Table of Contents AMG Hardware Manual

Safety Procedures and Warnings

Read this manual in its entirety before installing, operating, or servicing this product. If you do not understand

the information contained herein, contact an Aerotech representative before proceeding. Strictly adhere to

the statements given in this section and other handling, use, and operational information given throughout

the manual to avoid injury to you and damage to the equipment.

The following statements apply wherever the Warning or Danger symbol appears within this manual. Failure

to observe these precautions could result in serious injury to those individuals performing the procedures

and/or damage to the equipment.

D A N G E R : This product contains potentially lethal voltages. To reduce the possibility of

electrical shock, bodily injury, or death the following precautions must be followed.

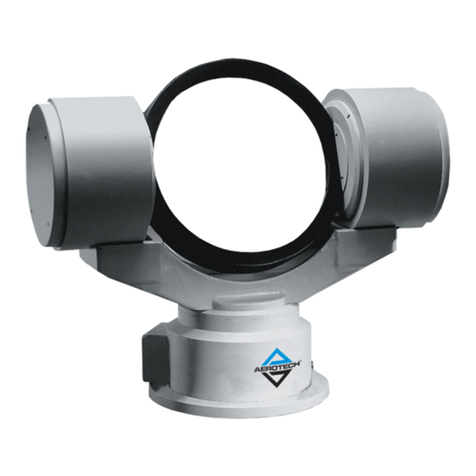

1. Access to the AMG and component parts must be restricted while connected to a power

source.

2. Do not connect or disconnect any electrical components or connecting cables while

connected to a power source.

3. Disconnect electrical power before servicing equipment.

4. All components must be properly grounded in accordance with local electrical safety

requirements.

5. Operator safeguarding requirements must be addressed during final integration of the

product.

W A R N I N G : To minimize the possibility of electrical shock, bodily injury or death the

following precautions must be followed.

1. Moving parts can cause crushing or shearing injuries. Access to all stage and motor parts

must be restricted while connected to a power source.

2. Cables can pose a tripping hazard. Securely mount and position all system cables to avoid

potential hazards.

3. Do not expose this product to environments or conditions outside of the listed

specifications. Exceeding environmental or operating specifications can cause damage to

the equipment.

4. The AMG stage must be mounted securely. Improper mounting can result in injury and

damage to the equipment.

5. Use care when moving the AMG stage. Lifting or transporting the AMG stage improperly

can result in injury or damage to the AMG.

6. This product is intended for light industrial manufacturing or laboratory use. Use of this

product for unintended applications can result in injury and damage to the equipment.

7. If the product is used in a manner not specified by the manufacturer, the protection

provided by the product can be impaired and result in damage, shock, injury, or death.

8. Operators must be trained before operating this equipment.

9. All service and maintenance must be performed by qualified personnel.

6 www.aerotech.com