Safety Procedures and Warnings

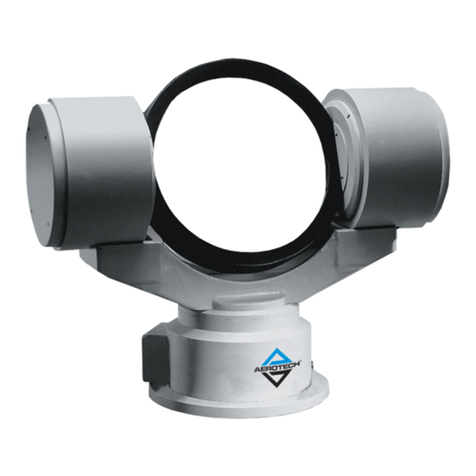

IMPORTANT: This manual tells you how to carefully and correctly use and operate the

gimbal.

lRead all parts of this manual before you install or operate the gimbal or before you

do maintenance to your system.

lTo prevent injury to you and damage to the equipment, obey the precautions in this

manual.

lAll specifications and illustrations are for reference only and were complete and

accurate as of the release of this manual. To find the newest information about this

product, refer to www.aerotech.com.

If you do not understand the information in this manual, contact Aerotech Global

Technical Support.

IMPORTANT: This product has been designed for light industrial manufacturing or

laboratory environments. If the product is used in a manner not specified by the

manufacturer:

lThe protection provided by the equipment could be impaired.

lThe life expectancy of the product could be decreased.

Safety notes and symbols are placed throughout this manual to warn you of the potential risks at the

moment of the safety note or if you fail to obey the safety note.

Shock/Electrocution Hazard Pinch, Shear, or Crush Hazard

General/Conditional Awareness Rotational Machinery Hazard

Hot Surface Hazard Pinch/Entanglement Hazard

Magnetic Field Hazard Trip Hazard

Heavy, Bulky Lifting Hazard Appropriate Equipment Required

Pressure/Explosive Atmosphere

Hazard Electrostatic Discharge Hazard

A blue circle symbol is an action or tip that you should obey. Some examples include:

General tip Read the manual/section

Wear personal protective equipment

(PPE): Safety Glasses If applicable, do not lift unassisted

Wear personal protective equipment

(PPE): Gloves

Wear personal protective equipment

(PPE): Hearing Protection

AMG Hardware Manual

8 www.aerotech.com