Ensemble LAB Hardware Manual Table of Contents

Table of Contents

Ensemble LAB Hardware Manual 1

Table of Contents iii

List of Figures v

List of Tables vi

EU Declaration of Conformity 7

Agency Approvals 8

Safety Procedures and Warnings 9

Quick Installation Guide 11

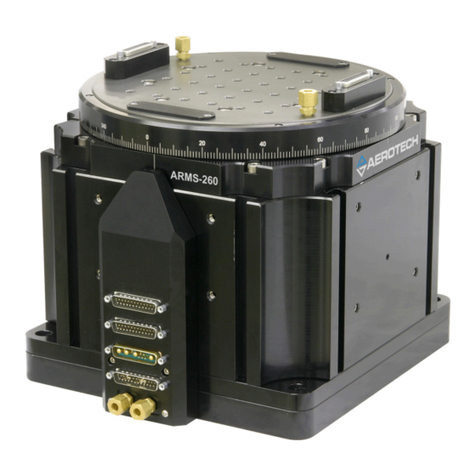

Chapter 1: Introduction 13

1.1. Electrical Specifications 16

1.1.1. System Power Requirements 17

1.2. Mechanical Specifications 18

1.3. Environmental Specifications 19

1.4. Drive and Software Compatibility 20

Chapter 2: Installation and Configuration 21

2.1. Unpacking the Chassis 21

2.2. Electrical Installation 22

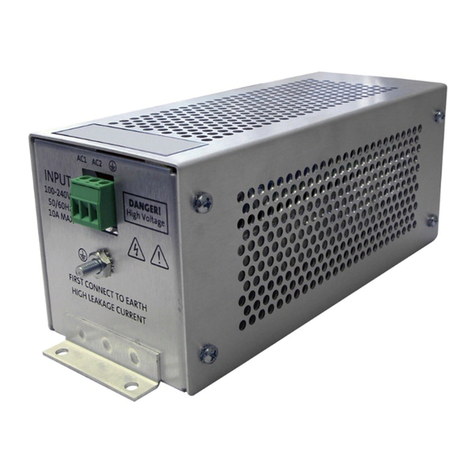

2.2.1. AC Power Connection 23

2.2.2. IO and Signal Wiring Requirements 24

2.2.3. Minimizing Conducted, Radiated, and System Noise 25

2.3. Motor and Feedback Connections 26

2.3.1. Encoder Interface 27

2.3.1.1. RS-422 Line Driver Encoder (Standard) 28

2.3.1.2. Analog Encoder Interface 29

2.3.1.3. Encoder Phasing 31

2.3.2. Hall-Effect Interface 33

2.3.3. Thermistor Interface 34

2.3.4. End of Travel Limit Input Interface 35

2.3.4.1. End of Travel Limit Phasing 36

2.3.5. Motor Output Interface 37

2.3.5.1. Brushless Motor Connections 38

2.3.5.2. DC Brush Motor Connections 41

2.3.5.3. Stepper Motor Connections 42

2.4. Emergency Stop Sense Input (TB101) 43

2.5. Auxiliary I/OConnector (J106) 44

2.5.1. Auxiliary Encoder Channel 45

2.5.2. Position Synchronized Output (PSO) 47

2.5.3. Opto-Isolated Outputs 0-3 49

2.5.4. Opto-Isolated Inputs 0-3 51

2.5.5. High-Speed User Inputs 4-5 53

2.5.6. Analog Output 0 54

2.5.7. Analog Input 0 55

2.6. Joystick Interface (J105) 56

2.7. Communication (Ethernet and USB) 58

2.7.1. USB Interface 58

2.7.2. Ethernet Interface 59

2.8. PC Configuration and Operation Information 60

Chapter 3: Maintenance 61

3.1. Preventative Maintenance 61

www.aerotech.com iii