Aeroquip ProCrimpT 1390 User manual

1

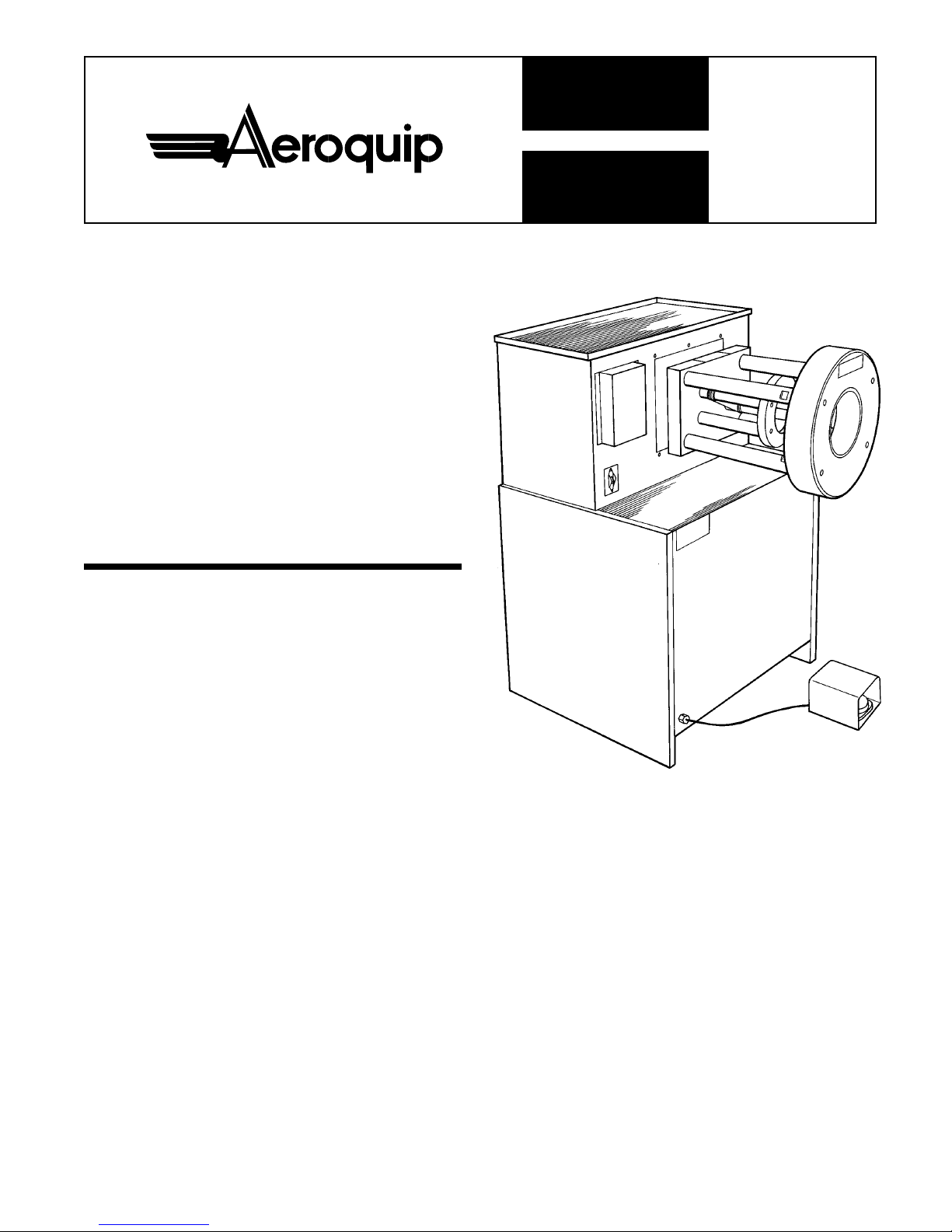

Aeroquip ProCrimp 1390 Crimp Machine

© Aeroquip Corporation 1996

Aeroquip

ProCrimpTM

1390

Crimp Machine

Operator’s

Manual

Table of Contents

Safety Instructions .................................................... 2

Specifications ............................................................ 3

Accessories............................................................... 3

Setup and Installation ............................................... 3

Operating Instructions

Loading and Unloading Die Cages ................... 4

Operating the Keypad ..................................... 4-5

Entering a Number into the Display .................. 5

Storing a Number from the Display ................... 5

Recalling a Preset into the Display ................... 5

Programmable Retract Stop ..................................... 5

Adjustable Back Stop ............................................... 5

Crimping Procedures ................................................ 6

Calibration ................................................................. 7

Maintenance

Intervals .............................................................. 8

Machine Maintenance Procedures .................... 8

Die Cage Maintenance Procedures................... 8

Troubleshooting Tips ................................................ 9

Crimp Machine Parts Breakdown ..................... 10-12

Die Cage Parts Breakdown .................................... 12

Electrical Schematics ........................................ 13-14

Hydraulic Schematic ............................................... 14

FT1390-500

www.TheCatalogRoom.com Purchase at: www.EatonProducts.com

2

Aeroquip ProCrimp 1390 Crimp Machine

© Aeroquip Corporation 1996

WARNING

Failure to follow Aeroquip process and

product instructions and limitations could

lead to premature hose assembly failures, resulting in

property damage, serious injury or death.

Aeroquip fitting tolerances are engineered to match

Aeroquip hose tolerances. The use of Aeroquip fittings

on hose supplied by other manufacturers and/or the use

of Aeroquip hose with fittings supplied by other manu-

facturers may result in the production of unreliable and

unsafe hose assemblies and is neither recommended

nor authorized by Aeroquip.

Read and understand the operator’s manual before

attempting to operate any equipment.

Aeroquip hereby disclaims any obligation or liability

(including incidental and consequential damages) arising

from breach of contract, warranty, or tort (under

negligence or strict liability theories) should Aeroquip

hose, fittings or assembly equipment be used with the

hose, fittings or assembly equipment supplied by

another manufacturer, or in the event that product

instructions for each specified hose assembly are

not followed.

Safety Instructions

1. PREVENT UNAUTHORIZED OPERATION. Do not per-

mit anyone to operate this equipment unless they have

read and thoroughly understand this manual.

2. WEAR SAFETY GLASSES.

3. AVOID PINCH POINTS. Do not rest your hand on the

crimp ring. Keep your hands clear of all moving parts.

Do not allow anyone, other than the operator, close to

the equipment while it is in operation.

4. MAINTAIN DIES WITH CARE. Dies used in the FT1390

crimp machine are hardened steel, offering the best

combination of strength and wear resistance for long

life. Hardened dies are generally brittle, and care should

be taken to avoid any sharp impact. Never strike a die

with a hardened instrument.

5. USE ONLY SPECIFIED AEROQUIP PRODUCTS. Make

hose assemblies using only Aeroquip hose and fittings

specified for this assembly equipment.

6. VERIFY CORRECT CRIMP DIAMETERS. Check and

verify correct crimp diameters of all fittings after crimp-

ing. Do not put any hose assemblies into service if the

crimp diameters do not meet Aeroquip crimp specifications.

7. Make sure all dies are completely in place and the cage

is positioned properly on the pressure plate.

8. DO NOT OVER PRESSURIZE. Do not exceed the 10,000

psi hydraulic pressure supplied to the machine. This setting

is preset at the factory and should not require adjustment.

NOTE: All components used to connect the pump and

crimp cylinder must meet the criteria set forth in Material

Handling Institute Specification #IJ100 for hydraulic jack-

ing applications.

9. DIE CHANGE. Do not insert/remove dies while the

power is on.

10. SECURE THE EQUIPMENT TO A STABLE WORK SUR-

FACE. Prior to operation, secure the crimp machine to a

stable work surface to prevent the equipment from tipping.

11. UNPLUG THE POWER SUPPLY WHEN NOT IN USE.

12. KEEP YOUR WORK AREA CLEAN. Cluttered areas and

workbenches invite accidents.

www.TheCatalogRoom.com Purchase at: www.EatonProducts.com

3

Aeroquip ProCrimp 1390 Crimp Machine

© Aeroquip Corporation 1996

Setup and Installation

1. Secure the Aeroquip ProCrimp 1390 crimp machine to

the floor using the holes provided in the corners of the

crimp machine base.

2. Remove the plug from the hydraulic reservoir vent port, and

replace it with the vent cap that is supplied with the unit.

CAUTION: Failure to do so will cause cavita-

tion and damage to the pumping mechanism.

Hand tighten the vent cap.

3 CAUTION: Provide electrical service with a

dedicated circuit (per the crimp machine elec-

trical requirements) in order to eliminate the

possibility of a low-voltage situation.

4. Never use an extension cord. Always plug the unit

directly into the power outlet.

Specifications

Electrical Requirements:

FT1390-115 ....... 110 to 120-Volt AC single phase 60 Hz

........................... circuit with a minimum of 20 amps

FT1390-23050 ... 208 to 230-Volt AC single phase 50 Hz

circuit with a minimum of 15 amps

Crimp Machine Dimensions:

Width ................. 29 inches

Depth ................. 28 inches

Height ................ 49 inches

Weight ............... 825 pounds

Production Capacity:

• All Aeroquip MatchMate Plus™braided and spiral

hose through -32 size

• Flat field crimp through -16

• Barrel field crimp through -20

• Flat single skive 1- & 2-wire braid crimp through -32

• Flat single skive 4-wire spiral crimp through -32

• Internal skive fittings

• Air conditioning hose fittings

• OTC flat crimp or OTC beer can crimp fittings

NOTE: A positive-stop backstop is required to crimp Aeroquip

2807, 2808, FC186, FC465, FC469 and FC505 hose styles.

Accessories

Crimp Die Cage Storage Cabinet

Aeroquip recommends that crimp die cages be kept free of

dust or dirt. An optional wall-mountable cabinet is offered

which has the capability to store nine crimp die cages.

Part Number ............................................................. FT1283

Die Cages

Part Number ........................................... FT1307-200-M070

........................................... FT1307-200-M090

........................................... FT1307-200-M120

........................................... FT1307-200-M150

........................................... FT1307-200-M180

........................................... FT1307-200-M210

........................................... FT1307-200-M240

........................................... FT1307-200-M280

........................................... FT1307-200-M320

........................................... FT1307-200-M370

........................................... FT1307-200-M420

........................................... FT1307-200-M465

........................................... FT1307-200-M520

........................................... FT1307-200-M550

........................................... FT1307-200-M570

........................................... FT1307-200-M630

........................................... FT1307-200-M690

Additional die cages are required for internal skive and spe-

cial application hoses.

.

www.TheCatalogRoom.com Purchase at: www.EatonProducts.com

4

Aeroquip ProCrimp 1390 Crimp Machine

© Aeroquip Corporation 1996

Operating Instructions

Loading and Unloading Die Cages

To load the die cage, press and hold the RETRACT switch

until the crimp cylinder reaches the “full retract” position

and stops. The die cage may be inserted or removed in this

position. (See Figure 1.) NOTE: To minimize cycle time

during normal operation, the Aeroquip ProCrimp 1390 crimp

machine can be programmed to stop retracting before it

has fully retracted. This reduces the crimping cycle time.

The die cage may not be able to be removed. Pressing and

holding RETRACT will always bring the cylinder to the full

retract position. See instructions on Page 5.

CAUTION: Figure 2 shows a die cage that is

installed improperly. When inserted properly, the

cage is flush against the pressure plate. If the

die cage is at an angle to the pressure plate,

lift it up and realign properly.

Operating the Keypad (Figure 3)

1. The DISPLAY shows the three-digit setting that will

determine the crimp diameter. The DISPLAY number

itself is a relative number, not a crimp diameter. The

ratio of crimp diameter change to the DISPLAY change

is 1 to 1. For example, if you crimp a fitting at a setting

of 250, and the crimp diameter is .014 inch too large,

you will need to decrease the DISPLAY by 014 to

(250-014) = 236. A display of 236 should produce the

correct crimp diameter.

2. The STORE button is used to store the DISPLAY read-

ing in any of the 10 numbered keys. The green light

next to the STORE button will illuminate when you are

working in the STORE mode.

3. The ENTER button is used to put any three-digit num-

ber into the DISPLAY. The green light next to the EN-

TER button will illuminate when you are working in the

ENTER mode.

Figure 2

Figure 1

Figure 3

1 23

Store Display Enter

Number

Buttons

www.TheCatalogRoom.com Purchase at: www.EatonProducts.com

5

Aeroquip ProCrimp 1390 Crimp Machine

© Aeroquip Corporation 1996

4. The numbered keys have two functions:

a. In the ENTER mode, their numeric value is put into

the DISPLAY.

b. In the STORE mode, they act as 10 different memory

locations in which to store a DISPLAY setting.

Entering a Number into the DISPLAY

1. Turn the power control switch below the keypad to the

ON position. The DISPLAY will illuminate to show that

the power is on.

2. Press the ENTER button. (The green light next to the

ENTER button will illuminate.)

3. Press three number buttons. (If more than five seconds

elapse between pressing the number buttons, the DIS-

PLAY reverts back to its previous setting.) After the third

number is pressed, the DISPLAY will remain and the

green light next to the ENTER button will turn off.

4. The FT1390 is now ready to crimp to the DISPLAY setting.

Storing a Number from the DISPLAY as a Preset

1. Enter a three-digit number as described in the pro-

cedure above.

2. Press the STORE button. (The green light next to the

STORE button will illuminate.)

3. Press and hold down any one of the 10 numerical but-

tons for three seconds. (After three seconds, the green

light next to the pressed button will illuminate, indicating

that the DISPLAY has been stored to that button.)

Recalling a Preset into the DISPLAY

1. Make sure that the STORE and ENTER lights are off. (If

one is on, it will go off in five seconds if the keypad is left

untouched.)

2. Press the numeric button that has the stored setting for a

given hose and fitting style. That setting will then be

seen in the DISPLAY, and the light next to the numeric

button will illuminate.

Programmable Retract Stop

1. Using the Crimp/Retract switch, place the cylinder in the

position where you want it to stop during retraction.

2. Press and hold the ENTER button until the green light

next to the button turns off (approximately three sec-

onds). The cylinder will now automatically stop retracting

at this position until another position is set or until the

crimp machine is shut off.

NOTE: Pressing and holding the RETRACT switch will allow

the cylinder to fully retract. This will not change or erase the

programmable retract stop.

NOTE: Turning the crimp machine off and back on erases the

programmable retract stop position.

Adjustable Backstop (Figure 4)

1. Turn off the power to the machine.

2. Insert the die cage.

3. Loosen the thumbscrew on the backstop.

4. Place the fitting against the locator cone. Pushing it too

hard will compress the spring, which will affect the accu-

racy of the position.

5. Slide the backstop to the desired position. (For Match-

Mate Plus fittings refer to Figure 5.)

6. Tighten the thumbscrew.

7. Turn the power on.

Figure 4

➚

Backstop

www.TheCatalogRoom.com Purchase at: www.EatonProducts.com

6

Aeroquip ProCrimp 1390 Crimp Machine

© Aeroquip Corporation 1996

Crimping Procedures

Refer to the current Aeroquip Crimp Specifications bulletin

for complete and detailed crimp specification information

for each hose and fitting style.

1. Retract the cylinder by pressing the RETRACT switch

until the cylinder is fully retracted. Select the proper die

cage from the current Aeroquip Crimp Specifications

bulletin. Insert the die cage onto the pressure plate.

(See Figure 1.)

2. Press the proper PRESET button or key in a value to

the DISPLAY. (See Example.) MatchMate Plus and

MatchMate BLUE™ target setting charts are available

from Aeroquip.

3. Position the fitting in the crimp die cage according to the

corresponding figure in the current Aeroquip Crimp Speci-

fications bulletin. (A MatchMate Plus fitting is shown in

Figure 5.)

4. To crimp the fitting, press the CRIMP switch or footswitch.

The die cage will advance until the fitting is fully crimped

(Figures 6 & 7). It will then automatically begin to retract,

signifying that the crimp is complete. Release the crimp

switch or footswitch. The die cage will automatically re-

tract and stop at the “full retract” position or at the pro-

grammable retract position if it has been set.

HINT: Retraction can be halted at any point by

momentarily pressing the RETRACT switch or footswitch.

5. Verify the correct crimp diameter.

REMINDER: Full retraction is required for changing

die cages.

Figure 7Figure 5

Example:

Enter the number “500” into the DISPLAY, and start the

crimping process. If the dies crimp the fitting, measure

the crimp diameter and decrease the DISPLAY setting

by the same amount that you wish to decrease the

crimp diameter. If the dies don’t touch the fitting, lower

the DISPLAY setting by 050 to “450” and crimp the

fitting again. If that still isn’t enough, continue to reduce

the DISPLAY setting by 050 increments until the dies

make contact with the fitting. Then, measure the crimp

diameter and decrease the DISPLAY setting by the

same amount that you wish to decrease the crimp

diameter.

If a display setting of “250”–using GH793-8 hose

with TTC fittings–produces a crimp diameter of 1.004

inches, subtract the crimp specification (0.990 inches)

from the diameter that you measured (1.004-

0.990=0.014). Then, subtract “014” from the DIS-

PLAY setting (250-014=236), and change the

DISPLAY to “236.” Crimp the fitting again, and mea-

sure the crimp diameter. If the crimp diameter is still

too large, repeat this process.

Figure 6

Proper Crimping Position

for MatchMate Plus Fittings

Scribe

Line

➚

www.TheCatalogRoom.com Purchase at: www.EatonProducts.com

7

Aeroquip ProCrimp 1390 Crimp Machine

© Aeroquip Corporation 1996

Calibration

The calibration procedure below will calibrate the Aeroquip

ProCrimp 1390 crimp machine to the original factory set-

ting. While new machines are calibrated at the factory and

will be ready to use upon receipt, this procedure should be

followed if the crimp machine has been disassembled or

has had components replaced. The procedure requires the

use of an FT1307-200-M180 die cage, a 1SB4 socket (or

TTC-4 fitting), and a 1SB8 socket (or a TTC-8 fitting).

NOTE: While in the calibration mode, follow the instructions

precisely, and press the keys deliberately. If a mistake is

made, the calibration procedure must be started over by

turning the machine off and then on again.

1. Insert an FT1307-200-M180 die cage.

2. Press the STORE and ENTER buttons simultaneously, and

then release. Both button lights will now illuminate and will

remain lit until the calibration procedure is finished.

3. Input the value of “210” using the keypad.

4. Center a 1SB4 socket or TTC-4 fitting (without a hose)

in the die cage, holding the socket or fitting in place with

a pencil or other suitable tool. Crimp the socket by

pressing the crimp switch or footswitch until the ma-

chine retracts by itself, indicating a completed cycle.

Allow the die cage to retract to the “full retract” position.

5. Using a micrometer, measure the crimp diameter. The

preferred method is to use the average of the four pairs

of indentations.

6. Locate the crimp diameter in Table A, below. Using the

keypad, enter in the three-digit DISPLAY reading that

corresponds to the crimp diameter.

NOTE: If your crimp diameter falls between the numbers

shown in Table A, simply determine or interpolate the DISPLAY

reading, since the numbers are a direct ratio.

7. Input in the value of “610” using the keypad.

8. Center a 1SB8 socket or TTC-8 fitting (without a hose)

in the die cage, holding the socket or fitting in place with

a pencil or other suitable tool. Crimp the socket by

pressing the crimp switch or footswitch until the ma-

chine retracts by itself, indicating a completed cycle.

Allow the die cage to retract to the full retract position.

9. Repeat steps 5 and 6 at left, using Table B for the -8 socket.

10. After the three-digit DISPLAY reading in Step 9 is entered,

the machine will automatically exit the calibration mode.

Table A for -4 Table B for -8

Crimp Display Crimp Display

Diameter Reading Diameter Reading

0.670 170 1.070 570

0.680 180 1.080 580

0.690 190 1.090 590

0.700 200 1.100 600

0.710 210 1.110 610

0.720 220 1.120 620

0.730 230 1.130 630

0.740 240 1.140 640

Calibration Example:

Crimp a 1SB4 socket, and measure the four crimp

diameters around the socket. Let's say, for example,

that the diameters measure .692, .693, .694 and .694

inches. To obtain the average diameter, add the four

diameters, and divide that sum total by 4.

(.692+.693+.694+.694) =2.773 = 0.69325 = 0.693

44

(round to nearest

thousandth)

Look at the crimp diameter column in Table A and

find your average diameter. If it falls between two

numbers, as this one does, interpolate the desired

setting. In this case, you would enter 193. If your

crimp diameter is .690, you would enter 190; if it is

.697, you would enter 197.

Crimp a 1SB8 socket, and measure the four crimp

diameters around the socket. This time, let's say that

the diameters measure 1.113, 1.115, 1.114 and 1.115

inches. Obtain the average diameter by adding the

four diameters and dividing that sum total by 4.

(1.113+1.115+1.114+1.115) =4.457 = 1.11425 = 1.114

44

(round to nearest

thousandth)

Look at the crimp diameter column in Table B and

find your average diameter. If it falls between two

numbers, as this one does, interpolate the desired

setting. In this case, you would enter 614. If your

crimp diameter is 1.110, you would enter 610; if it is

1.119, you would enter 619.

www.TheCatalogRoom.com Purchase at: www.EatonProducts.com

8

Aeroquip ProCrimp 1390 Crimp Machine

© Aeroquip Corporation 1996

Maintenance Intervals

Die Cage Lubrication

Every 50 crimps............. Relube sliding surfaces of dies

Every 500 crimps .......... Remove old grease and relube

Every 1000 crimps ........ Die cage maintenance

(See below.)

Crimp Ring Maintenance

Every 500 crimps .......... Remove old grease and relube

Every 2000 crimps ......... Remove old grease, inspect for

wear or damage and relube if OK.

Cylinder Plate Bushing Maintenance

Every 2000 crimps ......... Remove old grease, inspect for

wear or damage and relube if OK.

Use NEVER•SEEZ lubricant (Aeroquip Part Number FT1092).

Maintenance Procedures

Machine Maintenance Procedures

1. Sliding surfaces must be kept free of dirt and other

abrasive materials.

2. All exposed black metal surfaces should be coated oc-

casionally with a light film of oil to prevent corrosion.

3. Periodically check the oil level in the fluid reservoir of

the hydraulic power unit. Maintain the oil level according

to the indicator on the top of the reservoir. Add ENERPAC

premium hydraulic oil as needed.

NOTE: Completely retract the crimp ring when checking

the oil level.

Die Cage Maintenance Procedures

1. Lubricate the die cage. For maximum service, die cages

require lubrication at 50-crimp intervals with NEVER•SEEZ

(Aeroquip Part Number FT1092). FT1092 is an eight-

ounce container that will provide sufficient lubricant for

about 5,000 crimps.

Periodically remove NEVER•SEEZ residue that has built

up on the sides of the dies and in the crimp ring during

the crimping process. Do not allow contaminated

NEVER•SEEZ to come into contact with the dies. (This

can cause dies to stick to the crimp insert.) NEVER•SEEZ

residue becomes contaminated with metal and plating

chips and airborne contaminants, which can cause pre-

mature wear of the dies and crimp ring.

2. Die cage maintenance should be performed at 1000-

crimp intervals or every six months, which ever occurs

first. Die cages should be free of grease and debris and

inspected for worn or damaged components.

a. The sliding surface of the dies should appear smooth

with no apparent galling. Galled dies must be re-

placed. Individual dies in a cage can be replaced

without replacing all eight dies.

b. Replace springs that show any sign of damage or

collapse such as those which are shorter than the

other springs.

c. The spring plate should appear smooth with no

apparent galling. Galled spring plates must be re-

placed.

d. Inspect remaining components, and replace those

that are badly worn.

Reassemble components, and liberally apply

NEVER•SEEZ to the die surface which slides along the

spring plate. Torque the die cage bolts to 50 in. -lbs.

Ensure that all dies slide in and out freely.

WARNING: Removal of the cylinder and hydraulic

power unit from a crimp machine that is not se-

cured to the floor will cause reduced stability.

www.TheCatalogRoom.com Purchase at: www.EatonProducts.com

9

Aeroquip ProCrimp 1390 Crimp Machine

© Aeroquip Corporation 1996

Troubleshooting Tips

Symptom Possible Cause Corrective Action

Pump will not start • No power or wrong voltage • Make sure that the unit is plugged in.

• Make sure that the power source is on.

• Make sure that the power voltage is correct.

• Check for loose wires on the circuit board.

• Check for loose wires on the CRIMP switch.

Motor stalls under load • Low voltage • Verify that the branch circuit conforms to the

electrical specifications on Page 3 of this manual.

• Remove any extension cords.

Electric valve will not • No power or wrong voltage • Check for loose wires on the circuit board.

operate • Low voltage • Check for loose wires on the CRIMP switch.

• Make sure that the power voltage is correct.

Pump fails to build • External leak in system • Wipe away spilled oil, and locate the source of

pressure • Internal leak in pump leak. If the hose assembly is leaking, tighten or

• Internal leak in valve replace it. If the pump or cylinder is leaking,

• Internal leak in system component refer to the ENERPAC Repair Parts Sheets.

Slight oil seepage of the cylinder is normal.

Pump builds less than • Relief valve set low • Refer to the ENERPAC Repair Parts Sheets for

full pressure • External system leak possible adjustment or leakage repair.

• Internal leak in pump

• Internal leak in valve

• Internal leak in system component

Pump builds full pressure, • Tie rods may be binding • Replace the tie rods.

but cylinder does not move • Flow to cylinder blocked • Refer to the ENERPAC Repair Parts Sheets.

Cylinder will not return • Valve malfunction • Refer to the ENERPAC Repair Parts Sheet for

• Restricted/blocked valve or cylinder repair.

• Tie rods may be binding • Replace the tie rods.

• Die cage may be binding • Check the die cage and crimp ring for damage,

and repair or replace them if necessary.

• Lubricate the die cage per the maintenance

procedures on Page 8.

• Lubricate the tie rod bushings per the

maintenance procedures on Page 8.

Crimp diameters change • Incorrect hose/fitting combination • Verify the correct hose/fitting combination.

• Incorrect die cage • Verify the correct die cage.

• Die cage or crimp insert damage • Repair or replace the damaged components.

• Transducer is loose • Tighten the transducer and brackets, and then

• Loose crimp machine components recalibrate them if necessary.

• External damage to crimp machine • Tighten any loose bolts or screws

• Insufficient lubrication on dies • Lubricate the die cage per the maintenance

procedures on Page 8.

• Lubricate the tie rod bushings per the

maintenance procedures on Page 8.

DISPLAY blinks • Loose or broken wires • Tighten any wires that may have become

loose on the circuit board, pump electrical

enclosure, or CRIMP switch.

If the symptom appears to be solely pump or cylinder related, refer to the ENERPAC Repair Parts Sheets.

Any electrical checks must be done by a qualified electrician.

Remember: The electric motor only runs during the

crimping process. The motor energizes when the crimp/

retract switch or footswitch is pressed and de-energizes

when the cylinder has retracted.

Refill oil reservoir with ENERPAC premium hydraulic oil only (ENERPAC P/N H-F-101).

www.TheCatalogRoom.com Purchase at: www.EatonProducts.com

10

Aeroquip ProCrimp 1390 Crimp Machine

© Aeroquip Corporation 1996

Detail Part Number Description Qty

1 1C02217GGG0310A Hose Assembly 2

2 FF2032T0606S 90°Adapter 2

(may have all 45°adapters)

3 FF2093T0606S 45°Adapter 2

4 FF9339-08-24S 1/2-13 X 1.50 SHCS 4

5 FT1289-2-2-14 Retaining Ring 1

6 FT1289-2-2-15 Crimp Ring Insert 1

7 FT1289-3-13 Push Rod 4

8 FT1289-3-15 Pressure Plate 1

9 FT1289-3-46 Plate 1

10 FT1289-3-60 Caution Decal 1

11 FT1289-3-62 Guard 1

12 FT1303-3-76 Shoulder Bolt 2

13 FT1330-3-64 Attention Decal 1

14 FT1330-3-68 Work Lamp 1

15 FT1330-3-7 Rubber Grommet 1

16 FT1340-2-2-19 Tie Bar 4

Detail Part Number Description Qty

Crimp Machine Parts Breakdown

➚

15

➚

48

44

➚

39

➚

56

➚

57

➚

17

➚

36

➚

42

➚

20

➚

(

19

➚

56

➚

34

47

49

OR

OR

➚

2

➚

1

➚

51

➚

38

➚

43

➚

51

➚

3

➚

35

28

➚

➚

44 48

➚

50

➚

58

17 FT1340-2-2-20 Nut 4

18 FT1340-2-2-23 Crimp Ring 1

19 FT1340-2-5-1 Motor Starter Switch 1

20 FT1340-3-2 Tray Matting (2 pieces) 1

FT1340-3-4 Backstop Assembly 1

(includes Details 22 through 27)

22 FT1340-3-4-1 Shoulder Bolt 1

23 FT1340-3-4-2 Spring 1

24 FT1340-3-4-3 Locator Plate 1

25 FT1340-3-4-4 Bronze Bushing 1

26 FT1340-3-4-5 Thumb Screw 1

27 FT1340-3-4-6 Locator Cone 1

28 FT1360-3-8 1/4-20 X .38 BHCS 4

29 FT1380-3-3 3-Position Switch 1

30 FT1380-3-6 Key Pad 1

31 FT1380-3-7 Electrical Enclosure 1

32 FT1380-3-18 #4-40x.188 lg. SHCS 4

➚

55

➚

40

➚

21

www.TheCatalogRoom.com Purchase at: www.EatonProducts.com

11

Aeroquip ProCrimp 1390 Crimp Machine

© Aeroquip Corporation 1996

100 Watt Maximum

13

➚

➚

41

➚

59 7

➚

➚

16

➚

26

➚

22

➚

27

➚

8

➚

4

➚

10

➚

18

➚

5

➚

6

➚

11

➚

52

➚

53

➚

9

➚

12

➚

23

24

➚

25

➚

➚

51

➚

31

➚

32

37

➚

➚

33

➚

29

➚

30

➚

46

➚

14

➚

54

Detail Part Number Description Qty

33 FT1380-3-31 Insulated Wire 3

34 FT1390-3-1 Hydraulic Power 1

Unit 115VAC 60HZ

35 FT1390-3-2 Hydraulic Cylinder 1

36 FT1390-3-3 Cylinder Adapter 1

37 FT1390-3-4 Control Card 1

38 FT1390-3-5 Transducer 1

(includes clips and rod adapter)

39 FT1390-3-6 Base (includes electrical box) 1

40 FT1390-3-7 Transducer Rod Extension 1

41 FT1390-3-8 Push Block 1

42 FT1390-3-9 Cylinder Mounting Plate 1

43 FT1390-3-10 Transducer Bracket 1

FT1390-3-11 Decal, Serialized (Not Shown) 1

44 FT1390-3-14 Compression Connector 3

45 FT1390-3-15 Compression Connector 1

46 FT1390-3-16 Foot Switch 1

Detail Part Number Description Qty

47 FT1390-3-17 Hydraulic Power 1

Unit 208-240VAC 60HZ

48 FT1390-3-18 Locknut 4

49 FT1390-3-19 Hydraulic Power 1

Unit 230VAC 50HZ

50 FT1390-3-6-2 Rear Panel 2

51 222003-1-8-6S #8-32 X .38 SHCS 8

52 FF9339-0108-06S #8-32 X .38 BHCS 2

53 FF90258-0110-06S #10-32 X .38 FHCS 2

54 FF9156-0110-08S #10-32 X .50 BHCS 2

55 FF9197-06-08S 3/8-16 X .50 SHSS 1

56 222003-6-12S 3/8-16 X 0.75 SHCS 10

57 222003-6-40S 3/8-16 X 2.50 SHCS 4

58 222003-8-56S 1/2-13 X 3.50 SHCS 2

59 222003-6-32S 3/8-16 X 2.00 SHCS 4

60 222003-1-10-6S #10-24 x .38 SHCS 2

FT1092 NEVER-SEEZ (not shown) 1

JA570 ProCrimp 1390 Decal (not shown) 1

JA146C Aeroquip Decal (not shown) 2

www.TheCatalogRoom.com Purchase at: www.EatonProducts.com

12

Aeroquip ProCrimp 1390 Crimp Machine

© Aeroquip Corporation 1996

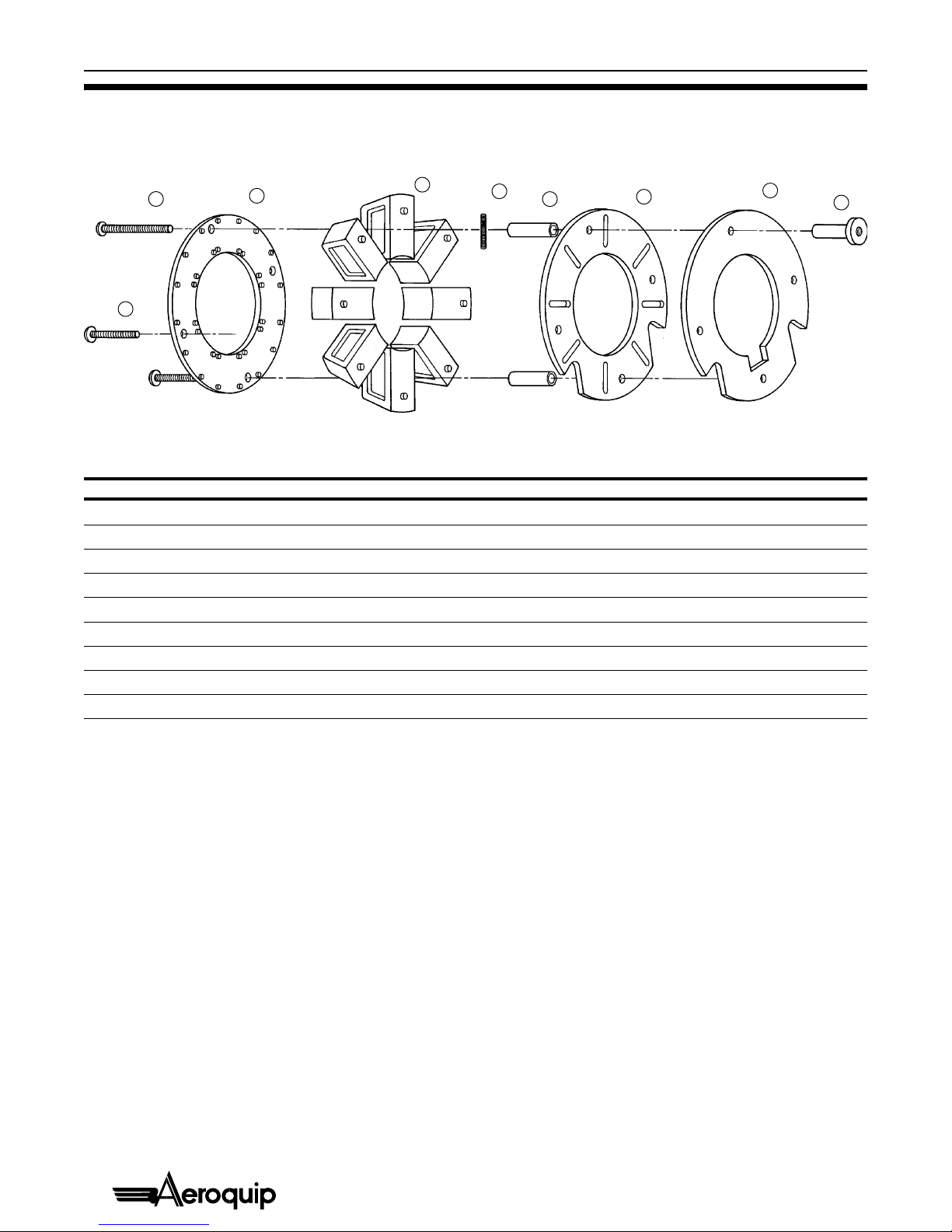

FT1307 Die Cage Parts Breakdown

Detail Qty Part Number Description

1 8 pc 21057-7 Roll Pin .25 dia x .62 long

2 8 pc FT1209-2-9-7 Spring

3 1 pc FT1307-2-9-3 Spring Plate

4 1 pc FT1307-2-9-4 Front Plate

5 3 pc FT1307-2-9-5 BHCS 5/16-18x2.56 long

6 4 pc FT1307-2-9-6 Spacer

7 1 pc FT1307-2-9-7 Nut

8 1 pc FT1307-2-9-8 Back Plate

9 1 pc FT1307-2-9-10 BHCS 5/16-18x3.00 long

18

7

5

➚

9

➚

4

➚

➚

2

➚

➚

63

➚

➚

➚

www.TheCatalogRoom.com Purchase at: www.EatonProducts.com

13

Aeroquip ProCrimp 1390 Crimp Machine

© Aeroquip Corporation 1996

Detaill Qty Part Number Description

1 3 pc FT1209-2-9-1 BHCS 5/16-18x3.90 long

2 1 pc FT1209-2-9-2 Front Plate

3 4 pc FT1209-2-9-3 Spacer

4 1 pc FT1209-2-9-4 Back Plate Assembly (Details 5 through 9)

5 1 pc FT1209-2-9-4-1 Back Plate

6 2 pc FT1209-2-9-4-2 Roll Pin .09 dia x .50 long

7 2 pc FT1209-2-9-4-3 Rod

8 2 pc FT1209-2-9-4-4 Spring

9 2 pc FT1209-2-9-4-5 Roll Pin .125 dia x .75 long

10 1 pc FT1209-2-9-5 Shoulder Screw

11 8 pc 21057-7 Roll Pin .25 dia x .62 long

12 1 pc FT1209-2-9-7 Spring

13 1 pc FT1209-2-9-8 BHCS 5/16-18x3.50 long

FT1209 Die Cage Parts Breakdown

➚

1

13

➚

2

➚

3

➚

8

➚

6

➚

7

➚

9

➚

10

➚

5

➚

4

OR

➚

11

➚

12

www.TheCatalogRoom.com Purchase at: www.EatonProducts.com

14

Aeroquip ProCrimp 1390 Crimp Machine

© Aeroquip Corporation 1996

Electrical Schematic for FT1390-115 (115V model)

Electrical Schematic for FT1390-230 (230V model)

www.TheCatalogRoom.com Purchase at: www.EatonProducts.com

15

Aeroquip ProCrimp 1390 Crimp Machine

© Aeroquip Corporation 1996

Electrical Schematic – Terminal Blocks and Pin Numbers

(115V and 230V models)

Terminal Pin

Block Number Voltage Wire Color Description

TB1 1 +12V AC Black From transformer

TB1 2 +0V AC White From transformer

TB1 3 None Green To earth ground

TB2 1 +4.04V DC Orange To transducer

TB2 2 +4.04 to 0.04V DC* Red To transducer

TB2 3 +0.04V DC Brown To transducer

TB2 4 +5V DC Red Crimp switch

TB2 5 0V DC White Switch common

TB2 6 +5V DC Red Retract switch

TB2 7 +5V DC Black Footswitch

TB2 8 0V DC White Footswitch common

TB3 1 +24V AC Blue To retract solenoid

TB3 2 +24V AC Orange To motor contractor

TB3 3 +24V AC Red To advance solenoid

*The voltage at TB2 pin 2 varies between 4.04V DC and 0.04V DC, depending on the position of the cylinder.

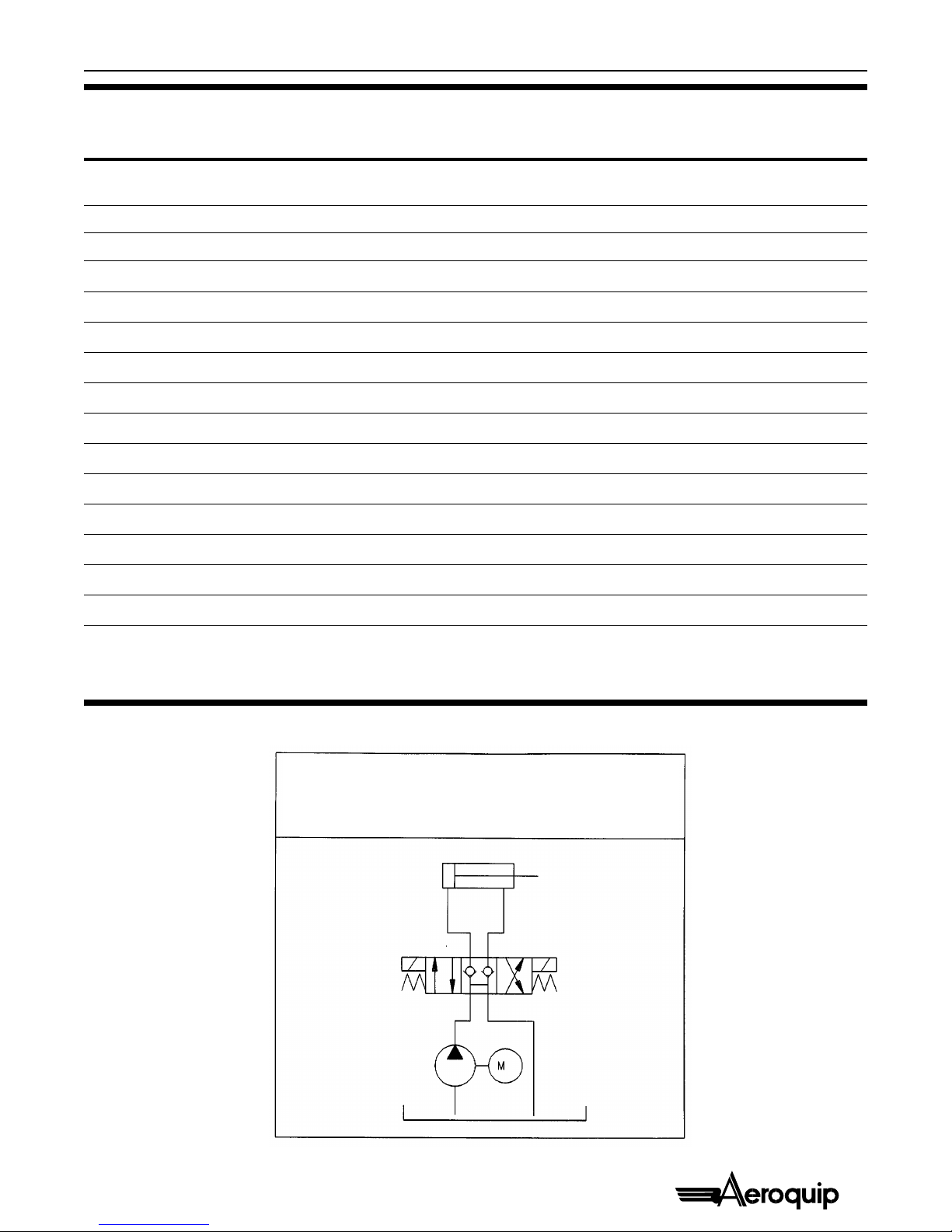

Hydraulic Schematic

SEQUENCE

1. Pump and extend solenoid on: Cylinder extends

2. Pump and retract solenoid on: Cylinder retracts

3. Pump and both solenoids off: Cylinder holds

www.TheCatalogRoom.com Purchase at: www.EatonProducts.com

16

Aeroquip ProCrimp 1390 Crimp Machine

© Aeroquip Corporation 1996

3-96 FT1390-500 Litho in U.S.A.

AMERICAS INDUSTRIAL DIVISION

1695 Indian Wood Circle

P.O. Box 700

Maumee, OH 43537-0700

Phone: 419-891-5100

Fax: 419-891-7890

http://www.aeroquip.com

Specifications subject to change without notice.

Aeroquip products are protected by patents internationally

www.TheCatalogRoom.com Purchase at: www.EatonProducts.com

Table of contents