www.h-v-c.com

Installation guide

NCA Series 400 single blade leakage rated fire damper c/w plate frame

Prior to installation

• Thermal links/probes in particular are vulnerable to damage, take extreme care if storing smaller

dampers within larger dampers. Damaged links/probes must be replaced.

• If damper is to be stored on site, ensure it is stored in a clean and dry environment.

• Immediately prior to fitment, remove all packaging from the unit. Take particular care inspecting

the inside of the unit for any packing materials which may disrupt damper operation.

• Perform a visual check of the damper to ensure it is free from damage.

Installation

• Fire damper installation should only be carried out by competent persons.

• Appropriate PPE should be used throughout the installation.

• Provision for access to both sides of the damper (inside the duct) must be made.

• Any cabling should be tied back so as not to be in contact with the duct.

• Breakaway joints should be used where ductwork connects to a damper spigot, for example

through the use of aluminium rivets.

• Case sealing rings should be lubricated to ease ductwork connection, for example with a

sprayed washing-up liquid solution or similar.

Installation guide: NCA Series 400 leakage rated single blade fire damper c/w plate frame

Approved installation method, operation and installation declaration

Page 1 of 2 - Issue A - 16/03/2022

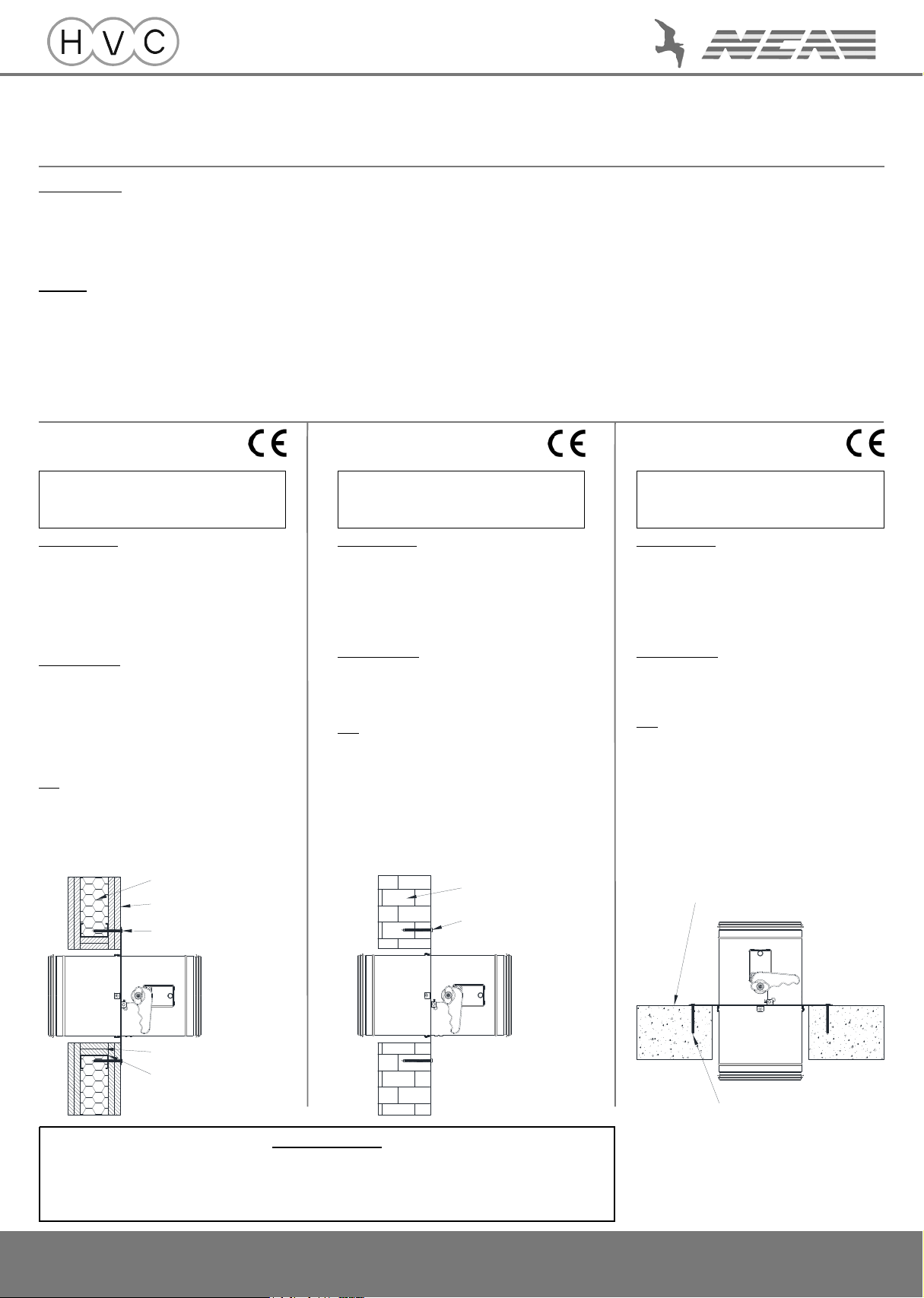

Installation classified to (in accordance with BS EN 13501-3):

E 120 (ve i↔o) S

120 minute rated reduced leakage vertical installation

Air permitted to flow in either direction through damper

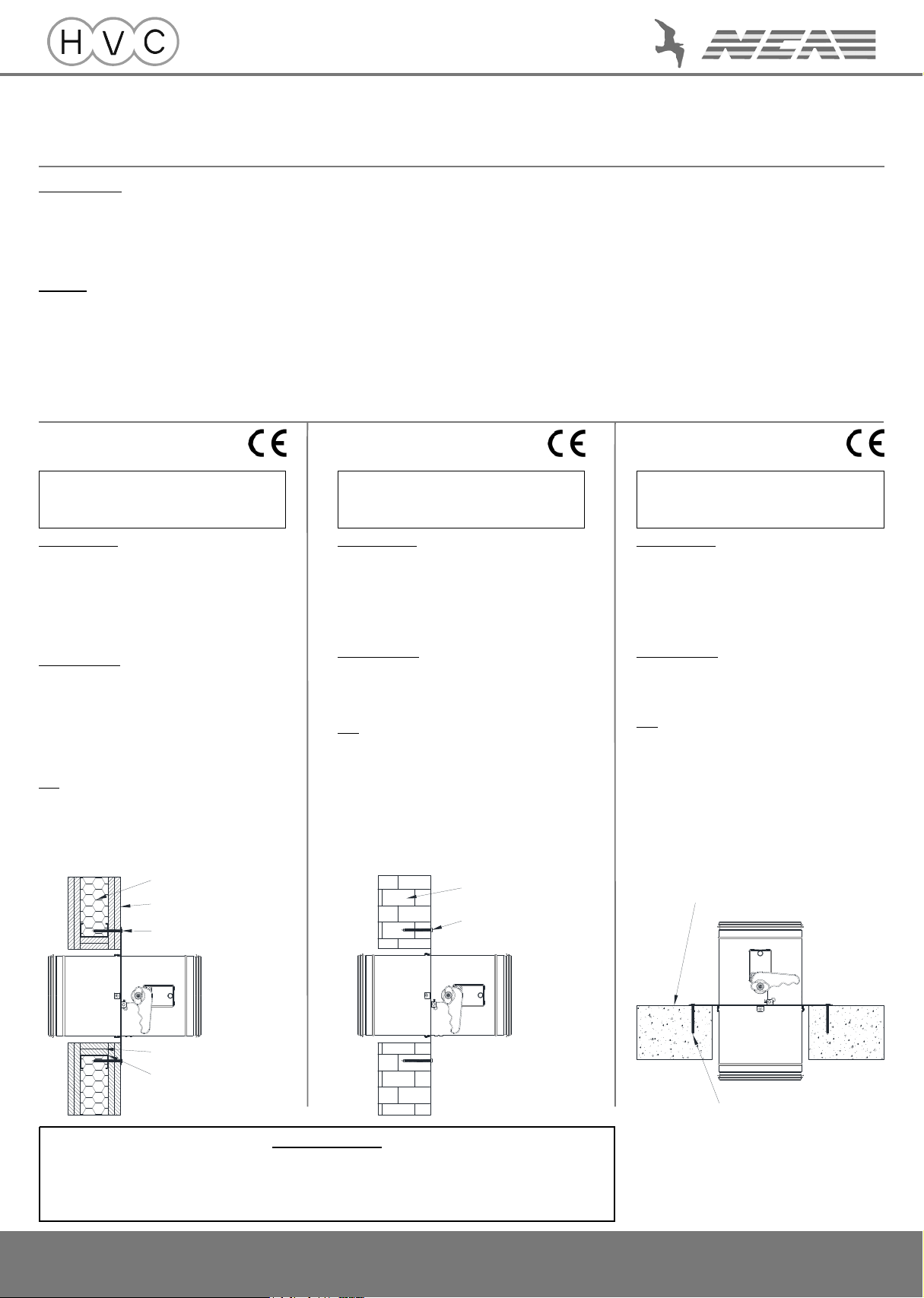

Installation S400-2VP

Drywall partition installation

Installation procedure

• Construct drywall partition steel frame incorporating a rectangular

aperture for the damper 94mm larger than damper nominal size.

• Fill wall cavity with mineral wool (optional, see note below) and fix two

layers of plasterboard to both sides of partition and inside of aperture

(lined aperture should be 34mm larger than damper nominal size).

• Centralise damper spigot within aperture.

• Screw damper to partition using all pre-cut 5mm holes in plate

frame, ensure all screws gain a positive fix on the steel aperture frame.

• S400A only - Fit thermal probe to top half of ductwork and connect

actuator to an appropriate power supply.

Material specifications

Wall: Constructed to achieve ‘EI 120’ classification

(or greater) in accordance with EN 1363-1

Minimum thickness 122mm

Stud depth: 62 - 100mm

Plasterboard: EN 520 F rated, 15mm thick

‘Gyproc Fireline’, ‘Knauf DF’ or equivalent

Mineral wool: Minimum density 100kg/m3

Minimum thickness 60mm

‘Rockwool RW5’ or equivalent

Fixing screws: Minimum spec 4.2mm x 65mm drywall screws

Notes

• No backfilling, sealing or pattress frame is required.

• The blade axis must be horizontal.

• The steel aperture frame must be joined to vertical frame members

which are themselves fixed to the supporting construction.

• Mineral wool infill is optional (as per EN 1366-2:2015, clause 13.7).

Installation S400-2VM

Masonry wall installation

Installation procedure

• Construct wall incorporating a square or circular aperture for the

damper 34mm larger than damper nominal size.

• Open the pre-cut 5mm diameter fixing holes in the plate frame out to

8mm.

• Centralise damper spigot within aperture.

• Screw damper to wall using all 8mm holes in plate frame, ensure all

screws gain a positive fix.

• S400A only - Fit thermal probe to top half of ductwork and connect

actuator to an appropriate power supply.

Material specifications

Wall: Constructed to achieve an equivalent or greater fire

resistance as a drywall partition of ‘EI 120’

classification in accordance with EN 1363-1

Minimum thickness 130mm

Fixing screws: Minimum spec 6mm x 60mm masonry screws

Notes

• No backfilling, sealing or pattress frame is required.

• The blade axis must be horizontal.

Installation S400-2HC

Concrete floor installation

Installation procedure

• Construct floor slab incorporating a square or circular aperture for the

damper 34mm larger than damper nominal size.

• Open the pre-cut 5mm diameter fixing holes in the plate frame out to

8mm.

• Centralise damper spigot within aperture.

• Screw damper to slab using all 8mm holes in plate frame, ensure all

screws gain a positive fix.

• S400A only - Fit thermal probe to ductwork and connect actuator to an

appropriate power supply.

Material specifications

Floor: Concrete slab (aerated or normal)

Minimum thickness 150mm

Minimum density 600kg/m3

Fixing screws: Minimum spec 6mm x 60mm masonry screws.

Notes

• No backfilling, sealing or pattress frame is required.

• The damper must sit on top of the floor, not be hung from below.

IMPORTANT NOTE

It is a legal requirement that fire dampers are installed in the way instructed by the manufacturer.

Any other installation is untested and therefore illegal.

Responsibility for ensuring correct installation lies with all parties in the supply chain.

Installation classified to (in accordance with BS EN 13501-3):

E 120 (ve i↔o) S

120 minute rated reduced leakage vertical installation

Air permitted to flow in either direction through damper

Installation classified to (in accordance with BS EN 13501-3):

E 120 (ho i↔o) S

120 minute rated reduced leakage horizontal installation

Air permitted to flow in either direction through damper

• There should be a minimum of 200mm of supporting construction between fire dampers

installed in separate ducts.

• There should be a minimum of 75mm of supporting construction between the fire damper

and any adjacent construction element, e.g. a wall or ceiling.

Where a damper is fitted such that the actuator shall be next to a wall, this should be increased

to 200mm to provide adequate clearance.

• An increase of the gap (area) between the damper and supporting construction of up to 50%

is permitted (as per EXAP report, EN 15882-2:2015, clause X.45).

• A decrease of the gap (area) between the damper and supporting construction is permitted

(as per EXAP report, EN 15882-2:2015, clause X.46).

Recommended spares: S400H - Thermal link in correct temperature rating

68°C (red bulb in link) or 93°C (green bulb in link)

S400A - Thermal probe tripping element - ‘Belimo ZBAT72’

Installation declaration overleaf →

Wall cavity filled with mineral wool

(optional)

2 x 15mm thick plasterboard

sheets each side of steel stud

2 x 15mm thick plasterboard strips

lining aperture

Drywall screws

securing damper to partition

Steel frame forming aperture

Masonry wall

Masonry screws

securing damper to partition

Concrete floor slab

Masonry screws

securing damper to slab