Aeroqual AQM 65 User manual

Aeroqual AQM60 User Guide

WWW.TEESING.COM | +31 70 413 07 50

Page | 2

Contents

User Guide Revision History ...................................................................................................................5

1. Description.......................................................................................................................................6

1.1. External Connections................................................................................................................. 7

1.2. Gas Modules.............................................................................................................................. 7

1.2.1. Gas Sensor Specifications.................................................................................................. 8

1.3. Thermal Management System .................................................................................................. 8

1.4. Sensirion SHT75 Temperature and Humidity Sensor ............................................................... 9

1.5. Auxiliary Module (Optional) ....................................................................................................... 9

1.6. Particle Monitor........................................................................................................................ 11

1.6.1. Nephelometer.................................................................................................................... 11

1.6.2. Inlet heater ........................................................................................................................ 11

1.6.3. Inbuilt filters....................................................................................................................... 11

1.7. Profiler ..................................................................................................................................... 12

1.7.1. Optical Particle Counter .................................................................................................... 12

1.7.2. Connections ...................................................................................................................... 12

1.7.3. Data Outputs..................................................................................................................... 12

1.8. Particle Mass Pump Modules.................................................................................................. 13

1.8.1. Profiler Pump Module........................................................................................................ 13

1.8.2. Nephelometer Pump Module ............................................................................................ 13

1.9. Electrical Connections............................................................................................................. 14

1.10. Pneumatic Connections........................................................................................................... 15

2. Set Up.............................................................................................................................................16

2.1. Unpacking................................................................................................................................ 16

2.2. Assembly................................................................................................................................. 16

2.2.1. Connect Mains Power....................................................................................................... 16

2.2.2. Connect Inlet System........................................................................................................ 18

2.2.3. Assembly of heated inlet for PM/Profiler (Optional).......................................................... 18

2.2.4. Connect third party sensors (Optional) ............................................................................. 19

2.3. Connect to the AQM 65........................................................................................................... 19

2.3.1. Initial Connection via Access Point Mode......................................................................... 20

2.4. Initial Commissioning............................................................................................................... 21

2.4.1. System Checks ................................................................................................................. 21

2.4.2. System Values .................................................................................................................. 22

2.4.3. Zero and Span Checks for Gas Modules.......................................................................... 22

3. Connecting to Aeroqual Connect and Cloud .............................................................................22

3.1. Connection Options................................................................................................................. 22

3.1.1. Client Mode....................................................................................................................... 22

3.1.2. Cellular Network Connection............................................................................................. 23

3.2. Aeroqual Cloud........................................................................................................................ 25

3.2.1. Manual Sync ..................................................................................................................... 26

3.3. Connection Scenarios.............................................................................................................. 26

4. Using Aeroqual Connect and Cloud ...........................................................................................27

4.1. Journal..................................................................................................................................... 27

4.2. Manage Data........................................................................................................................... 28

4.2.1. Charts................................................................................................................................ 28

4.2.2. Table ................................................................................................................................. 29

4.2.3. Download Data.................................................................................................................. 29

4.2.4. Auto Export (Only Available in Aeroqual Cloud)............................................................... 29

4.3. Calibration and Service ........................................................................................................... 30

4.3.1. Gain and Offset................................................................................................................. 30

4.3.2. AirCal 8000........................................................................................................................... 30

4.4. Diagnostics and Advanced...................................................................................................... 31

4.4.1. Diagnostics........................................................................................................................ 32

4.4.2. Module Settings ................................................................................................................ 32

4.5. Configure Instrument............................................................................................................... 32

WWW.TEESING.COM | +31 70 413 07 50

Page | 3

4.5.1. Settings ............................................................................................................................. 32

4.5.2. Configuring the System..................................................................................................... 33

4.5.3. Configuring the Sensors.................................................................................................... 33

4.5.4. Alerts (Only Available in Aeroqual Cloud)......................................................................... 34

4.5.5. Sensor List ........................................................................................................................ 34

4.5.6. Data filters......................................................................................................................... 34

5. Gas Module Calibration................................................................................................................35

5.1. Introduction.............................................................................................................................. 35

5.2. Calibration Gas Humidity......................................................................................................... 35

6. Calibration setup...........................................................................................................................36

6.1. Zero Calibration Procedure ..................................................................................................... 37

6.2. Span Calibration Procedure .................................................................................................... 38

6.2.1. Recommended Span Points and Acceptance limits......................................................... 39

6.2.2. Gas Phase Titrations......................................................................................................... 39

6.3. AirCal 8000 (Optional)............................................................................................................. 39

6.3.1. Overview ........................................................................................................................... 39

6.3.1. Gas Cylinder Housing ....................................................................................................... 41

6.3.2. Configuring the AirCal 8000 Scheduler............................................................................. 41

6.4. Calibration Standards and Equipment..................................................................................... 42

6.4.1. Calibration Gas ................................................................................................................. 42

6.4.2. Recommended Span Points and Cylinder Concentrations............................................... 42

6.4.3. Gas cylinders .................................................................................................................... 42

6.4.4. Gas regulators................................................................................................................... 43

6.4.5. Recommended fittings and Tubing for Aircal 1000........................................................... 44

6.5. Calibration Frequency.............................................................................................................. 45

7. Third Party Sensors......................................................................................................................46

7.1. Met One MSO.......................................................................................................................... 46

7.2. Vaisala Weather Transmitter WXT520.................................................................................... 46

7.3. Gill WindSonic ......................................................................................................................... 47

7.4. Cirrus MK427 Noise Sensor.................................................................................................... 47

7.5. Novalynx 240-200SZ Silicon Pyranometer.............................................................................. 48

8. Field Installation............................................................................................................................48

8.1. Site Selection........................................................................................................................... 48

8.2. Dimensions.............................................................................................................................. 49

8.3. Mounting.................................................................................................................................. 50

9. Maintenance...................................................................................................................................50

9.1. Safety Requirements............................................................................................................... 50

9.2. Maintenance Schedule............................................................................................................ 50

9.2.1. Standard AQM .................................................................................................................. 50

9.2.2. Particle Monitor ................................................................................................................. 51

9.2.3. Profiler............................................................................................................................... 51

9.3. AQM Maintenance Procedures ............................................................................................... 51

9.3.1. Replacing the Inlet Filter ................................................................................................... 51

9.3.2. Measuring Sample Inlet Flow Rate................................................................................... 52

9.3.3. Gas Sensor Module Flow Rate......................................................................................... 52

9.3.4. Leak Check Gas Sensor Plumbing................................................................................... 53

9.3.5. Removing and Replacing AQM Modules.......................................................................... 54

9.4. Particle Monitor........................................................................................................................ 54

9.4.1. Sample Flow Check .......................................................................................................... 54

9.4.2. Purge Flow Check............................................................................................................. 55

9.4.3. Sheath Flow Check........................................................................................................... 56

9.4.4. Leak Check ....................................................................................................................... 56

9.4.5. Manual Zero Air Check ..................................................................................................... 57

9.4.6. Fibre Span Check ............................................................................................................. 57

9.4.7. Laser Current Check......................................................................................................... 57

WWW.TEESING.COM | +31 70 413 07 50

Page | 4

9.4.8. Filter Changes................................................................................................................... 57

9.4.9. Cyclone and Inlet Cleaning............................................................................................... 58

9.4.10. Changing the Size Fraction Measured.............................................................................. 59

9.5. Profiler ..................................................................................................................................... 59

9.5.1. Sample Flow Check and Adjustment ................................................................................... 59

9.5.2. Sheath Flow Check........................................................................................................... 60

9.5.3. Leak Check ....................................................................................................................... 60

9.5.4. Filter Changes................................................................................................................... 61

9.5.5. Inlet Cleaning .................................................................................................................... 62

10. Troubleshooting............................................................................................................................62

10.1. AQM 65 Basics........................................................................................................................ 62

10.2. Particle Monitor/Profiler ........................................................................................................... 63

10.3. Diagnostics .............................................................................................................................. 64

11. Appendix........................................................................................................................................65

11.1. Guidelines................................................................................................................................ 65

11.2. Technical support .................................................................................................................... 65

11.3. Copyright ................................................................................................................................. 65

11.4. Compliance.............................................................................................................................. 66

WWW.TEESING.COM | +31 70 413 07 50

Page | 5

User Guide Revision History

Current version: 1.0

Description: User guide for AQM 65

This user guide is a newly created document for the use of the AQM 65.

Date

Revision number

Description of change

Affected

Sections

March 2015

1.0

New User Guide

All

WWW.TEESING.COM | +31 70 413 07 50

Page | 6

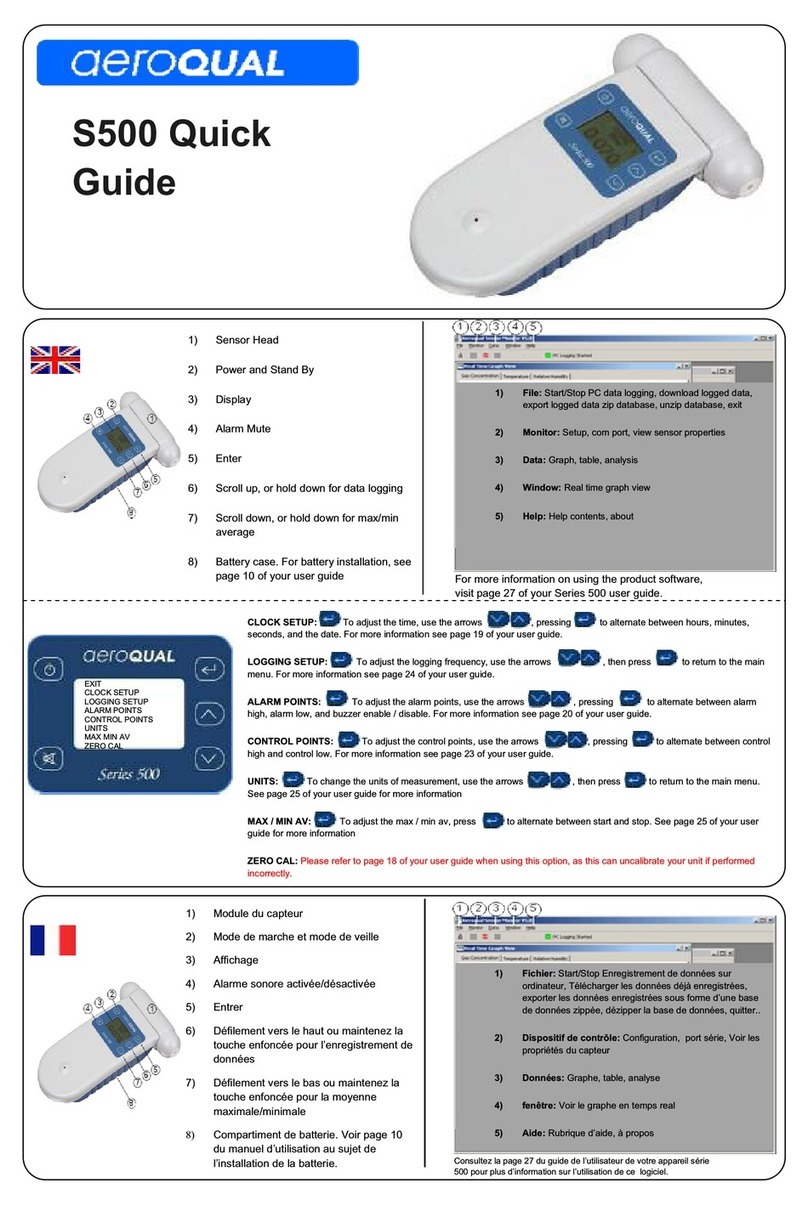

1. Description

The Aeroqual AQM 65 is a compact air quality station designed for precise measurement of ambient

pollution and environmental conditions. Its platform is configurable to measure a wide range of air

pollutants such as ozone (O3), nitrogen dioxide (NO2), carbon monoxide (CO), sulphur dioxide (SO2)

PM10, and PM2.5 as well as meteorological parameters such as temperature, humidity, wind speed and

direction.

The AQM 65 is complete air quality station consisting of a custom made IP65 rated aluminium

enclosure which houses a power module, thermal management system, embedded PC running

Aeroqual Connect software and user configured analyser modules.

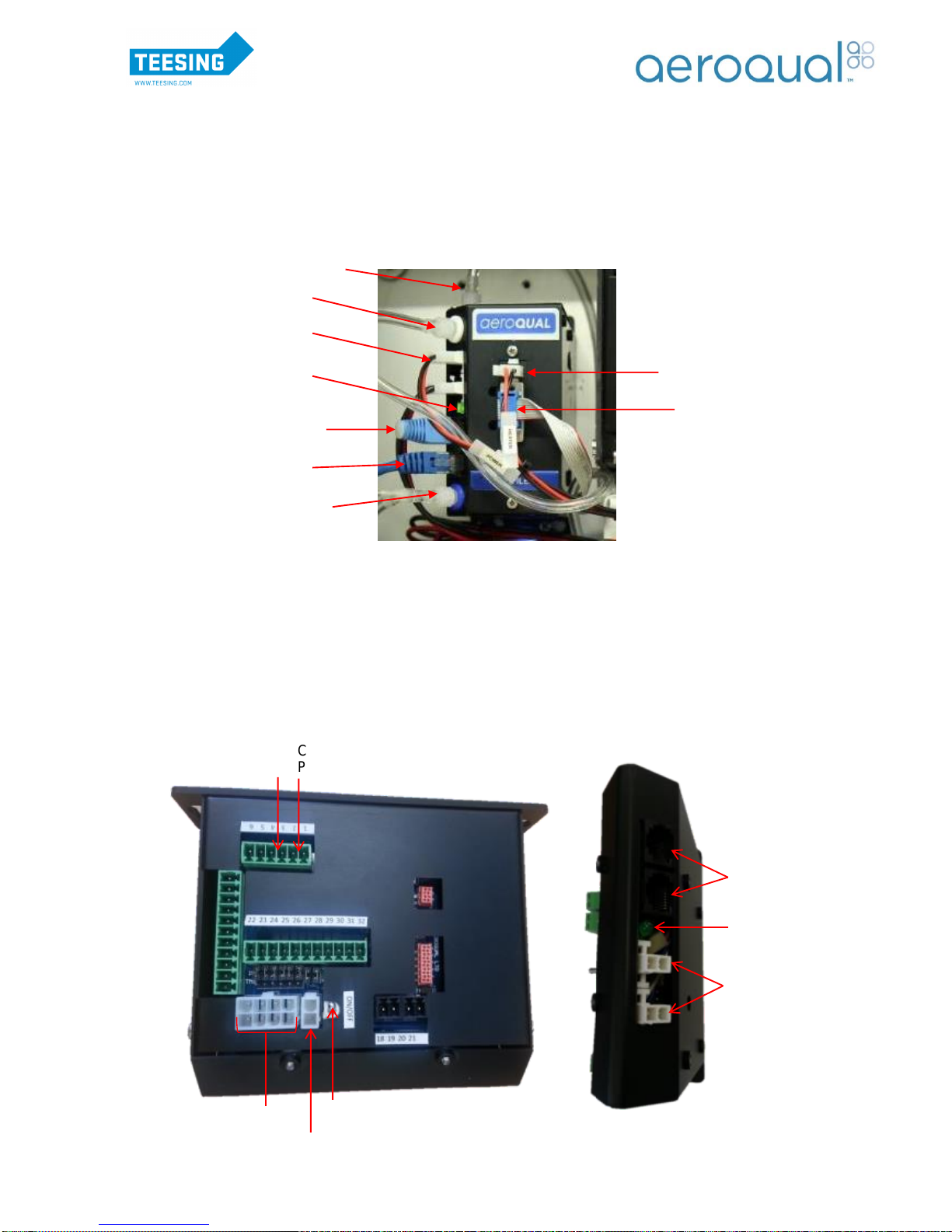

Note 1: The placement of individual modules will vary depending on the user configuration

12 and 0 VDC

Terminals

Fuse Holder

Cooling ducts

Compressor

Cassette

Thermal

Management

System Module

Sample Pump

Embedded PC

PM Pump module

Gas Cylinder

Enclosure for

AirCal 8000

AirCal 8000

module

Inlet filter on

sample line

Gas Modules

(User Configurable)

PM Engine

Sharp Cut

Cyclone

TSP Inlet

PM Inlet

Sample Inlet

WWW.TEESING.COM | +31 70 413 07 50

Page | 7

1.1. External Connections

There are 4 external water tight glands located on the right hand side of the AQM 65 enclosure. The

black gland is an Ethernet output for use when a wired connection to the instrument is required (See

Section 3.1.1. for more information). The 3 other glands are designed to allow third party sensors to be

wired into the instrument.

1.2. Gas Modules

The AQM 65 can be configured with a range of gas modules. All modules are mounted onto the base

plate using 4 or 2 screws depending on the module size. Inlet and outlet tubes are connected to the gas

distribution manifold and exhaust respectively. The inlet tubing used is PFA 3.2ID x 0.75WT and the

exhaust tubing used is Tygon R3603.2ID x 1.6WT.

Sample Exhaust

RJ45 Connectors for RS485 bus

12VDC Power

Connectors

Sample inlet

Status LED

WWW.TEESING.COM | +31 70 413 07 50

Page | 8

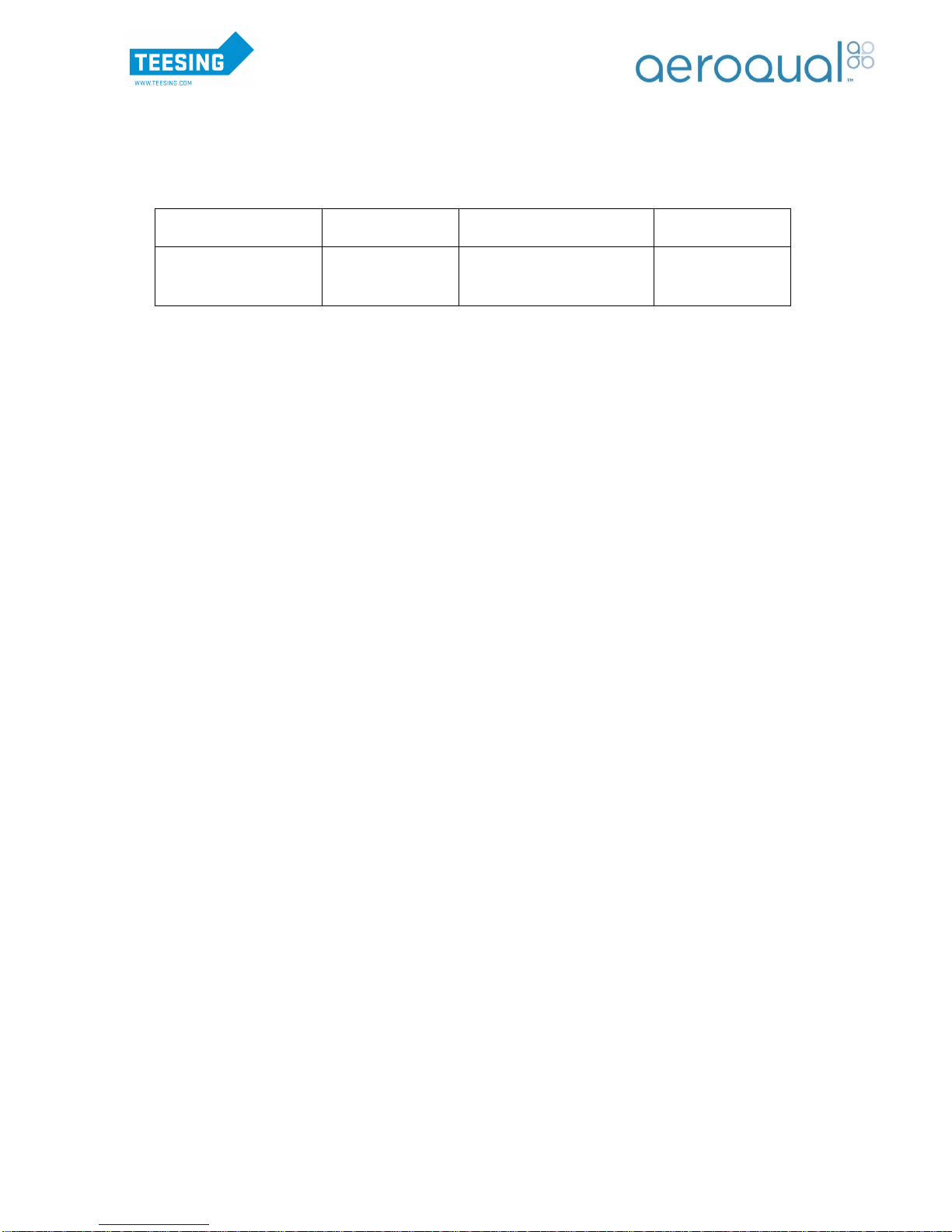

1.2.1. Gas Sensor Specifications

Note: The sensor specifications are subject to change; please contact Aeroqual for latest performance data

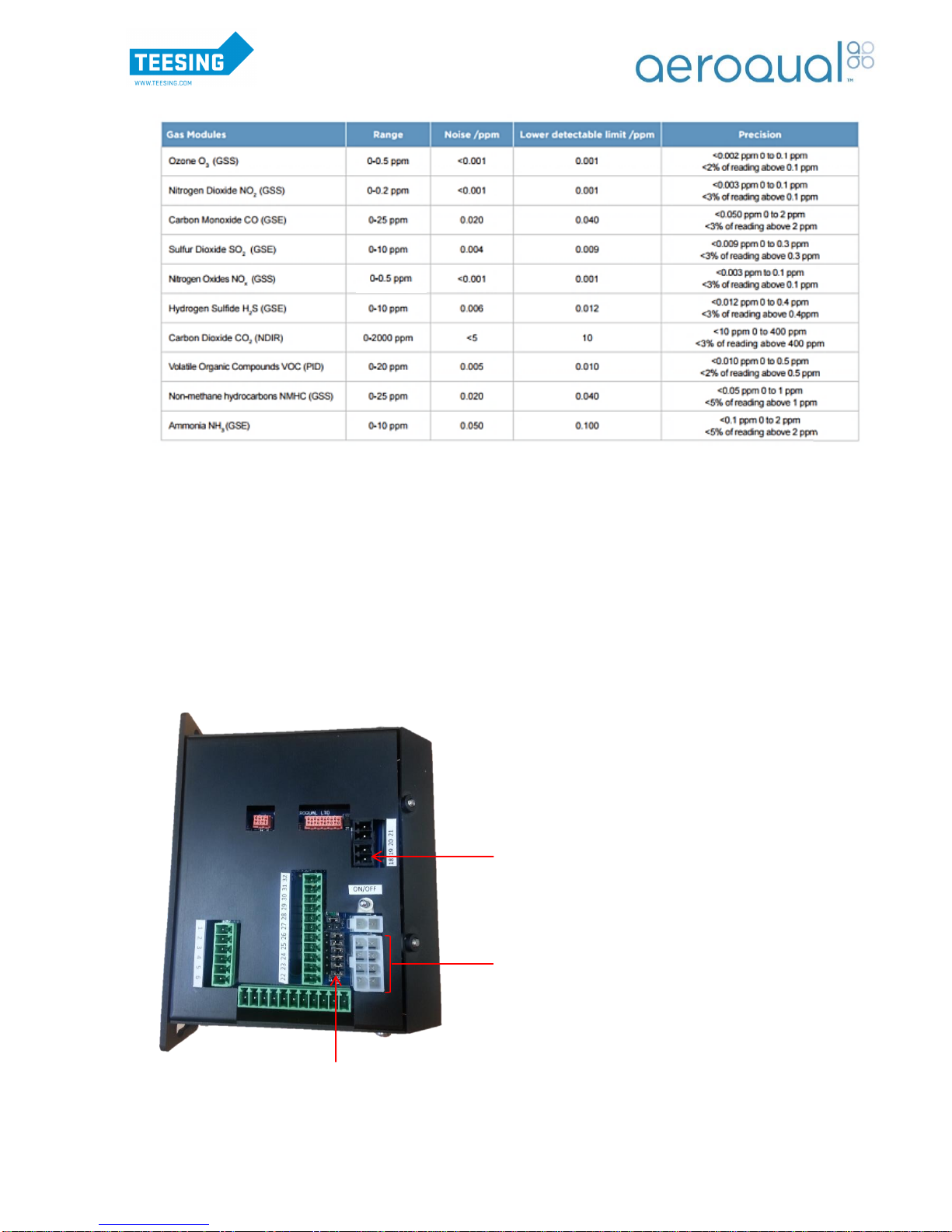

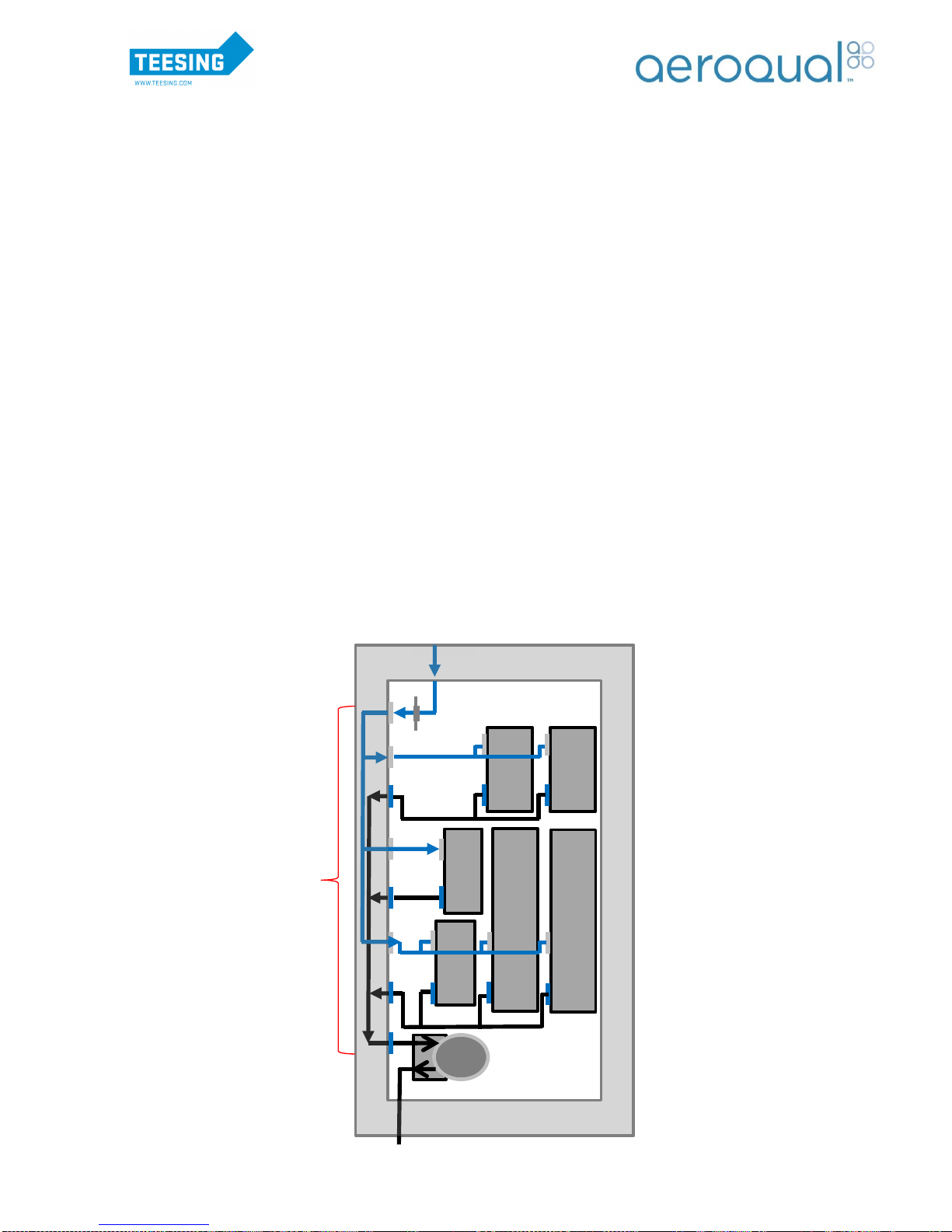

1.3. Thermal Management System

The AQM 65 has a thermal management control system to maintain a stable internal temperature

irrespective of ambient temperature changes. The TMS cassette is located at the base of the instrument

and comprises of a Danfoss compressor, IP55 cooling fan and ducting. The TMS cassette is separate

from the main enclosure and can be removed if required.

The control software is stored on the System Management module which is installed inside the main

housing. The module initiates the compressor, fans and heater when necessary to maintain the internal

temperature at a constant of within ±0.2°C.

System Management Module

Note: The jumpers in the system management module should be positioned as shown in the

image above.

TMS

Communication

Connector

ITemp Sensor

Connection

Jumpers

WWW.TEESING.COM | +31 70 413 07 50

Page | 9

1.4. Sensirion SHT75 Temperature and Humidity Sensor

The Humidity and Temperature Sensor is a Sensirion single chip device which contains a capacitive

polymer sensing element for relative humidity and a band-gap temperature sensor. More detailed

specifications are in the table below. The temperature and humidity sensor is housed in a connector

located on the bottom of the enclosure. It is connected directly to the system manager module. For full

details visit the company website www.sensirion.com.

1.5. Auxiliary Module (Optional)

The auxiliary module acts as an interface between third party sensors and the AQM 65 communication

bus. It is configured with different operating modes which can be user selected by adjusting the

dipswitches located on the side of the module. Aeroqual has integrated a number of third party sensors

and is able to supply the auxiliary module preconfigured for your sensor.

The tables below list the various functions:

Firmware: AUX_MODULE_01.

Use for: Analogue inputs, Vaisala WXT520 weather, Gill Windsonic wind, Cirrus MK: 427 noise

1

2

3

4

Function

OFF

OFF

OFF

OFF

Default - standard Auxiliary module with AN1, AN2, Freq

ON

OFF

OFF

OFF

Vaisala WXT520 with RS232 communication + AN1, AN2, Freq

OFF

ON

OFF

OFF

Vaisala WXT520 with RS232 communication + Cirrus MK427 Noise

ON

ON

OFF

OFF

Wind Sonic with RS232 communication + AN1, AN2, Freq

OFF

OFF

ON

OFF

Wind Sonic with RS232 communication + Cirrus MK427 Noise

ON

OFF

ON

OFF

Cirrus MK427 Noise module only

Air Temperature

Range

Accuracy

Resolution

-40°C to + 124°C

±0.3°C

0.01°C

Relative Humidity

Range

Accuracy

Resolution

0-100 %RH

±2 %RH

0.1 %RH

Programming Dip

Switch

Programming Port

WWW.TEESING.COM | +31 70 413 07 50

Page | 10

Firmware: AUX_MODULE_02.

Use for: Analogue inputs, Met One MSO weather, Met One 034b wind, Cirrus MK:427 noise.

1

2

3

4

Function

OFF

OFF

OFF

OFF

Default - standard Auxiliary module with AN1, AN2, Freq

ON

OFF

ON

OFF

Cirrus MK427 Noise module only

OFF

ON

ON

OFF

Met One MSO with RS232 communication + Cirrus MK427 Noise

ON

ON

ON

OFF

Met One MSO with RS232 communication + AN1, AN2, Freq

OFF

OFF

OFF

ON

Met One 034B analogue module + Cirrus MK427 Noise

The third party sensor needs to be correctly wired into the auxiliary module for it to function correctly.

The image and table below provide further information on wiring the auxiliary module.

Example of wiring:

Wind Sonic

(Pin 1) GND,

SIGNAL GND

(Pin 2) 12V

(Pin 5) RX

(Pin 6) TX

Vaisala

(Pin 1) GND for

operating, data &

heating

(Pin 2) 12V for

operating & heating

(Pin 5) RX

(Pin 6) TX

Met One MSO

(Pin 1) GND,

SIGNAL,

COMMON, SHIELD

(Pin 2) 12V

(Pin 5) RX

(Pin 6) TX

Met One 034B

(Pin 1) GND

(Pin 11) METONE

034B PWR

(Pin7) WD

(Pin 9) WS

Cirrus MK:427

(Pin 1) GND,

ACTUATOR GND

(Pin 2) 12V, LOOP

IN

(Pin 8) LOOP OUT

(Pin 12)

ACTUATOR IN

A programming port is also exposed through the side of the module to allow custom programs to be

loaded into the module.

Note 1: Aeroqual can supply a standard programming tool for distributors to reprogram the

auxiliary module to the specified requirements.

Pin 12

Pin 1

Status LED

12VDC Power

Connectors

RJ45 Connectors

for RS485 bus

Wiring of Aux Module:

PIN 1: GND

PIN 2: 12V FUSED

PIN 3: RESERVED

PIN 4: RESERVED

PIN 5: RX

PIN 6: TX

PIN 7: 0-5V IN

PIN 8: 4-20mA IN

PIN 9: FREQ IN

PIN 10: AGND

PIN 11: METONE 034B PWR

PIN 12: CIRRUS ACTUATOR

WWW.TEESING.COM | +31 70 413 07 50

Page | 11

Note 2: The above wiring connections are subject to change, please refer to the third party

sensor manuals for the latest wiring instructions.

Note 3: The Wind Sonic comes with an Aeroqual supplied cable and therefore the latest wire

outputs will be sent with the cable.

1.6. Particle Monitor

The particle monitor is an optional device that can be installed in the AQM 65 to provide reliable real

time indicative particulate measurement of TSP, PM10, PM2.5 or PM1 using a well proven near forward

light scattering nephelometer and high precision sharp cut cyclone.

1.6.1. Nephelometer

Aeroqual uses a customised nephelometer optical sensor from Met One Instruments. The optical sensor

uses light scattering from particulate matter to provide a continuous real-time measurement of airborne

particle mass. The light source is a visible laser diode and scattered light is measured in the near

forward angle using a focusing optics and a photo diode.

The sensor has an on-board temperature sensor which is corrected for thermal drift, sheath air filter to

keep the optics clean, automatic baseline drift correction and a fibre optic span system to provide a

check of the optical components.

The electrical connections to the nephelometer are summarised below:

Wire colour

Function

Orange (x2)

Fibre optic solenoid

Red

5V (power in)

Black

Ground

White

Signal out (0-5 V)

Black/white

Signal Ground

Yellow

Laser current monitor ( 10mV = 1 mA laser current)

Grey

Temperature output

1.6.2. Inlet heater

The nephelometer uses a 12 V heater on the sample inlet tube to reduce the humidity of sampled air to

prevent particle growth and fogging of the nephelometer optics in high RH conditions.

1.6.3. Inbuilt filters

The nephelometer contains two filters which should be replaced at specified intervals. The “Sample”

filter is a coarse filter designed to protect the sample pump from excessive particle build-up. The

“Purge” filter is a fine filter which filters the sheath air flow and also produces particle-free air during the

auto-zero cycle. See Section 8.4.8 for information on changing the filters.

Safety: This sensor is considered a Class I laser product. Class I laser products are not

considered to be hazardous. There are no user serviceable parts inside the cover of the

sensor. The device contains a laser operating at 670 nm which is visible to the eye and can

cause damage to the eye if directly exposed. Only trained service personnel should

attempt servicing or repair of the sensor.

WWW.TEESING.COM | +31 70 413 07 50

Page | 12

1.7. Profiler

1.7.1. Optical Particle Counter

Aeroqual uses a customised optical particle counter from Met One Instruments. The particle counter

uses scattered light to measure and count particles. Light from a laser diode is collimated to illuminate

the aerosol sample flow. When a particle is present it scatters the incident laser light which is detected

using a 60osolid angle elliptical mirror at right angles to the laser beam. The amount of scattered light is

converted to a voltage pulse and the amplitude of the pulse is calibrated to a particle diameter. The

particles are thus assigned on the basis of size to one of eight channels.

1.7.2. Connections

The connections to the optical particle counter are at the bottom of the unit. There is also a LED which

turns red if there is a fault condition. The optical unit requires an earth wire to be connected between the

housing and the 0VDC line on the power bus. Please check that this is fitted if the unit has been

replaced.

1.7.3. Data Outputs

The Profiler can be configured to display and log the measurements detailed in the table below. The

sensor name is that used in the active sensors list and module settings.

Sensor

Name

Definition

Range

Units

8PC0.3

number of particles with diameter larger than 0.3 µm

0-100000

particles/L

8PC0.5

number of particles with diameter larger than 0.5 µm

0-100000

particles/L

8PC0.7

number of particles with diameter larger than 0.7 µm

0-100000

particles/L

8PC1.0

number of particles with diameter larger than 1.0 µm

0-100000

particles/L

8PC2.0

number of particles with diameter larger than 2.0 µm

0-100000

particles/L

8PC2.5

number of particles with diameter larger than 2.5 µm

0-100000

particles/L

8PC5.0

number of particles with diameter larger than 5.0 µm

0-100000

particles/L

8PC10

number of particles with diameter larger than 10 µm

0-100000

particles/L

PM1

Particle mass below 1 µm

200

ug/m3

PM2.5

Particle mass below 2.5 µm

2000

ug/m3

PM10

Particle mass below 10 µm

5000

ug/m3

TSP

Total suspended particle mass

5000

ug/m3

RS232 serial

LED

Green = normal

Red = fault

Air out

Not used

12 VDC in

Not used

WWW.TEESING.COM | +31 70 413 07 50

Page | 13

1.8. Particle Mass Pump Modules

The pump modules for the Nephelometer and Profiler contain a microprocessor for mass calculation

and a pump for sampling. The pump module varies depending on whether a Nephelometer or Profiler

has been installed in the AQM 65.

1.8.1. Profiler Pump Module

1.8.2. Nephelometer Pump Module

The Pump Module is split into two sections:

1. The electronics

2. The pump and pneumatics

The functionality of the electronics module can be seen below:

Status LED

12VDC Power

Connectors

RJ45 Connectors for

RS485 bus

Connection

80180 engine

PM Fibre Span Switch

Inlet Heater

Connection to

Purge Pump

Connection to

Sample Pump

Termination Dongle

Purge line

Exhaust line with

flow adjuster

Inlet heater connector

RS232 connector from

optical engine.

12VDC power

connection

RS485 bus cable

Sample line

Power on LED

WWW.TEESING.COM | +31 70 413 07 50

Page | 14

Note: The jumpers in the current module should be positioned as shown in the previous image.

The pump and pneumatics are easy to access for servicing and replacement:

1.9. Electrical Connections

Pin 1 = 12V (blue)

Pin 2 = GND (white)

Purge Pump

Pin 3 = 12V (red)

Pin 4 = GND (black)

Sample Pump

Purge

Pump

Sample Pump

Exhaust Line

Sheath Air Out

Sample In

Connection to

electronics module

(Pin 1 to 4)

Embedded PC

Compressor

SM

Module

Gas

Module 1

TMS

Heater

Power supply 1

12V DC

Mains Power in (Section 2.2.1)

12V DC

Power

Signal

Mains

Power

TMS = Thermal Management

System

Power supply 2

12V DC

AC

SWITCH

BOX

BOX

DC

SWITCH

BOX

Cabinet

Air in

Blower

TMS

fan

T/RH

Sensor

Gas

Module 2

WWW.TEESING.COM | +31 70 413 07 50

Page | 15

RS485 Bus

The two wire RS485 bus connections are made using 20 cm CAT5 cables between the sensor modules

12 VDC Power Bus

All modules inside the AQM 65 operate from the 12VDC power. The power is supplied by a daisy chain

of black and red cables. To turn off the 12VDC power to the upper cabinet release the fuse holder.

Status LED

Each module includes a status LED which indicates that the electrical status of the module is

functioning correctly. It does not indicate the calibration status of the module.

a) Continuous on indicates correct electrical functionality

b) Slow flash (1 second) indicates warm up period

c) Fast flash (0.2 seconds) sensor failure

d) LED not on indicates no power to module.

e) The System Manager LED is a special case. This flashes to indicate RS485 bus traffic.

1.10. Pneumatic Connections

The sample gas passes into a PFA manifold behind the left hand side wall and is distributed to the

sensors. The gas modules sample via a single pump located in the bottom left of the enclosure. The

pump is easily accessible for maintenance. The sample inlet tubing is PFA tubing which is inert and

smooth walled. The module exhaust tubing is Tygon 3603 PVC tubing.

Note: The ports on the manifold which are not used must be capped off to prevent leaks.

Note 2: The blue lines represent the sample flow and the black lines represent the exhaust flow.

Exhaust

Inlet

PFA manifold

Pump

Module

Module

Module

Module

Module

Module

WWW.TEESING.COM | +31 70 413 07 50

Page | 16

An adjustable bypass valve is included between the vacuum and pressure side of the pump. This is to

allow an adjustment to be made to the module flow rates and to relieve the excess pressure placed on

the pump when only one or two modules are installed.

The total sample flow rate will be dependent on the number of gas sensor modules in the AQM. All

module flows are controlled by critical orifices located within the sensor modules. See Section 8.3.3.for

expected flow rates.

2. Set Up

The purpose of this section is to enable the user to correctly assemble, configure and commission their

AQM 65 prior to field installation.

2.1. Unpacking

a) Examine the Shockwatch label on the side of the shipping box. If the indicator is red do not

refuse shipment. Make a notification on delivery receipt and inspect for damage. If damage is

discovered, leave item in original packaging and request immediate inspection from carrier

within 15 days of delivery date (3 days international).

b) Verify the serial number label on the documentation matches the serial label on the AQM

(located on inside of enclosure).

c) Verify that all components have been shipped as per the packing slip. Contact your Distributor

or Aeroqual if you suspect any parts are missing.

d) Unpack the AQM.

e) Remove all internal shipping/packaging material from the AQM enclosure.

f) Retain the packaging.

Note: Always transport the AQM in the three piece aluminum skins with foam packing provided

to avoid breakages. Wrap all peripheral assemblies in their original packaging also. The AQM is

a sensitive instrument and should be transported with care.

2.2. Assembly

2.2.1. Connect Mains Power

Caution: The high voltage mains supply must be wired by a certified electrician in

compliance with local electrical regulations.

To connect the mains power follow the steps below:

1. Unscrew the front panel of the AQM 65 TMS cassette. There are 4 screws at each corner that

need to be removed to allow the front panel to slide off. The door must be open to access these

screws.

2. Unscrew the lid of the terminal box to access the wiring.

WWW.TEESING.COM | +31 70 413 07 50

Page | 17

AC Switch Box

3. The mains electrical cable needs to be fed through the gland at the base of the instrument into

the terminal box.

Note 1: The AQM65 can be placed flat on its back to access the gland

Note 2: Ensure the nut gland and rubber plug have been fed through the electrical cable before

feeding the cable through the gland at the base of the instrument

4. Wire the cable to the terminal block

5. Tightly screw the gland at the base of the instrument to secure the cable in place and create a

waterproof seal.

6. Replace the lid of the terminal box and the front panel of the TMS cassette.

Connected by local

electrician:

Brown = Live

Blue = Neutral

Yellow/Green = Ground

Connected by Aeroqual (Do

not remove)

Mains electrical cable from

base of instrument

WWW.TEESING.COM | +31 70 413 07 50

Page | 18

2.2.2. Connect Inlet System

Once the AQM 65 has been wired the inlet

system needs to be connected before the

instrument is turned on. The inlet system consists

of an inert fluoropolymer and glass inlet with

mesh fitting which is designed to prevent

unwanted materials, such as water and dust,

being drawn into the instrument. The inlet pipe is

connected to the top of the AQM 65.

A 5/8 spanner is required to securely tighten the

¼” stainless steel compression fitting.

If an external filter holder has been purchased with the AQM 65, remove the mesh fitting from the inlet

pipe and screw the filter holder into place. The arrow on the filter holder should be pointing upwards.

2.2.3. Assembly of heated inlet for PM/Profiler (Optional)

If the AQM 65 is configured with a Nephelometer or Profiler the heated inlet needs to be connected prior

to the instrument being turned on.

Parts List:

A. Inlet Tube/Heater including power cable

B. Sharp Cut Cyclone (if fitted)

C. TSP Inlet

i. Connect parts A, B and C

ii. Open door of enclosure and remove protective cap from the optical engine

A

B

C

Protective

Cap

Mesh

fitting

External

filter holder

WWW.TEESING.COM | +31 70 413 07 50

Page | 19

iii. Insert Inlet Tube Assembly through base mount and fix the three mounting screws

Note 1: Ensure the power cable is fed through the inlet hole when connecting the inlet

iv. Connect power to Inlet Tube/Heater inside the enclosure

2.2.4. Connect third party sensors (Optional)

Third party sensors such as the Vaisala Weather Transmitter WXT520 or Met One MSO are connected

to the unit via the external glands located on the right hand side of the enclosure. Feed the cable

through the glands and connect to the auxiliary module using the instructions in Section 1.5.

Note: Turn off the AQM 65 before plugging in any external third part sensor.

2.3. Connect to the AQM 65

Aeroqual Connect is the standard user interface which comes with the AQM instrument and allows the

user to be connected directly to the AQM instrument. It can be accessed via WiFi, Ethernet or a cellular

modem. The on-board computer has an Ethernet output for direct wired connection. . Alternatively,

connection can be made over WIFI by connecting to the AQM network (Access point mode), a local

network (Client mode) or via a modem.

Mounting

Screws

Power cable from

heated inlet

WWW.TEESING.COM | +31 70 413 07 50

Page | 20

2.3.1. Initial Connection via Access Point Mode

The default setting of the instrument when first purchased will be to connect to Aeroqual Connect via

access point mode. Access point mode allows connection to the AQM via the AQM network signal

which will show up on a laptop, tablet or smart phone within range. This type of connection will most

commonly be used when working on the AQM in the field. However, it will also be used to initially

connect when the instrument first arrives.

Connecting by this mode will mean the user’s device is connected via WIFI directly to the AQM. There

will be no internet connection on the user device when using this option. To connect you will need to

select the AQM WIFI network and enter the password.

Note: The default password will be “Aeroqual”.

Once a WiFi connection has been made Aeroqual Connect can be accessed via the PC browser by

entering the IP address 10.10.0.1 in the address bar. The login screen below will then be displayed.

1. An Aeroqual Connect login name and password will be provided when Aeroqual Connect is first

2. Once you have logged in the homepage will be displayed.

Note 1: Different applications will appear depending on the user accessibility configured for

your account.

Note 2: See Section 3 for more connection options

AQM Network

Signal

WWW.TEESING.COM | +31 70 413 07 50

Other manuals for AQM 65

1

Table of contents

Other Aeroqual Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Tektronix

Tektronix TTR500 series manual

Mobeye

Mobeye ThermoGuard CM2200 user manual

Silva

Silva Alba Windwatch user guide

Critical Environment Technologies

Critical Environment Technologies YES IMS Operation manual

Exotek Instruments

Exotek Instruments MC-160SA user manual

Milwaukee

Milwaukee Smart Monitoring System SMS110 user manual