De Nora 200 Series User manual

- 1 - 100.6015.10

Instruction Manual — Series 200

Remote Meter Panels 500 PPD

(10 kg/h) Maximum Capacity

100 PPD (2 kg/h) Maximum 200 PPD (4 kg/h) Maximum

(250 PPD [5 kg/h] Chlorine only)

500 PPD (10 kg/h) Maximum

100.6015.10 - 2 -

These instructions describe the installation, operation and maintenance ofthe subject equipment. Failure to strictly

follow these instructions can lead to an equipment rupture that may cause significant property damage, severe

per-sonal injury and even death. If you do not understand these instructions, please call De Nora Water

Technologies for clarification before commencing any work at 215-997-4000 and ask for a Field Service Manager.

De Nora Water Technologies, Inc. reserves the rights to make engineering refinements that may not be

described herein. It is the responsibility of the installer to contact De Nora Water Technologies, Inc. for

information that cannot be answered specifically by these instructions.

Any customer request to alter or reduce the design safeguards incorporated into De Nora Water Technologies

equipment is conditioned on the customer absolving De Nora Water Technologies from any consequences of

such a decision.

De Nora Water Technologies has developed the recommended installation, operating and maintenance procedures

with careful attention to safety. In addition to instruction/operating manuals, all instructions given on labels or

attached tags should be followed. Regardless of these efforts, it is not possible to eliminate all hazards from the

equipment or foresee every possible hazard that may occur. It is the responsibility ofthe installer to ensure that the

recommended installation instructions are followed. It is the responsibility of the user to ensure that the

recommended operating and maintenance instructions are followed. De Nora Water Technologies, Inc. cannot be

responsible deviations from the recommended instructions that may result in a hazardous or unsafe condition.

De Nora Water Technologies, Inc. cannot be responsible for the overall system design ofwhich our equipment may

be an integral part of or any unauthorized modifications to the equipment made by any party other that De Nora

Water Technologies, Inc.

De Nora Water Technologies, Inc. takes all reasonable precautions in packaging the equipment to prevent shipping

damage. Carefully inspect each item and report damages immediately to the shipping agent involved for

equipment shipped “F.O.B. Colmar” or to De Nora Water Technologies for equipment shipped “F.O.B Jobsite”. Do

not install damaged equipment.

De Nora Water Technologies, COLMAR OPERATIONS

COLMAR, PENNSYLVANIA, USA

IS ISO 9001: 2008 CERTIFIED

- 3 - 100.6015.10

Table of Contents

1 INTRODUCTION ..........................................................................4

1.1 General ...........................................................................4

1.2 Warranty and Service................................................................ 4

1.3 Remote Meter Panel Data .............................................................4

2 OPERATION .............................................................................5

2.1 General ...........................................................................5

2.2 Installation .........................................................................5

3 START-UP ...............................................................................8

4 SERVICE ...............................................................................12

4.1 Cleaning the Flowmeter Assembly......................................................12

4.2 Rate Adjustment Valve Cleaning .......................................................12

5 TROUBLESHOOTING CHART ..............................................................13

FIGURES

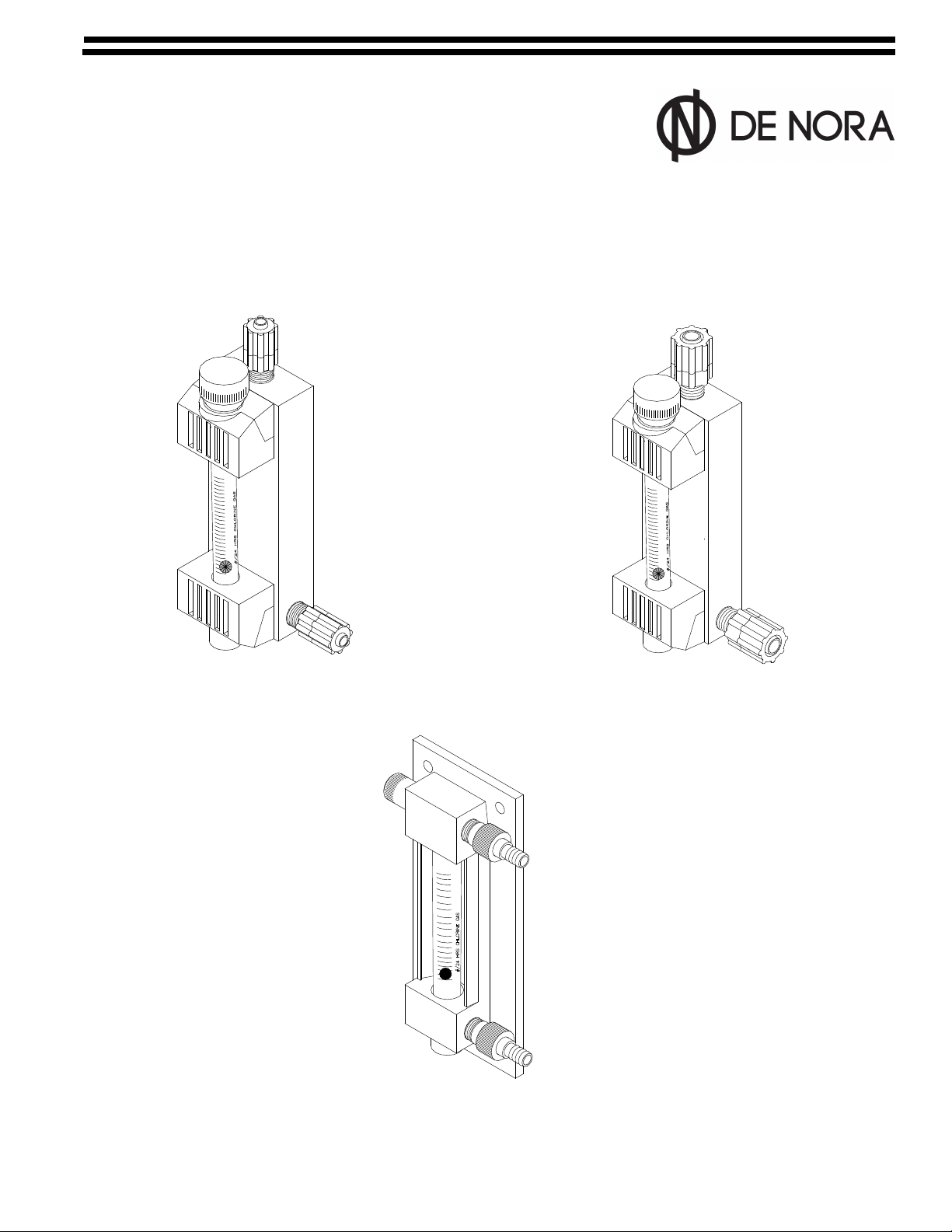

1 100 PPD (2 kg/h) Meter Panel ..........................................................6

2 200 PPD (4 kg/h) (250 PPD/5 kg/h Chlorine only) Meter Panel .................................7

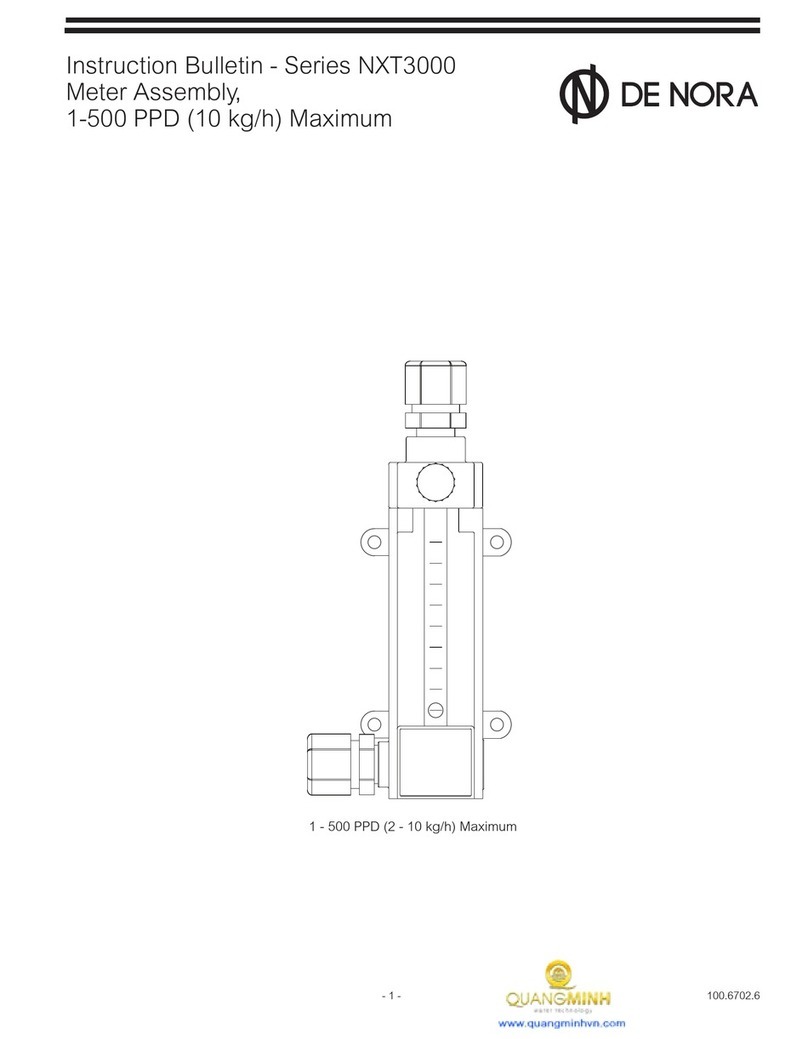

3 500 PPD (10 kg/h) Meter Panel .........................................................8

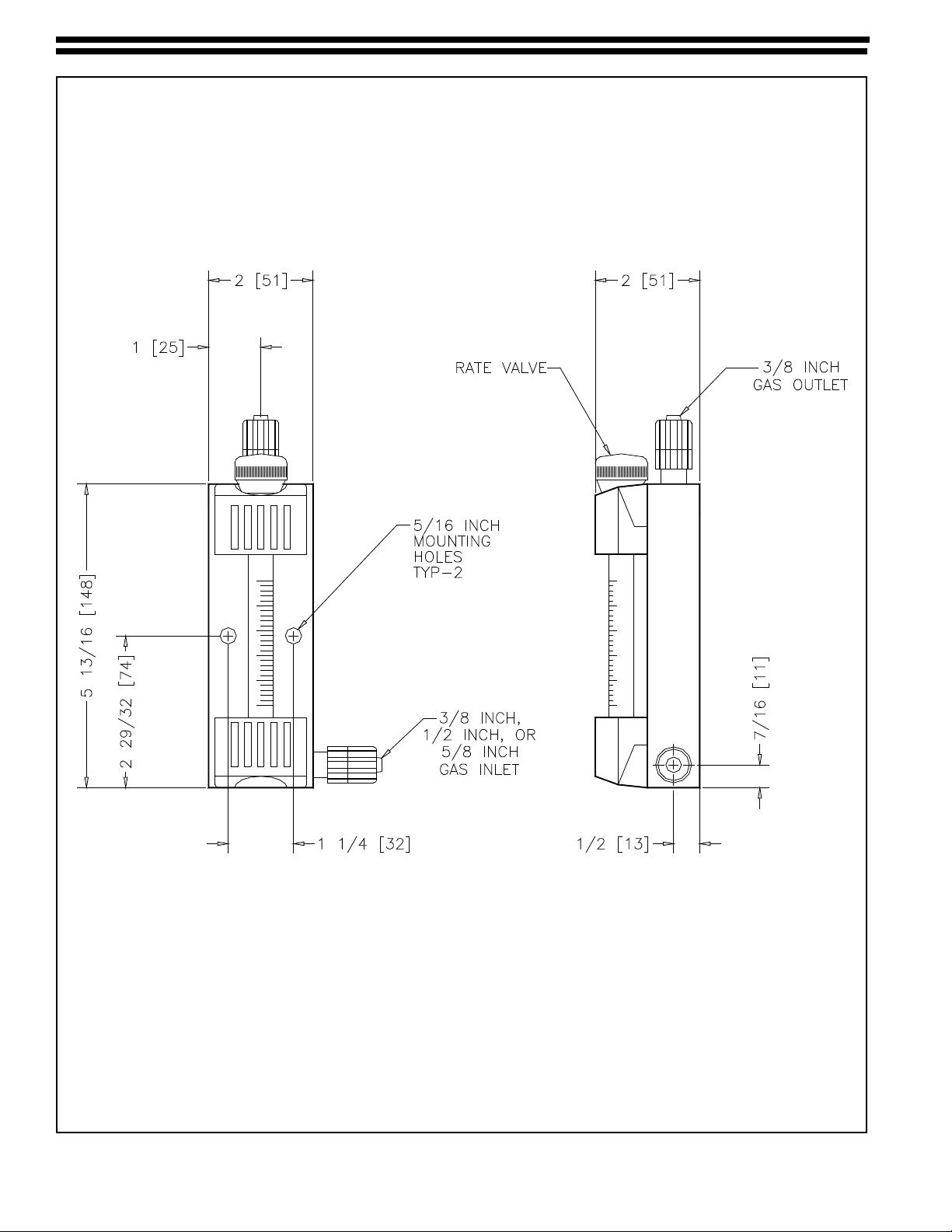

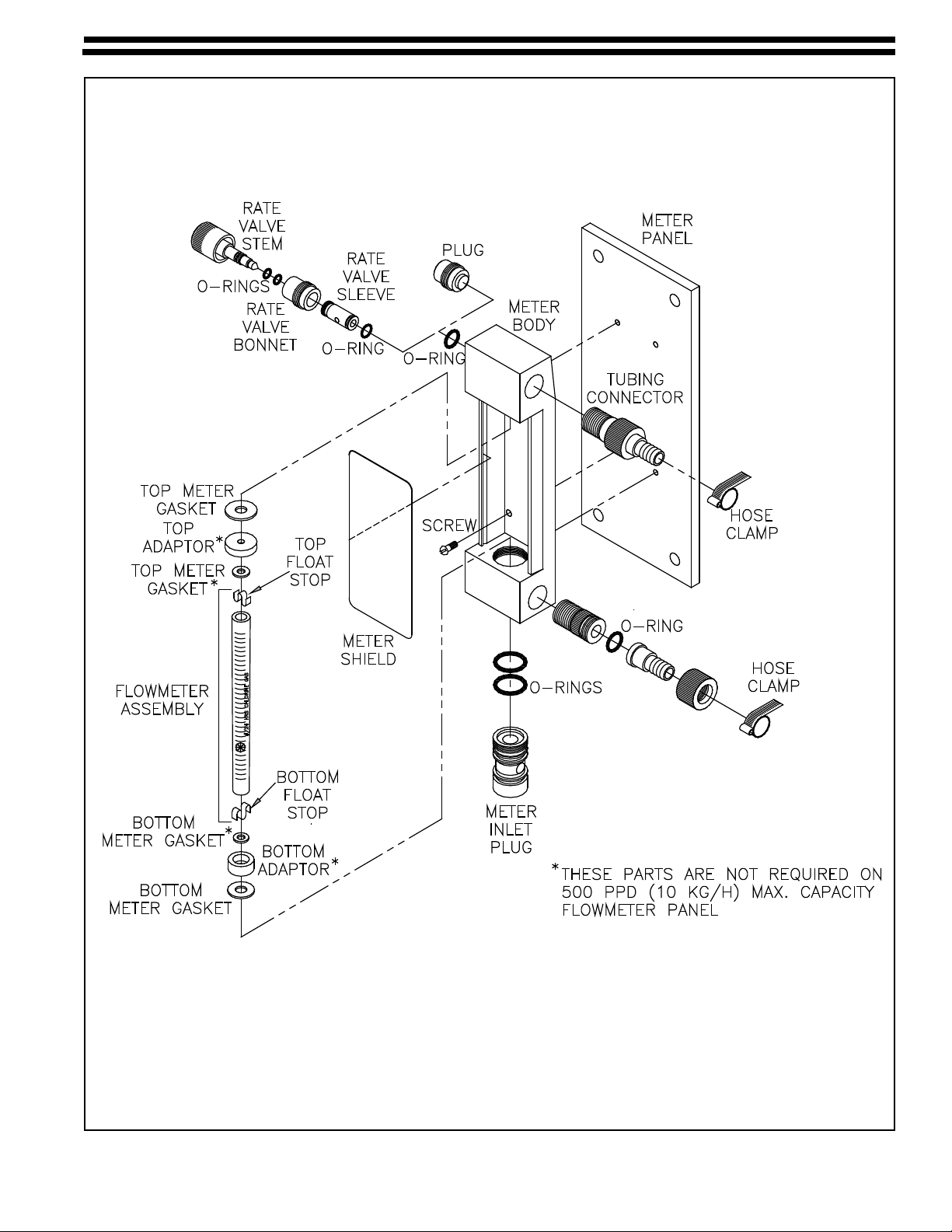

4 100 PPD (2 kg/h) Meter Panel Components ...............................................9

5 250 PPD Max (4 kg/h) Meter Panel Components...........................................10

6 500 PPD (10 kg/h) Meter Panel Components .............................................11

100.6015.10 - 4 -

1 INTRODUCTION

1.1 General

The ADVANCE®remote meter panels are expertly engineered and carefully tested to assure years of

satisfactory operation. The meter panels are constructed of the finest materials available for gas service.

Proper installation and care will ensure the best operation. Read instructions carefully and retain for future

reference.

These instructions cover Series 200 Remote Meter panels only. Refer to the following for other components:

Remote Meter Panel Dimensions - 100.3004

Vacuum regulator -100.6010

Ejector - 122.6005

Automatic Switchover -100.6030

1.2 Warranty and Service

See 005.9001 for ADVANCE equipment warranty.

NOTE: The Series 200 Remote Meter Panel is designed for use with a Series 200 gas feeder. The ADVANCE

equipment warranty and service policy is null and void, as it pertains to user protection, if the Series 200

Remote Meter Panel is misapplied.

It is recommended that the Gas Dispensing System be inspected and serviced a minimum of once per

year.

More frequent service periods may be required due to: 1) the type, quality and quantity of the gas being

handled, 2) the complexity of the gas supply system, 3) the quality and quantity of water or process liquid

being used to operate the ejector(s), and 4) operation procedures.

More frequent service periods are especially indicated when venting of the VR is occurring during the one

year operational period. This is usually indicative of foreign debris holding the inlet valve open or destruction

of the inlet valve parts caused by the gas quality not up to industry purity standards.

1.3 Remote Meter Panel Data

Capacity Meter Tube Size Capacities Available as Chlorine

(For Carbon Dioxide, see note)* Tubing Connection

100 PPD

(2 kg/h) 3" 4, 10, 25, 50, 100 PPD

(75 & 200 g/h, 0.5, 1, 2 kg/h)

Inlet - 3/8", 1/2", 5/8"

Outlet - 3/8"

250 PPD

(5 kg/h) 3" 25, 50, 100, 200, 250 PPD

(0.5, 0.9, 2, 4, 5 kg/h)

Inlet - 1/2", 5/8"

Outlet - 1/2"

500 PPD

(10 kg/h) 6" 25, 50, 100, 200, 300, 500 PPD

(0.5, 0.9, 2.0, 4, 6, 10 kg/h)

Inlet - 5/8"

Outlet - 5/8"

Accuracy: 4% of maximum flowmeter capacity

* Chlorine meter tubes are used for carbon dioxide service with factor tag x 0.78.

1.4 Multiple Meter Panels

Multiple meter panels are available with up to four (4) meter. These meters are usually mounted on a panel

with a common inlet block and individual gas flowmeter outlets. The multiple meter panels are used for the

same gas only.

- 5 - 100.6015.10

2 OPERATION

2.1 General

The remote meter panel is designed to complement the Capital Controls’ Series 200 vacuum regulators.

When multiple chlorine gas feed points from the same vacuum regulator are required, a remote meter

panel is utilized. Each remote meter panel is manually set, via the rate valve, to meter the proper amount of

chlorine gas to the feed point. The combined gas feed rate from the remote meters must not exceed the total

feed rate capacity of the vacuum regulator.

NOTE: When remote meter panels are desired to be used for gas flow indication only , the rate valve at the

vacuum regulator is used to adjust gas flow. Therefore, if the vacuum regulator has a rate valve, the remote

meter's rate valve should be removed and replaced with a plug.

2.2 Installation - See Figures 1, 2, and 3

The remote meter panel must be installed in an upright and level position in order to function properly.

The remote meter panel is installed in the vacuum line between the ejector and the vacuum regulator. Locate

the meter panel on a vertical surface convenient for observation and operation, usually in the operator’s area,

with the point of chlorine injection at the desired remote location. Mount the meter panel using two (2) 1/4"

mounting screws for a 3" meter panel, or four (4) 3/8" mounting screws for a 6" meter panel. If the surface is

not suitable for wood screws, choose an appropriate anchor bolt to that surface.

Black polyethylene tubing is normally used for the vacuum line. Do not kink this tubing. It may be desirable

to use tubing connectors, tees or 90° elbows to provide as direct run as possible and minimize kinking

conditions. Use enough tubing length to allow movement of the vacuum regulator for servicing or cylinder

change. Connect the tubing as follows:

2.2.1 Remove the bottom vacuum inlet connector nut from the remote meter panel and slip the connector

nut onto the vacuum tubing coming from the vacuum regulator.

2.2.2 Push the tubing onto the tubing connector and tighten the connector nut HAND TIGHT.

2.2.3 Remove the connector nut from the vacuum outlet (top) of the remote meter and slip onto vacuum

tubing going to the ejector.

2.2.4 Push the tubing onto the tubing connector and tighten the connector nut HAND TIGHT.

NOTE: There may be installations where multiple meter panels may be used from one vacuum

regulator. If this occurs, additional tees may be required to complete the installation.

2.2.5 Some meter panels may be provided as a complete block with a common vacuum manifold, Each

meter would have an individual outlet.

General Design Note: Routing vacuum tubing through unventilated conduit is discouraged. A minute

portion of gas flowing through tubing under vacuum conditions, will slowly diffuse at a molecular

level through its walls and collect in the closed conduit over an extended period of time.

100.6015.10 - 6 -

Figure 1 - 100 PPD (2 kg/h) Meter Panel

- 7 - 100.6015.10

Figure 2 - 200 PPD (4 kg/h) Meter Panel

100.6015.10 - 8 -

Figure 3 - 500 PPD (10 kg/h) Meter Panel

250 PPD [5 kg/h] & 300PPD (6 kg/h) Chlorine only)

3 START-UP

Follow the instructions provided in the vacuum regulator instruction manual 100.6010 for complete system

start-up procedures.

After the system has been tested for leaks and is operating, adjust the rate valve to the desired gas flow rate.

The flow rates are in PPD (pounds per day) of chlorine.

If feeding sulfur dioxide, the actual flow rate is 0.95 of the scale value. For example, a reading of 50 PPD

(1 kg/h) is actually 45 PPD (0.95 kg/h) sulfur dioxide.

If feeding ammonia, the actual flow rate is 0.50 of the scale value. For example, a reading of 50 PPD (1 kg/h)

is actually 25 PPD (0.5 kg/h) ammonia.

Read the flowmeter scale at the center of the ball.

NOTE: NEVER use the rate valve on the remote meter panel to shut off the gas supply. This valve is for

adjusting flow rate while the system is in operation. If used for shutoff, this valve will be damaged. To shut off

the gas, close the gas container valve.

- 9 - 100.6015.10

Figure 4 - 100 PPD (2 kg/h) Meter Panel Components

100.6015.10 - 10 -

Figure 5 - 250 PPD Max (4 kg/h) Meter Panel Components

- 11 - 100.6015.10

Figure 6 - 300 (6 kg/h) & 500 PPD (10 kg/h) Meter Panel Components

100.6015.10 - 12 -

4 SERVICE

Preventative maintenance kits for each of the assemblies are available from the factory. Each kit contains all

the parts and detailed instructions that are required for complete maintenance. All o-rings and gaskets that

have been disturbed during the disassembly must be replaced during reassembly in order to insure safe,

trouble free operation. Failure to replace these parts could result in a shortened operation period and bodily

injury.

Refer to Figures 4, 5, and 6

4.1 Cleaning the Flowmeter Assembly

4.1.1 Use a coin or washer as a screwdriver and loosen the bottom meter inlet plug while holding the

flowmeter assembly to make sure it does not drop out. It may be necessary to use pliers if the plug

has not been removed for some time.

4.1.2 Loosen the plug about three (3) turns and remove the meter assembly. (Push up and out on the

flowmeter to remove).

4.1.3 Bend a paper clip or wire and pull out the ball stops on each end of the glass tube. DO NOT LOSE

THE METERING BALL.

4.1.4 Clean the inside of the glass tube with a pipe cleaner or bottle brush using wood alcohol, and rinse

thoroughly with warm water.

4.1.5 Clean the metering ball using wood alcohol, and rinse thoroughly with warm water.

4.1.6 Thoroughly dry the glass metering tube. Reassemble the metering stops and ball.

4.1.7 Reinstall the meter assembly by tightening the meter inlet plug making sure that it is on center with

the top and bottom gasket.

NOTE: The meter gaskets can usually be reused. Turn the gaskets over for best results.

4.2 Rate Valve Cleaning

4.2.1 Unscrew the rate valve plug from the valve bonnet.

4.2.2 Remove the valve bonnet from the top of the front body.

4.2.3 Clean the parts by immersing in alcohol or soapy water, rinse, and dry thoroughly with a clean cloth.

4.2.4 The o-rings on the valve bonnet may need replacing if scratched or bruised.

4.2.5 Examine the valve sleeve for nicks or any marks. The sleeve may be removed for this purpose. Use

caution to avoid marking the surfaces.

4.2.6 The o-ring on the outside of the valve sleeve usually may not require replacing.

4.2.7 Inspect the rate valve hole in the meter housing and clean with a damp cloth if necessary. DO NOT

use any sharp tools that may scratch the internal surface. Never use any solvent for cleaning the

plastic, as it will deteriorate rapidly. Wood alcohol can, however, be used successfully.

4.2.8 Apply a thin film of fluorolube grease to o-rings and slide the valve sleeve into the top body.

4.2.9 Replace rate valve.

- 13 - 100.6015.10

5 TROUBLESHOOTING CHART

Since the operating performance of the remote meter panel can be effected by the vacuum regulator and

ejector, also refer to the Troubleshooting Chart in bulletin 100.6005, 122.6006, 122.6010, or 122.6015.

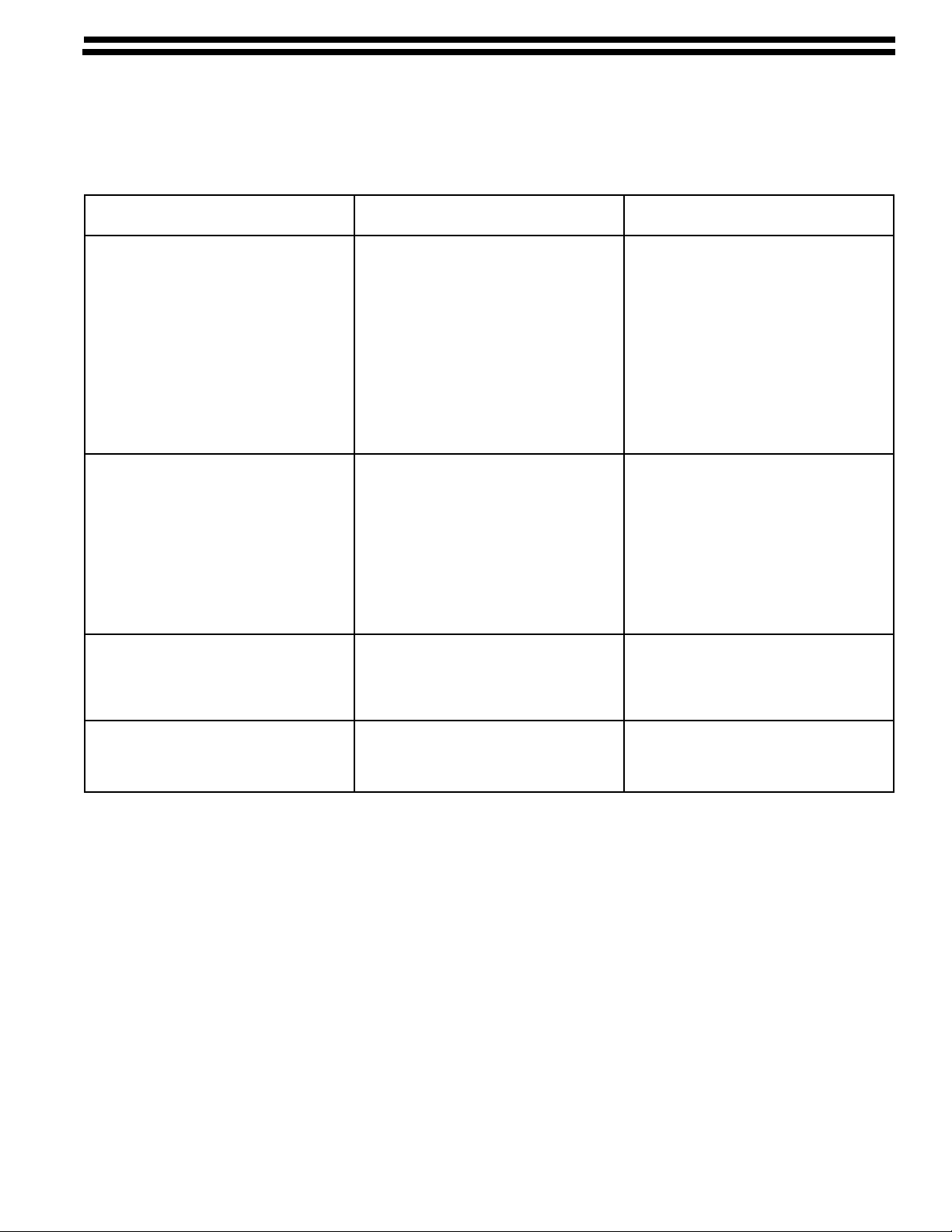

TROUBLE PROBABLE CAUSE CORRECTIVE ACTION

1. The required gas feed rate is

not achieved at start-up.

a. Insufficient ejector vacuum due

to insufficient water supply pres

sure for existing back pressure

conditions.

b. Leakage at vacuum line

connections, vacuum regulator

and/or inlet to ejector.

c. Vacuum line(s) crimped.

d. Length of vacuum line(s)

exceeds maximum allowable

transport distance.

a. Refer to Trouble 2.

b. Inspect each connection and

remake as necessary.

c. Replace vacuum tubing and

arrange line(s) to eliminate

2. Flowmeter ball bounces and/or

maximum gas feed rate cannot

be achieved during normal

operation.

a. Vacuum regulator inlet filter

screen dirty.

b. Rate valve dirty.

c. Flowmeter dirty.

d. Ejector water supply pressure

fluctuating causing insufficient

ejector vacuum. (Ball bouncing

only)

a. Replace gas inlet filter.

b. Clean the rate valve. See

Service section.

c. Clean the flowmeter. See

Service section.

d. Check water supply pressure.

Correct as necessary

3. Flooded metering tube. a. Dirt on the ejector check valve

seat, or worn seat

a. Clean or replace ejector check

valve seat. Refer to Ejector

instruction manual 122.6006,

122.6010, or 122.6015.

4. Vacuum leaks a. Rate valve o-rings worn.

b. Tubing connector loose.

c. Cracks in tubing

a. Replace o-ring.

b. Tighten tubing connector.

c. Replace tubing.

100.6015.10 - 14 -

Represented by:

Design improvements may be made without notice.

SEP 2015

De Nora Water Technologies

3000 Advance Lane Colmar, PA 18915

ph +1 215 997 4000 • fax +1 215 997 4062

web: www.denora.com

mail: [email protected]

®Registered Trademark. © 2015. All Rights Reserved.

Table of contents

Other De Nora Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Endress+Hauser

Endress+Hauser Proline Promag 55 operating manual

Emerson

Emerson Rosemount 585 Annubar Quick installation guide

TESTO

TESTO 230 instruction manual

Spectroline

Spectroline AccuPRO XP-2000 quick guide

Extech Instruments

Extech Instruments EN150 user manual

Seikom Electronic

Seikom Electronic RLSW 7 user manual