AEROPRODUKT BSK-J/EI90 User manual

innovative air-flow solutions

fire protection

fire damper

BSK-J/EI90(G)

multi-blade

The multi-blade fire damper type BSK-J/EI90(G) is used to prevent fire and reduce smoke spreading

from one fire compartment to another through the air ductwork system which may penetrate fire

separating walls and floors.

According to standard EN 1336-2 they assure minimum 90 minutes reliable closing.

The multi-blade fire damper can mounted in vertical (in/on rigid and light walls) or horizontal (in/on

floor) position.

BSK-J/EI90(G)

multi-blade fire damper

BSK-J/EI90(G) multi-blade fire damper

BSK-J/EI90(G)/2

APPLICATION

STANDARD and NORMS

The multi-blade fire damper type BSK-J/EI90(G) is tested by PAVUS a.s. Fire testing laboratory.

Production of the fire damper is according to EN 15650 standard:

Tests of the fire damper is according to EN 1366-2 standard:

Determination of the fire resistance performance criteria is

according to EN 13501-3 standard:

Fire resistance tests for service installations.

Part 2: Fire dampers

Ventilation for buildings: Fire dampers.

Fire classification of construction products and building elements.

Part 3: Classification using data from fire resistance tests on products and

elements used in building service installations:

fire resisting ducts and fire dampers.

Ventilation for buildings. Air terminal devices.

Aerodynamic testing of damper and valves

Determination of the leakage of the fire damper is according to 1751 standard:

And all locally relevant regulations must be observed.

Fire resistance performance

EI 90 (v h i↔o) S

e o

EI 120 (v h i↔o) S*

e o

EN 1366-2

EN 15650

Certificates Of Constancy Of Performance

1391-CPR-2017/0086

Declaration of Performance

DoP/BSK-J/001-v2/2017

Casing leakage

class B

Valve leakage

class 2

EN 1751

* some mounting options

www.aeroprodukt.hu

BSK-J/EI90(G)

multi-blade fire damper

BSK-J/EI90(G)/3

MODELS

FIRE RESISTANCE CLASS

min.

min.

max.

max.

max. max.

200 1000 1050 1500

150

1050

1200

1500

BSK-J/EI90

BSK-J/EI90/G

height H (mm)

width B (mm)

parallel with the axle

Nominal dimension of the multi-blade fire damper width(B) x height (H):

min. dimension:

200 x 150 mm

max. dimension:

1000 x 1050 mm -ig - BSK-J/EI90

max. dimension:

1500 x 1500 mm-ig - BSK-J/EI90/G

mounting lenght:

200 mm (+ optional 100 mm extra frame)

EI 90 (v h i ↔ o) S

e o

S

i ↔ o

v - h

e o

90 or 120

EI

indicate the suitability for vertical and horizontal use in wall and floor

tt - classification time in minutes

3 -1 2

max. leakage permitted for smoke control dampers is < 360 m (h *m )

3 -1 2

max. leakage permitted for smoke control dampers is < 200 m (h *m )

fire from inside or fire from outside or both

BSK-J/EI90(G) multi-blade fire damper

Main features Prescriptions of

standard EN 15650 Performance criteria Compliance

It keeps continuously its separating function, without

exceeding the temperature on the protected side

a) with more than 140 ºC the initial average

temperature or

b) on any place ( including the thermocouple) with

more than 180 ºC the initial average temperature

(expressed in minutes)

- Operating durability 4.3.3.2- C annex 10 000 cycles at nominal operating current passed

- Opening - closing test 4.3.3.2 End of cycle in less than 120 seconds passed

Prescription

Fire resistance classification

- Leakage 4.1.1 c) EI…S

The leakage through the fire damper can not exceed

200 m 3/(h*m 2)- measured with 5 minutes after the

fire test.

It keeps continuously its separating function, without

having fire-raising effect respectively the leakage

trough the damper can not exceed the value of 360

m3/(h*m 2)

passed

- Insulation 4.1.1 b) EI passed

Conform

EN 1366-2,

EN 13501-3

Conform

EN 1366-2,

EN 13501-3

Conform

EN 1366-2,

EN 13501-3

passed

Operational reliability

operation test cycle

Opening-closing cycle test

- Integrity 4.1.1 a) E

BSK-J/EI90(G)/4

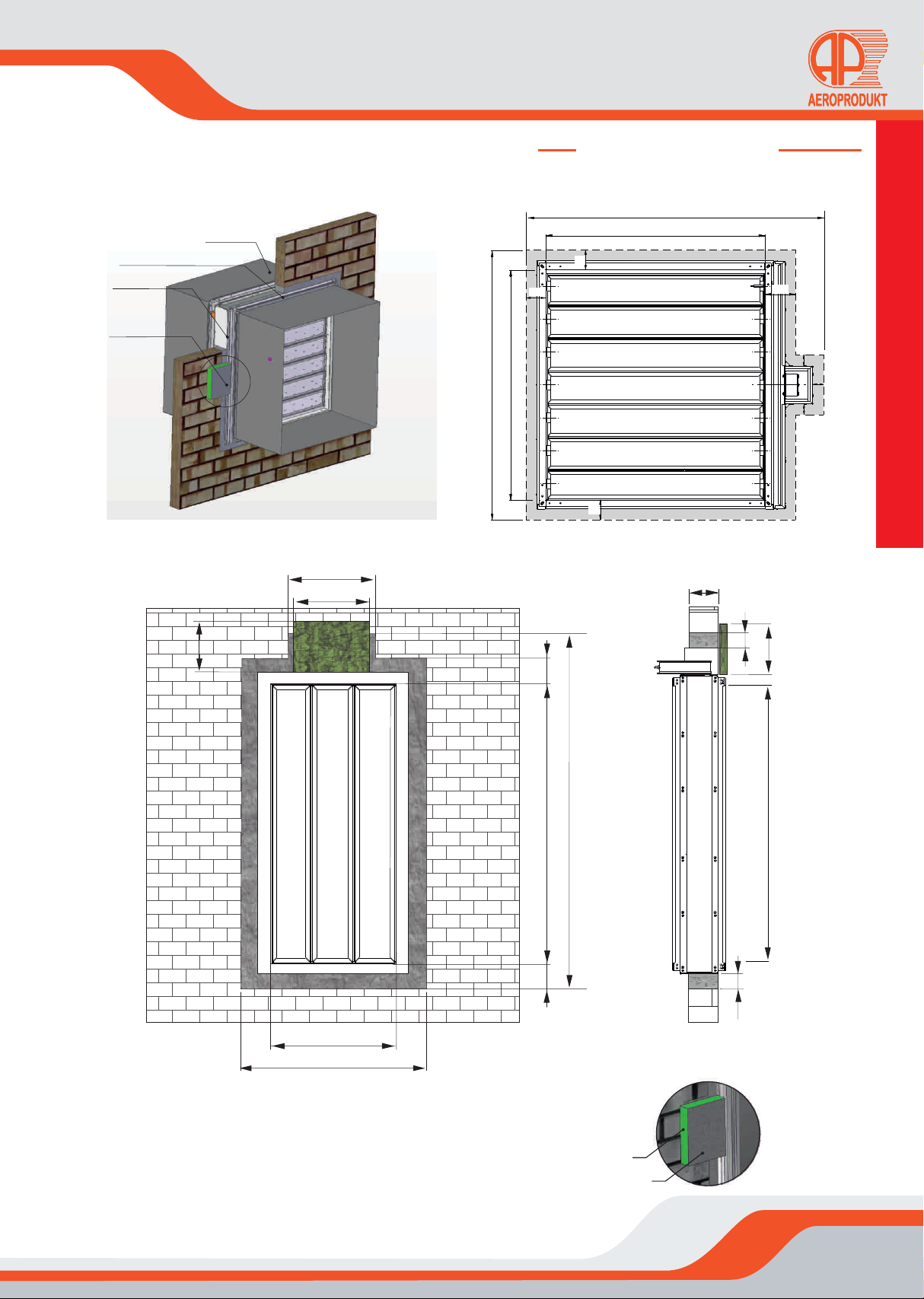

CONSTRUCTION

Dimensions of BSK-J/EI90 fire damper

DIMENSIONS

OPTCIÓ

L1L2 173

10

9

8

11

127

90,530300

100

30

10,5

10,5

30

28,5 200

143

SECTION A-A

2

B

H

A

A

6

5

3

7

4

3

2

3

1

4

3

10,5

1 drive opposite side lower-upper side blades - intermadiate blade - drive drive side 2 3 4 5

drive casing protecting box of actuator thermo sensor actuating motor connection frame extension (optoinal) 6 7 8 9 10 11

H L1 L2

150 31,3 31,3

300 31,3 181,3

450 181,3 181,3

600 181,3 331,3

750 331,3 331,3

900 331,3 481,3

1050 481,3 481,3

BSK-J/EI90(G)

multi-blade fire damper

BSK-J/EI90(G) multi-blade fire damper

COLD LEAKAGE - P profile

BLADES

HOUSING

The housing of the damper is

made of 4 double-walled,

fireproof calcium silicate sides,

that are assembled with rivets

using corner braces. The

connecting frame is made of

galvanized steel.

T h e d o u b l e - w a l l e d ,

overlapping damper blades

with steel bracing are placed

with 150 mm step. The louvers

have the same movement

direction. The louvers are

embedded in a heat resistant

bush that is extruded in the

double-walled house.

The “cold” leakage (20 ºC) of

the house is ensured by the

heat stabilized, customized

rubber profile placed on the

lower and upper gap closings,

on the side panels respectively

on the out- and inside edges of

the leaves.

CONNECTION FRAME

WARM LEAKAGE

BLADE DRIVING:

The blade driving consists of

a rod that is connected to all

the blades . The blade driving

is placed inside the casing,

outside the airflow.

The “warm” leakage of the

damper ( in safety position ) is

en sur ed b y th e foa mi n g

sealant sunked the side panels

and placed on the edge of the

damper leafs that are closing

due to heat effect.

The installation depth of the

BSK-J/EI90 multi-blade fire

damper with the connection

f r a m e i s 2 0 0 m m . T h e

connection to the ductwork

system is done with a 30 mm

MEZ flange that has 4 pcs

(ø9,1x19 mm) oval holes on

the corners.

www.aeroprodukt.hu

BSK-J/EI90(G)/5

DIMENSIONS

1 drive opposite side lower-upper side blades - intermadiate blade - drive drive side 2 3 4 5

drive casing protecting box of actuator 8 actuating motor 9 connection frame6 7

WEIGHTS

Weight of BSK-J/ EI90(G) fire damper [kg]

(without actuators)

B x H 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500

150 13,3 15,5 17,8 20,1 22,4 24,7 27,0 29,3 31,5 52,8 63,3 73,8 84,3 94,8

300 18,8 21,8 24,9 27,9 30,9 34,0 37,0 40,1 43,0 61,3 71,8 82,6 93,1 103,6

450 24,2 28,0 31,8 35,6 39,3 43,1 46,8 50,7 54,4 75,7 86,2 96,7 107,2 117,7

600 26,0 34,2 38,7 43,2 47,7 52,3 56,7 61,3 65,8 87,1 97,6 108,0 118,5 129,0

750 35,1 40,4 45,6 50,9 56,1 61,4 66,6 71,9 77,1 98,4 109,0 119,5 130,0 140,5

900 40,6 46,6 52,6 58,6 64,5 70,5 76,5 82,5 88,5 109,8 125,9 134,8 145,3 155,5

1050 47,6 54,4 61,1 67,9 74,6 81,3 88,0 94,8 101,5 122,8 133,3 143,7 154,2 164,6

1200 68,4 76,2 84,0 91,8 99,6 107,4 115,2 123,0 130,8 138,6 146,4 154,2 162,0 169,8

1350 82,0 89,8 97,6 105,4 113,2 121,0 125,6 136,4 144,4 152,2 160,8 169,4 178,3 196,0

1500 95,6 103,4 111,2 119,0 126,8 134,6 139,8 149,8 158,0 165,8 175,2 184,6 194,6 212,7

2

4

8

B

H

3

4

5

6

7

9

48,5

H L1 L2

150 60,1 60,1

300 60,1 214,3

450 214,3 214,3

600 214,3 364,7

750 364,7 364,7

900 364,7 514,7

1050 514,7 514,7

1200 514,7 664,7

1350 664,7 664,7

1500 664,7 814,7

SECTION A-A

143

200

28,5

12799

30

48,5

30

30

30

1

L1L2

3

3

2

BSK-J/EI90(G)

multi-blade fire damper

BSK-J/EI90(G) multi-blade fire damper

Dimensions of BSK-J/EI90/G fire damper

BSK-J/EI90(G)/6

EFFECTIVE CROSS-SECTION

B x H 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500

150 0,0098 0,0151 0,0204 0,0257 0,0310 0,0363 0,0416 0,0469 0,0522 0,0575 0,0628 0,0681 0,0734 0,0787

300 0,0290 0,0447 0,0604 0,0761 0,0918 0,1075 0,1232 0,1389 0,1546 0,1703 0,1860 0,2017 0,2174 0,2331

450 0,0483 0,0744 0,1005 0,1266 0,1527 0,1788 0,2049 0,2310 0,2571 0,2832 0,3093 0,3354 0,3615 0,3876

600 0,0675 0,1040 0,1405 0,1770 0,2135 0,2500 0,2865 0,3230 0,3595 0,3960 0,4325 0,4690 0,5055 0,5420

750 0,0868 0,1337 0,1806 0,2275 0,2744 0,3213 0,3682 0,4151 0,4620 0,5089 0,5558 0,6027 0,6496 0,6965

900 0,1060 0,1633 0,2206 0,2779 0,3352 0,3925 0,4498 0,5071 0,5644 0,6217 0,6790 0,7363 0,7936 0,8509

1050 0,1252 0,1929 0,2606 0,3283 0,3960 0,4637 0,5314 0,5991 0,6668 0,7345 0,8022 0,8699 0,9376 1,0053

1200 0,1445 0,2226 0,3007 0,3788 0,4569 0,5350 0,6131 0,6912 0,7693 0,8474 0,9255 1,0036 1,0817 1,1598

1350 0,1637 0,2522 0,3407 0,4292 0,5177 0,6062 0,6947 0,7832 0,8717 0,9602 1,0487 1,1372 1,2257 1,3142

1500 0,1830 0,2819 0,3808 0,4797 0,5786 0,6775 0,7764 0,8753 0,9742 1,0731 1,1720 1,2709 1,3698 1,4687

2

Effective surface of BSK-J/ EI90(G) fire damper - A [m ]

eff

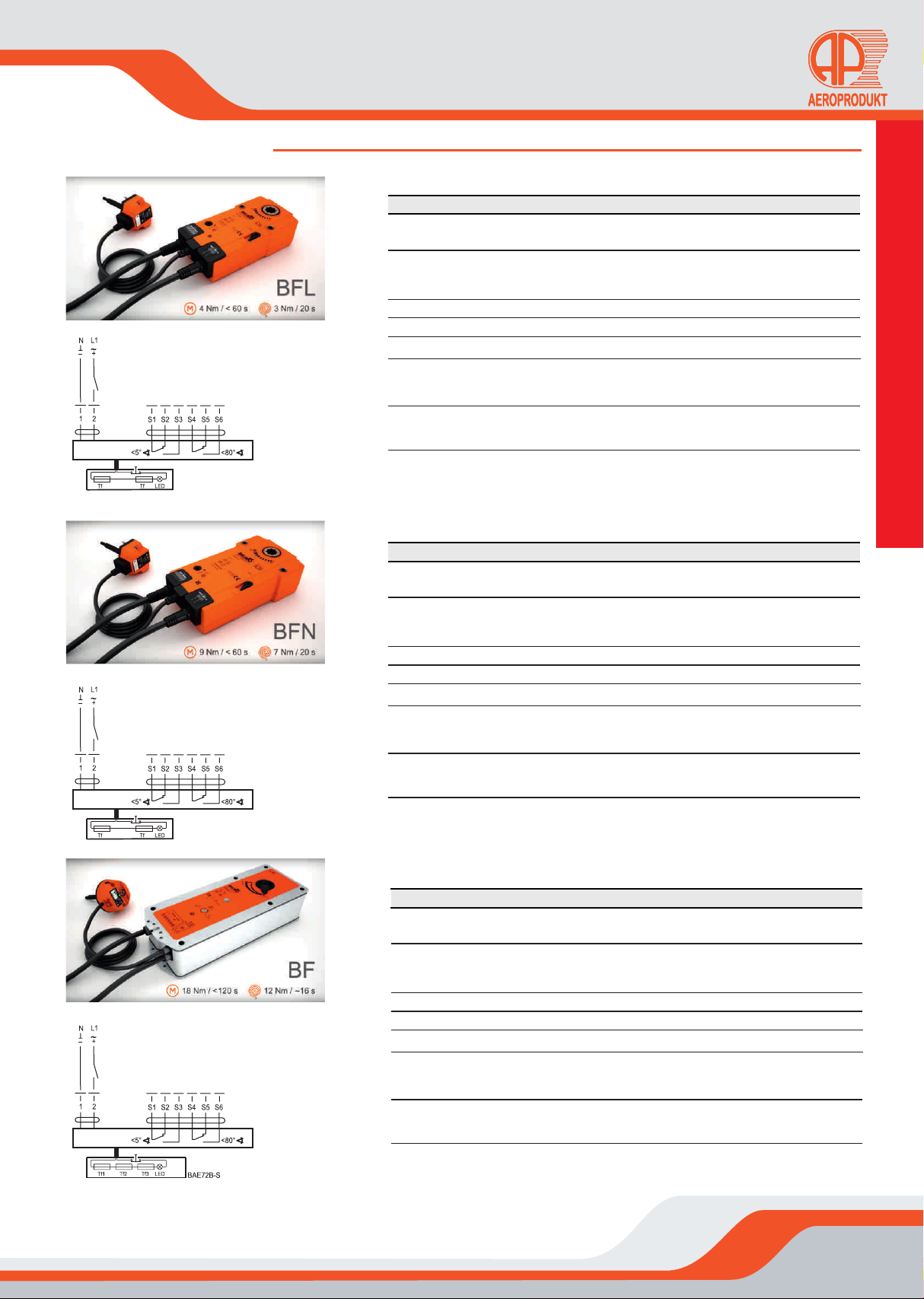

MOVEMENT

Actuator types:

fire damper with BFL 24-T actuator

fire damper with BFN 24-T actuator

fire damper with BF 24-T actuator

fire damper with BFL 230-T actuator

fire damper with BFN 230-T actuator

fire damper with BF 230-T actuator

The BSK-J/EI90 multi-blade fire dampers are installed on the protected space in wall, ceiling, or air

duct. When the ventilation system is working the dampers are opened default. In case of fire the

dampers close automatically.

The closing is done with the help of spring return motor. Taking away the actuating power from the

motor the spring resets the motor and brings the damper in closed position.

The interruption of the power supply can be done in two ways:

in case of fire the thermo sensor installed together with the motor at 72 °C interrupts the power

supply of the motor,

or the monitoring system interrupts the power supply of the motor.

The operability of the dampers can be checked with the test switcher mounted on the sensor. When

the power is switched off the damper must be closed. When the switcher is released the damper is

resettled in open position.

The spring return motor has position sensors, so it is possible to display the opened and closed

position of the damper (for example in monitoring system). The thermo electrical actuator is always an

accessory of the damper actuating motor.

The damper actuating motors are placed parallel with the direction of the airflow. The actuating motor

is protected with a casing against fire.

The damper can be mounted in the walling only when the thermo sensor and the motor are placed on

the upper part of the vertical side. As an option can be ordered an 100 mm extension element that

allows the installation in wider walling and if there is no other solution the placement of the thermo

sensor.

BSK-J/EI90(G)

multi-blade fire damper

BSK-J/EI90(G) multi-blade fire damper

www.aeroprodukt.hu

BSK-J/EI90(G)/7

ACTUATORS

AC 230 V, Open-Close

AC/DC24V, Open-Close

AC 24 V, 50/60 Hz

DC 24 V

7 W

2 W

10 VA (Imax 8,3 A @ 5 ms)

III

IP 54

o

<120 mp / 90

~16 mp

18 Nm

12 Nm

o o

-30 C ... 50 C

o o

-40 C ... 50 C

BF 24-T BF 230-T

AC 230 V, 50/60 Hz

8,5 W

3 W

11 VA (Imax 0,5 A @ 5 ms)

II

o

<120 mp / 90

~16 mp

18 Nm

12 Nm

AC 24 V, 50/60 Hz

DC 24 V

2,5 W

0,8 W

4 VA (Imax 8,3 A @ 5 ms)

III

IP 54

o

<60 mp / 90

~20 mp

4 Nm

3 Nm

o o

-30 C ... 55 C

o o

-40 C ... 55 C

BFL 24-T BFL 230-T

AC 230 V, 50/60 Hz

3,5 W

1,1 W

6,5 VA (Imax 4 A @ 5 ms)

II

o

<60 mp / 90

~20 mp

4 Nm

3 Nm

1 - blue

2 - brown

S1 - violet

S2 - white

S3 - white

S4 - white

S5 - white

S6 - white

1 - black

2 - red

S1 - violet

S2 - red

S3 - white

S4 - orange

S5 - pink

S6 - grey

AC 230 V, Open-Close

AC/DC24V, Open-Close

BAT

AC 230 V, Open-Close

AC/DC24V, Open-Close

BAT

AC 24 V, 50/60 Hz

DC 24 V

4 W

1,4 W

6 VA (Imax 8,3 A @ 5 ms)

III

IP 54

o

<60 mp / 90

~20 mp

9 Nm

7 Nm

o o

-30 C ... 55 C

o o

-40 C ... 55 C

BFN 24-T BFN 230-T

AC 230 V, 50/60 Hz

5 W

2,1 W

10 VA (Imax 4 A @ 5 ms)

II

o

<60 mp / 90

~20 mp

9 Nm

7 Nm

BSK-J/EI90(G)

multi-blade fire damper

BSK-J/EI90(G) multi-blade fire damper

1 - black

2 - red

S1 - violet

S2 - red

S3 - white

S4 - orange

S5 - pink

S6 - grey

MOTOR TYPE

Nominal voltage

Power consumption:

- in operation

- at rest

Protection class

Degree of protection

Running time

- motor

- spring-return

Torque

- motor

- spring-return

Temperature

- normal duty

- non-operating

Power consumption for wire sizing

MOTOR TYPE

Nominal voltage

Power consumption:

- in operation

- at rest

Protection class

Degree of protection

Running time

- motor

- spring-return

Torque

- motor

- spring-return

Temperature

- normal duty

- non-operating

MOTOR TYPE

Nominal voltage

Power consumption:

- in operation

- at rest

Protection class

Degree of protection

Running time

- motor

- spring-return

Torque

- motor

- spring-return

Temperature

- normal duty

- non-operating

Power consumption for wire sizing

Power consumption for wire sizing

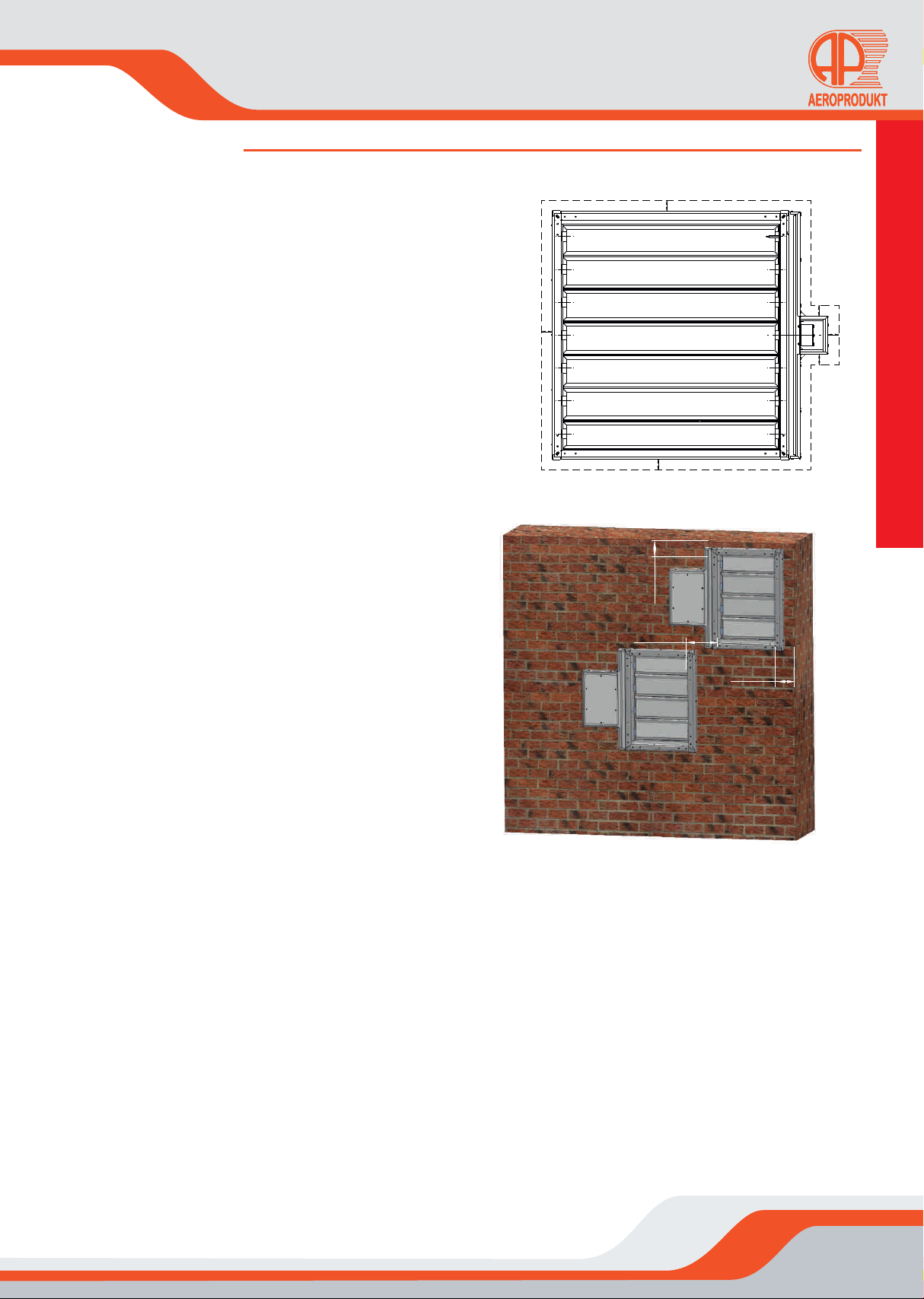

MOUNTING

BSK-J/EI90(G)/8

The A BSK-J/EI90 fire damper can be installed in concrete wall, lightweight wall, ceiling and outside

the wall in air ductwork.

horizontal mountingvertical mounting vertical mounting

The damper can be installed with horizontal or vertical shaft as well. The motor at vertical shaft position

can be at the top or bottom as well. The direction of the airflow is independent from the point of view of

operation, but it is advisable to place the servomotor and the control unit on the opposite side with the

expected fire.

The installation depth of the BSK –J/EI90 multi-

blade fire damper with the connection frame is

200 mm. The connection to the ductwork system

is done with a 30 mm MEZ flange that has 4 pcs

(ø9,1x19 mm) oval holes on the corners.

In the case of installation within a solid wall the

required minimal wall width is 100 mm

3

( density ≥ 500 kg/m )

In case of installation within a ceiling the

required minimal wall width is 150 mm

3

( density ≥ 600 kg/m )

In case of installation within a lightweight wall

the required minimal wall width is 100 mm

In plasterboard walls, traditional walls (brick,

concrete) the damper can be build up or

concreted, respectively with fire protection HILTI

or other equivalent material.

sizes of the connection frame

BSK-J/EI90(G)

multi-blade fire damper

BSK-J/EI90(G) multi-blade fire damper

www.aeroprodukt.hu

BSK-J/EI90(G)/9

MOUNTING

In opened position the blades do not overhang

the housing of the damper. Any part of the

element (ex. grid louver) connected to the

damper should not overhang in the housing of the

damper in order to not obstruct the free

movement of the blades. The BSK-J/EI90 multi-

blade fire dampers can be built in independent

from the access direction of the motor. There is no

need of separately right or left hand version.

The servomotor is shipped with a connection

cable (approx. 1 m long, with free ends). The

servomotor is equipped with protection casing in

order to prevent damages. The thermal relay can

be fixed on the optionally ordered extension or on

the ductwork built before or after the damper. It is

FORBIDDEN to make a hole on the housing of

the damper in order to place the sensor!

Take care to avoid damages. If the connecting

surface is not flat or the connecting frame is not

rectangular, the damper can be stretched. When

installing even connecting surfaces and

perpendicular edges must be assured. After

installing the easy move must be controlled. The

damper must be installed with closed blades.

The contact with splashing or running water must

be avoided, therefore it must be protected (ex.

outdoors must be fitted with a protective roof

against rainwater). The special fireproof material

of the damper absorbs moisture. In case of

excessive moisture the material gets soft, cracks

can appear. These can cause the damage of the

damper.

If the damper gets wet after drying it can be

operated without any problem. The water

resistance can be increased if we coat the

fireproof insulation parts of the damper with

PROMAT 2000 impregnating material.

Recommended thermal insulation materials for

different installation modes:

HILTI fire protection board – CFS-CT B 1S

HILTI acryl fire protection paste CFS-S ACR

CONLIT Ductrock 90 mineral wool fire

protection board

ROCKWOOL Steprock HD mineral wool board

PROMATECT -H fire protection board

PROMASTOP-P fire protection paste

min. 75

min. 75

min. 200

Separation between fire dampers and fire

dampers and construction elements:

Minimal distance from the construction

elements (wall/foloor): 75 mm

Minimal distance between two fire dampers:

200 mm

50

5050

50

50

50

BSK-J/EI90(G)

multi-blade fire damper

BSK-J/EI90(G) multi-blade fire damper

BSK-J/EI90(G)/10

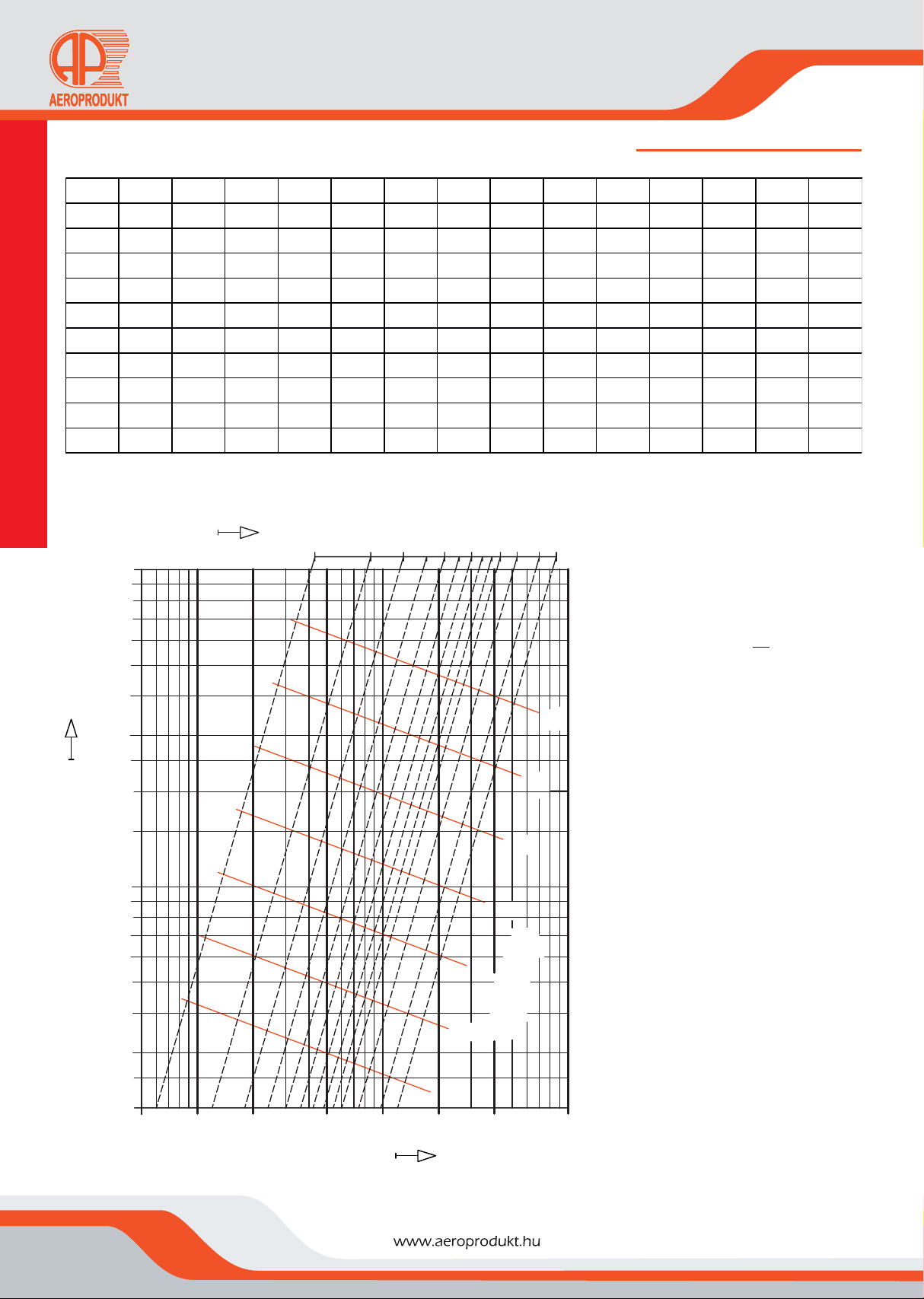

PRESSURE LOSS and SOUND LEVEL

Air pressure loss and sound level of BSK-J/E90(G) fire damper in opened position

2

A (m )

ΔP (Pa)

100

70

50

30

20

10

5

4

3

2

500 1000 2000 5000 10000 20000 40000 100000

3

V (m /h)

45 50 55

60 65

70

40

L , [dB(A)]

wa 0

o

0,1 0,2 0,3 0,5 0,7 11,21,5 2

40

6

8

H x B 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500

150 1,454 1,439 1,418 1,400 1,383 1,372 1,349 1,335 1,317 1,300 1,284 1,268 1,252 1,237

300 1,418 1,383 1,349 1,317 1,261 1,255 1,223 1,192 1,162 1,134 1,106 1,099 1,091 1,027

450 1,383 1,335 1,261 1,239 1,192 1,143 1,106 1,065 1,027 0,989 0,953 0,918 0,884 0,852

600 1,349 1,261 1,223 1,162 1,106 1,091 1,001 0,953 0,906 0,895 0,884 0,781 0,744 0,706

750 1,317 1,239 1,162 1,093 1,027 0,965 0,906 0,852 0,827 0,767 0,706 0,667 0,628 0,589

900 1,261 1,192 1,106 1,027 0,953 0,884 0,820 0,773 0,706 0,656 0,621 0,588 0,555 0,522

1050 1,273 1,143 1,091 0,965 0,884 0,840 0,778 0,731 0,628 0,593 0,555 0,516 0,478 0,461

1200 1,223 1,106 1,001 0,906 0,820 0,778 0,699 0,621 0,577 0,533 0,489 0,445 0,401 0,357

1350 1,192 1,065 0,953 0,852 0,773 0,697 0,621 0,571 0,522 0,472 0,423 0,373 0,324 0,277

1500 1,162 1,027 0,906 0,827 0,706 0,628 0,577 0,522 0,467 0,412 0,357 0,302 0,255 0,213

Δp = r 2

v

2

.

.

The leakage of the BSK-J/EI90(G) fire damper

- resistance factor [] -

BSK-J/EI90(G)

multi-blade fire damper

BSK-J/EI90(G) multi-blade fire damper

Pressure drop:

The calculation of the pressure drop

is done with the following formula:

Δp [Pa] - pressure loss

v [m/s] - air velocity on the

nominal section of the damper

-3

r [kg/m ] - air density

x [-] - resistance factor

2

A [m ]- free cross-section

3

V [m /h] - airflow

www.aeroprodukt.hu

BSK-J/EI90(G)/11

INSTALLATION IN RIGID WALL

H

H + 180

50

5050

140

90

90

90

B

+ 358

B

H

H + 180

140

B + 358

B

90

273

250

200

B x H

≥100

50

50

200

1.

2.

BSK-J/EI90

PLASTER, MORTAR and CONCRETE

BSK-J/EI90(G)

multi-blade fire damper

BSK-J/EI90(G) multi-blade fire damper

fire damper

plaster, mortar or concrete

air duct system

Fire protection

panel (coated)*

*Coated fire protection panel

Materials can be used:

1. )HILTI fire protection panel CFS-CTB 1S 140/50

2.) HILTI fire protection coating CFS-CT

or equivalent materials

vertical position - horizontal axis

vertical position - vertical axis

BSK-J/EI90(G)

BSK-J/EI90(G)/12

vertical position - horizontal axis

H

H + 258

179

B + 435

B

129

273

250

200

B x H

≥100

50

50

200

1.

2.

vertical position - vertical axis

BSK-J/EI90/G

H

H + 258

B

129

129

50

50

50

129

+ 435

B

multi-blade fire damper

BSK-J/EI90(G) multi-blade fire damper

PLASTER, MORTAR and CONCRETE

fire damper

plaster, mortar or concrete

air duct system

Fire protection

panel (coated)*

*Coated fire protection panel

Materials can be used:

1. )HILTI fire protection panel CFS-CTB 1S 140/50

2.) HILTI fire protection coating CFS-CT

or equivalent materials

INSTALLATION IN RIGID WALL

www.aeroprodukt.hu

BSK-J/EI90(G)/13

H

H + 180

50

5050

140

90

90

90

B

+ 358

B

FIRE PROTECTION PANEL

1.

2.

3.

H

max. 2200

min 20,

max 400

max. 2400

B

250

200

min 20,

max 400

B x H

≥100

200

BSK-J/EI90(G)

multi-blade fire damper

BSK-J/EI90(G) multi-blade fire damper

vertical position - horizontal axis

vertical position - vertical axis

Fire protection wall- max. dimension 1650x2050 or 2050x1650 mm

Materials can be used:

1.) HILTI fire protection panel CFS-CTB 1S 140/50

2.) HILTI fire protection coating CFS-CT

3.) HILTI acryl fire protection paste CFS-S ACR

or equivalent materials

INSTALLATION IN RIGID WALL

fire damper

plaster, mortar or concrete

air duct system

Fire protection

panel (coated)*

BSK-J/EI90(G)

BSK-J/EI90(G)/14

INSTALLATION ON FACE OF RIGID WALL

H

H + 180

B + 180

B

B x H

≥100

90 90

60

60

min. 50

1.

3.

2.

4.

INSTALLATION IN AIR DUCT

H

H + 180

B + 180

B

60

min. 100

min. 100

min. 400

60

B x H

≥100

90 90

60

min. 50

1.

3.

2.

4.

multi-blade fire damper

BSK-J/EI90(G) multi-blade fire damper

3

1.) 15 mm thick fire protection board with 870 kg/m density – Promatec-H

2.) with 1 mm thick seal - Promastop-P

3.) mineral stone wool fire panel coated on one side with

aluminium foil for air duct isolation with fire resistance

3

class EI90 2x60 mm thickness and 300 kg/m density - Conlit Ductrock EI90

4.) mineral wool panel with 140 kg/ m3 density - Rockwool Steprock

or equivalent materials

multi-blade fire damper

air duct system

3.) stone wool

4.) mineral wool

1.) fire board

3

1.) 15 mm thick fire protection board with 870 kg/m density – Promatec-H

2.) with 1 mm thick seal - Promastop-P

3.) mineral stone wool fire panel coated on one side with

aluminium foil for air duct isolation with fire resistance

3

class EI90 2x60 mm thickness and 300 kg/m density - Conlit Ductrock EI90

4.) mineral wool panel with 140 kg/ m3 density - Rockwool Steprock

or equivalent materials

multi-blade

fire damper

air duct system

4.) mineral wool

3.) stone wool

1.) fire board

vertical position - horizontal axis vertical position - vertical axis

vertical position - horizontal axis vertical position - vertical axis

www.aeroprodukt.hu

BSK-J/EI90(G)/15

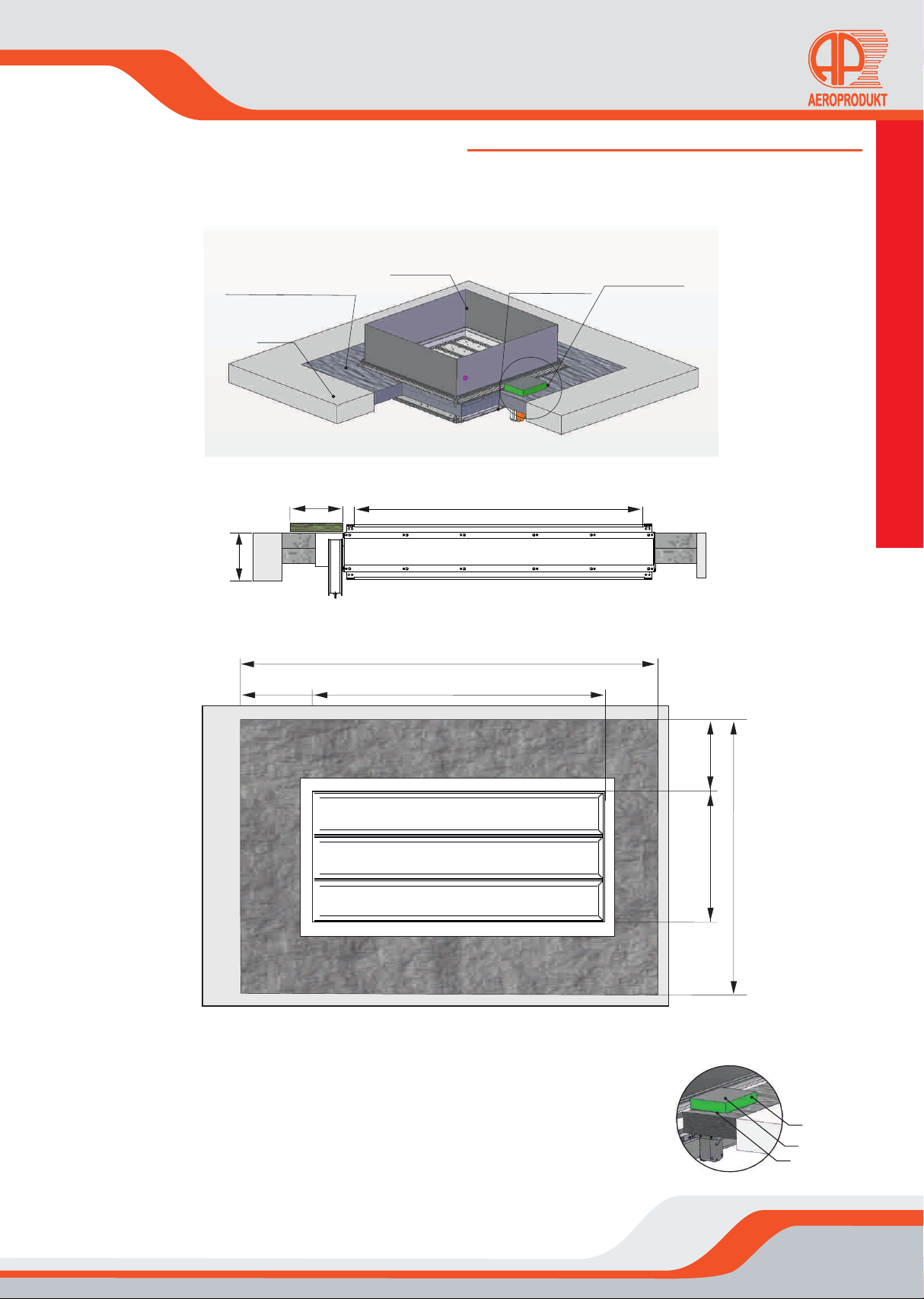

BSK-J/EI90

2.

1.

fire board

air duct system

floor

B x H

≥150

50 50

200

H

H + 180

140

B + 358

B90

273

250

200

BSK-J/EI90(G)

multi-blade fire damper

BSK-J/EI90(G) multi-blade fire damper

INSTALLATION IN FLOOR

PLASTER, MORTAR and CONCRETE

*Coated fire protection panel

Materials can be used:

1. )HILTI fire protection panel CFS-CTB 1S 140/50

2.) HILTI fire protection coating CFS-CT

or equivalent materials

horizontal position

plaster, mortar or concrete Fire protection

panel (coated)*

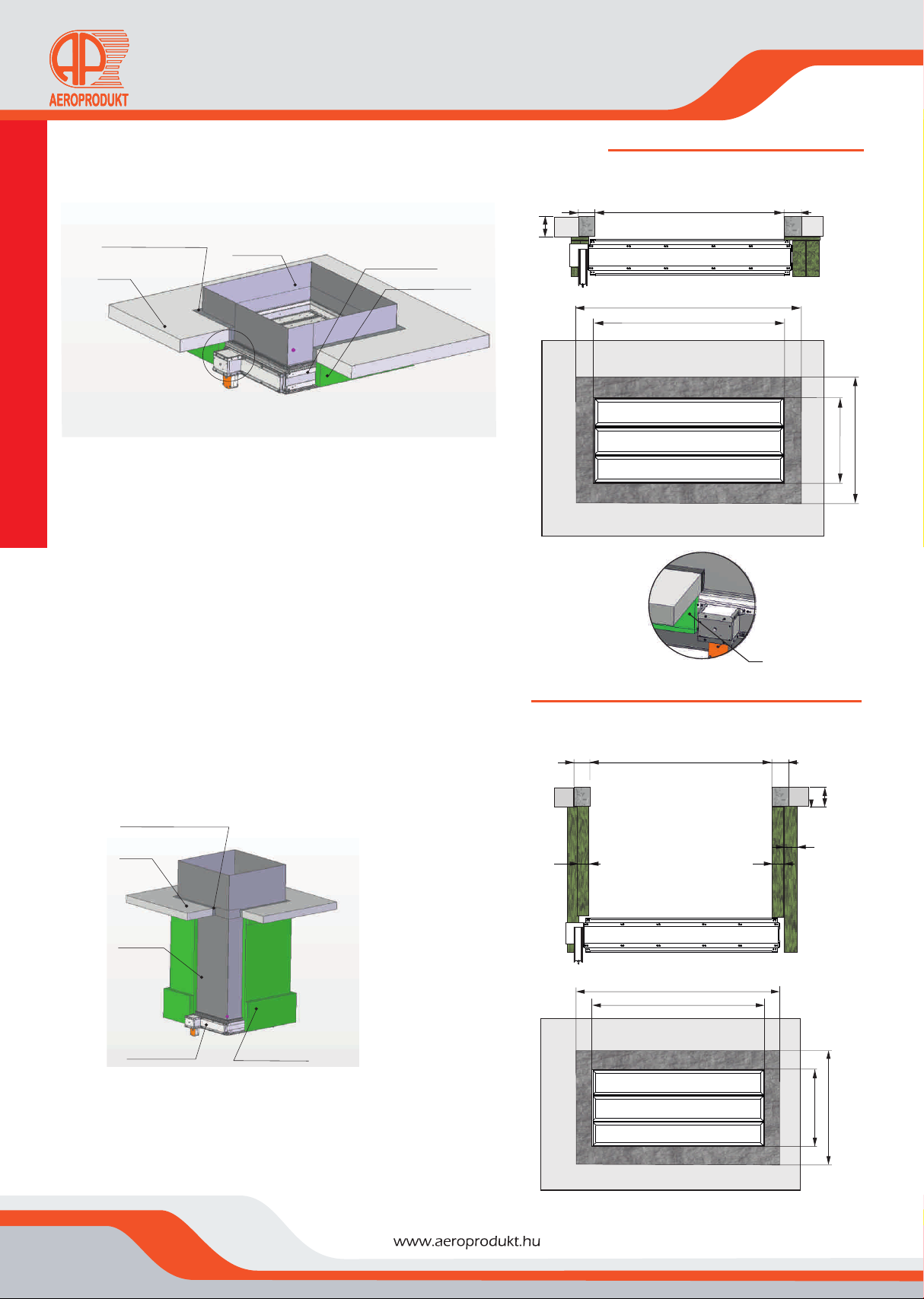

BSK-J/EI90(G)

BSK-J/EI90(G)/16

BSK-J/EI90/G

2.

1.

B x H

≥150

50 50

200

H

H + 258

179

B + 435

B129

273

250

200

multi-blade fire damper

BSK-J/EI90(G) multi-blade fire damper

fire board

air duct system

floor

INSTALLATION IN FLOOR

PLASTER, MORTAR and CONCRETE

*Coated fire protection panel

Materials can be used:

1. )HILTI fire protection panel CFS-CTB 1S 140/50

2.) HILTI fire protection coating CFS-CT

or equivalent materials

horizontal position

plaster, mortar or concrete Fire protection

panel (coated)*

www.aeroprodukt.hu

BSK-J/EI90(G)/17

1.

2.

3.

min 30,

max 400

max. 2400

B

250

200

H

max. 2200

min 30,

max 400

B x H

≥150

200

BSK-J/EI90(G)

multi-blade fire damper

BSK-J/EI90(G) multi-blade fire damper

FIRE PROTECTION PANEL

horizontal position

Fire protection wall- max. dimension 1650x2050 or 2050x1650 mm

Materials can be used:

1.) HILTI fire protection panel CFS-CTB 1S 140/50

2.) HILTI fire protection coating CFS-CT

3.) HILTI acryl fire protection paste CFS-S ACR

or equivalent materials

INSTALLATION IN FLOOR

fire board

air duct system

floor

plaster, mortar or concrete Fire protection

panel (coated)*

BSK-J/EI90(G)

BSK-J/EI90(G)/18

INSTALLATION UNDER THE FLOOR

INSTALLATION IN THE DUCT

1.

B x H

≥150

90 90

H

H + 180

B + 180

B

fire damper

floor 1.) mineral wool

air duct system

vízszintes beépítés

H

H + 180

B + 180

B

6060

B x H

≥150

90 90

60

air duct

fire damper 1.) mineral wool

floor

multi-blade fire damper

BSK-J/EI90(G) multi-blade fire damper

PLASTER, MORTAR and CONCRETE

PLASTER, MORTAR and CONCRETE

1.) mineral stone wool fire panel coated on one side with

aluminium foil for air duct isolation with fire resistance

3

class EI90 2x60 mm thickness and 300 kg/m density -

Conlit Ductrock EI90

or equivalent materials

1.) mineral stone wool fire panel coated on one side with

aluminium foil for air duct isolation with fire resistance

3

class EI90 2x60 mm thickness and 300 kg/m density -

Conlit Ductrock EI90

or equivalent materials

plaster, mortar or concrete

plaster, mortar or concrete

www.aeroprodukt.hu

BSK-J/EI90(G)/19

H

max. 2200

min 30,

max 400

max. 2400

B

250

200

B x H

200

min 20,

max 400

1.

2.

≥100

B x H

90 90

60

60

min. 50

H

H + 180

B + 180

B

1.

3.

2.

4.

≥100

BSK-J/EI90(G)

multi-blade fire damper

BSK-J/EI90(G) multi-blade fire damper

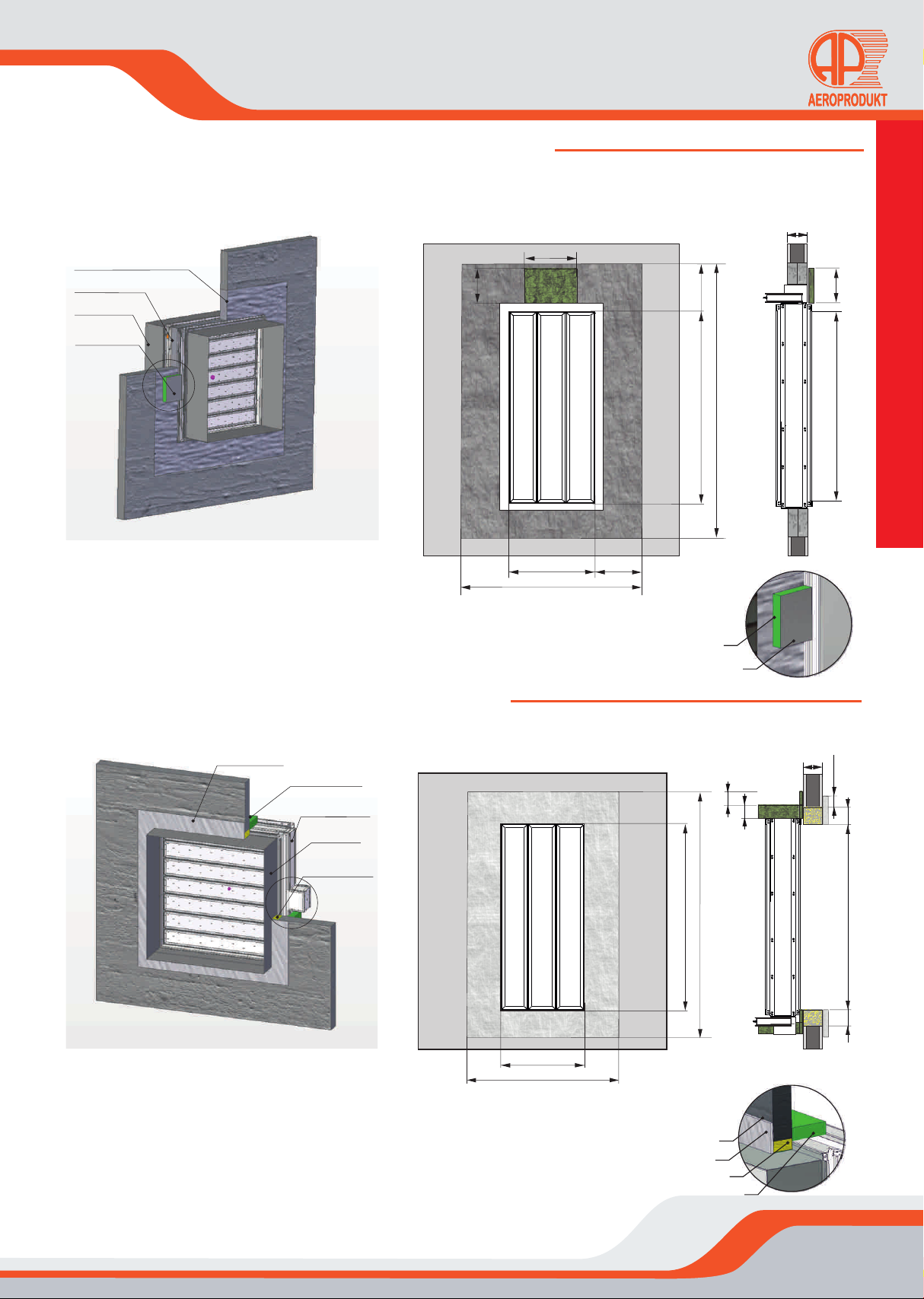

INSTALLATION IN LIGHT WALL

INSTALLATION IN AIR DUCT

3

1.) 15 mm thick fire protection board with 870 kg/m density – Promatec-H

2.) with 1 mm thick seal - Promastop-P

3.) mineral stone wool fire panel coated on one side with

aluminium foil for air duct isolation with fire resistance

3

class EI90 2x60 mm thickness and 300 kg/m density - Conlit Ductrock EI90

4.) mineral wool panel with 140 kg/ m3 density - Rockwool Steprock

or equivalent materials

vertical position - horizontal axis vertical position - vertical axis

vertical position - horizontal axis vertical position - vertical axis

FIRE PROTECTION PANEL

*Coated fire protection panel

Materials can be used:

1. )HILTI fire protection panel CFS-CTB 1S 140/50

2.) HILTI fire protection coating CFS-CT

or equivalent materials

fire board ex.: HILTI

air duct system

Fire protection

panel (coated)*

fire damper

multi-blade

fire damper

air duct system

4.) mineral wool

3.) stone wool

1.) fire board

BSK-J/EI90(G)

BSK-J/EI90(G)/20

H

H + 180

B + 180

B

60

60

B x H

90 90

60

min. 50

fire damper

air duct system

3.) mineral wool

4.) mineral wool

1.) fire board

1.

3.

2.

4.

≥100

SUSPENDED INSTALLATION

1 2 3

4

5

1

6

5

1

2

1.) Threaded shaft M8 - M20, galvanised steel

2.) Hexagon mother DIN EN ISO 4034

3.) Pads DIN ISO 7089/7090

4.) winged mother, galvanised steel

5.) Metal dowel, galvanised steel

6.) Fixing plate min. 10 mm, galvanised steel

Size As [mm2]

M8 36,6 22 44

M10 58 35 70

M12 84,3 52 104

M14 115 70 140

M16 157 96 192

M18 192 117 234

M20 245 150 300

Weight [kg]

1 pc 2 pcs

multi-blade fire damper

BSK-J/EI90(G) multi-blade fire damper

INSTALLATION ON THE FACE OF LIGHT WALL

3

1.) 15 mm thick fire protection board with 870 kg/m density – Promatec-H

2.) with 1 mm thick seal - Promastop-P

3.) mineral stone wool fire panel coated on one side with

aluminium foil for air duct isolation with fire resistance

3

class EI90 2x60 mm thickness and 300 kg/m density - Conlit Ductrock EI90

4.) mineral wool panel with 140 kg/ m3 density - Rockwool Steprock

or equivalent materials

FIRE PROTECTION PANEL

This manual suits for next models

1

Table of contents

Popular Fire And Smoke Damper manuals by other brands

Mandik

Mandik FDMB Series installation instructions

Trox Technik

Trox Technik FKR-EU Supplementary Operating Manual

Kampmann

Kampmann WKD CM24-SX-L Assembly instructions

KOOLAIR

KOOLAIR FDS-3G Series manual

mercor

mercor mcr Prosmoke FS Operation and maintenance manual

Schako

Schako BSK-RPR Series Additional operating instructions

mercor

mercor mcr FID PRO Series Operation and maintenance manual

Geba

Geba WFK Series Assembly and operating instructions

Swegon

Swegon Actionair A60 manual

Mandik

Mandik FDMC installation instructions

HVC

HVC NCA Series installation guide

GILBERTS

GILBERTS Ductgard Series Installation,operation and maintenance instruction