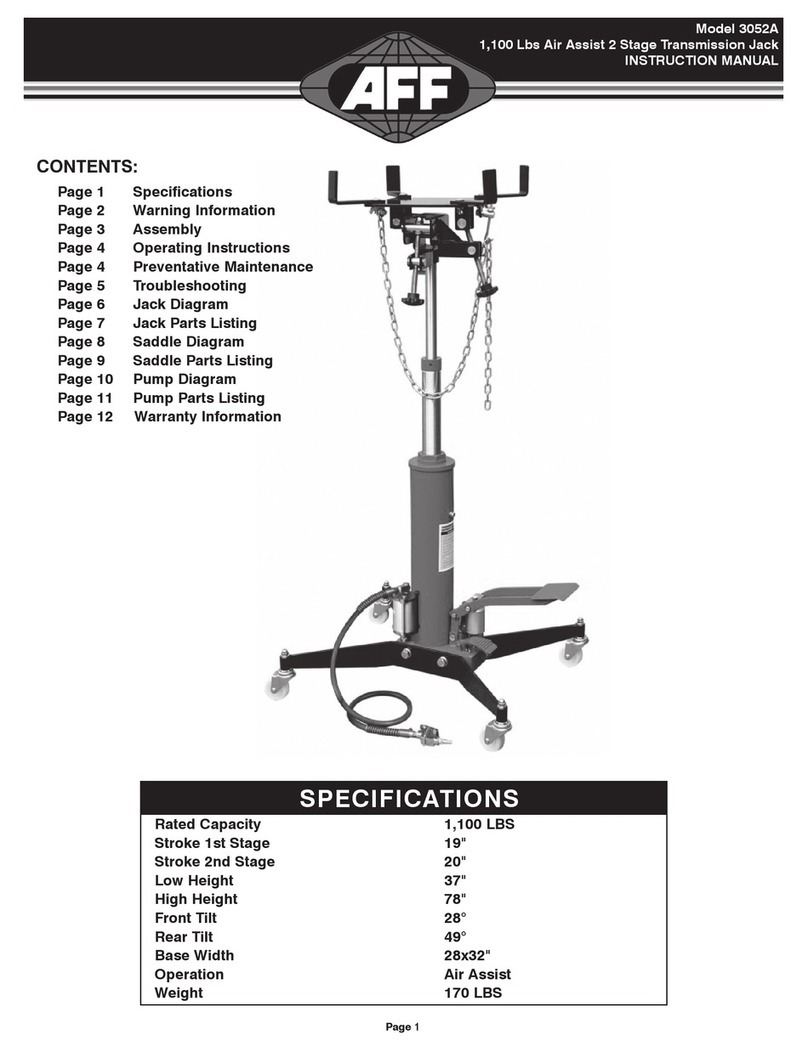

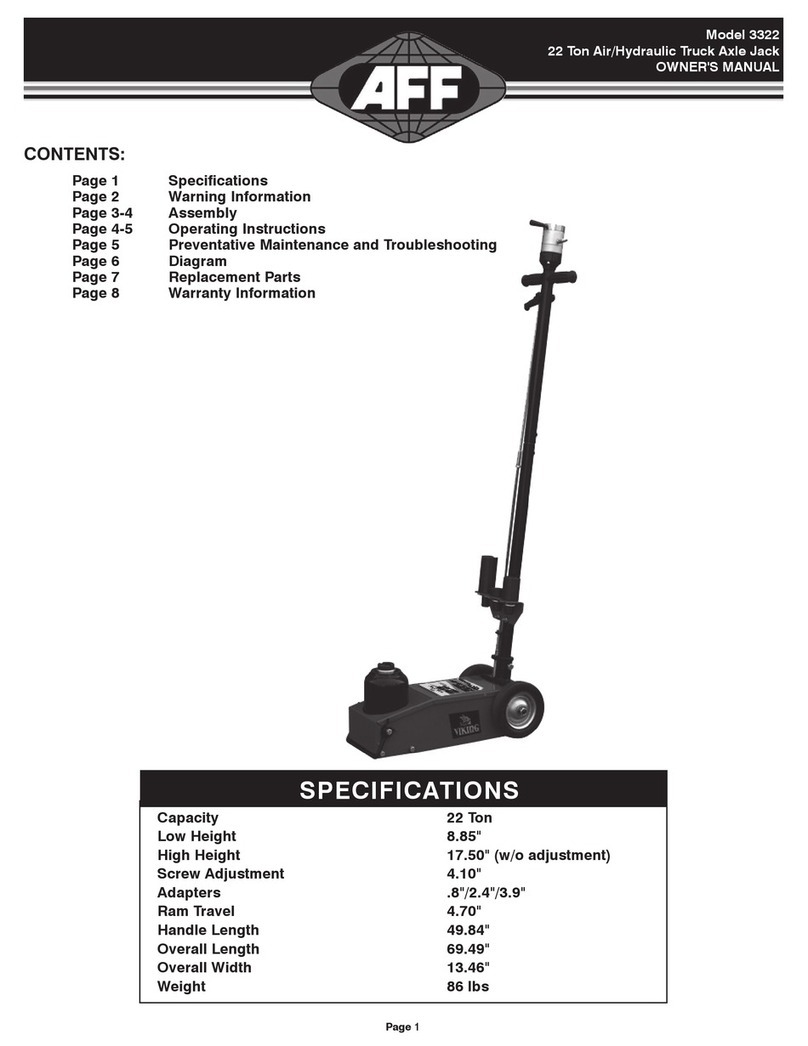

AFF 202LCJ User manual

AFF 202LCJ-INST-3.23.23-FA

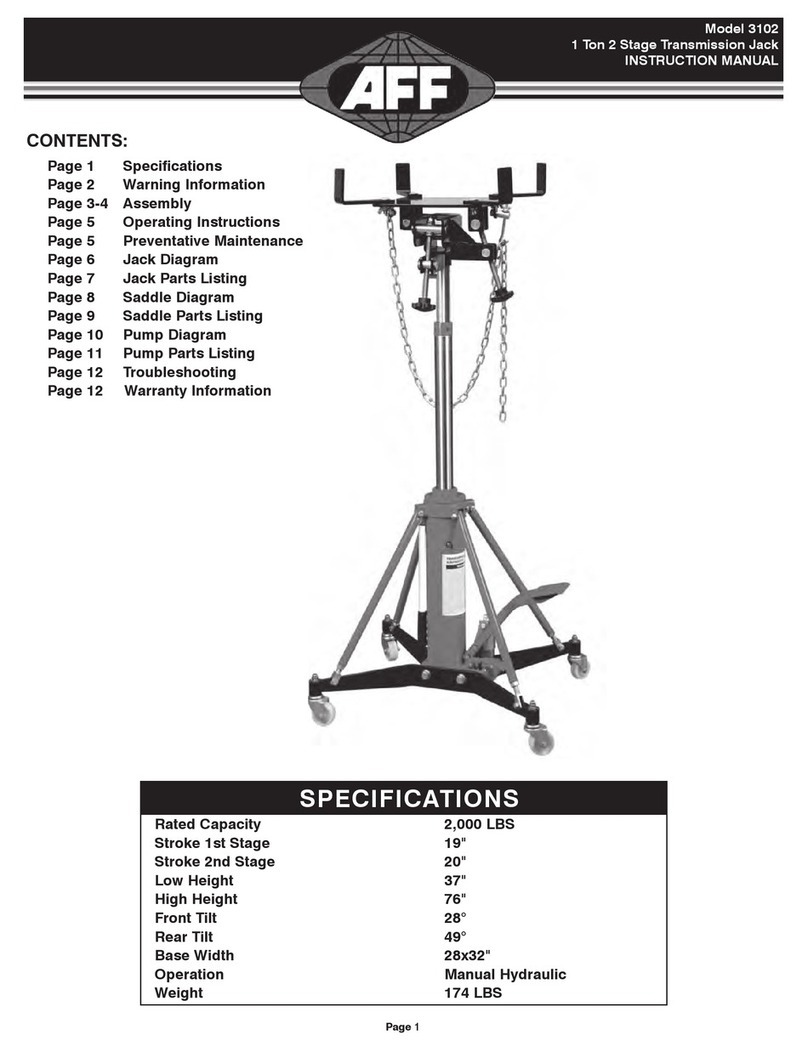

MODEL NO.: 202LCJ

WARNING:

IMPORTANT: READ THESE INSTRUCTIONS AND ALL

WARNINGS PRIOR TO USING THIS EQUIPMENT. UNDERSTAND

ALL OPERATING PROCEDURES, SAFETY WARNINGS AND

MAINTENANCE REQUIREMENTS. FAILURE TO DO SO COULD

CAUSE AN ACCIDENT RESULTING IN SERIOUS OR FATAL

INJURY AND/OR PERSONAL PROPERTY DAMAGE.

!

!

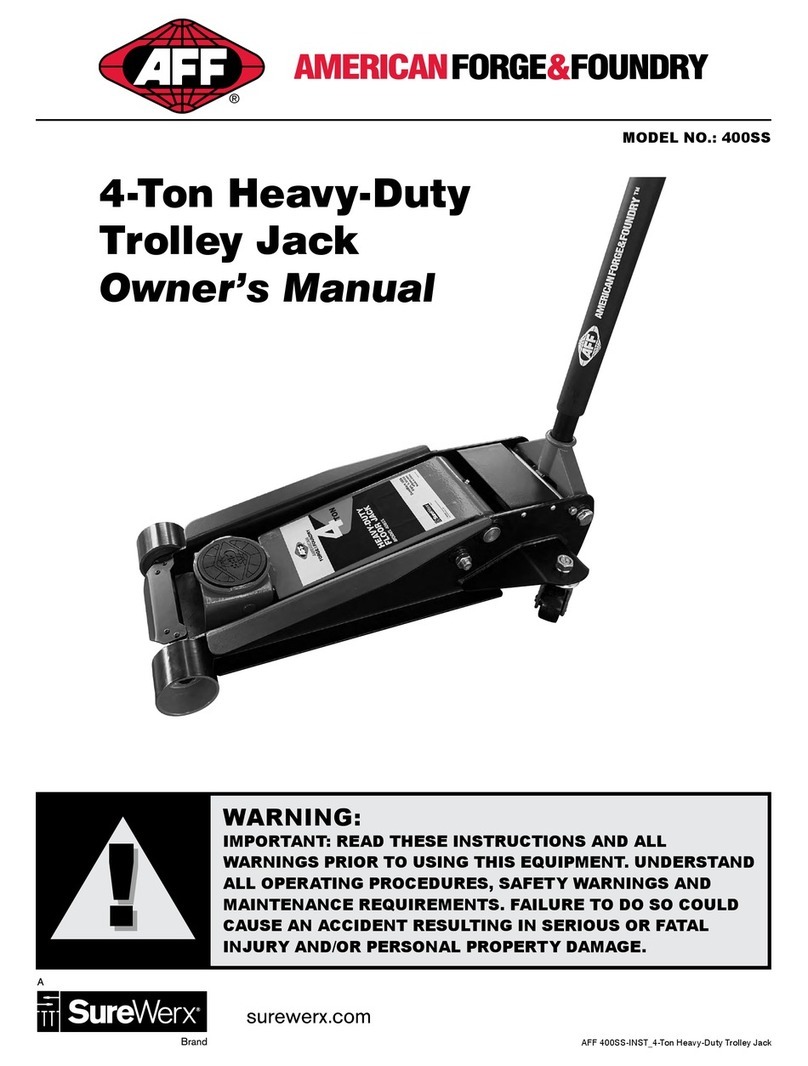

2-Ton Long Chassis

Floor Jack —

Super Duty

Owner’s Manual

affjaxx.com

2

GENERAL DESCRIPTION

SAFETY INFORMATION

PRODUCT DESCRIPTION

Hydraulic floor jacks are designed to lift, but not support, one end of a vehicle. Immediately after lifting, loads must be supported by

a pair of appropriately rated jack stands.

2.1 Locate the jack in a suitable working area.

2.2 Inspect the jack before each use. Do not use jack if damaged, altered, modified, in poor condition, leaking hydraulic fluid,

or unstable due to loose or missing hardware or parts. Make corrections before using.

2.3 Use jack on level and solid ground.

2.4 Ensure the vehicle handbrake is engaged, engine is switched off and transmissions in gear

(or “PARK” if automatic).

2.5 Ensure minimum distance of 0.5 m between vehicle and static objects such as doors, walls, etc.,

to allow for vehicle tilting.

2.6 Ensure all non-essential persons keep a safe distance while the jack is in use.

2.7 Do not exceed rated capacity of jack.

2.8 Place jack under only those lifting points recommended by vehicle manufacturer

(see vehicle handbook).

2.9 Check that the lifting point is stable and centered on the jack saddle.

2.10 Ensure the jack wheels are free to move and that there are no obstructions.

2.11 Use suitable axle stands under the vehicle before proceeding with any task.

2.12 Ensure there are no persons or obstructions beneath the vehicle before lowering.

2.13 Ensure proper routine maintenance is performed by a qualified individual.

2.14 Wear ANSI-approved safety goggles and heavy-duty working gloves during use.

2.15 When not in use store jack, fully lowered, in a safe, dry, childproof location.

DO NOT operate the jack if damaged.

DO NOT allow untrained persons to operate the jack.

DO NOT exceed the rated capacity of the jack.

DO NOT move or dolly the vehicle while it is on the jack.

DO NOT lift vehicle if there is a risk of spillage of fuel, battery acid, or other dangerous substances.

DO NOT work under the vehicle until appropriately supported.

DO NOT fill hydraulic system with brake fluid, alcohol or transmission oil. Use hydraulic jack oil only.

DO NOT adjust the safety overload valve.

The warnings, precautions, and instructions discussed in this manual cannot cover all possible conditions and situations that may

occur. The operator must understand that common sense and caution are factors, which cannot be built into this product, but must

be supplied by the operator.

WARNING: This product can expose you to chemicals including nickel, which is known to the State of California to cause cancer

and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov

affjaxx.com 3

A S S E M BLY

3.1 IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage. If any shipping damage is found, notify carrier at once.

Shipping damage is NOT covered by warranty. The carrier is responsible for all repair or replacement cost

resulting from damage in shipment.

3.1.1 CHECK THE PARTS IN THE CARTON

Visually inspect all components for any missing parts or damage. Refer to the packing list below.

No. Description Qty

1 Handle tube 1 1

2 Handle tube 2 1

3Jack body 1

4Instruction manual 1

3.2 ASSEMBLY

3.2.1 The jack comprises the following parts: Jack body, two-part pumping handle.

3.2.2 Unscrew the bolt from handle tube 1. Insert the upper handle into the lower handle.

Secure the two pieces together with the bolt (A).

Handle tube 1 Unscrew the bolt from the handle

Insert the upper tube Tighten the bolt

A

affjaxx.com

4

HYDRAULIC SYSTEM PURGING

4.1 Open the release valve by turning it two full turns counter-clockwise.

4.2 Pump the handle a minimum of four full strokes quickly.

4.3 Close the release valve by turning it clockwise.

4.4 Pumping the handle with full strokes to check if it can reach the maximum height by eight pumps.

If it can’t reach the maximum height by eight pumps, please refer to the following special purging process:

4.5 Open the release valve by turning counter-clockwise and lower the lifting arm to the minimum height.

4.6 Put the jack on a flat working table, carefully lift and support the front part of the jack to make sure

the front part is at least 500 mm higher than the end part of the jack.

4.7 Pump the handle a minimum of four full strokes quickly.

4.8 Put the jack on a flat surface and close the release valve by turning it clockwise.

4.9 Pumping the handle with full strokes to check if it can reach the maximum height by eight pumps,

if not please repeat the special purging process again.

3.2.3 Undo the screw (B) in the handle socket, until it no longer protrudes into the handle socket.

3.2.4 Insert the pump handle into the handle socket hole completely.

3.2.5 Ensure that the handle is completely inserted into the socket, then tighten the handle socket screw (B).

Please make sure that the handle can be turned smoothly

B

IMPORTANT

affjaxx.com 5

OPERATING INSTRUCTIONS

5.1 RAISING A VEHICLE

5.1.1 Ensure that the jack and the vehicle are on a hard, level surface.

5.1.2 Always ensure that the vehicle handbrake is engaged and that the vehicle wheels are chocked.

5.1.3 Consult the vehicle manual to determine the location of jacking points.

Position the jack under a suitable lifting point.

5.1.4 Turn the handle clockwise, to close release valve. DO NOT over-tighten.

5.1.5 Raise the vehicle to the desired height by pumping the handle up and down.

5.1.6 Immediately support the vehicle with appropriate means such as vehicle support stands.

5.1.7 Turn the release valve slowly counter-clockwise to lower the vehicle on to the vehicle support stands.

5.2 LOWERING A VEHICLE

5.2.1 Ensure that the area under and around the vehicle is clear of people and obstructions.

5.2.2 Turn the release valve clockwise to close it.

5.2.3 Pump the handle to raise the vehicle off the vehicle support stands.

5.2.4 Remove the vehicle support stands from beneath the vehicle.

5.2.5 Turn the release valve slowly counter-clockwise to lower the vehicle to the ground.

NOTE: When the jack not in use, ALWAYS leave the saddle and ram fully retracted.

CAUTION: Keep hands and feet away from the hinge mechanism of the jack.

IMPORTANT: Only fully qualified personnel should attempt maintenance or repair.

Before use ensure you have read and understood Section 2, Safety Information.

Before use, the operator is to visually inspect the jack for cracked welds, damaged or missing parts or hydraulic leak.

affjaxx.com

6

MAINTENANCE

6.1 MONTHLY MAINTENANCE

Periodic lubrication is critical to jacks. Any restriction due to dirt or rust can cause either slow jack movement, or extremely

rapid jerks, causing damage to the internal components. To keep the jack well lubricated, carry out the following steps.

6.1.1 Lubricate the linkages the saddle and pump mechanism with light oil.

6.1.3 Keep all jack surfaces and warning labels clean.

6.2 TRI-MONTHLY MAINTENANCE

6.2.1 At tri-monthly intervals, check the pump for any signs of rust or corrosion.

Clean the pump as required and wipe with an oil cloth.

6.3 CHECKING THE OIL LEVEL

6.3.1 Fully retract the ram by turning the release valve counter-clockwise.

6.3.2 Loosen and take off the four top plate retaining screws and remove the top plate vertically as pictured below.

Linkage (1)

Roller Pin (right)

Linkage (2)

Roller Pin (left)

Linkage (3)

Lifting Arm

6.1.2 Grease the wheel bearing and axles.

affjaxx.com 7

6.3.3 With the jack in the level position, remove the oil filler plug.

6.3.4 The proper oil volume should be the maximum distance from the oil surface level to the top of pump and

should be less than 11 mm. If there is not enough oil, please add hydraulic oil according to Section 6.4.

6.3.5 Replace the oil filler plug.

6.3.6 After adding oil, please checking if the jack can reach the maximum height with eight pumps.

If not, please purge air from the hydraulic unit as required. Refer to Section 4.

6.3.7 Cover the top plate, then tighten the four screws.

6.4 ADDING OIL

6.4.1 Fully retract the ram by turning the release valve counter-clockwise.

6.4.2 Loosen and take off the four top plate retaining screwsand remove the top plate vertically as pictured below.

6.4.3 With the jack in the level position, remove the oil filler plug.

6.4.4 Fill with oil through the oil hole and make sure the oil surface level to the top of oil tank is less than 11 mm.

affjaxx.com

8

6.4.5 Replace the oil filler plug, purge air from the hydraulic unit as required. Refer to Section 4.

6.4.6 Replace the top plate and tighten the four screws.

TROUBLESHOOTING

PROBLEM CAUSE REMEDY

Jack will not lift to full height 1. Oil level low

2. Release valve not closing

1. Check / add oil

2. Close the release valve

Jack will not hold the load 1. Release valve not closing

2. Hydraulic oil is contaminated

3. Pump leaking

1. Close the release valve

2. Contact authorized

service agent

Lift arm will not lower 1. Pump cylinder binding

2. Parts worn

3. Internal component damage

4. Return spring broken or unhooked

5. Lift arm linkage either bent or binding

6. Air in the hydraulic system

1. Contact authorized

service agent

After hydraulic purging, the jack still

can’t reach the maximum by eight pumps

1. Still have air in the hydraulic system 1. Purge air according to

manual Part 4.5

Poor lift performance 1. Fluid level low

2. Hydraulic unit malfunction

1. Ensure proper fluid level

2. Discontinue use, contact

authorized service agent

28

38

37

39

36

35

33

32

34

39

40

41

42

27

27

43

44

45

29

23

22

24

27

202118

15 17 16 14

14

13

5

5

6

8

9

7

4

1

1

2

2

3

3

11

11

10

12

12

26

25

19

31 30

34

13

40

41

8

6

5

affjaxx.com 9

PART

NUMBER

KIT DESCRIPTION RE F. # KIT INCLUDES

202LCJ-24 Handle 24 Upper Handle

25 Lower Handle

26 Handle Protection

202LCJ-26 Handle Protection 26 Handle Protection

202LCJ-37 Saddle Complete 37 Saddle Complete

38 Bolt

28 Saddle Pad

202LCJ-29 Cover 29 Cover

15 Screws Qty 4

202LCJ-7 Caster 7Caster

5 Washer

18 Nut

PART

NUMBER

KIT DESCRIPTION RE F. # KIT INCLUDES

202LCJ-27 Oiler Bowl 27 Oiler Bowl

202LCJ-3 Wheel 3Wheel

2 Washer

1 Retaining Ring

202LCJ-30 Power Unit 30 Power Unit

202LCJ-3 Spring 31 Spring

202LCJ-33 Block Linkage 33 Block Linkage

34 Retainer Ring

202LCJ-22 Handle Screw 22 Handle Screw

202LCJ-50 Release Valve 50 Release Valve

202LCJ-RK Repair Kit Repair Kit

PARTS LIST: 2-TON LONG CHASSIS FLOOR JACK — PARTS BREAKDOWN —

Prod. No. 202LCJ

31

37

36

35

34

39

40

41

42

43

44

45

45

46

47

48

49

50

51

52

53

54

58

45

14

13

12

11

10

17

16

15

18

19

20

21

22

23

24

25 26

9

8

5

6

7

6

5

4

3

2

1

45

55

56

57

38

33

32

17

16

30

29

28

27

affjaxx.com

10

affjaxx.com 11

PART

NUMBER

KIT DESCRIPTION REQ.

1Tank Nut 1

2 O-Ring 36 x 3.5 1

3Washer 1

4Ram 1

5 Backup Ring 2

6 O-Ring 12.5 x 2.65 2

7 Backup Ring 1

8Guide Ring 1

9 Snap Ring 17 1

10 Spacer Ring 1

11 Guide Ring 1

12 Washer 1

13 U-Seal 1

14 Retaining Ring 25 1

15 Cylinder Outer Case 1

16 O-Ring 8.5 x 1.8 2

17 Screw 2

18 Cylinder Outer Case 1

19 Backup Ring 1

20 O-Ring 46.2 x 2.2 1

PART

NUMBER

KIT DESCRIPTION REQ.

21 Washer 1

22 Washer 1

23 Piston Rod 1

24 Washer 1

25 Permanent Magnet 1

26 Valve Base 1

27 Washer 1

28 Pump Case 1

29 U-Seal 1

30 Backup Ring 1

31 O-Ring 10 x 2.65 1

32 Backup Ring 1

33 Pump Core 1

34 Pressure Spring 1

35 Pump Outer Case 1

36 Pump Cover 1

37 Snap Ring 1

38 Safety Valve 1

39 Relief Valve Spring 1

40 Screw 1

PART

NUMBER

KIT DESCRIPTION REQ.

41 Screw 1

42 Ball 10 1

43 Separator 1

44 Ball 8 1

45 Ball 6 4

46 O-Ring 8 x 1.8 1

47 Locker 1

48 Spring Washer 6 1

49 Screw 1

50 Release Assembly 1

51 Screw 1

52 Backup Ring 1

53 O-Ring 6 x 2.65 1

54 Pressure Spring 1

55 Ball 4 1

56 Screw M6 x 10 1

57 Ball 5 1

58 Ball Saddle 1

PARTS LIST: 2-TON LONG CHASSIS FLOOR JACK — PARTS BREAKDOWN —

Prod. No. 202LCJ

affjaxx.com

12

LIMITED WARRANTY

SureWerx USA WARRANTS TO ITS CUSTOMERS THAT THE COMPANY’S SureWerx USA “AFF” BRANDED

PRODUCTS ARE FREE FROM DEFECTS IN WORKMANSHIP AND MATERIALS.

SureWerx USA will repair or replace its SureWerx USA “AFF” branded products which fail to give satisfactory

service due to defective workmanship or materials, based upon the terms and conditions of the following described

warranty plans attributed to that specific product. This product carries a ONE-YEAR warranty. During this warranty

period, SureWerx USA will repair or replace at our option any part or unit which proves to be defective in material

or workmanship.

Other important warranty information:

This warranty does not cover damage to equipment or tools arising from alteration, abuse, misuse, damage and

does not cover any repairs or replacement made by anyone other than SureWerx USA. The foregoing obligation is

SureWerx USA’s sole liability under this or any implied warranty and under no circumstances shall we be liable for

any incidental or consequential damages.

Note: Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you. If you have any questions about warranty service, please contact

SureWerx USA. This warranty gives you specific legal rights and you may also have other rights which vary from

state to state.

SureWerx, USA Inc.,

325 Corporate Drive, Elgin, IL USA 60123

surewerx.com/usa

affjaxx.com

800-323-7402

520-INST-0922

Table of contents

Other AFF Jack manuals

Popular Jack manuals by other brands

Mega

Mega BR2 Operation and maintenance instructions

K Tool International

K Tool International KTI-XD63133 owner's manual

Pro-Lift

Pro-Lift F1800A owner's manual

Sealey

Sealey 2800HL instructions

Gude

Gude GHS 1000 Translation of original operating instructions

Lippert

Lippert 285420 Installation and owner's manual