THERMA TESC Installation and operation manual

1

INFORMATION BOOKLET

Thermaco Ltd

TESC

REMOTE GAS VALVE

2

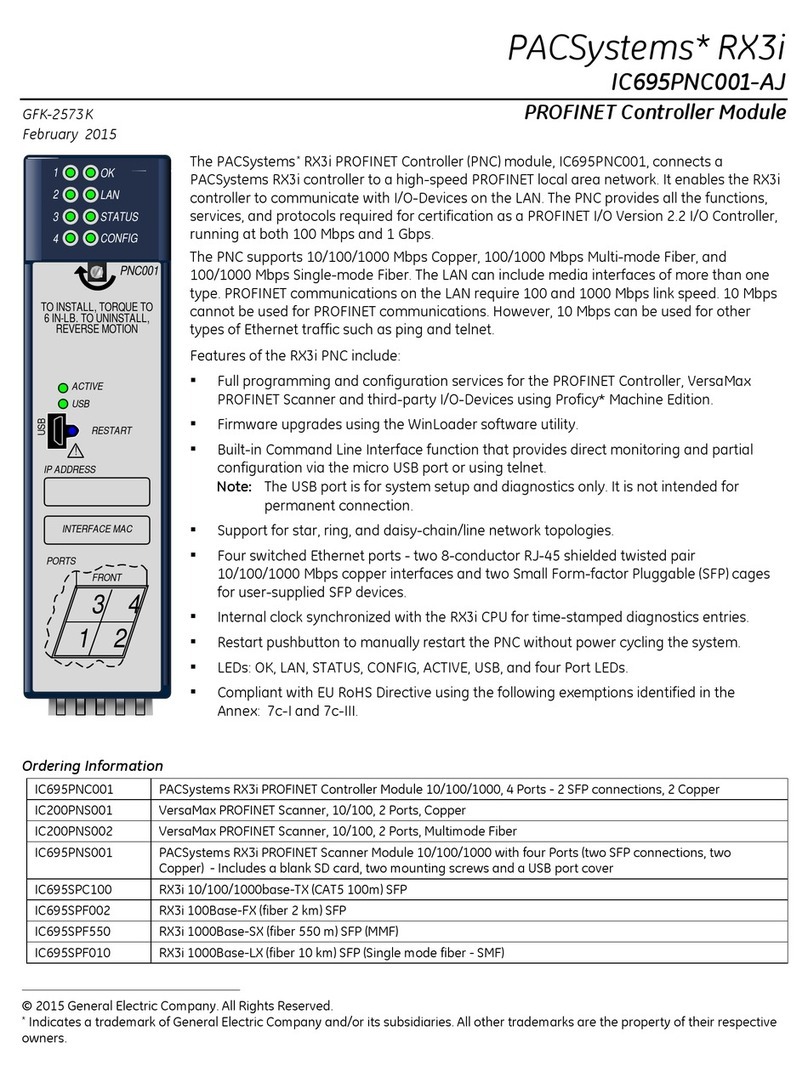

BASIC COMPONENTS

TESC VALVE

DISPLAY

HANDSET

NON-DISPLAY

HANDSET

3

CONTENTS

SECTION 1

CARE AND MAINTENANCE OF THE FIRE CONTROL

PAGE

1.0

What you should do?

4

1.1

How do you know when to replace the batteries?

4

1.2

What happens if I do not replace the batteries?

4

1.3

How to replace the batteries.

4

1.4

What is the meaning of the red indicator (non-display handset, valve, or

switch)

5

1.5

What should I do if valve indicating an error?

5

SECTION 2

FREQUENTLY ASKED QUESTIONS

6

2.0

What should I do if my fire does not light or stay lit?

6

2.1

Restoring communication with a display type handset.

7

2.2

Pairing the handset with a display type handset.

8

2.3

General notes on the handset that may be of interest.

8

2.4

Using the display type handset.

9

2.5

Restoring communication with a standard non-display handset.

10

2.6

Pairing the handset standard non-display type.

10

2.7

Using the Standard non-display handset.

11

SECTION 3

GAS ENGINEER SERVICING INFORMATION

12

3.0

Important information for installers.

12

3.1

System operation explanation.

12

3.2

Error codes.

14

3.3

Pilot information and servicing.

19

3.4

Other useful information.

22

3.5

Where to obtain spares.

24

3.6

Where to obtain more information.

24

4

SECTION 1 –CARE AND MAINTENANCE

1.0 WHAT SHOULD YOU DO?

•Replacing the batteries at least every 12 months will help prevent damage to the valve and handset

through leaking batteries.

•Only use new, high quality, alkaline batteries.

•Always replace the complete set of batteries and do not mix brands.

•Keep contacts clean and do not bend.

•Remove batteries if valve and/or handset is not used for an extended period.

•Do not operate fire without battery covers fully in place.

•If handset is dropped and damaged, obtain a replacement (see spares section)

1.1 HOW DO YOU KNOW WHEN TO REPLACE THE BATTERIES?

•Replace batteries at least every 12 months, during the annual service of the fire.

•The display handset will show a low/empty battery symbol on the screen and produce an audible tone.

•The non-display handset will show a blinking red light (approx. every 10 seconds) and produce an

audible tone.

•The red indicator light on the valve flashes (approx. every 10 seconds).

•The red indicator light on the panel switch control (if fitted) flashes (approx. every 10 seconds).

1.2 WHAT HAPPENS IF IDO NOT REPLACE THE BATTERIES?

•The fire will stop working, or will only work intermittently.

•The handset (or valve) may give error codes, which may or may not be correct.

•The batteries may leak and cause permanent, irreversible damage to the electronics meaning a

replacement item must be sought (not covered by warranty).

1.3 HOW TO REPLACE THE BATTERIES.

•The control consists of a handset and a gas valve, within the fire, which both run on batteries.

•The handset requires 2 x AA batteries.

•The valve requires 3 x AA batteries (unless mains powered).

•The battery covers can be opened and removed without tools by pressing the tab down and pulling the

cover towards you, example images follow.

5

NOTE:WHEN REMOVING AND REPLACING BATTERIES,ENSURE NOT TO BEND OR DISPLACE BATTERY CONTACTS.THE BATTERIES SHOULD BE HELD

FIRMLY IN PLACE BY THE METAL CONTACTS.IT IS IMPORTANT TO ENSURE CONTACTS ARE CLEAN,DRY,AND FREE FROM ANY CONTAMINANTS OR

SURFACE DAMAGE.PAY CLOSE ATTENTION TO THE ORIENTATION MARKINGS ON BATTERIES AND EQUIPMENT,ENSURE THAT SYMBOL “+”IS

LOCATED IN THE CORRECT PLACE –ADJACENT BATTERIES ARE MOUNTED IN OPPOSITE DIRECTIONS.

1.4 WHAT IS THE MEANING OF THE RED INDICATOR -

(NON-DISPLAY HANDSET,VALVE,OR SWITCH).

RED INDICATOR

MEANING

PERMANENTLY LIT

UNSUCCESSFUL IGNITION SEQUENCE –

VALVE IN LOCKOUT (E00)

FLASHING RAPIDLY

VALVE BUSY (WILL NOT ACCEPT ANY

COMMAND)

FLASHING (APPROX ONCE A SECOND)

ERROR DETECTED

FLASHING (APPROX ONCE EVERY 10 SECONDS)

LOW BATTERY (VALVE)

FLASHING (APPROX TWICE EVERY 10 SECONDS) [HANDSET

ONLY]

LOW BATTERY (HANDSET)

FLASHING (APPROX THREE EVERY 10 SECONDS) [HANDSET

ONLY]

LOW BATTERY (HANDSET & VALVE)

PERMANENTLY OFF

STANDBY OR STABLE OPERATION

ON MOMENTARILY AFTER POWER UP

VALVE SELF-TEST

APPEARS AFTER PRESSING START

RELEASE START BUTTON

1.5 WHAT SHOULD IDO IF VALVE INDICATING AN ERROR?

•Let the fire cool down (if hot).

•Check if batteries are good, and mounted correctly. Replace with new batteries if any doubt.

•Reset the error –press power button, then press again to start fire.

•If error repeats refer to section 3.

6

SECTION 2 –FREQUENTLY ASKED QUESTIONS

NOTE: USE THIS GUIDE IN ASSOCIATION WITH YOUR GAS FIRE USER HANDBOOK, ONLY

ATTEMPT WORK AS RECOMMENDED IN THOSE INSTRUCTIONS AND WHERE SUITABLY QUALIFIED

2.0 WHAT SHOULD IDO IF MY FIRE DOES NOT LIGHT OR STAY LIT.

•Check if gas supply is on.

•If the fire is hot, wait for fire to cool down.

•If your fire has a remote handset, put the handset to one side and access the gas valve in the fire

(check user instructions for details on how to do this).

•Remove battery cover from valve and check batteries are ok, with no leaks visible, or any other

contamination present. If in doubt replace with new, unused batteries.

•When replacing batteries, ensure contacts are clean, dry, and free from any contaminants or surface

damage. Be careful not to bend or displace contacts.

•Ensure to mount batteries in correct orientation.

•Replace battery cover on valve.

•Check ceramic parts (matrix, coals, logs, etc.) are in correct place and in good condition.

•Perform any general cleaning of the fire as recommended by manufacturer’s user instructions,

particularly around the pilot assembly.

•Replace correctly any part of the fire that was removed to allow access to the valve.

•If the red light on the valve is lit, reset by pressing on/off button briefly (light should go out).

•Start fire using control buttons on valve.

•If fire does not light normally, wait until red light on valve indicates error or lockout. NOTE: the valve

may make several attempts to start the fire, this may take some minutes. DO NOT interrupt the valve

while it completes this process.

If the fire still does not function correctly:-

•Double check all of the above, in particular that the batteries are good, mounted correctly, and all

contacts are clean and sturdy.

•If the manufacturer’s user instruction manual details cleaning of the pilot, follow these instructions

carefully.

•Reset the valve as above.

•Attempt to restart the valve several times.

If the fire still does not function correctly you may need assistance from a service engineer. Refer to

manufacturer’s user manual to seek engineer assistance.

If the fire lights, and appears to work correctly, pick up the handset to check correct function:-

•Hold the handset firmly, the unlock keypad light should be lit, solid green.

If NO LIGHT present on handset:-

•Check the batteries in the handset are good, mounted correctly and firmly, and there is no

contamination or surface damage to the contacts.

•Clean and replace batteries as necessary.

7

•NOTE: If the battery contacts are contaminated (e.g. previous battery leakage) the handset may be

permanently and irreversibly damaged, meaning a new handset may need to be purchased.

IMPORTANT NOTE: THE HANDSET IS PAIRED WITH THE VALVE IN THE FIRE DURING

MANUFACTURE. PAIRING IS NOT LOST IF BATTERIES ARE REMOVED. THE DISPLAY HANDSET MAY

LOSE RECORD OF THE TIME IF BATTERIES ARE REMOVED BUT PAIRING WITH THE VALVE WILL REMAIN.

REFER TO INSTRUCTIONS RELATING TO SETTING THE TIME TO RESTORE TIME TO THE DISPLAY.

If the green indicator light is flashing like a heartbeat, the handset is not communicating with the valve (on the

display handset the communication symbol will be missing)

Communication can be lost for various reasons including, but not limited to:-

•The slide switch on the valve not in ON (I) position.

•The batteries in the valve being low on power, or out of power.

•The handset being too far from the fire.

If the above are all in order and the handset is still flashing, pairing with the valve may have been

unintentionally altered. The handset will need to be reset, and a new pairing with the valve established (see

section on restoring handset communication).

If this does not resolve the problem a service engineer will be required.

2.1 RESTORING COMMUNICATION WITH A DISPLAY HANDSET.

If the handset has lost communication with the control valve, when activated the handset will display a constant

green light which pulses brighter periodically, and the symbol will be missing from the display.

The handset will need to be reset to allow it to accept a new pairing, in order to do this follow the steps below:-

1. Ensure good batteries are firmly and correctly mounted in the handset.

2. Hold the handset firmly to unlock the keypad (keep hold of the handset during the remaining steps).

3. Press and hold the SET button (approx. 3 seconds) until you hear a second beep.

4. Release SET button. PROG and SETUP should now be visible at the top of the display.

5. With SETUP flashing, press and release SET to enter the menu.

6. Keep pressing SET until CA 0 is displayed on screen.

7. Press + or - to change CA 0 to CA 1, then press SET.

8. The display should now read 7ESC rX (where Xis a number).

A video companion for this process is available here, or search “TESC Gas Control - Display Handset - Factory

reset - to enable it to be paired again”.

The handset has now been reset to factory settings and is ready to receive a new pairing instruction (section

2.2).

8

2.2 PAIRING THE VALVE WITH A DISPLAY HANDSET.

Ensure the handset and fire control valve have good batteries as described in section 1.3.

If the handset is in factory reset condition (as section 2.1) the display will read 7ESC rX (where Xis a number).

Picking the handset up, and holding firmly, will unlock the handset and the green unlock light will illuminate. If

the ambient light level is low, the display backlight may also illuminate.

Follow the steps below:-

1. Ensure the power isolation slide switch on the valve is in the ON (I) position.

2. Place the unlocked handset near the fire (ideally within 1 metre).

3. Simultaneously press and hold the +and –buttons on the valve, the red light on the valve should

begin to flash rapidly.

4. Immediately release the +and –buttons, and press the power button (marked ) located directly

below. n.b. the power button must be pressed within 1 second of releasing +and –buttons.

5. If steps 3 and 4 are completed correctly, the handset will produce an audible tone, the green light will

be flashing, and the display will show ⎤- -⎡,the pairing must now be accepted within 60 seconds.

6. To accept pairing pick up the handset and hold firmly to unlock, press and hold SET for a few seconds.

7. The handset will beep, and the display will enter the SETUP menu.

8. Keeping hold of the handset, it is now possible to set the display functions.

9. Pressing SET will advance through the menus, and pressing MENU returns to previous options. Use +

or –to change the variables.

10. When setup is completed, will be visible on the screen. This indicates the handset is in fire operation

mode, and has established good communication with the valve.

A video companion for this process is available here, or search “TESC Gas Control - Display handset pairing

(May 2014 onwards)”.

IMPORTANT NOTE: Even if setup is not completed in full, the handset will still remember the pairing with the

valve. The handset will re-enter setup mode the next time it is unlocked, or by manual selection of the setup

mode. DO NOT RE-SEND PAIRING REQUEST FROM VALVE. This will then require a further reset of

handset, and completion of a new pairing process.

2.3 GENERAL NOTES ON THE DISPLAY HANDSET.

THE FOLLOWING GENERAL NOTES MAY BE OF INTEREST.

The communication symbol will not be visible on the display if any of the below situations occur:-

•The handset is paired correctly but is out of range of the gas fire control.

•The batteries in the gas fire control are flat, or have bad connections.

•The slide switch on the gas fire control is in the OFF (0) position.

•The handset pairing has been broken.

The display will show only the time, day of the week, handset temperature, and handset battery state. The

handset will not control the fire if the communication symbol is absent.

Remedy as above to re-establish handset control of fire.

9

2.4 USING THE DISPLAY HANDSET.

IMPORTANT USER INFORMATION –READ THIS BEFORE ATTEMPTING TO OPERATE THE FIRE

NOTE: The handset is paired to the fire during manufacture. DO NOT ALTER THE PAIRING.

For safety reasons, the handset is designed so as to avoid accidental operation. If, during proper use, the

handset fails to communicate with the valve there is a possibility that the pairing has been inadvertently altered

–in this case the handset will need to be reset and re-paired with the valve.

For normal use:-

Prior to using the handset for the first time insert new, alkaline, AA batteries into the valve and handset. Ensure

they are mounted firmly and in the correct orientation, and that the battery covers are replaced fully. Ensure

the small isolation switch on the gas control is switched to the ON (I) position.

Hold the handset as shown, wrapping your hand around the handset to make good

contact with both sides. The green unlock light should illuminate, activating the buttons

(if the light is not illuminated, the buttons will not work).

Press and hold the power button, release as soon as PILOT appears on the display

(approx. 1-2 seconds). The fire will commence ignition sequence. If successful, the fire

will automatically go to maximum heat output.

NOTE: Releasing the power button too soon or depressing for too long after the PILOT appear, will cause the

fire not to light because system assumes press to be unintentional.

To adjust the flame, hold handset to activate buttons, and use +and –to increase or

decrease flame power accordingly. Tapping the button will increase or decrease flame

stepwise, holding the button will skip through steps. The fire basket display on the

handset will illustrate the level of flame being produced.

To STOP the fire, hold handset to activate buttons, then press the power button. The

fire should shut off immediately (n.b. residual heat will remain). If you wish to start the

fire again you must wait for OFF to be displayed on the handset before trying to re-start.

NOTE: THE HANDSET IS DESIGNED TO MAKE REMOTE OPERATION OF THE FIRE AS SAFE AS POSSIBLE. IT HAS BEEN SPECIFICALLY

DESIGNED TO MINIMIZE THE RISKS OF ACCIDENTAL OPERATION, WITH THE EXPRESS INTENTION THAT SUCCESSFUL OPERATION CAN

ONLY BE ACHIEVED BY A CONSCIOUS, DELIBERATE ACT. ERGO IT MAY TAKE SOME TIME TO BECOME FAMILIAR WITH THE INTRICACIES

OF HANDSET OPERATION.

10

2.5 RESTORING COMMUNICATION WITH A NON-DISPLAY HANDSET.

If the valve is operating correctly when controlled with the on-board control buttons but the handset green light

pulses (approx. once per second) when activated then either:-

•The handset is paired correctly but is out of range of the gas fire control.

•The batteries in the gas fire control are flat, or have bad connections.

•The slide switch on the gas fire control is in the OFF (0) position.

•The handset pairing has been broken.

IMPORTANT NOTE: THE HANDSET IS PAIRED WITH THE VALVE IN YOUR FIRE DURING

MANUFACTURE. PAIRING IS NOT LOST IF BATTERIES ARE REMOVED.

To re-establish communication between the valve and the handset, the handset must be reset to factory

condition to allow pairing to commence.

To reset the non-display handset, follow the below instructions:-

1. Ensure good and properly connected batteries in the handset and valve.

2. Hold the handset to activate buttons (green light will illuminate).

3. Press and hold SET for 10-15 seconds, until red and green lights flash simultaneously.

4. Whilst red and green lights flash together, quickly remove one battery, wait for about 30 seconds, then

replace battery and battery cover.

5. Hold handset to activate buttons, the green light should now be flashing multiple times per second

meaning it is ready to be paired with the valve.

A video companion for this process is available here,or search “TESC Gas Control - Displayless Handset factory

reset (to enable to be paired again)”.

NOTE: IF THE RED AND GREEN LIGHTS DO NOT FLASH TOGETHER THE HANDSET IS PROBABLY ALREADY

RESET AND READY FOR A PAIRING REQUEST.

2.6 PAIRING THE VALVE WITH A NON-DISPLAY HANDSET.

Ensure the handset and fire control valve have good batteries as described in section 1.3.

If the handset is in factory reset condition (as section 2.5) the green light will flash rapidly when the handset is

activated.

Follow the steps below:-

1. Ensure the power isolation slide switch on the valve is in the ON (I) position.

2. Place the unlocked handset near the fire (ideally within 1 metre).

3. Simultaneously press and hold the +and –buttons on the valve, the red light on the valve should

begin to flash rapidly.

4. Immediately release the +and –buttons, and press the power button located directly below. n.b.

the power button must be pressed within 1 second of releasing +and –buttons.

5. If steps 3 and 4 are completed correctly, the handset will produce an audible tone, the green light will

be flashing slower than previous. The pairing must now be accepted within 60 seconds –if pairing not

accepted within 60 seconds the green light will go out.

11

6. To accept pairing pick up the handset and hold firmly to unlock, press and hold SET for a few seconds.

7. The handset will beep, and the green light will be permanently lit when held.

8. A solid green light, when held, indicates the handset is in fire operation mode, and has established

good communication with the valve.

A video companion for this process is available here, Or search “TESC Gas Control - Displayless handset pairing

(May 2014 onwards)”.

2.7 USING THE NON-DISPLAY HANDSET.

IMPORTANT USER INFORMATION –READ THIS BEFORE ATTEMPTING TO OPERATE THE FIRE.

NOTE: The handset is paired to the fire during manufacture. DO NOT ALTER THE PAIRING.

For normal use:-

Prior to using the handset for the first time insert new, alkaline, AA batteries into the valve and handset. Ensure

they are mounted firmly and in the correct orientation, and that the battery covers are replaced fully. Ensure

the small isolation switch on the gas control is switched to the ON (I) position.

Hold the handset as shown, wrapping your hand around the handset to make good

contact with both sides. The green unlock light should illuminate, activating the buttons

(if the light is not illuminated, the buttons will not work).

Press and hold the power button (approx. 2 seconds). Release power button as soon

as red light comes on. The fire will then light.

NOTE: Releasing the power button too soon or depressing for too long after the red light illuminates, will

cause the fire not to light because system assumes press to be unintentional.

To adjust the flame, hold handset to active buttons, and use +and –to increase or

decrease flame power accordingly. Tapping the button will increase or decrease flame

stepwise, holding the button will skip through steps.

To STOP the fire, hold handset to activate buttons, then press the power button. The

fire should shut off immediately (n.b. residual heat will remain). The red light will flash

for a few seconds. If you wish to start the fire again you must wait for light to stop

flashing before trying to re-start.

A video companion for this process is available here, or search “TESC Gas Control - using Non Display Handset”.

12

SECTION 3 –GAS ENGINEER SERVICING INFORMATION

3.0 IMPORTANT INFORMATION FOR INSTALLERS.

THE INFORMATION CONTAINED IN THIS SECTION IS FOR EXCLUSIVE USE OF QUALIFIED AND

APPROVED SERVICE PERSONNEL.

•THE HANDSET IS SUPPLIED PAIRED TO THE VALVE BY FIRE MANUFACTURER.DO NOT ALTER PAIRING.

•THE HANDSET IS CONSCIOUSLY DESIGNED TO MINIMIZE THE RISK OF ACCIDENTAL OPERATION AND CAN THEREFORE TAKE

A LITTLE TIME TO LEARN TO USE COMFORTABLY.

•PLEASE READ SECTION 2AND EXPLAIN TO THE CUSTOMER TO ENSURE UNDERSTANDING OF EACH PARTICULAR HANDSET.

•THERE ARE COMPANION VIDEOS AVAILABLE ON YOUTUBE (SEARCH:TESC GAS CONTROL)

•IF PAIRING HAS BEEN INADVERTENTLY ALTERED THE HANDSET WILL NOT WORK,IT WILL NEED A FACTORY RESET –

FOLLOW INSTRUCTIONS IN SECTION 2.

MOST COMMON CAUSES FOR FAULT.

•BATTERIES NEED REPLACING.

•BATTERIES MOUNTED INCORRECTLY.

•CONTAMINATION OF BATTERY CONTACTS (CLEAN WHERE POSSIBLE,REPLACE VALVE/HANDSET IF NECESSARY).

•CONTAMINATION OF PILOT (SEE BELOW).

•CONTAMINATION OF VALVE INTERNALS FROM GAS PIPE PARTICLES.

•FAULTY GAS SUPPLY.

•FAULTY THERMOCOUPLE OR CONNECTIONS.

•CONTAMINATION IN GAS SUPPLY.

3.1 SYSTEM OPERATION EXPLANATION.

The gas control valve is one component, containing the gas valve, control electronics, ignition unit, and battery

box.

It is a full sequential ignition system (with no standing pilot).

It utilizes both a conventional thermoelectric thermocouple, and electronic flame sensing for its operation.

The ignition phase (first 15-30 seconds) operates with the thermocouple excluded from the circuit, subsequently

the thermocouple holds the valve magnet open, as per a conventional system. (If the burner stays lit only for

this duration, it is a sign of no thermocouple current, or insufficient thermocouple current reaching the valve).

The electronic flame sensing device is in constant operation whilst the valve is in operation.

It is important that, at all times, the pilot flame is in good order, both the thermocouple tip and electrode tip are

immersed within the pilot flame, and the ignition cable is undamaged & well connected to the valve.

The handset is not essential for operation, it is a wireless interface, it is not the control.

When problem solving it is important to check operation using the buttons on the valve itself, this should be

done in the first case, DO NOT rely on the handset.

13

ASSESSMENT.

Ensure fire is cool before commencing any work.

Ensure batteries are new, mounted correctly, and connections are good.

Start with the valve in standby position –slide switch in ON (I) position, red light on valve off, and fire burner

also off.

Press the power button, marked , and hold for approx. 1 second, or until the red LED lights up, then release.

This should start the ignition sequence, and within a few seconds a repetitive spark should be produced at the

electrode.

The fire may make up to 3 automatic attempts to ignite. Each ignition cycle takes 15-30 seconds, with a pause

of approx. 10 seconds between each cycle. Multiple attempts DOES NOT signify that there is a fault, each fire

and installation is unique, and may account for this.

If the fire fails to ignite after 3 automatic cycles, the red light on the valve will stay permanently lit, indicating

valve lockout. A connected display handset will also return the error code E00. To reset the lockout press the

power button to return the valve to standby, and try normal start-up process again.

If problem persists, and valve repeatedly goes to lockout, refer to the cleaning and maintenance section. It is

possible that the valve has become contaminated with debris, and requires cleaning to restore normal

operation.

If the fire does not light and/or…

•There is an error code EXX (where XX is a two-digit number) displayed on the handset.

•The red LED on the valve is flashing like a heartbeat.

•The display handset is showing low battery.

…check troubleshooting section and error codes section for further information.

14

3.2 ERROR CODES.

Error codes are produced to assist diagnosis of why the fire cannot/will not start. They appear if the control

detects abnormal conditions with the fire, environment, installation, components, or internal electronics.

Even if a display handset is not connected, checking for the below faults is still valid. The illuminated red LED on

the valve body shows the valve is in error state.

NOTES:

To reset any error, press the power button, marked on the valve.

False errors can be reported if the batteries are faulty or low on power.

E00

This is the only code where the red indicator LED remains permanently lit without flashing. (n.b. the LED may

dim to conserve battery power but remains illuminated).

E00 occurs when fire fails to light after all automatic ignition cycles complete. It is a sign that the

electromagnet within the valve has not received enough power from the thermocouple at the end of the

ignition cycle. The main burner may light for 15-30 seconds, but then extinguish.

Possible reasons:-

•Thermocouple not being heated, or being heated too slowly.

•No gas to pilot or main burner.

•No gas supply, or supply blocked through contamination.

•Pilot pipe blocked between valve and pilot.

•Pilot injector blocked.

•Pilot head damaged or contaminated.

•Fire ceramic misplaced causing carbon deposits to contaminate pilots.

•Pilot air inlet hole blocked by lint.

•No spark at electrode –tracking out somewhere –check for damaged insulation, distance of spark

gap, electrode damage, ceramic damage, dirt or soot on electrode.

•Flame not touching spark electrode (electrode needs to be in the flame so that valve can sense flame

through electrode as well as thermocouple).

•Flame signal shorted out (this can occur if any liquids e.g. leak detection spray has contaminated

pilot terminals connection).

•Spark cable is open circuit (spark may still be present due to ability to jump gaps, but if there is a

break in cable, or terminal connection is not good, valve will not receive sensing current –pilot may

also light but then continue to spark).

•Thermocouple aged or damaged and not producing enough output.

•Thermocouple insulation wire is damaged, electrical current shorting (e.g. to body).

NOTE: If stop is pressed during ignition cycle, E00 may also be generated. This is normal, and not a failure

condition.

THE VALVE CAN ATTEMPT TO SELF FIX ISSUES –When an E00 code has been displayed an internal

recalibration is initiated to attempt to compensate for possible deviations due to contamination, ageing, etc.

If the fire does not light on the first ignition cycle, allow the valve to complete the automatic recycles to

enable the valve to progress to E00 to recalibrate.

Reset error and try again.

15

E01

Indicates that there is a possibility that the level of CO in ambient atmosphere is too high.

This error will usually be generated when there had been a good electronic flame signal, and the temperature

of the thermocouple was hot enough, but has since become cooler.

Possible reasons:-

•Problems with chimney, or room, air inlets (insufficient air circulation).

•Unstable pilot flame (e.g. wind, unsuitable thermocouple position).

•Contaminated pilot (poor flame to thermocouple).

•Poor position of ceramic parts (e.g. coal, logs, or matrix).

•Intermittent failure in thermocouple when hot (inner wire in head perhaps making contact when cold,

but not when hot).

E02

Indicates that the ambient temperature around the gas control valve within the fire has exceeded 72°C.

NOTE: This error protects the fireplace and valve from excessive temperatures.

Possible reasons:-

•Faulty installation of the fire (not sealed correctly in fire opening).

•Problems with the chimney (insufficient air circulation).

•Poor position of ceramic parts (e.g. coals, logs, or matrix).

NOTE: Batteries do not tolerate high ambient temperatures, eventually this may cause leaking which could

damage the valve, meaning a new valve required (not covered under any warranty). Typically the maximum

ambient temperature for alkaline batteries is 50°C.

E03

Indicates there is an issue with the thermocouple connection to the valve, or that there is an incorrect

reading from the thermocouple.

Possible reasons:-

•No thermocouple connected.

•Thermocouple connection reversed/incorrect.

•Insulated thermocouple wire shorting to chassis earth (damaged insulation).

•Damaged, defective, or worn out thermocouple.

E04

Indicates a flame is detected on pilot after valve has shutdown.

Possible reasons:-

•Carbon or other conductive contamination on spark electrode.

•Combustible material burning on pilot near electrode (carbon deposits etc.).

•If EASYTEST box used –simulate flame mode not operated correctly.

16

E05

Indicates a flame is detected on pilot before valve has started.

Possible reasons:-

•Carbon or other conductive contamination on spark electrode.

•Combustible material burning on pilot near electrode (carbon deposits etc.).

•If EASYTEST box used –simulate flame mode not operated correctly.

E06 & E07

Indicates supply voltage is too low to operate valve.

Possible reasons:-

•Batteries are completely flat (random error codes may also be displayed in this case).

•Damaged battery contacts (dirty, corroded, bent –not making strong stable connections).

•Short circuit in external wiring or connected accessories.

•Defective mains power supply (if used) or damaged wiring.

•Problem with internal contacts of slide switch (sliding on/off multiple times may clear this issue).

•Batteries mounted incorrectly.

E08, E09, E10, E51

Indicates a device connected to TESC extension socket does not work correctly.

Possible reasons:-

•If nothing connected –are links missing, in wrong position, or connected badly?

•Failure in extension module connected to extension port.

E11, E12, E13, E18, E25, E28, E29, E30, E31, E33, E44, E45, E63

NOT APPLICABLE –SHOULD ONLY APPEAR DURING MANUFACTURE, IF AT ALL.

RESERVED FOR FUTURE USE.

E15, E15, E16, E17

Indicates buttons on valve (or wired control panel) do not work, or are incorrectly wired.

Possible reasons:-

•Buttons are sticking or blocked.

•Buttons are damaged.

•Cable damaged, or short circuit to ground (wired control panel).

NOTE: Disconnect wired panel (if applicable) and re-test to determine root cause.

17

E19, E20, E27, E50, E54, E57, E58, E59, E60, E61

Indicates internal CPU diagnostic self-test has returned invalid results.

Possible reasons:-

•EMC issue (try twisting ignition cable around thermocouple wire several times to quench radiated

EMC emissions).

•Spark tracking out somewhere other than at electrode causing unusual interference.

E21, E22

NOT APPLICABLE.

RESERVED FOR FUTURE USE.

E23

Indicates valve has performed 40k start operations.

END OF LIFE –valve has produced more than 40,000 burner starts.

Under normal use 40,000 starts will allow for 7 starts per day, every day, for more than 15 years.

E24

Indicates the thermocouple has not reached nominal final temperature within 1 minute of startup.

Possible reasons:-

•Aged thermocouple.

•Thermocouple wire insulation is damaged and shorting to metal chassis.

•Problems with chimney, or room, air inlets (insufficient air circulation).

•Unstable pilot flame (e.g. wind, unsuitable thermocouple position).

•Contaminated pilot (poor flame to thermocouple).

•Poor position of ceramic parts (e.g. coals, logs, or matrix).

E26

Indicates power supply with incorrect pin orientation connected to USB inlet.

E32, E43, E46, E47, E52, E53, E55, E56, E62

Indicates self-test procedure of valve electronics has failed.

Possible reasons:-

•Completely flat batteries.

•Liquid ingress affecting electronics (e.g. following leak test with soapy water).

18

E33, E34, E35, E36, E37, E38, E39, E40, E41, E42

Indicates internal piston is not moving freely.

Possible reasons:-

•Contamination of valve inlet/outlet with debris from supply pipe or other.

•Mechanical damage of valve.

NOTE: After cleaning and before resetting error codes, ensure fire has been allowed to fully cool. Upon

starting the valve will reinitialize and perform a re-calibration. The valve MUST be cold to perform this task.

NOTE: If the valve needs to be replaced, ensure to check pipework for contamination prior to fitting new

valve to help avoid repeated problems.

E48

Indicates that the control has detected a short circuit of the thermocouple.

Possible reasons:-

•Thermocouple connection reversed/incorrect.

•Insulated thermocouple wire shorting to chassis earth (damaged insulation).

•Damaged, defective, or worn out thermocouple.

•Weak connection from thermocouple to valve.

E49

Indicates valve has detected a false flame signal on electrode.

Possible reasons:-

•Contamination of the electrode with carbon deposits, conductive liquids (leak detection spray), or

similar.

•Contamination of thermocouple/valve connection with conductive liquids (leak detection spray), or

similar.

NOTE: It is critical to avoid leak detection fluid making contact with any part of the valve other than the

threaded pipe connections. Leak detection fluids are highly corrosive and will damage any electronics with

which they make contact. Other forms of leak detection should be used where possible.

19

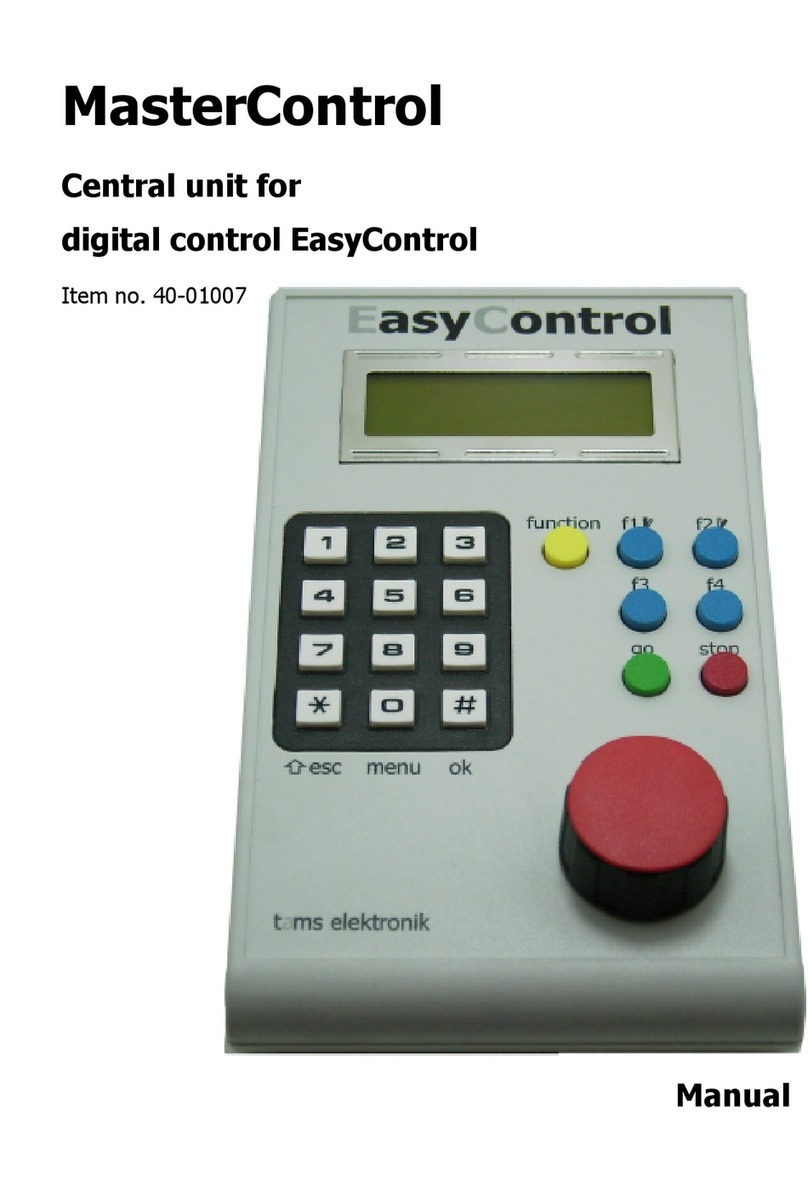

3.3 PILOT INFORMATION AND SERVICING.

Under normal circumstances, changing the pilot every 12 months forms part of any warranty

applicable to the fire. The pilot is a critical part for continued safety and good operation.

Cleaning of the pilot may be required more frequently than just the annual service, depending on the

fire construction and installation.

Images on the next pages give some examples of common problems, and illustrations of correct pilot

operation.

20

DUST BLOCKING AIR INLET APERTURE

EFFECT ON PILOT FLAME IF AIR INLET BLOCKED

CORRECT APPEARANCE OF PILOT FLAME

BOTH ELECTRODE TIP AND THERMOCOUPLE TIP IN BLUE FLAME

Table of contents

Popular Control Unit manuals by other brands

Cypress

Cypress CapSense CY3280-BMM quick start

Roger Technology

Roger Technology H70/101AC Instructions and Recomendations for the Installer

Texas Instruments

Texas Instruments TPS7A8300EVM-209 user guide

Strand

Strand Vision.Net DMX quick start guide

SIGLENT

SIGLENT STB3 user manual

Nordson EFD

Nordson EFD 752V-HL operating manual