WARNING

NEVER FORGET TO LOCK THE

CASTOR WHEELS

02USAGE ADVICEUSAGE ADVICE

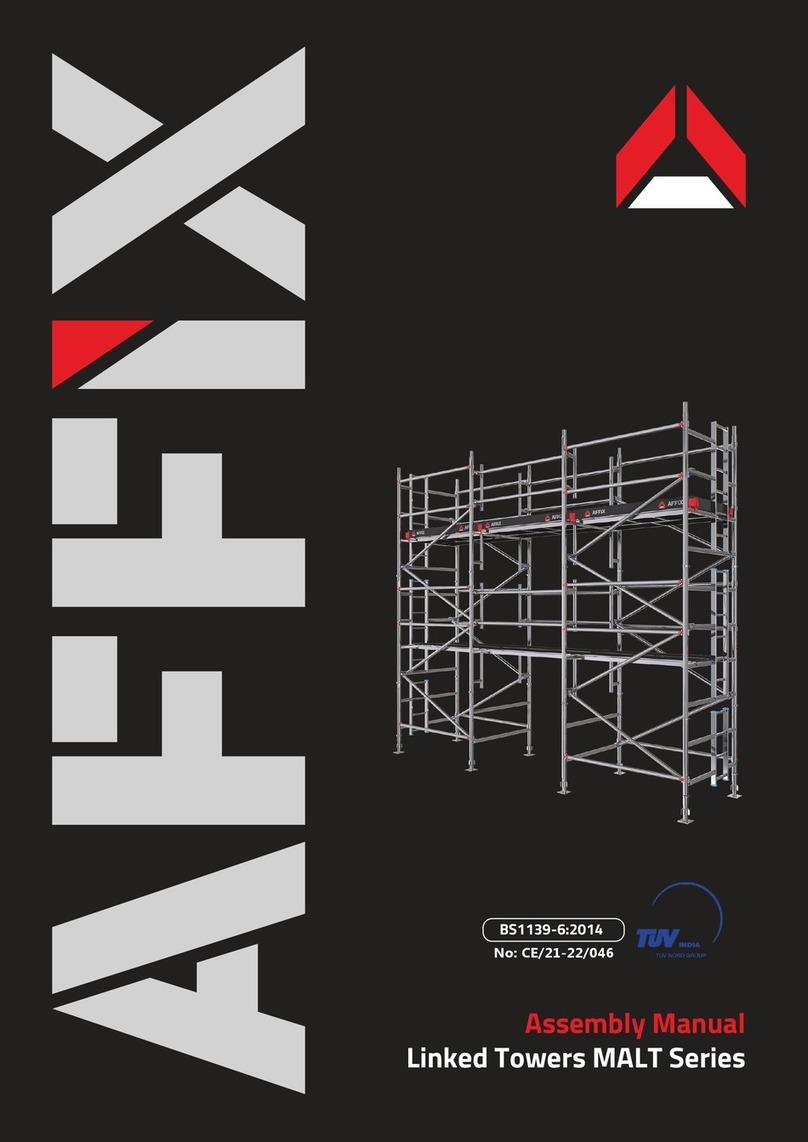

DESCRIPTION:

Through The Trapdoor (3T) Method:

The 3T method of construction is an approved method of assembly and it minimizes the risk of

a fall from height. The erector can complete an ‘assembly or access’ platform level from which

the ‘next lift’ of frames, braces and platform is added, until the final working height of the tower

is achieved. By following the 3T method, the erector sits through the hatch of the platform with

their feet resting on the frame rungs. In this position the erector can attach the guardrail braces.

Once guard-rails are secured in position the erector can climb onto the platform and continue

constructing the next level.

Compliances:

The Affix MAST Tower structure and its components have been designed in accordance with

BS1139-6: 2014.

The Affix MAST Series Stair Tower are versatile and user-friendly and safe portable access

solution which is specifically designed for use on commercial and domestic staircases. It has a

compact width of just 0.9 Mtr which enables easy transportation through standard doorways

and stairways. It gives a work platform for use by a maximum of two people, with weight evenly

distributed across the platform. The tower can be easily erected and with highly customizable

assembly it meets almost all the site constraints and provides safe and efficient working

platform. The key safety feature is the smart locking claws provided for the horizontal and

diagonal bracings. It allows an instant lock-up performed by single hand use, however, with the

reverse unlocking plug, two hands are needed to unplug the bracing.

The information and instructions included in this manual are provided to help get the best

possible service from your MAST Series Stair Tower. This user guide provides you with step by

step instructions to ensure your system is assembled easily and safely, using the 3T (Through

the Trapdoor) method.

MAST620_AM-3T_V3.0