D

IOM

www.actionair.co.uk

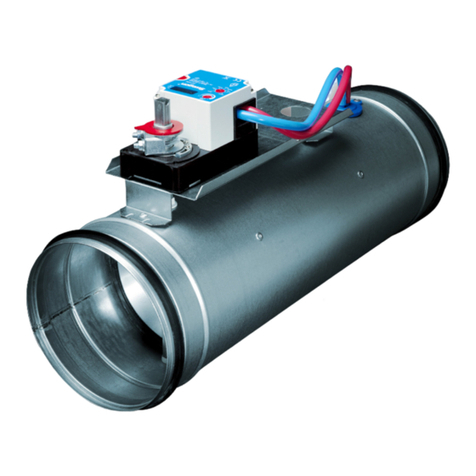

A60 Marine

Fire Damper

With ATEX rated

Pneumatic

(Hytork) Actuator

1. Description

The actionair Marine Fire Damper is tested and approved for

fitting to class A-0 A-15 A-30 A-60 divisions (bulkheads and

decks), when suitably insulated.

A-0 does not require any insulation to the casing.

2. Tests, approvals and certification

Lloyds Register Approved.

DNV-GL Approved.

ABS Approved

USCG Approved.

Transport Canada approved.

MED Marine Equipment Directive Compliant.

Fire tested to the latest IMO FTP code & in compliance

international convention for the safety of life at sea (SOLAS)

Sira certification (Ex) category 2 equipment

Corrosion Tested - EN60068-2-52 severity 2 conditions

Vibration Tested – EN60068-2-6 (5Hz to 350Hz @2g)

3. Health and Safety

Care must be taken when installing and inspecting dampers,

as they are likely to close without warning due to loss of

electrical power, or a temperature rise in the ductwork. This is

their prime function.

Do not introduce any items, fingers or limbs between the

blades.

Larger dampers are heavy and must be handled in accordance

with current local regulations and good practice.

All wiring should be carried out in accordance with the wiring

details provided, to the IEC regulations.

4. General Information

The actionair Marine Fire Damper is suitable for both vertical

and horizontal applications, with airflow in either direction.

The dampers tested to IMO fire test procedures Code, Annex 1

Pt 3, are normally open, and fail-safe to the closed position. The

actionair Marine Fire Dampers are supplied with the blades in

the fully interlocked closed position to avoid damage during

transit and installation. It is recommended that the dampers

remain closed until actual date of commissioning. All fire

dampers are life safety products and must be treated with care

during handling, storage and installation.

Actionair Marine Fire Dampers are designed for applications in

normal dry filtered air systems and should be subjected to a

planned inspection programme.

5. Installation - see below.

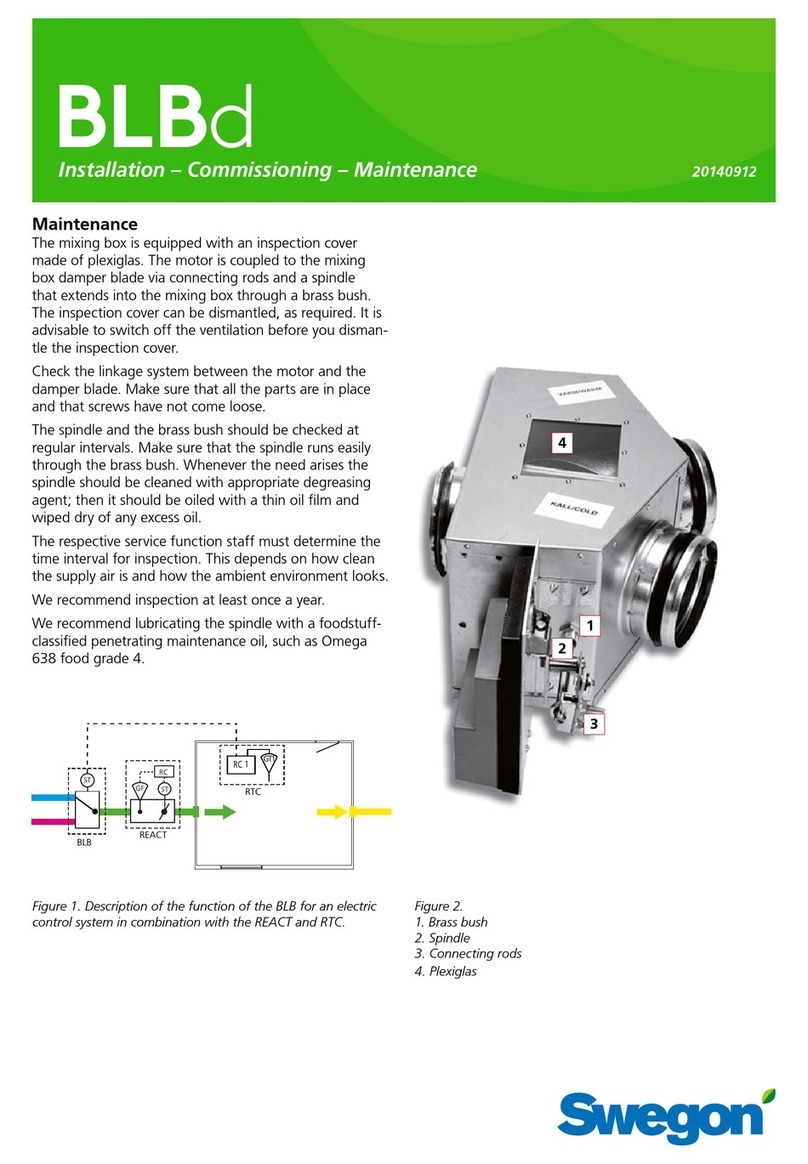

6. Maintenance & Cleaning

Dampers are supplied in two casing and blade material

options: -

Galvanised Steel casing and 430 Stainless steel blades, only

suitable for installation in dry filtered systems.

316 Stainless steel casing and blades and drive - more suited

for corrosive conditions, but even this will rapidly corrode and

fail if not properly maintained, when used in air intake systems

at sea. The addition of a mist eliminator is highly recommended,

and access must be provided for maintenance.

7. Testing

Two levels of testing exist.

Routine testing - Monthly, or in accordance with maintenance

programme, release and reset damper (via control system or

ETR test switch). Check remote indication or visual check of

mechanical pointer as appropriate.

Visual check at damper - At commissioning and at least once

a year, check damper operation by removing and

re-applying power to actuator. (via ETR test switch).

Visually check blades for damper closed and open positions.

Prove remote indication if applicable.

8. Routine Maintenance

Depending upon environmental conditions, each damper will

merit its own cleaning regime. Particularly hostile areas.

‘Frequency of maintenance’ should be determined by

collecting historical data from previous visits, and for this

reason, commence maintenance programmes.

Dampers in ‘Dry Filtered Air’ require very limited maintenance.

When exposed to fresh air intakes and/or inclement conditions

this may require monthly cleaning and lubrication maintenance

to be performed.

9. Cleaning

Using light lubricant, clean all exposed surfaces, using a cloth.

Remove all traces of surface staining, as this will deteriorate

further causing deeper material corrosion.

For 316 stainless steel blades and case, pay specific attention

to the blade rivets where crevice corrosion will cause rapid

failure of blades if not kept in check.

If damper is stiff to operate lubricate blade ends, open and

close damper successively until the damper moves with ease.

(This may necessitate removal of the actuator and operating

the blades manually by the drive shaft).

Refit actuator and re-test.

Clean off excessive lubricant.

YYYY Denotes

the year the

Wheel mark

is affixed to damper

0038/YYYY