

cause damage to the airframe and propeller.

- remove the old grease from the surfaces of the nose leg trailing link subjected to

friction;

- apply thin layer of new grease;

- re-install the leg in the reversed order;

- squirt grease into the nose leg hinge till grease comes out;

- remove the excessive grease with rags.

Any lubricating grease for bearings may be used for the nose leg.

After servicing the nose leg re-install the nose wheel fairing.

Recommended special tools: none.

Necessary parts/materials: grease gun, grease.

If the spring shock absorber is seriously damaged, then it must be removed for repair

or replacement.

To remove the shock absorber do the following:

- set the parking brake to ON;

- remove the nose wheel fairing;

- remove the split pins and undo the nuts of the shock absorber attachment;

- carefully push down the airplane tail near the AFHT attachment points till the

airplane sets on the tail skid and remove the shock absorber (this operation must be

done by two persons);

AEROPRAKT-32 Airplane Maintenance Manual A32-002-AMM

19

- set the airplane level on a wooden support under its bottom as close to the frame

No. 1 (firewall) as possible (the support width must be equal or bigger than the

fuselage width).

To re-install the spring shock absorber perform the above actions in the reversed

order. Before installation of the spring shock absorber lubricate its attachment bolts

with bearing grease.

WARNING! When installing the shock absorber tighten the nuts as follows: first

tighten to remove the axial play, then rotate a little back to alight the nearest slot of

the castle nut with the hole for the split pin and secure it with a split pin. Tightening of

the shock absorber bolts must not restrict its free motion.

Recommended special tools: none.

Necessary parts/materials: none.

1.10 Remove the pilot seat and wheel fairing. Inspect the MLG attachment beam and

spring for fatigue cracks, deformation and play following the instructions of 1.1 (2nd

and 3rd paragraph) of "Structures" section. Pay special attention to the areas of the

spring attachment to the beam and wheel axle attachment to the spring.

If axial play is detected in the MLG attachment, check the attachment bolts' torque. If

radial play is detected, contact the manufacturer to obtain the required technical

support.

After 5000 landings careful inspection of the MLG spring is required. The MLG leg

must be removed for that.

To remove the MLG leg do the following:

- put the wheel chokes under the nose and opposite main wheel;

- remove the pilot seats;

- remove the wheel fairing;

- cut the plastic cable ties fixing the brake system tube to the MLG spring;

- lift the airplane using a jack placed under a special plate near the opening in the

fuselage bottom skin for the MLG spring;

- remove the safety wire and undo the brake disk screws and wheel axle nut;

- remove the wheel and brake disk;

- leaving the braking system tube assembled, disconnect the braking unit from the

supporting plate (undo two bolts and three screws of the braking unit and move the

brake unit with the tube aside);

WARNING! When handling the brake pads and disk avoid smearing their working

surfaces with any lubricating materials. Do not use braking system with a braking disk

removed.

- remove the split pins and undo the nuts of the upper and lower bolts of the MLG

spring attachment and carefully force the bolts out of the holes;

- remove the spring.

Inspect carefully the spring and fittings of the MLG attachment beam for fatigue

cracks. Pay special attention to the areas around the attachment holes in the beam

and spring. Upon detecting fatigue cracks in the MLG spring or MLG attachment

beam contact the manufacturer to obtain the required technical support.

If no defects were detected, install the MLG leg back by doing the above actions in

the reversed order.

AEROPRAKT-32 Airplane Maintenance Manual A32-002-AMM

20

Before re-installing the attachment screws of the brake disk and pilot seats apply

Loctite 222 on their thread.

Recommended special tools: none.

Necessary parts/materials: plastic cable ties.

1.11 Remove the wheel fairing. Inspect the tire for cracks and cuts. Determine the nature

and degree of the tire wear. In case of normal operation the wear will be uniform over

entire operating surface of the tire. Tire operation is allowed until exposure of its cord.

In case if exposed cord or deep cuts are detected the tire must be replaced.

To replace the nose wheel tire do the following:

- set the parking brake to ON;

- remove the split pin of the nose wheel axle nut and undo it;

- carefully push down the airplane tail near the stabilizer attachment points till the

airplane sets on the tail wheel and remove the nose wheel (this operation must be

done by two persons);

-

- replace the tire;

- inflate the wheel (1.6 bar) and install it back on the airplane making the above

actions in the reversed order.

To replace a main wheel tire do the following:

- put wheel chokes under the opposite main wheel and nose wheel;

- remove the split pin of the main wheel axle nut and undo it;

- lift the airplane using a jack placed under a special plate near the opening in the

fuselage bottom skin for the MLG spring;

- remove the safety wire and undo the brake disk screws and wheel axle nut;

- remove the wheel;

- replace the tire;

- inflate the wheel (1.6 bar) and install it back on the airplane making the above

actions in the reversed order.

Before re-installing the attachment screws of the brake disk apply Loctite 222 on their

thread.

If no defects were found, check the wheel pressure and inflate if necessary. The

pressure must be equal to 1.6 bar. Install the wheel fairing after servicing.

For more detailed information regarding the servicing (repairing) the wheels visit the

http://www.matcomfg .com.

Recommended special tools: none.

Necessary parts/materials: none.

1.12 Inspect the fairing for cracks, ruptures and paintwork damage. If damaged paint is

detected, remove the fairing, clean the damaged area with sand paper and repaint. If

cracks and ruptures were detected, remove the fairing, clean the damaged area with

sand paper from inside, and apply a patch of fiberglass cloth with epoxy resin. After the

resin solidifies properly, sand the damaged area outside with sandpaper and re-paint.

Check the torque of the fairing attachment bolts/nuts.

Recommended special tools: torque wrench, rubber gloves.

Necessary parts/materials: fiberglass cloth, epoxy adhesive, paint.

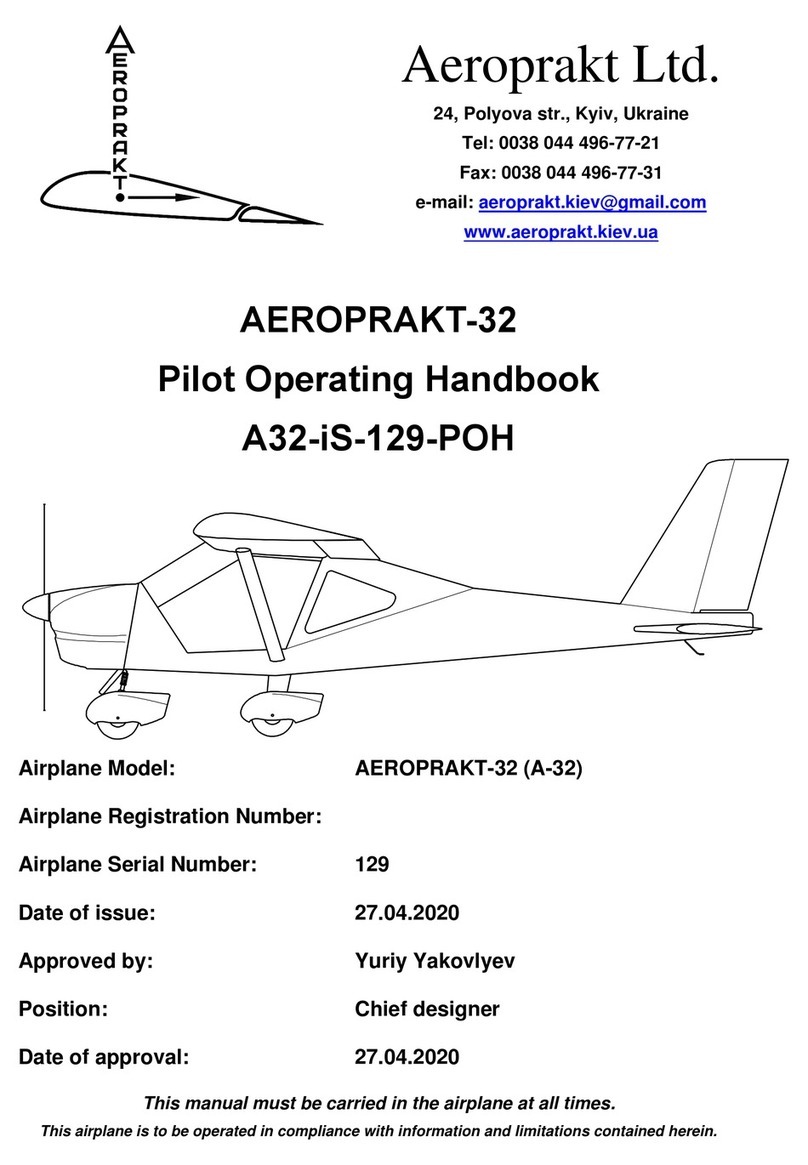

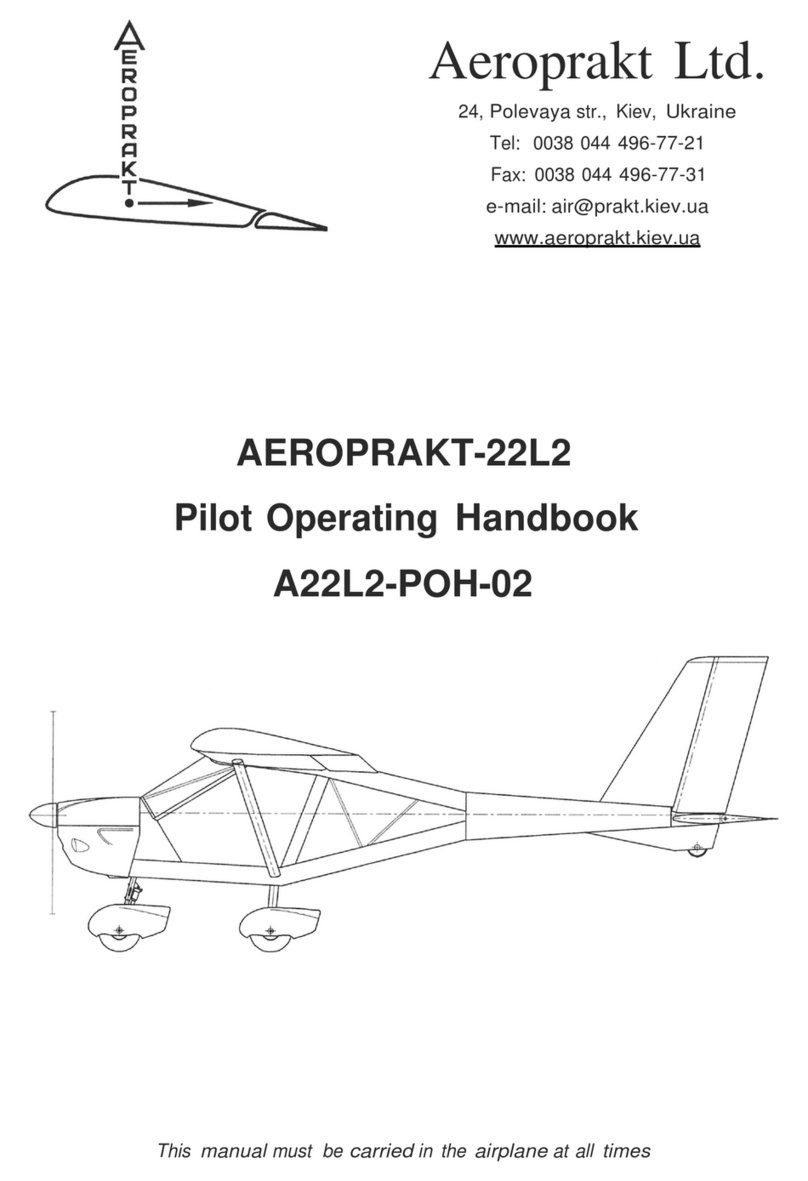

Other manuals for AEROPRAKT-32

1

Table of contents

Other AEROPRAKT Aircraft manuals

AEROPRAKT

AEROPRAKT A32-029-POH Owner's manual

AEROPRAKT

AEROPRAKT AEROPRAKT-32 Owner's manual

AEROPRAKT

AEROPRAKT A32-iS-129-POH Owner's manual

AEROPRAKT

AEROPRAKT AEROPRAKT-22L2 Owner's manual

AEROPRAKT

AEROPRAKT A32 Owner's manual

AEROPRAKT

AEROPRAKT A32 User manual

AEROPRAKT

AEROPRAKT A22LS User manual

AEROPRAKT

AEROPRAKT 22LS Owner's manual

AEROPRAKT

AEROPRAKT N226AM Owner's manual

AEROPRAKT

AEROPRAKT AEROPRAKT-22LS User manual