Caution! Carefully read the owners manual and the following warnings prior

to use. Failure to comply with the following may result in serious bodily

injury, death, or damage to the lift. If you have questions, contact Customer

Support at (USA) 434-515-2321 (Provide your Serial Number 'E9997' and

contact information when you call).

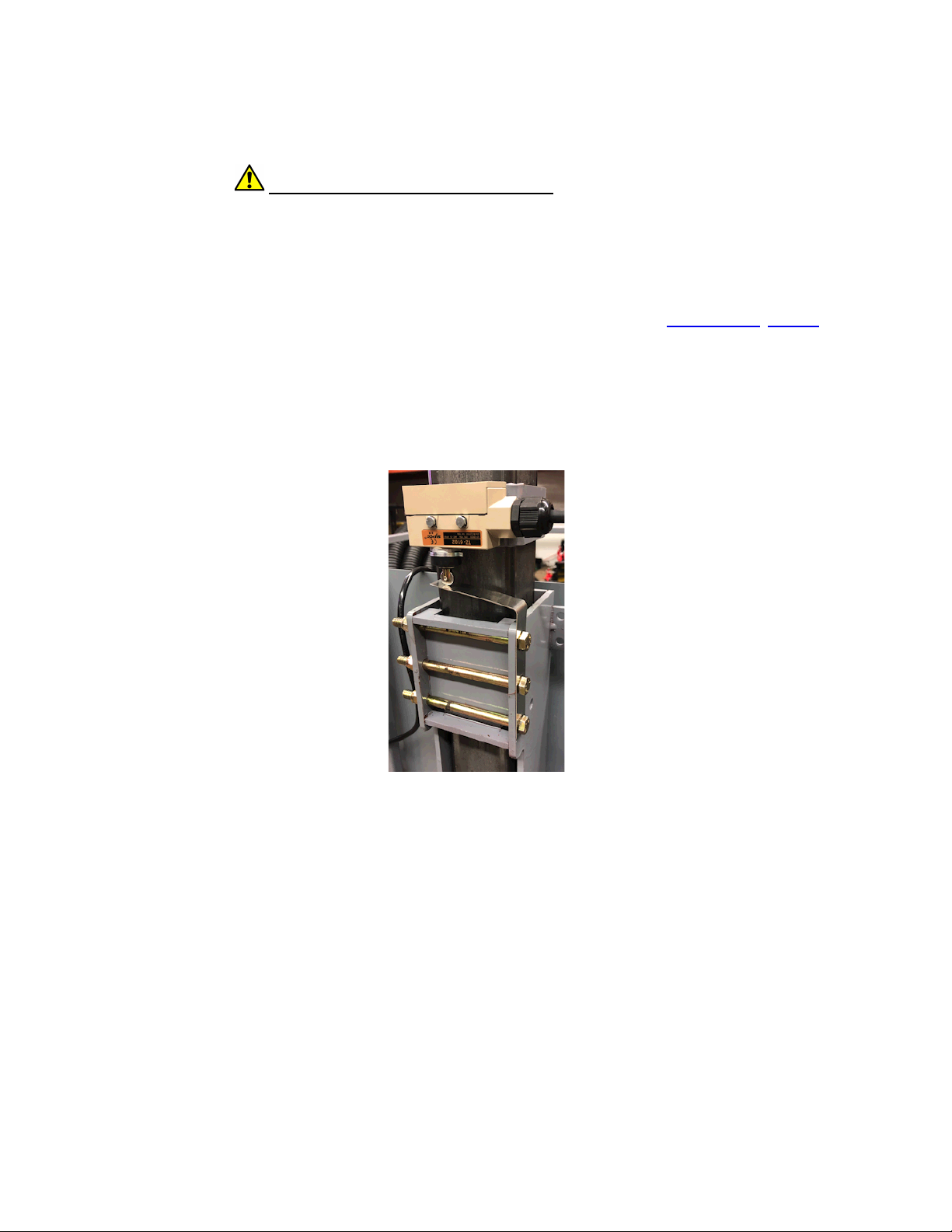

Prior to use, ensure that the safety mechanism is in place properly. Never use a lift without a safety mechanism properly

installed and functional!

Prior to each use, inspect the cable and components for signs of fraying or damage.

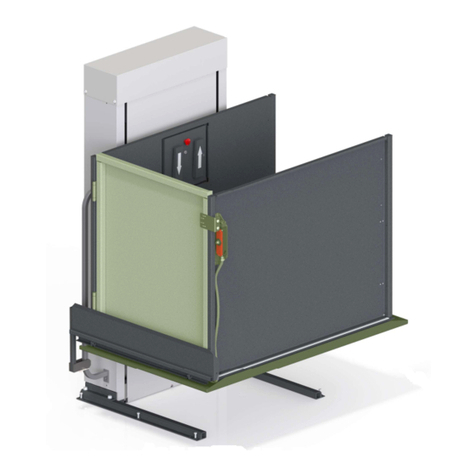

Always lock gates prior to use. Never operate the lift with any gates unsecured.

Always lock/secure wheelchair or cargo from shifting while in use.

This lift is to be used exclusively for the transport of cargo or a wheelchair and occupant and an additional adult where

Improper use of lift may result in personal injury or damage to the lift. All users must read and follow operating

instructions prior to use of lift.

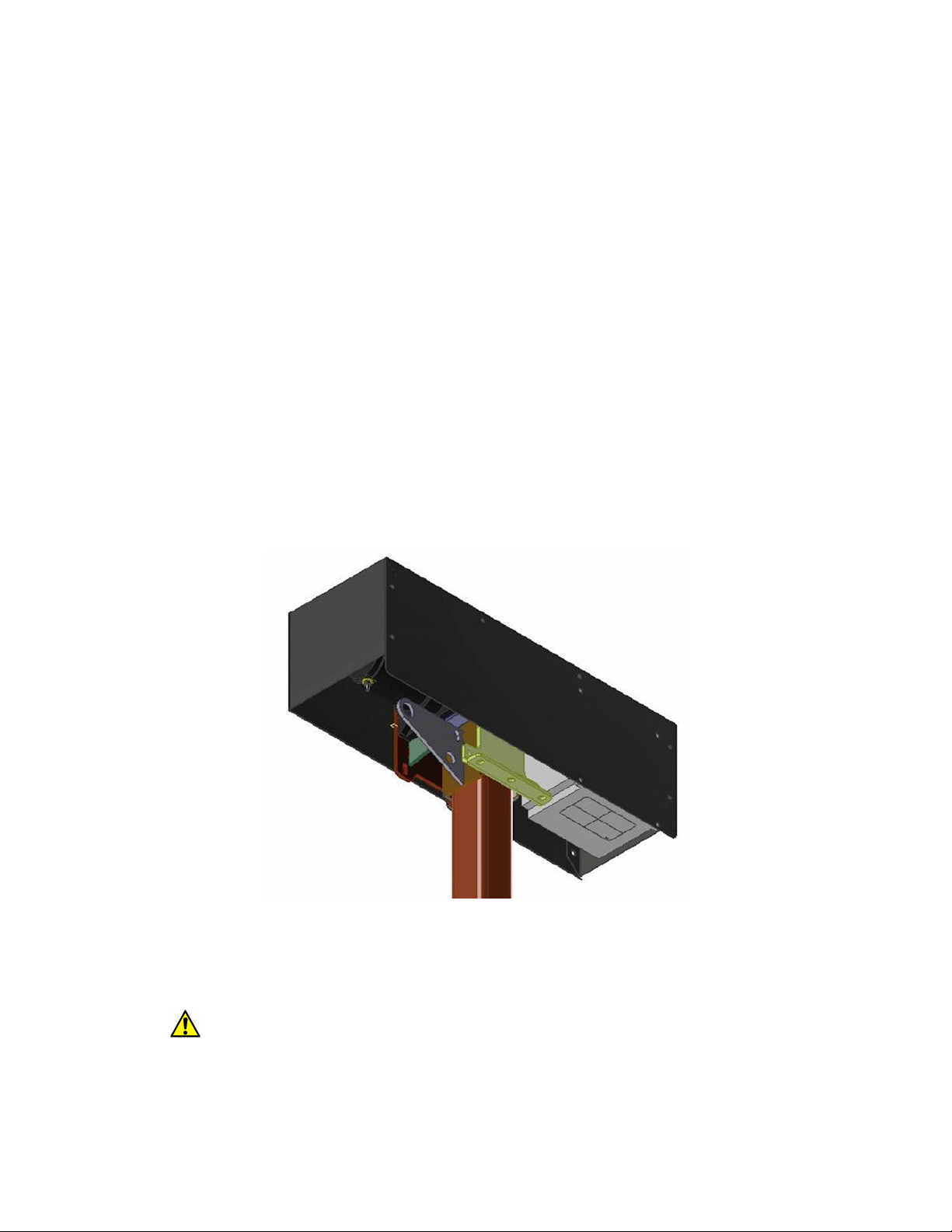

Ensure that the lift is properly installed and is stable prior to use of the lift. Failure to ensure proper installation may result

in an increased risk that the lift will tip over or otherwise malfunction, resulting in damage to the lift and/or personal injury.

Do not exceed the maximum load capacity.

Remain in the correct, upright position while the lift is in use. Keep entire body within the lift at all times. Failure to

remain in position may result in pinch or crush hazards at the deck/flooring platform and property damage or personal

injury from a malfunction of the lift or falling from the lift.

If the lift is installed to go through an opening to another level, it is particularly important to never rest arms, feet or limbs

on handrails or extending from the lift. Narrow openings pose a substantial risk of injury to the lift or serious personal

Prior to use, ensure that electrical power is installed on a grounded electrical circuit.

Prior to use, inspect for proper function, required maintenance, or damage. If a problem exists, cease use of the lift

immediately. Do not attempt to make repairs or alterations to the lift. Contact a licensed professional or customer support

for any necessary repairs.

Do not conduct any maintenance, repairs, or otherwise work on this lift while it is operational or plugged in unless

instructed to do so by customer support.

Do not alter or modify this lift or any of its safety devices in any way.

Do not expose any electronic part of this lift to liquid or harsh weather conditions.

Do not use if snow, ice, or other debris have accumulated on the lift.

Do not operate this lift in the presence of combustible or explosive gas or fumes.

Completely disconnect the lift from its power source prior to cleaning the lift.

Do not operate this lift if you are under the age of eighteen (18) years old. All users of this lift who are under the age of

eighteen (18) years old must be accompanied by an adult who is authorized to use this lift and has read its operating

Keep children away from this lift at all times unless using this lift while accompanied by an authorized adult who has

read its operating instructions.

Do not stand or place any body part under the lift platform at any time.

When using the lift, ensure that no persons, pets or objects are in the upward or downward path of the lift platform or

Keep all loose articles, hair, and other objects away from the moving portions of the lift at all times.

Keep hands and feet away from moving parts while the lift is operational

Do not store any items or objects on or under the lift platform.

Store lift in a temperature controlled, dry environment when not installed for use.

Ensure that the lift platform is fully in the down position and all electrical components are disconnected from power prior

Use appropriate lifting/transport precautions when moving the lift. The lift is very heavy.

Keep lift controllers in a secure location out of reach of children.

Remain aware of your surroundings and ensure you are able to hear well at all times while the lift is in use

FAILURE TO COMPLY WITH ANY OF THE ABOVE WARNINGS MAY RESULT IN

SERIOUS BODILY INJURY, DEATH, CRUSH, ELECTRICAL, TRIPPING

HAZARDS OR DAMAGE TO THE LIFT.