Aeroqual Dust Sentry Pro User manual

MRK-D-0048 V4 Aeroqual Dust Sentry / AQS User Guide Page | 2

User Guide Revision History

Date

Revision number

Description of change

Affected Sections

June 2017

1.0

First release

-

September 2017

2.0

NO2 and VOC added

1, 1.1

May 2018

3.0

Calibration section updated

5.0

February 2019

4.0

Combining AQS, Dust

Sentry, Dust Sentry Profiler

All

Alternative sources of information and help

In addition to this user guide, Aeroqual offers other sources of information which can assist in the

operation of the monitors. The Aeroqual website contains brochures, technical notes and user guides

for all products.

www.aeroqual.com

Aeroqual’s training website contains a comprehensive document library of technical notes and service

and calibration templates to download and print. The training website has detailed descriptions of

service activities and calibration and installation examples and is updated regularly. Video tutorials

are featured heavily.

www.training.aeroqual.com

For technical support, contact the Aeroqual distributor in your local country. If local technical support

is not available contact the Aeroqual support team: technical@aeroqual.com.

Where possible, references to further material will be provided throughout this document

Online reference

training.aeroqual.com

Online video

YouTube Channel: Aeroqual Service and Maintenance playlist

MRK-D-0048 V4 Aeroqual Dust Sentry / AQS User Guide Page | 3

Table of Contents

1Dust Sentry / Dust Sentry Pro / AQS 1 Introduction........................................................................5

1.1 Overview .................................................................................................................................5

1.2 Product comparison ................................................................................................................6

1.3 Applications by product...........................................................................................................6

1.4 Optional external sensors .......................................................................................................7

1.5 Dimensions..............................................................................................................................7

1.6 Specifications..........................................................................................................................8

2Quick Setup Guide...........................................................................................................................9

2.2 Pre-planning..........................................................................................................................11

2.3 Unpacking .............................................................................................................................11

2.4 Assembly...............................................................................................................................12

2.5 Power Requirements.............................................................................................................15

2.6 Wiring auxiliary sensors ........................................................................................................16

3Mounting and Site Positioning Guidelines.....................................................................................18

3.1 Mounting................................................................................................................................18

3.2 Inlet height.............................................................................................................................18

3.3 Measurement Interference....................................................................................................18

3.4 Safety....................................................................................................................................19

4Connectivity ...................................................................................................................................20

4.1 Aeroqual Connect (via Direct WIFI / LAN) ............................................................................20

4.2 Aeroqual Cloud (via Network WIFI / Modem) .......................................................................21

4.3 Communication settings........................................................................................................25

4.4 Resetting the communication settings back to factory settings ............................................26

5Operation .......................................................................................................................................27

5.1 Manage Data.........................................................................................................................27

5.2 Calibration and Service.........................................................................................................29

5.3 Configure Instrument.............................................................................................................29

5.4 Diagnostics and Advanced....................................................................................................30

5.5 Administration........................................................................................................................31

6Service & Maintenance..................................................................................................................32

6.1 Service frequency guidelines ................................................................................................32

6.2 Flow meters and flow measurement.....................................................................................33

6.3Manual Service Mode ...........................................................................................................33

6.4 Journal...................................................................................................................................34

6.5 Maintenance procedures.......................................................................................................34

6.6 Factory calibration of Particle Monitor...................................................................................46

6.7 Scheduled maintenance........................................................................................................47

7Calibration......................................................................................................................................48

7.1 Gas module calibration .........................................................................................................48

7.2 Particle Monitor calibration....................................................................................................57

MRK-D-0048 V4 Aeroqual Dust Sentry / AQS User Guide Page | 4

8Troubleshooting .............................................................................................................................60

9Copyright........................................................................................................................................62

10 Compliance ...............................................................................................................................62

11 Warranty....................................................................................................................................62

12 Appendix ...................................................................................................................................63

12.1 Gas module design ...............................................................................................................63

12.2 Particulate Matter module design..........................................................................................65

12.3 Mains wiring color guide........................................................................................................67

12.5 Calibration Records...............................................................................................................68

MRK-D-0048 V4 Aeroqual Dust Sentry / AQS User Guide Page | 5

1 Dust Sentry / Dust Sentry Pro / AQS 1 Introduction

1.1 Overview

Dust Sentry / Dust Sentry Pro / AQS 1 (collectively referred to herein as ‘monitors’) are tools for air

quality professionals to target specific applications of interest in industrial, urban environment and

regulatory applications. It is a flexible air quality monitoring system that can be configured for a range

of uses.

Key technology features of the monitors enable them to deliver data with very strong correlation to

EPA-approved monitors –‘Near Reference’–over extended periods of time; several years with

appropriate maintenance.

Housed in a rugged, lockable weatherproof (IP 65) enclosure, the monitors include an embedded PC

and full software system for remote technical support, data management and analytics.

Users can make use of the embedded PC running proprietary Aeroqual Connect software, or

optional web-based Aeroqual Cloud software for data storage and management of networks of

monitors.

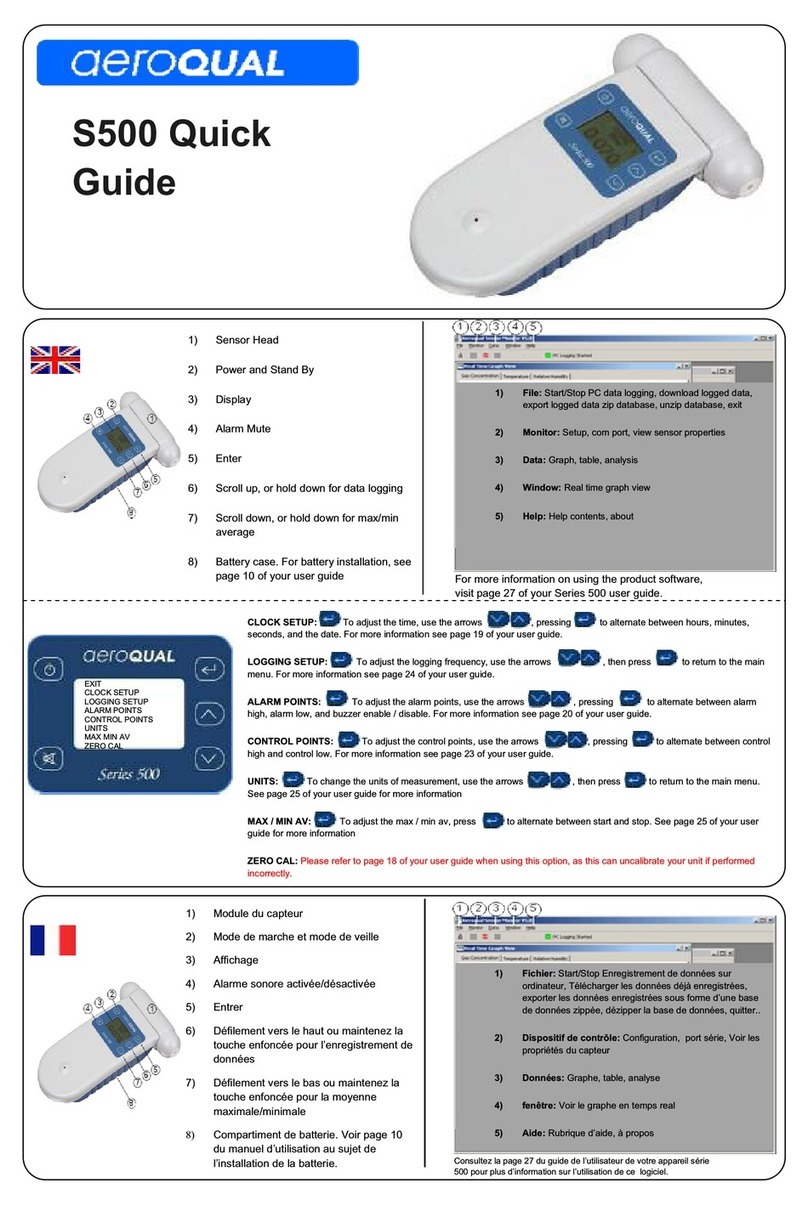

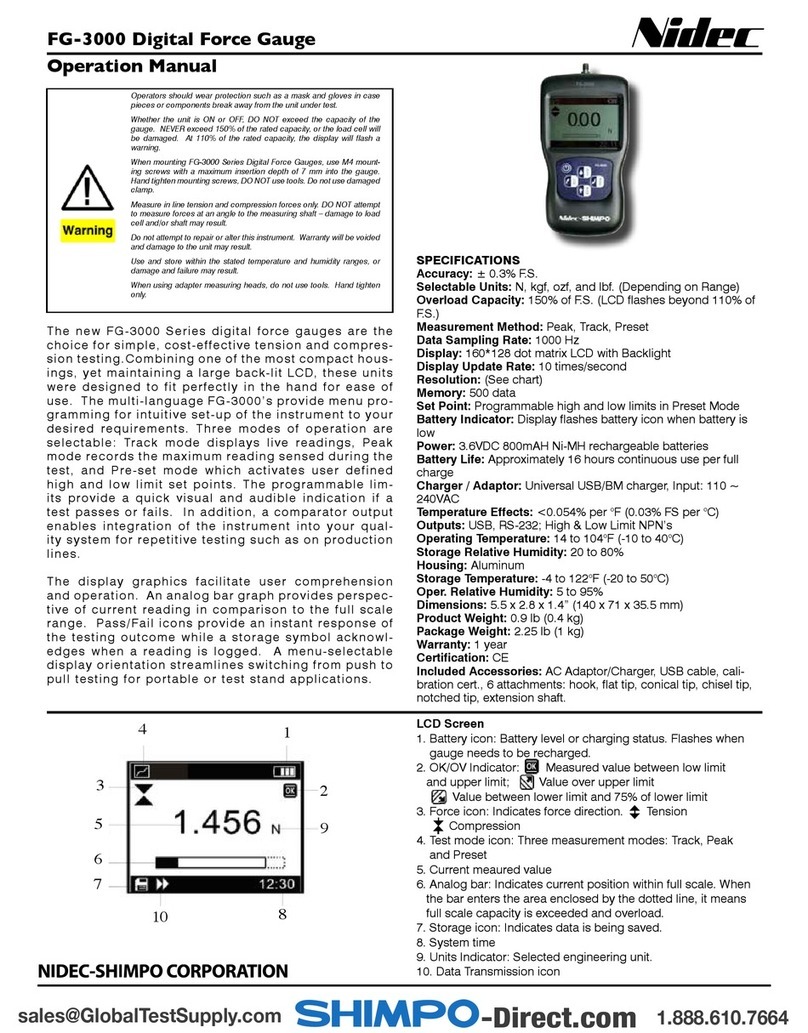

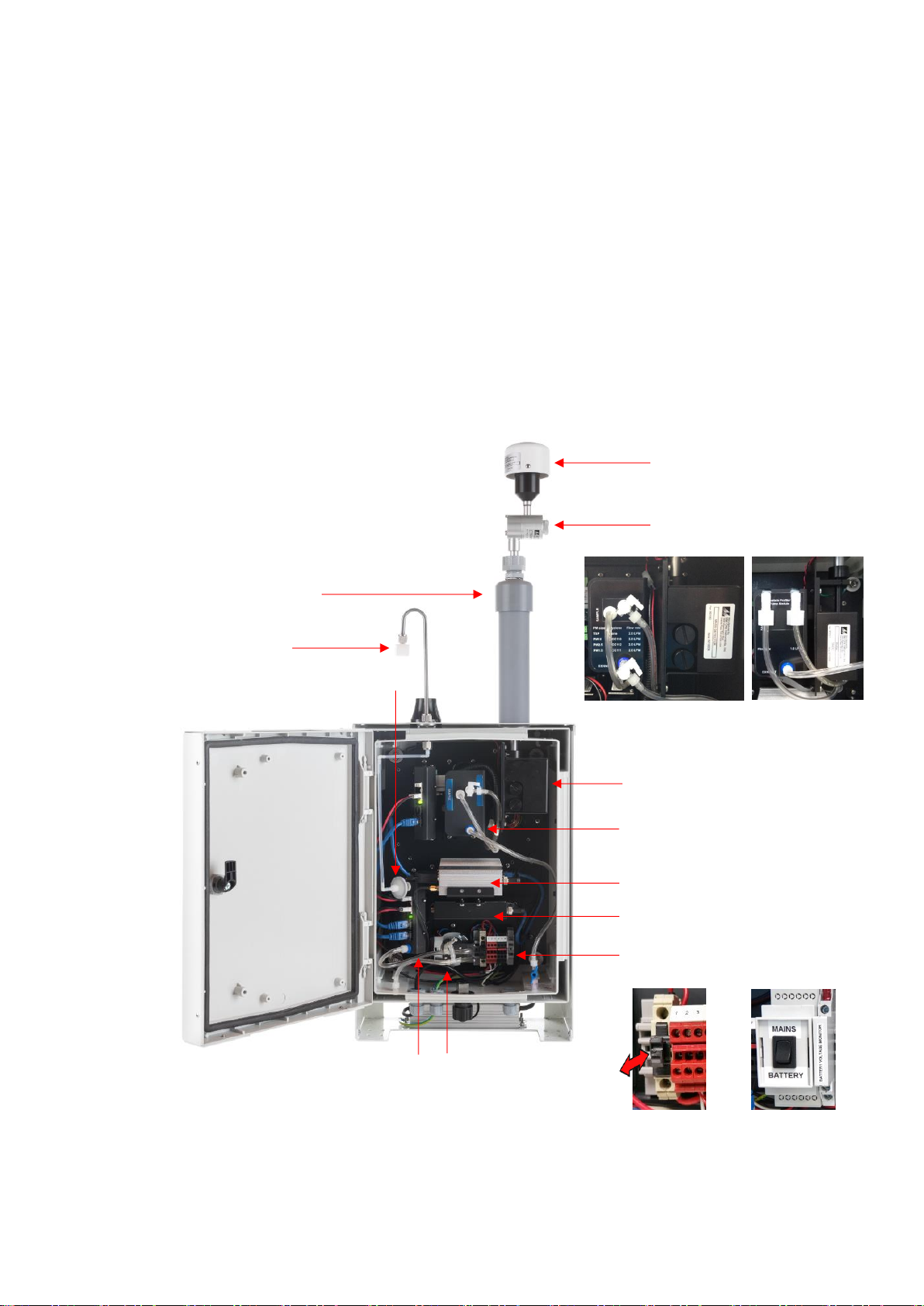

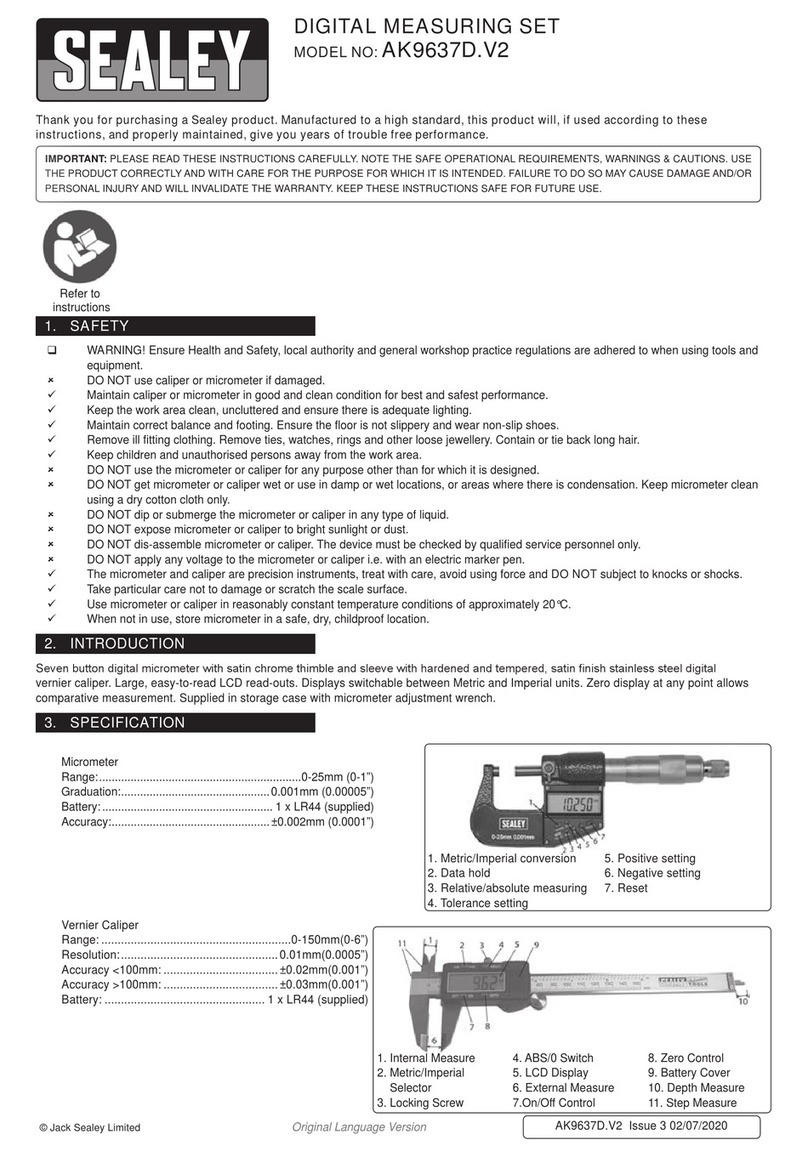

Figure 1-1 Key components

Gas sampling inlet

(AQS only)

TSP inlet

Sharp cut cyclone

(PM10 or PM2.5 or PM1)

Particle sampling inlet

Particle sampling pump

Particle monitoring engine

(Nephelometer or OPC)

See section 12.2

Embedded computer

12V DC power rail and fuse

Gas sampling module

(AQS only)

Gas sampling pump

(AQS only)

Modem (Optional)

Inlet filter on gas sampling line

(AQS only)

Fuse and On

/ Off switch

Mains / Solar or

Battery switch

(Optional)

Particle Monitor

Nephelometer)

Particle Profiler

(Optical Particle

Counter (OPC))

MRK-D-0048 V4 Aeroqual Dust Sentry / AQS User Guide Page | 6

1.2 Product comparison

Dust Sentry and Dust Sentry Pro both measure particulate concentrations using laser light scattering

but the methodology and optics design are different, this means that the Dust Sentry measures a single

size fraction selected by the user but the Dust Sentry Pro measures four size fractions simultaneously.

AQS 1 also measures gases in addition to particulate, up to three gas modules may be integrated.

Product

Particulate Measurement

Gas Measurement

Dust Sentry

TSP or PM10 or PM2.5 or PM1.0

None

Dust Sentry Pro

TSP and PM10 and PM2.5 and PM1.0 and 8 size counts

None

AQS 1

TSP or PM10 or PM2.5 or PM1.0

O3, NO2VOC

TSP and PM10 and PM2.5 and PM1.0 and 8 size counts

1.3 Applications by product

Applications for Dust Sentry

Designed for those who need to monitor and manage specific outdoor dust and particulate emissions

continuously and in real-time.

The Dust Sentry is a nephelometer-based monitor that delivers defensible and accurate mass

measurement for PM10, PM2.5, PM1, or TSP.

MCERTS certified and SCAQMD 1466 pre-approved.

For more detail see: https://www.aeroqual.com/product/dust-sentry-pm10-monitor

Applications for Dust Sentry Pro

Designed for those who need to monitor and manage multiple outdoor dust and particle size fractions

simultaneously and in real-time.

The Dust Sentry Pro delivers simultaneous measurement of PM10, PM2.5, PM1, TSP, and particulate

counts for 8 channels; 0.3, 0.5, 0.7, 1.0, 2.0, 3.0, 5.0, 10 microns.

For more detail see: https://www.aeroqual.com/product/dust-profiler-particle-counter

Applications for AQS 1

Designed for those who need to monitor and manage specific outdoor dust and particulates, and gases

continuously and in real-time.

The AQS 1 delivers affordable and defensible measurement of PM10,or PM2.5,or PM1, or TSP, and up

to three gases, all simultaneously.

MCERTS certified and SCAQMD 1466 pre-approved.

For more detail see: https://www.aeroqual.com/outdoor-air-quality/aqs-mini-air-quality-stations

MRK-D-0048 V4 Aeroqual Dust Sentry / AQS User Guide Page | 7

1.4 Optional external sensors

The monitors can integrate a number of external sensors such as weather sensors, solar radiation

and noise sensors. These sensors are mounted outside the monitor enclosure. The external sensors

below are available factory tested and ready to connect to the monitors.

MetOne MSO

weather station

Cirrus MK427

noise meter

Vaisala WXT536

weather station

Gill Instruments

Windsonic

Li-Cor LI-200

Pyranometer

See Section 2.6.1 for wiring external sensors.

1.5 Dimensions

These dimensions are for a visual representation only, for full details.–see section 1.6 Specifications.

Dimensions are in millimetres (mm).

.

330

187

483

360

MRK-D-0048 V4 Aeroqual Dust Sentry / AQS User Guide Page | 8

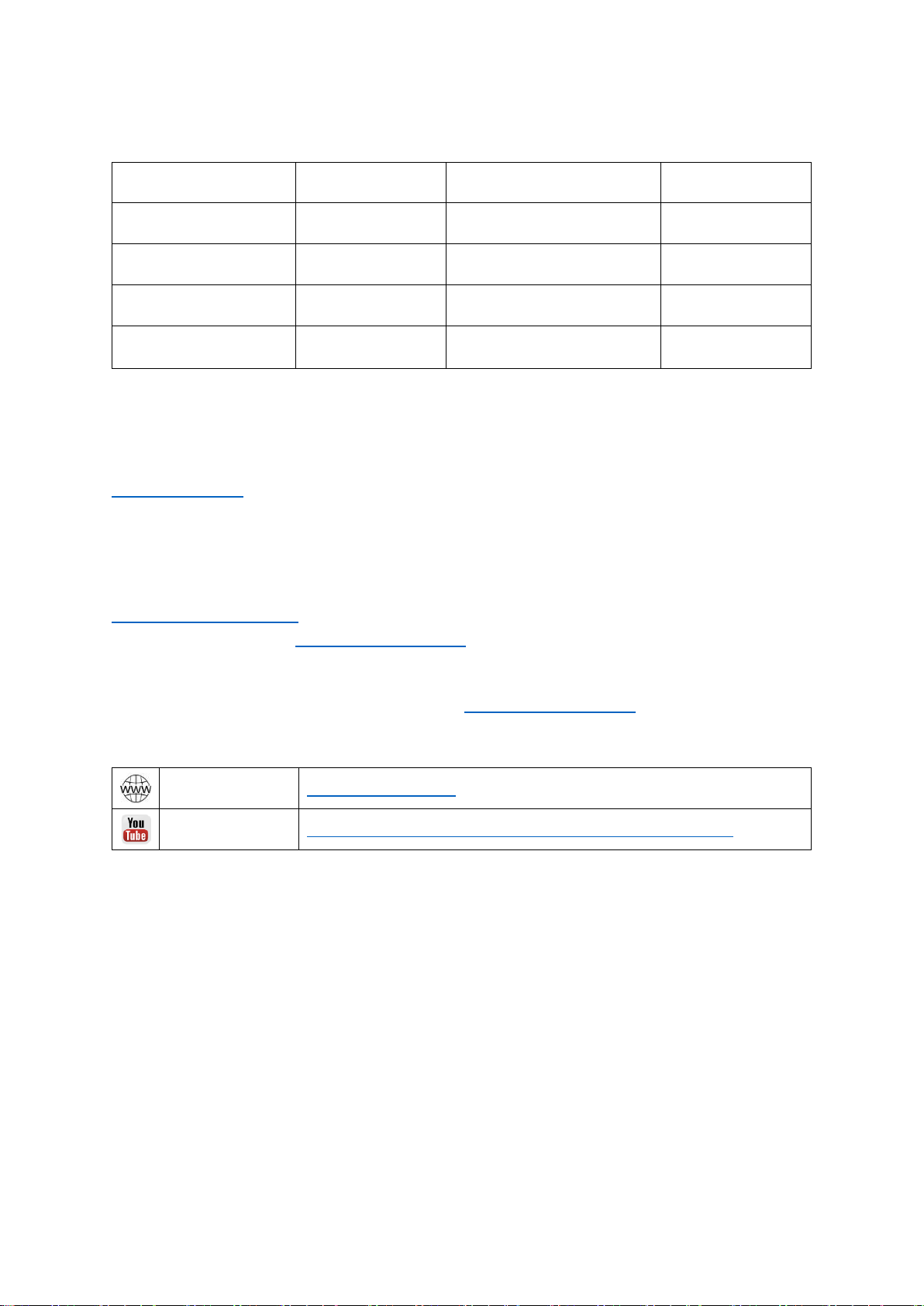

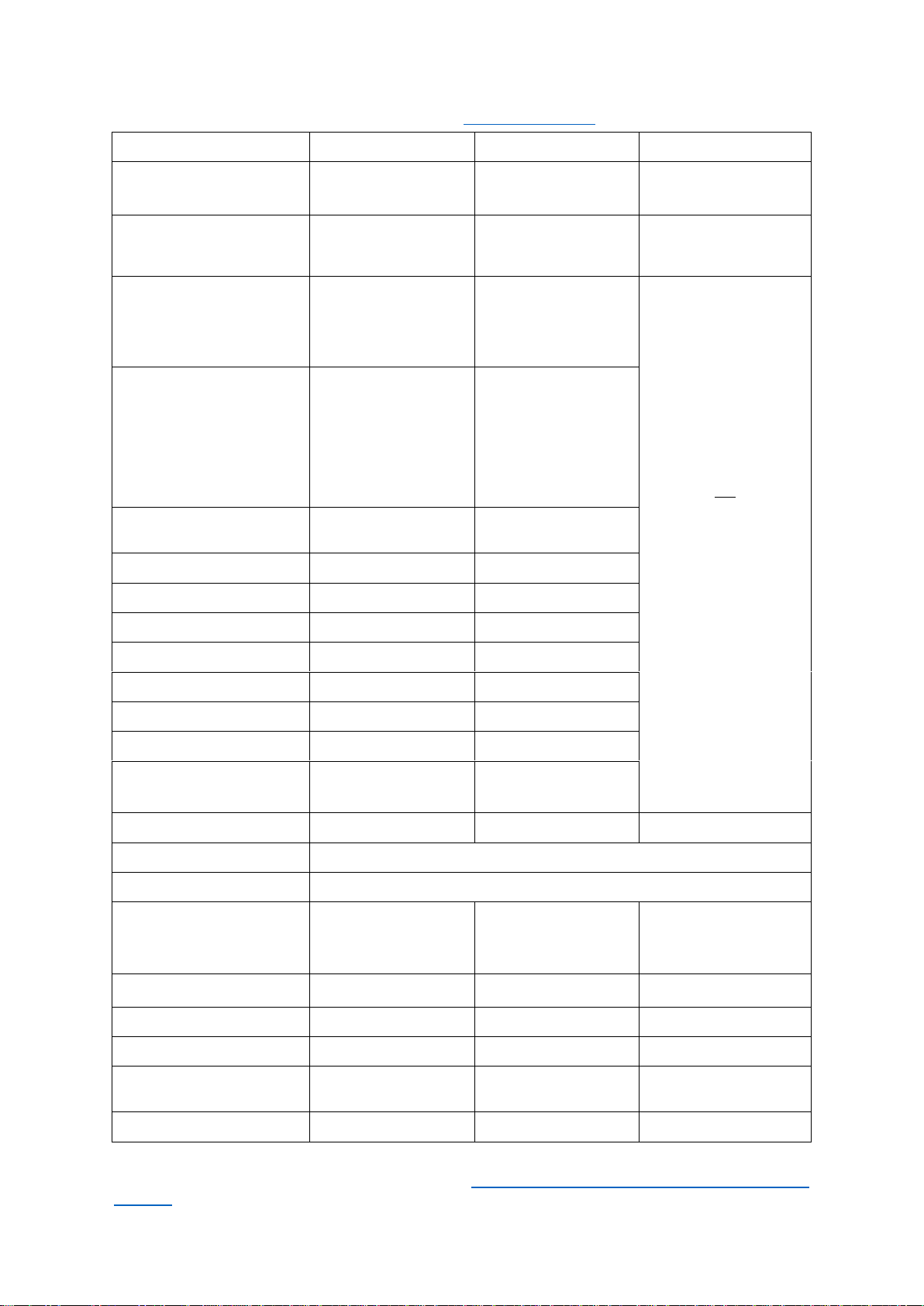

1.6 Specifications

Specifications are subject to change, please check www.aeroqual.com for the current specifications.

Dust Sentry

Dust Sentry Pro

AQS

Particulate

Measurement

Measurement technology

Near forward angle

laser scattering

nephelometer

Right angle laser

scattering particle

counter

Particle Counts

Range

Size channels

N/A

0-1,000,000 particles/L

0.3, 0.5, 0.7, 1.0, 2.0,

3.0, 5.0,10.0 µm

The AQS 1 can be

specified with either a

Near forward angle laser

scattering nephelometer

OR

Right angle laser

scattering particle

counter

Particulate

measurement

specifications will reflect

the measurement

technology chosen –see

panels to the left.

Particle Mass Measurement

PM1

PM2.5

PM10

TSP

Simultaneous?

Range / ug/m3

0 - 60000

0 - 60000

0 - 60000

0 - 60000

No –requires cyclone

Range / ug/m3

0 - 200

0 - 2000

0 - 5000

0 - 5000

Yes

Accuracy

<±(2 μg/m3+ 5 % of

reading)

<±(5 μg/m3+ 15 % of

reading)

Resolution

0.1 μg/m3

0.1 μg/m3

MCERTS certified

Yes

No

SCAQMD Rule 1466

Pre-approved

No

Auto zero check

Yes

No

Sample flow

2 LPM

1 LPM

Connect/ Cloud software

Yes

Yes

Factory calibration interval

24 months

12 months

Operating temperature

-10 °C to +50 °C

(14 °F to 122 °F)

-10 °C to +45 °C

(14 °F to 122 °F)

Heated inlet

Yes

Yes

Yes

Power consumption

24 W Max, depends upon configuration

Additional sensors

Weather station / Wind Speed and Direction / Noise / Solar incidence

Dimensions (H x W x D)

Weight

483 x 330 x 187 mm

(19 x 13 x 7.4 inches)

<13 kg

(28.6 lbs)

483 x 330 x 187 mm

(19 x 13 x 7.4 inches)

<13 kg

(28.6 lbs)

483 x 330 x 187 mm

(19 x 13 x 7.4 inches)

<15 kg

(33 lbs)

Gas Measurement

Ozone (GSS)

-

-

0 -500 ppb (0.1 ppb)

Nitrogen Dioxide (GSE)

-

-

0 -500 ppb (0.1 ppb)

Volatile Organic

Compounds (PID)

-

-

0 -500 ppb (0.1 ppb)

Gas calibration interval

-

-

As required

*Above 40 °C the laser may require more frequent servicing.

All monitors use the same software platform: https://www.aeroqual.com/product/air-monitoring-

software

MRK-D-0048 V4 Aeroqual Dust Sentry / AQS User Guide Page | 9

2 Quick Setup Guide

Before the monitor arrives (for full pre-planning details see section 2.2)

1. Visit the site and assess monitor location and suitability

Site will be representative of the pollutants you intend to measure.

Site is secure but with adequate access.

Site is appropriately open to all wind directions.

If you are planning a permanent deployment, check that there is nothing nearby

which could change and affect your project –like trees, planned buildings or new

roads and other potential interferences.

2. Ensure power is available on site

Ensure power is available Both Mains and Solar power can be used, but these

will need to be available and/or installed before the monitor arrives.

When installing power outlets (110 VAC to 230 VAC) for the monitor, they should

be weatherproof and installed safely.

Allow for 2 power outlets, one for the monitor and one for calibration equipment.

NOTE: A power lead with local plug will need to be supplied and wired to a connector

supplied with the monitor.

3. Install any additional infrastructure required for the installation

Mounting location and method has been identified. Most sites will require a way

of securely mounting the monitor. Pole Brackets (50.8 mm / 2 “304 Stainless U-

Bolt) are included to mount the monitor on a pole, anchored to the ground. Small

platforms have also been used successfully too.

If you have ordered Auxiliary sensors (Weather, noise etc.) you will need to

provide a means of mounting these also. You will need to supply a pole and

fixings to mount the sensor. Siting may be subject to local regulations.

Check you have the required tools.

4. Confirm communications specification (WIFI and/or cellular)

Check communications specifications and how the monitor software will be

accessed on site

For cellular access, purchase a dynamic IP network SIM card with at least 1 GB

data / month.

5. Plan for your time on site

When setting up for the first time allow at least four hours on site.

Allow for travel time to and from the site.

Confirm site operation times available for access.

Confirm personal protective equipment (PPE) that may be required on site.

6. Read the user guide

Familiarise yourself with the assembly steps.

Confirm the method of data access that will be supplied with the monitor (e.g.

Aeroqual Connect or Aeroqual Cloud).

Send any questions about things you are unsure about to

7. Write a checklist

Write your own checklist to ensure a smooth installation and setup.

Include any reporting requirements that will be required.

MRK-D-0048 V4 Aeroqual Dust Sentry / AQS User Guide Page | 10

After the monitor arrives

1. Unpack the monitor and inspect

Inspect the packaging and monitor for damage.

Check all items have been supplied

NOTE: A power lead with local plug will need to be supplied and

wired to a connector supplied with the monitor.

Section 2.3

2. Mount monitor

Mount the monitor to your platform or pole.

Attach the PM inlet.

Attach the gas inlet.

Open the door and check that all tubing, power and data

connections are secure.

Section 2

Section 2.4.1

Section 2.4.3

3. Power on the unit

Turn on the unit by pushing in the fuse.

Check that the Status LEDs on the modules, Embedded PC

and Modem (if fitted) are on and green.

Check that the sampling pump (PM only) or pumps (PM and

Gas) are running.

Section 2.5.4

4. Set up Wi-Fi / Modem and connect to the monitor

Connect to Aeroqual Connect

Connect to Aeroqual Cloud

Section 4.1

Section 4.2

5. Check sampling flow rates

Put the monitor into Service mode

Write a comment in the Journal that you are on site for

monitor commissioning.

Check the sampling system for leaks, rectify any leaks.

Check and adjust gas module flow rates to specification.

Check PM inlet flow rates and adjust if required.

Section 5.1

Section 6.4

Section 6.5.4

Section 6.5.4.2

Section 6.5.4.3

6. Attach optional auxiliary sensors

If you have purchased any auxiliary sensors (Weather,

Noise) mount these and run the cabling through the external

glands, and connect to the AUX module.

Section 2.6

7. Document setup in Journal

Note in the Journal that commissioning is complete.

Exit Service mode.

Section 6.4

Section 5.1

Installation and commissioning

Commissioning is the process of setting up a new monitor to work correctly on site. It is important that

the correct procedure for commissioning the monitors is followed to ensure reliable monitor operation

and to meet or exceed your data quality objectives. All monitors are supplied with a traceable factory

calibration. This calibration is applicable to the commissioning phase and accordingly Aeroqual does

not recommend an initial calibration as part of monitor commissioning.

Aeroqual provides a commissioning procedure which should be completed during this period. This

report details the tasks carried out during commissioning, and can be used to demonstrate correct

commissioning to end customers.

The commissioning procedure is available from: https://www.aeroqual.com/support/resources/aqm-65

NOTE: Please allow at least 30 min for the monitor to warm up to counter the effects of humidity.

Complete the Commissioning report and provide to customer

This report details the settings of the monitor at the time of commissioning. The completed report

should be provided to the customer, along with the factory logbook which is provided with every

monitor.

MRK-D-0048 V4 Aeroqual Dust Sentry / AQS User Guide Page | 11

2.2 Pre-planning

The monitors require only basic assembly out of the box.

Wire a mains AC power cable

Attach Particle Monitor inlet

Attach gas inlet (AQS only)

Attach third party sensors (where supplied)

Configure MOXA modem (where supplied)

Aeroqual recommends these steps be performed in an office or laboratory as part of a quality control

check of the monitor to make sure the monitor has arrived undamaged and the flow system, electrical

system and communication system are working as expected.

Some of the steps described here will be repeated in the field as part of the installation and

commissioning process.

After these steps have been carried out, the Monitor can be safely transported to the monitoring site

for installation and commissioning.

Key points to consider for assembly and first power up:

The monitors run on single phase mains AC power 100 - 260 VAC (standard): 21W / 30W, or

if required a regulated 12 VDC: 21W / 30W. For more details see section 2.4.

Configuration used for power calculations: base unit, nephelometer, PM10 sharp cut, O3

module, modem, heater off / heater on.

You need to supply a mains power cable and local plug, Aeroqual recommends a residual

current device (RCD) be used to protect against power spikes.

You will need a Phillips head screwdriver, and if you have an external sensor you will also

need a small flat blade screwdriver.

There is no software to download and install, and no cables are required for communication.

Communication to the monitor is through your web browser on your laptop, tablet or smart

phone using WIFI.

If you have purchased a MOXA modem, this needs a local SIM (dynamic IP) same as you

would have in your smart phone, but you must know the APN of your chosen

telecommunications provider, you can look this up: www.apnchanger.org

2.3 Unpacking

The monitors are packaged in a cardboard carton with moulded protective

inserts.

Dimensions: 62 x 32 x 55 cm (L x W x H)

Weight: < 12.5 kg (Configuration used for weight calculations: base unit,

nephelometer, PM10 sharp cut, O3 module, modem, heater off / heater on.

Additional components such as weather or noise sensors will be packaged in

additional boxes.

a) Examine the ShockWatch®label on the side of the shipping box. If the

indicator is red do not refuse the shipment. Make a notification on

delivery receipt and inspect for damage. If damage is discovered, leave item in original

packaging and request immediate inspection from carrier within 15 days of

delivery date (3 days international).

b) Verify the serial number label on the documentation matches the serial

label on the monitor –the label is located inside the monitor on the bottom

right side.

c) Verify that all components have been shipped as per the packing slip. Contact your Distributor

or Aeroqual if you suspect any parts are missing.

MRK-D-0048 V4 Aeroqual Dust Sentry / AQS User Guide Page | 12

2.4 Assembly

Online reference

https://training.aeroqual.com/mod/page/view.php?id=624

Online video

YouTube Channel: Aeroqual Service and Maintenance playlist

Assemble the PM inlet

The particle sampling inlet is easy to assemble by push fitting the various supplied parts together. If

no sharp cut cyclone has been ordered then only a sampling inlet assembly and TSP head will need

to be assembled.

Figure 2-1 Particle sampling inlet parts including (L-R): inlet tube, cyclone adaptor, cyclone, TSP head.

Attach PM inlet

Turn off power to the monitor during this process by pulling out the 12 DC fuse as show in

Figure 2-8.

If not already fitted, attach a PM inlet O-ring to the aluminium retaining ring and apply a small

amount of lubricant.

Figure 2-2 Add the O-ring and a small amount of lubricant.

Inside the sampling inlet assembly has a sampling tube extending out of it. The sampling tube

has a thin film heater further up the shaft which is powered by the black and red cable exiting

the bottom of the assembly with white plug on the end.

Carefully thread the white plug through the PM inlet port on the roof of the monitor.

Continued next page.

MRK-D-0048 V4 Aeroqual Dust Sentry / AQS User Guide Page | 13

IMPORTANT The Particle Monitor ships from the factory with a thin film of tape or coloured

cap which protects the inlet, this must first be removed as shown in

Figure 2-3.

Figure 2-3 Remove the protective tape or cap from the PM inlet

Figure 2-4 Gently feed in the power cable and over the particle engine mounting bracket on the left. The

aluminium tube must push all the way into the PM module.

IMPORTANT Ensure sure that the aluminium inlet tube is pushed all the way into the

optical engine block.

If the aluminium tube does not fully push down in to the optical engine block, then create

more length in the aluminium tube by removing the grey retaining nut and then sliding up the

rubber grommet on the top of the inlet. Replace the nut after you have done this.

Remove

protective

tape or

coloured cap

MRK-D-0048 V4 Aeroqual Dust Sentry / AQS User Guide Page | 14

Figure 2-5 Create more length to the inlet by sliding the black rubber grommet up the tube.

You need to make sure you have correctly and securely inserted the aluminium tube fully in to

the optical engine block.

When you are satisfied the inlet is fully pushed in to the engine block, then connect the heater

plug on the inlet to the plug coming from the adjacent particle engine control module.

Insert the three supplied 6/32 UNC retaining screws to secure the inlet to the aluminium

retaining ring

Push the fuse holder in to the “On” position to begin flowing air through the inlet.

Then perform a leak check and flow check. See Section 6.5.6 and 6.5.7.

Figure 2-6 During field installation, secure the PM inlet using the retaining screws and plug in the heater

Attach gas inlet (AQS Only)

Figure 2-7 (L-R) Dust Sentry, Dust Sentry Pro come with insert. AQS supplied with Swagelok fitting.

The gas inlet is held by a ¼ inch Swagelok compression fitting.

Attach the inlet and perform a flow check to make sure the inlet is fitted correctly and the

sample pump is working properly.

When the AQS is sampling ambient air in the field, a Kynar inlet fitting with mesh is attached

to the Swagelok nut at the end of the sample cane.

MRK-D-0048 V4 Aeroqual Dust Sentry / AQS User Guide Page | 15

2.5 Power Requirements

The internal power requires regulated 12 VDC to maintain a constant pump speed. An external

mains to 12VDC power supply (Meanwell HLG80-12A 60W 12V) is fitted on the outside of the

enclosure and comes with an IP rated outdoor electrical plug. You must wire the other end of

the plug to mains power.

Where possible, visit the site and assess monitor location and suitability

AC power source

Both Mains and Solar power can be used, but these will need to be available and installed before the

monitor arrives When installing power outlets (110 VAC to 230 VAC) for the monitor, they should be

weatherproof and installed safely. Install 2 power outlets, 1 for the monitor and one for calibration

equipment.

NOTE: Aeroqual does not supply the mains power cable or the electrical plug for your local power

socket, you must supply this yourself.

DC power source

Occasionally mains AC power is not available at the site where the Monitor is installed and an

alternative power solution is required. More detailed information is in a Technical Note for remote

powering the monitors available from https://www.aeroqual.com/support/technical-documents

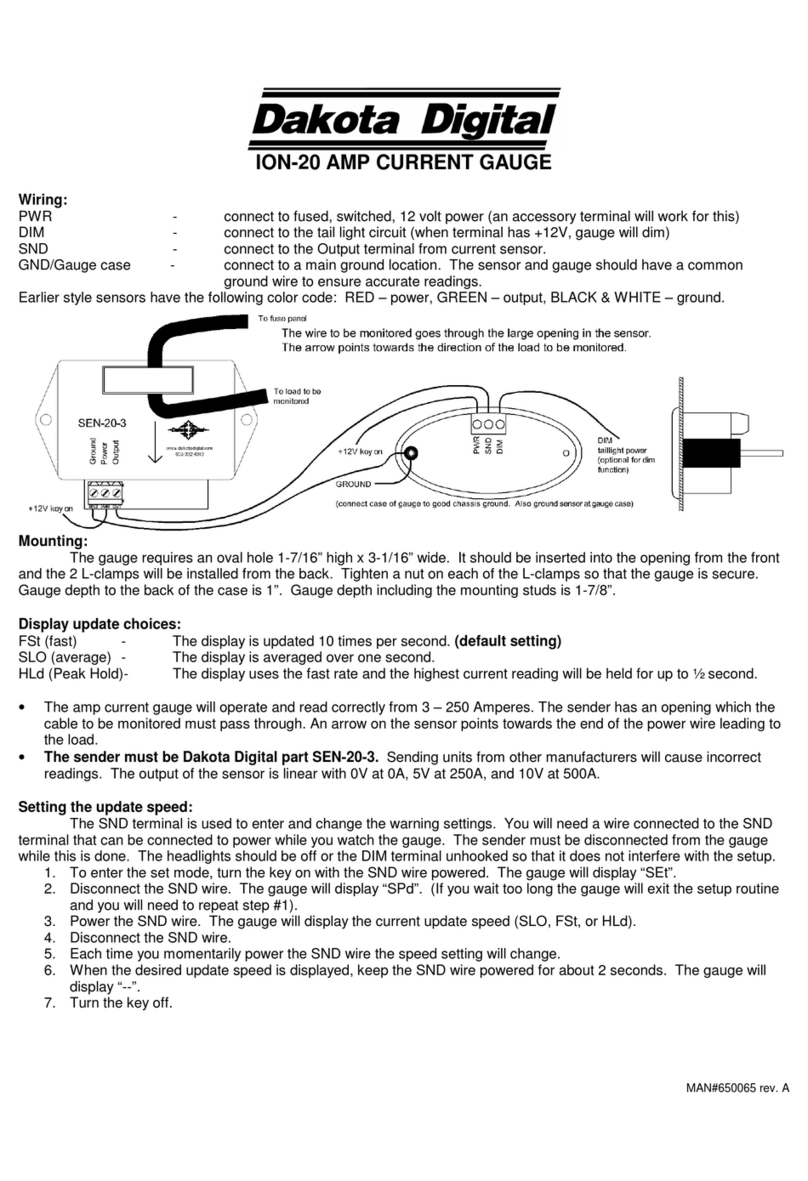

Wiring the power supply connector

1. Locate the power connector terminal which is situated outside the enclosure at the bottom. The

power supply will already be wired to the connector however the cable to connect to mains power

needs to be wired.

Caution: The high voltage mains supply must be wired by a certified electrician in

compliance with local electrical regulations.

A wiring color guide

is in section 12.3

3. Reconnect into the connector

ensuring the plugs are fitted securely

and the nut gland tightened.

Plug

Nut gland

Connector

Terminal block

Neutral

(Blue)

Earth

(Yellow/Green)

Live

(Brown)

2. Feed the power cable through the nut gland

plugs and connector and wire the cable to the

terminal block according to the diagram.

To separate the

connectors, twist the nut

gland to loosen the

terminal blocks, then pull

connectors apart

MRK-D-0048 V4 Aeroqual Dust Sentry / AQS User Guide Page | 16

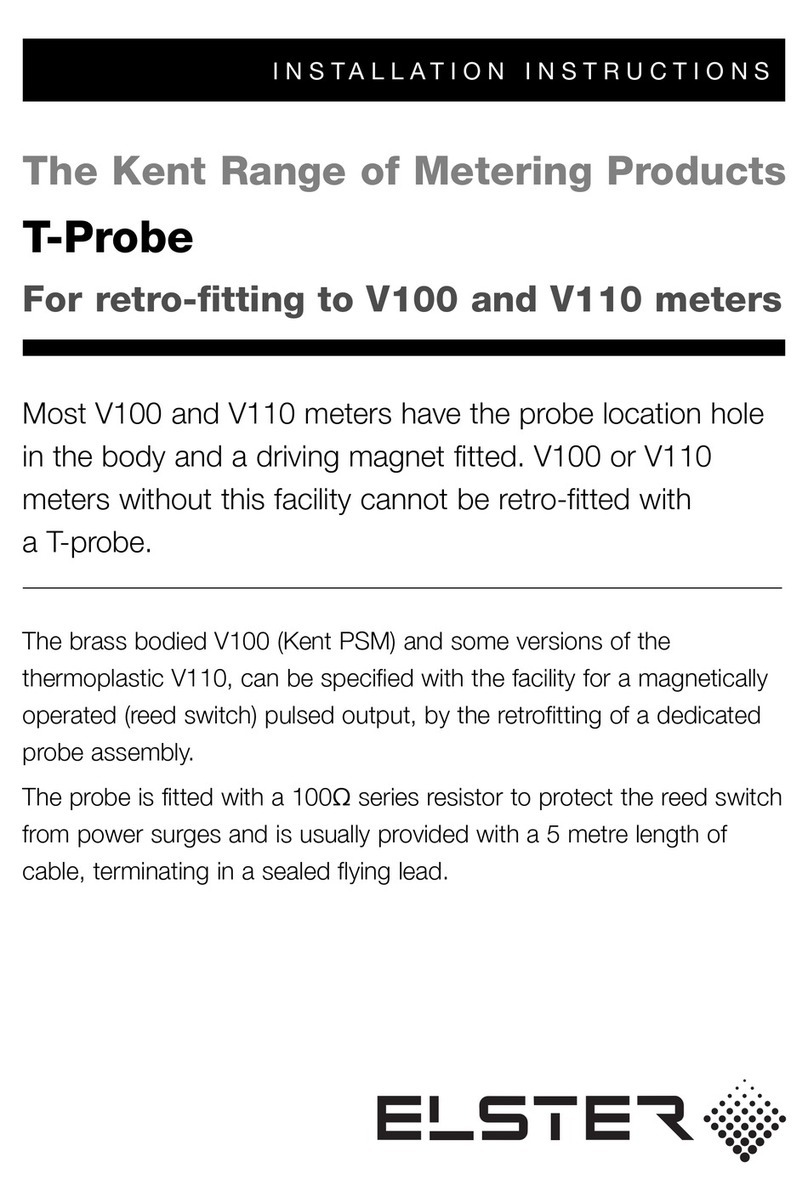

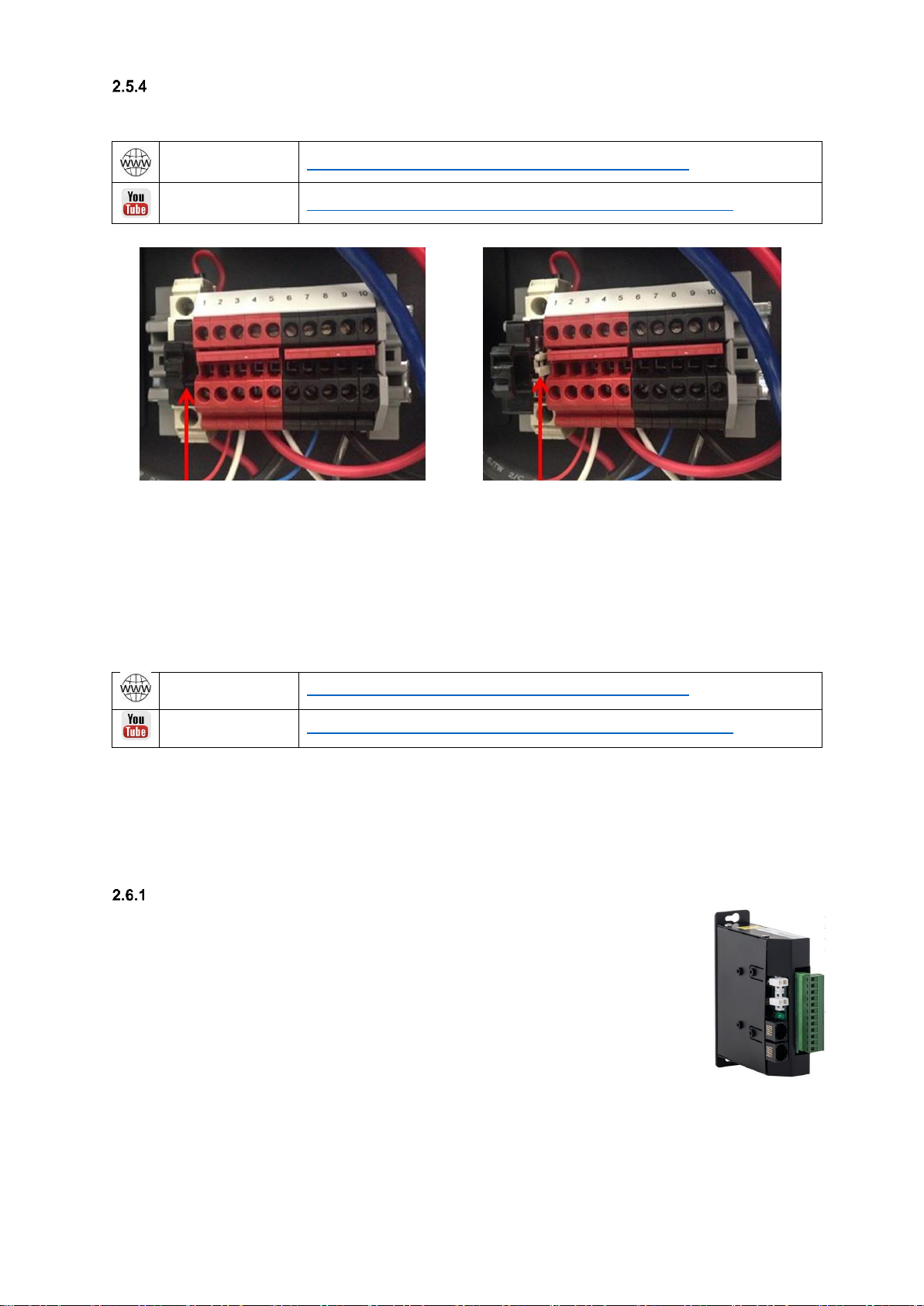

Powering monitor On/Off

NOTE: Pull the 12 VDC fuse out from the fuse holder “off position” before testing the mains

connection. See Figure 2-8.

Online reference

http://training.aeroqual.com/mod/page/view.php?id=623

Online video

YouTube Channel: Aeroqual Service and Maintenance playlist

12 V DC fuse pushed in, the “on” position

12 V DC fuse pulled out, the “off” position

Figure 2-8 The 12V DC fuse can be pulled out to turn off the monitor or pushed in to power the monitor

Push in the 12 DC fuse to the “on” position as shown on the left in Figure 2-8.

The pump/s will start and the ePC will boot up with a series of beeps.

The green power LED lights should light up on the modules when power is applied, this confirms the

power is being correctly delivered to the modules.

2.6 Wiring auxiliary sensors

Online reference

http://training.aeroqual.com/mod/page/view.php?id=625

Online video

YouTube Channel: Aeroqual Service and Maintenance playlist

NOTE: To check the operation of the third party sensor in your office or laboratory prior to site

installation it is not required to feed the cable through the gland.

External sensors such as weather stations and noise meters need to be wired to the green connector

plug on the front of the auxiliary module. To connect third party sensors such as weather sensors,

feed the cable through a free cable gland and wire to the green plug.

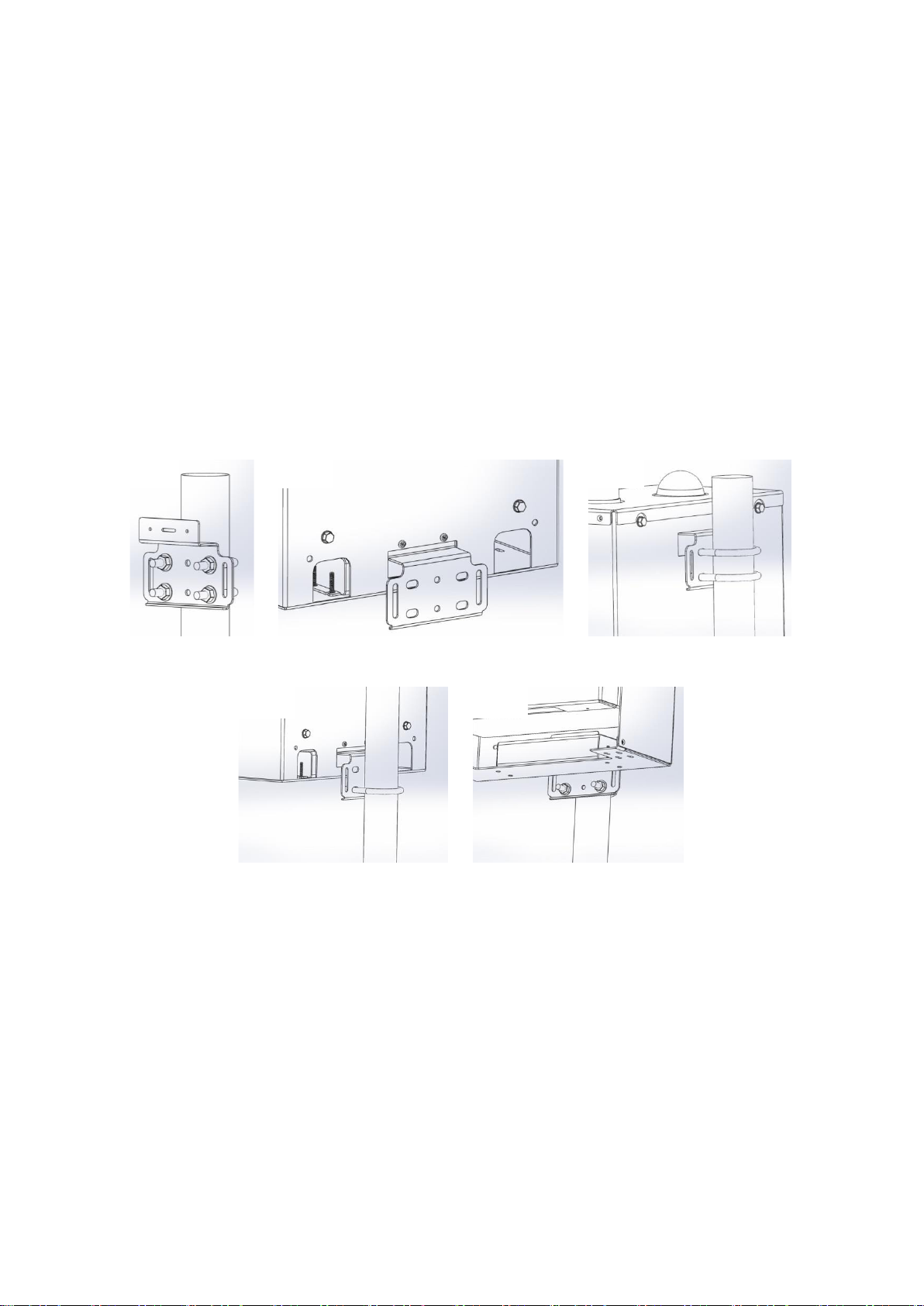

AUX module

An AUX module is used to provide power to an external sensor and to process data

from the sensor. The AUX module is shown to the right.

The AUX module uses a 12 way green connector plug to connect to the external

sensor. The cable from the external sensor is passed through a waterproof gland on

the underside of the monitors and then connected to the green plug on the front of

the AUX module. Each third party sensor requires a different wiring configuration.

See 2.6.2 Auxiliary sensor wiring diagrams.

When you are happy with the wiring then apply power, and log on to the Aeroqual

Connect software as described in section 4.1 Aeroqual Connect (via Direct WIFI /

LAN). After some minutes you should see the parameters associated with the third party sensor being

shown in the software in the APP “Configure Instrument”, view settings then the active sensor column.

To See the data, go to “Manage Data”, then Charts or Table, adjust the “Averaging Period” as

required.

NOTE: Retain the certificate of compliance that is shipped with the monitor.

MRK-D-0048 V4 Aeroqual Dust Sentry / AQS User Guide Page | 17

Auxiliary sensor wiring diagrams

IMPORTANT The auxiliary module orientation may vary, observe the correct numbering

order as labelled on the green connector.

Gill Ultrasonic Wind Sensor

Cirrus MK427 Noise Sensor

Vaisala WXT536 Weather Sensor

Met One MSO Weather Sensor

Novalynx Silicon Pyranometer

Online reference

training.aeroqual.com DM 1.3 Tech training Section 2.3

MRK-D-0048 V4 Aeroqual Dust Sentry / AQS User Guide Page | 18

3 Mounting and Site Positioning Guidelines

It is important that the positioning of the monitor is suitable so as to yield data which is representative

of that specific location.

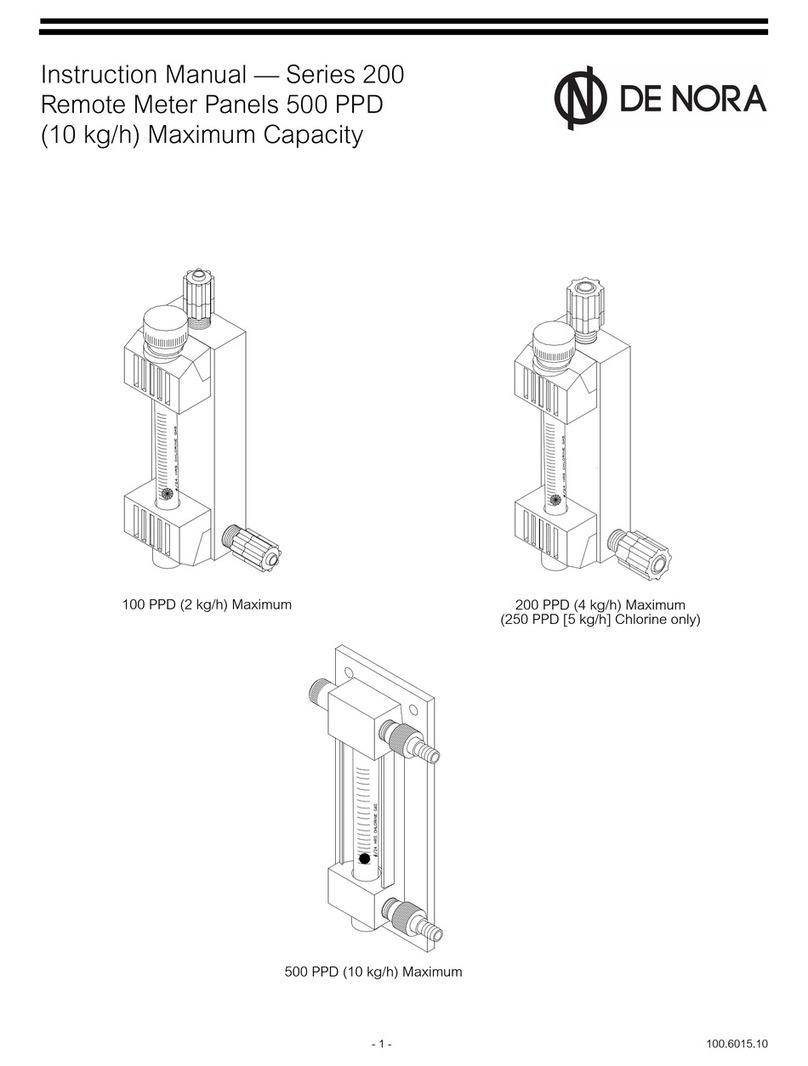

3.1 Mounting

The monitor comes with 2x mounting brackets and 3x U-bolts for 2 inch poles. The same brackets are

used for both pole and wall mounting. To wall mount the monitor the brackets are screwed into the

wall instead of using the U-bolts.

For pole mounting:

1. Secure top mounting bracket at a suitable height using 2x U-bolts provided

2. Fix lower mounting bracket to the Dust Sentry chassis with screws

3. Hang the monitor on the top mounting bracket

4. Place U-bolt through lower mounting bracket

5. Add nuts and washers and tighten the bottom U-bolt into position

NOTE: Only one U-bolt is used to secure the bottom bracket.

3.2 Inlet height

If monitoring is related to human exposure, the sampling inlet height should be positioned in

the “breathing zone”. This is located between 2 and 15 meters above ground level.

If monitoring is related to specific emission sources, the position of the sampling inlet can be

more flexible. It is more important that there is no obstruction between the approaching air

from the emission source and the sampling inlet.

If more than one monitor, or any other particulate instrument, is being used at the site, the

height of the inlets should be uniform.

If the monitor inlet is the highest point at the site, a lightning rod must be installed to prevent

damage to the unit during electrical storms.

3.3 Measurement Interference

The meteorological conditions of the site should be taken into consideration when positioning

the monitor. For example, there should be no obstruction to the air flow in the predominant

wind direction. A minimum clear sky angle of 120 degrees is recommended.

1.

2.

3.

4.

5.

MRK-D-0048 V4 Aeroqual Dust Sentry / AQS User Guide Page | 19

The inlet should be at least 1 meter away from any objects that could potentially influence the

airflow characteristics e.g. trees, vertical surfaces or walls.

Avoid overhead high-voltage cables which may cause electrical interference with the

sampling equipment.

Demolition/construction activities and change to normal transport patterns due to road works

etc. can significantly affect the data. Ensure a record of such events is kept to account for

unexpected peaks in concentration.

3.4 Safety

The intended data capture rate should be considered when positioning the monitor. If data

capture above 90% is essential, the unit should be located in an area which has 24 hour

access available.

The positioning should allow for routine maintenance checks to be performed safely by

personnel.

If using a tripod, ensure the tripod legs are bolted to the ground to prevent the unit from

falling.

Ensure the monitor is in a secure location to avoid vandalism or theft.

MRK-D-0048 V4 Aeroqual Dust Sentry / AQS User Guide Page | 20

4 Connectivity

The monitors use an industrial embedded PC (ePC) for data logging and monitor control. A cellular

modem can be fitted underneath the ePC to facilitate remote connection and support from Aeroqual

technical support. –see section 4.2.2 Connecting using a cellular modem.

There are two ways to connect to your monitors:

Aeroqual Connect (via Direct WIFI / LAN) for initial set up and when access to the internet

is limited;

Aeroqual Cloud (via Network WIFI / Modem) for remote access, visibility of all your

monitors, and remote technical support from Aeroqual Care.

Aeroqual highly recommends every monitor is connected to Aeroqual Cloud for the best user

experience, additional data features, and Aeroqual Care.

Engineers who need to perform service or data analysts who need to view or download data can do

so using a web browser on their PC, tablet or smart phone. There is no software to download and

install.

Data Security

The data belongs to you. We look after it in the same way that a bank looks after your money. Who

you let access your data is entirely up to you –our job is to carry out your instructions.

If you do choose to store data with us, then here are some of the security assurances we provide:

We use only ISO 27001 approved data centres

Infrastructure is monitored and protected 24/7

Data is accessed via a secure website with 256-bit SSL encryption

User defined passwords

4.1 Aeroqual Connect (via Direct WIFI / LAN)

Aeroqual Connect contains all of the tools necessary to view and download the data and maintain and

calibrate a single monitor.

No internet connection is required for Aeroqual Connect. Aeroqual Connect is always running on the

monitor and can be accessed via WIFI through an internet browser on any device, there is no

software to install.

Figure 4-1 Aeroqual Connect Home page

Connect to Aeroqual Connect via Direct WIFI

A few minutes after powering on, you should see a new WIFI network in your device’s list of WIFI

networks. The WIFI name (SSID) will match your serial number, connect to this network using the

password below.

WIFI SSID: DS DDMMYYYY-XXX or AQS1 DDMMYYYY-XXX

Password: Aeroqual

This manual suits for next models

2

Table of contents

Other Aeroqual Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

AMO

AMO AMOSIN WMI-300 Installation and mounting instructions

ELKOR

ELKOR WattsOn-MCM Installation & user guide

SPY

SPY PJM Pocket JeepMeter operating instructions

Mitutoyo

Mitutoyo Digimatic MDC-S user manual

Pepperl+Fuchs

Pepperl+Fuchs PMI360D-F130-IE8-V15 manual

Comet

Comet COMMETER C3631 instruction manual

De Nora

De Nora 200 Series instruction manual

Dwyer Instruments

Dwyer Instruments WDPM-002 Specifications-installation and operating instructions

Sealey

Sealey AK9637D.V2 instructions

Vega

Vega VEGACAL 65 operating instructions

KYORITSU

KYORITSU KEW SNAP 2002PA instruction manual

Fieldpiece

Fieldpiece SC66 Operator's manual