AFFORDABLE LIFTS KCSPM3648 Setup guide

Assembly And Installation Manual For

Affordable Lift Model KCSPM3648

Specifically For Serial Number E9997B

Manual Print Date: Dec 01, 2023, 12:50 PM EST

Lift E9997B Specifications:

Station Height:

38.0"

Weight Capacity:

500 lbs

Column Length:

78.0"

Color:

Gloss Black

Motor:

1500 lbs w/ Tethered Controller

Base:

Armed Base

Safety System:

Self Retracting Lifeline (SRL)

Column Bracing:

None/NA

Wheel Kit:

Yes

Rain Guard:

Yes

Battery Backup:

Not Purchased

Shipped As:

Disassembled

Shipped On:

On A Regular Pallet

All images in this manual are representational only.

Table of Contents

Click on a Section to jump to that section.

Section

Section Number

Introduction

Section 1

Safety

Section 2

Warnings

Section 3

Ter mi no lo gy

Section 4

Prepare to Install Your Lift

Section 5

The Wheel Kit

Section 6

Unpack Your Lift

Section 7

Remove Safety Guard

Section 8

Connect the Armed Base, Column and Hoist Assembly

Section 9

Attach the Platform to the Column

Section 10

Safety Backup System

Section 11

Electrical Power

Section 12

Connect Your Synthetic Rope

Section 13

Test Your Lift

Section 14

Adjust Your Lift’s Maximum Height

Section 15

Anchoring The Armed Base

Section 16

Finalize Column Bracing

Section 17

Reinstall Safety Guard

Section 18

Platform Gates

Section 19

Minimize Platform “Twist”

Section 20

Controller Storage Box

Section 21

The Transition Ramp

Section 22

Battery Backup

Section 23

Canopy Frame

Section 24

Maintenance

Section 25

Troubleshooting

Section 26

1. Introduction

Congratulations on your purchase of a new platform lift! We sincerely hope that this lift will help you accomplish the things that

are important to you and those you love.

Note:

If you are like me, then you hate reading instructions almost as much as you hate having to do things over because you

did it wrong. Unfortunately, this product can be assembled backwards, and doing so cannot be remedied without taking it

all apart and starting over. These instructions are specifically written to prevent those mistakes. So, please refer to these

instructions with each step, and have a pleasant assembly.

Note:

We have many of the assembly steps recorded on video for your reference. These videos are not a substitute for this

manual. They should be used alongside this manual. To find the videos use the video links throughout this manual or

Click

Here

.

Note:

The photos in this guide display lifts in various stages of installation. It is often the case that some recommended safety

feature is not yet in place in a specific photo. In particular, an anti-pinch point wall and a basic stair handrail are missing in

some of the scenarios we photographed.

Note:

There are some minor design changes between different lifts pictured here. These photos might not exactly match your

particular lift.

Note:

Even if your lift was shipped disassembled, some portions of it may have been pre assembled for you.

Note:

If your lift was shipped with some bolts and fasteners already in place and you find it necessary to temporarily remove

them, they must be re-inserted in the same direction. Inserting the bolt in the opposite direction may cause problems.

Note:

Throughout this document this is used as a caution symbol:

Please abide by all safety precautions so that you can

safely enjoy your lift and all that it has to offer.

2. Safety

2.1.

Safety is paramount!

If you have a question or concern about the safe installation or operation of your lift please call

Customer Support at (USA) 434-515-2321 (Provide your Serial Number 'E9997B' and contact information when you call).

2.2.

DO NOT USE YOUR LIFT OR ALLOW OTHERS TO USE YOUR LIFT IF YOU SUSPECT IT MAY BE IN AN

UNSAFE CONDITION

2.3. Warning:

No one should ride the lift until the Safety Backup System is installed and all lift testing is complete.

2.4.

Use common sense when installing or operating this equipment. Please read all the instructions before beginning

assembly and installation.

2.5.

The installer and operator are responsible for the safe operation of this equipment.

It is your responsibility to ensure

and verify that this equipment is safely installed. It is your responsibility to ensure and verify that inspections and

maintenance is done.

It is your responsibility to know and comply with all applicable legal codes and regulations regarding

your platform lift.

2.6.

Be sure to lift heavy objects using your legs, not your back.

2.7.

Do not allow children or people who are not able to understand the safe operation of the lift to use or play with the

controllers. Letting unqualified people operate the lift without supervision puts them and anyone around the lift at severe

risk. Allow only capable persons to operate the lift.

2.8.

"Pinch Point" risk is inherent in any mechanical device of this nature. This is the risk of something (such as a toe) getting

caught underneath something as the Platform ascends.

Inadequate vigilance and safety in pinch point risk areas can

cause injury or death or can harm your lift.

A common and prominent pinch point risk area is any gap underneath a

landing, such as a porch or deck. We recommend that you identify any such areas in and around your lift and take safety

precautions. Eliminate pinch point risk by covering openings below the landing with a vertical or angled plywood wall to

prevent body parts and items from being trapped between a landing or floor and the Platform as the lift ascends upwards

from the ground.

Below are two "shear points" before and after installing two different types of shear protection:

Misuse of this equipment can cause serious injury or even death

3. Warnings

Caution! Carefully read the owners manual and the following warnings prior

to use. Failure to comply with the following may result in serious bodily

injury, death, or damage to the lift. If you have questions, contact Customer

Support at (USA) 434-515-2321 (Provide your Serial Number 'E9997B' and

contact information when you call).

!"

Prior to use, ensure that the safety mechanism is in place properly. Never use a lift without a safety mechanism properly

installed and functional!

!"

Prior to each use, inspect the cable and components for signs of fraying or damage.

!"

Always lock gates prior to use. Never operate the lift with any gates unsecured.

!"

Always lock/secure wheelchair or cargo from shifting while in use.

!"

This lift is to be used exclusively for the transport of cargo or a wheelchair and occupant and an additional adult where

assistance is required.

!"

Improper use of lift may result in personal injury or damage to the lift. All users must read and follow operating

instructions prior to use of lift.

!"

Ensure that the lift is properly installed and is stable prior to use of the lift. Failure to ensure proper installation may result

in an increased risk that the lift will tip over or otherwise malfunction, resulting in damage to the lift and/or personal injury.

!"

Do not exceed the maximum load capacity.

!"

Remain in the correct, upright position while the lift is in use. Keep entire body within the lift at all times. Failure to

remain in position may result in pinch or crush hazards at the deck/flooring platform and property damage or personal

injury from a malfunction of the lift or falling from the lift.

!"

If the lift is installed to go through an opening to another level, it is particularly important to never rest arms, feet or limbs

on handrails or extending from the lift. Narrow openings pose a substantial risk of injury to the lift or serious personal

injury.

!"

Prior to use, ensure that electrical power is installed on a grounded electrical circuit.

!"

Prior to use, inspect for proper function, required maintenance, or damage. If a problem exists, cease use of the lift

immediately. Do not attempt to make repairs or alterations to the lift. Contact a licensed professional or customer support

for any necessary repairs.

!"

Do not conduct any maintenance, repairs, or otherwise work on this lift while it is operational or plugged in unless

instructed to do so by customer support.

!"

Do not alter or modify this lift or any of its safety devices in any way.

!"

Do not expose any electronic part of this lift to liquid or harsh weather conditions.

!"

Do not use if snow, ice, or other debris have accumulated on the lift.

!"

Do not operate this lift in the presence of combustible or explosive gas or fumes.

!"

Completely disconnect the lift from its power source prior to cleaning the lift.

!"

Do not operate this lift if you are under the age of eighteen (18) years old. All users of this lift who are under the age of

eighteen (18) years old must be accompanied by an adult who is authorized to use this lift and has read its operating

instructions.

!"

Keep children away from this lift at all times unless using this lift while accompanied by an authorized adult who has

read its operating instructions.

!"

Do not stand or place any body part under the lift platform at any time.

!"

When using the lift, ensure that no persons, pets or objects are in the upward or downward path of the lift platform or

collar.

!"

Keep all loose articles, hair, and other objects away from the moving portions of the lift at all times.

!"

Keep hands and feet away from moving parts while the lift is operational

!"

Do not store any items or objects on or under the lift platform.

!"

Store lift in a temperature controlled, dry environment when not installed for use.

!"

Ensure that the lift platform is fully in the down position and all electrical components are disconnected from power prior

to moving the lift.

!"

Use appropriate lifting/transport precautions when moving the lift. The lift is very heavy.

!"

Keep lift controllers in a secure location out of reach of children.

!"

Remain aware of your surroundings and ensure you are able to hear well at all times while the lift is in use

FAILURE TO COMPLY WITH ANY OF THE ABOVE WARNINGS MAY RESULT IN

SERIOUS BODILY INJURY, DEATH, CRUSH, ELECTRICAL, TRIPPING

HAZARDS OR DAMAGE TO THE LIFT.

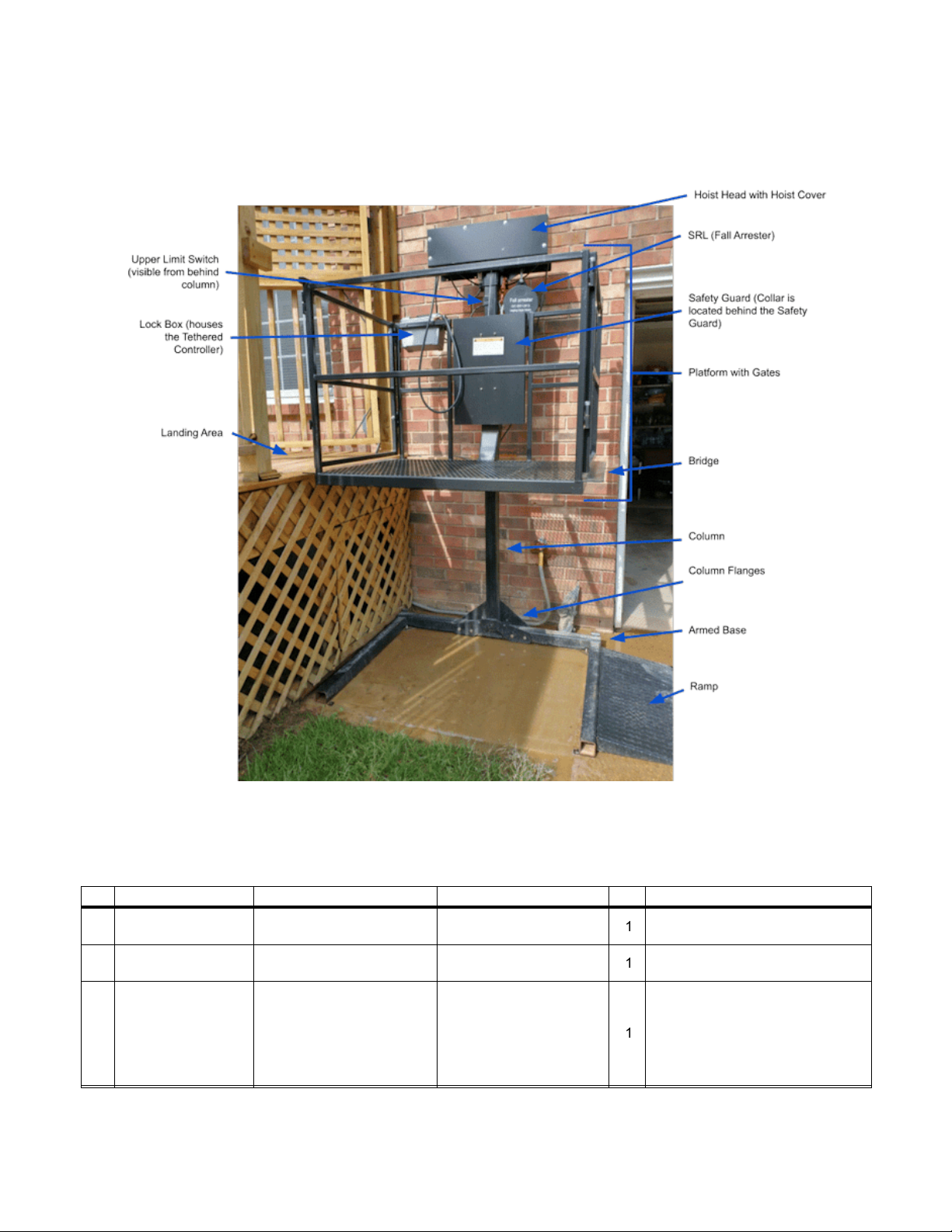

4. Terminology

4.1.

Front, Back, Right and Left Sides:

The Column is located on the back side of the lift. The side of the lift opposite the

back side is the front side. Right and left are determined when you face the lift's Platform from the front.

4.2.

Please look over the sample photo below to familiarize yourself with the important parts of your Affordable Lift.

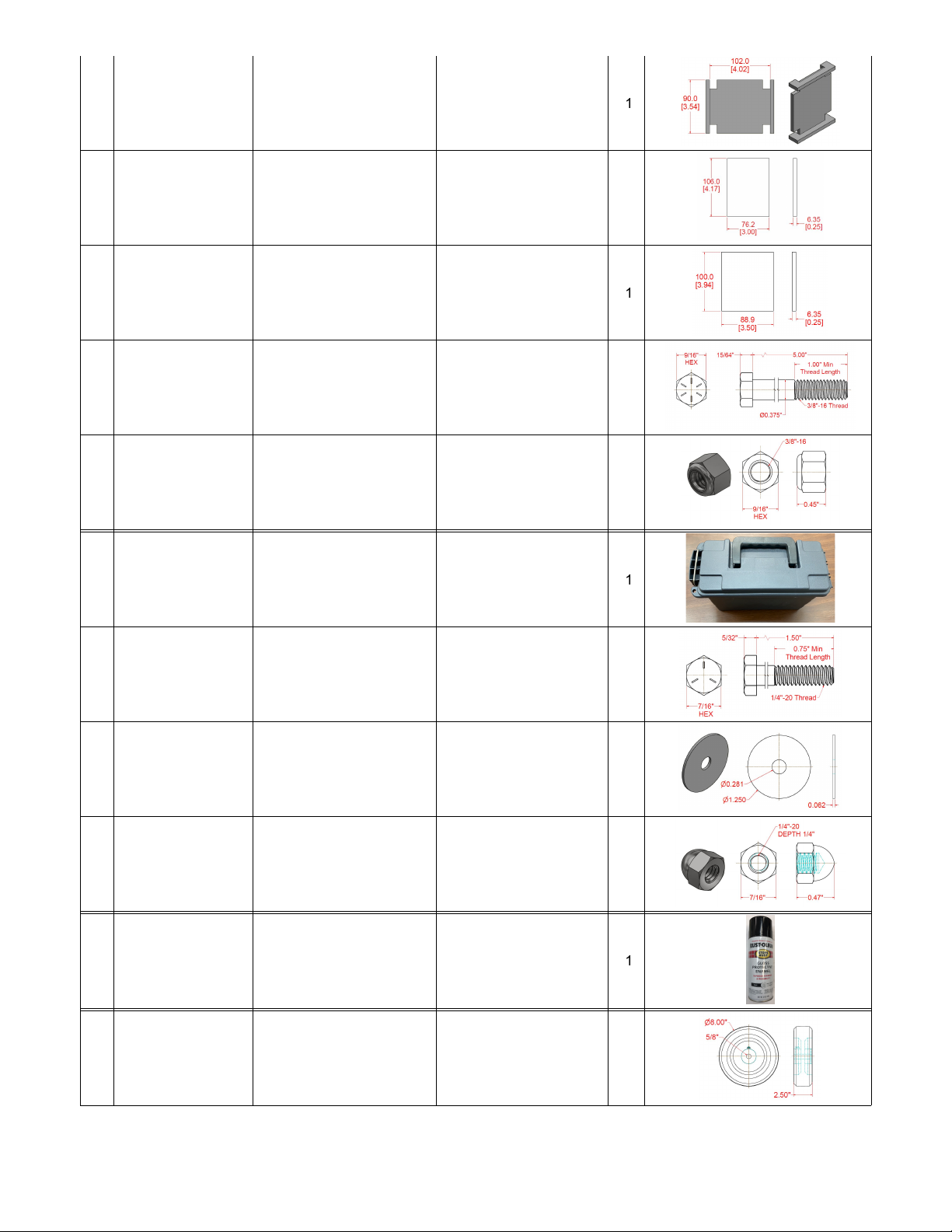

Below are the names and images of lift parts and components that were

shipped to you:

Row

Part Number

Item

Description

Qty

Sample Image

1

Welcome Letter

Welcome Letter and

Instructions

1

None

2

Packing List

List of all parts and

components shipped

1

None

3

Assembly and Installation

Manual for the KCSPM3648

Also available via email

on request - call (USA)

434-515-2321 (Provide

your Serial Number

'E9997B' and contact

information when you call)

1

None

4

Affordable Lift -

Disassembled

42.0"x52.0"x35.2", Gloss

Black

1

5

Hoist Assembly - 1500 lbs

w/ Tethered Controller

8.25"x26.0"x7.5", Gloss

Black

1

6

RTS3x3x.25X78

Standard Steel Lift Column

- Flanged

3.5"x20"x83"x1/4" (.25") -

70 lbs

1

7

AWB52x40

Base with Arms

52.0"x40.0"x3.25", Gloss

Black

1

8

HBH0.5-13x5

Base with Arms - Bolts

.5"-13x4.5" Grade 8

4

9

Base with Arms - Washers

.5" SAE

4

10

HNN0.5-13xNylock

Z

Base with Arms - Nuts

.5\"-13 Nylock Nuts

4

11

SRL Unit

Fall Arrestor with hook

1

12

SRL Pulley

4.25"x2.75"x1" (Shipped

attached to Collar)

1

13

6000144GA

ULS Rain Guard

5"x3"x3" Galvanized

Sheet Metal

1

14

6000107

Actuator Spring

3"x3"x1" Steel

1

15

6000106

Collar - Backing Plate

3.5"x4.7"x1" Plate

1

16

6000014

Collar - Regular Slip Pads

.25"x3"x4.1"

5

17

6000013

Collar - Backing Plate Slip

Pad

.25"x3.5"x3.9"

1

18

HBH0.375-16x5

Collar - Bolt

3/8"-16x5"

4

19

HNW0.375-16x

Collar - Bolt - Nylock Nuts

3/8"-16 Nylock Nuts

4

20

3500010

Controller Storage Box

7.1"x11.6"x5.1"

1

21

BHM40.25-x

Controller Storage Box -

Bolts

.25"-20x1.5"

2

22

HWA0.25-1.25

Controller Storage Box -

Washers

.25"x1.25"

2

23

HNA0.25-20x

Controller Storage Box -

Nuts

.25"-20 Acorn Nuts

2

24

Spray Paint Can

Rustoleum Protective

Enamel, Gloss Black, 12

oz

1

25

3500009

Wheel Kit - Standard

Wheels

8"x2.5"

2

26

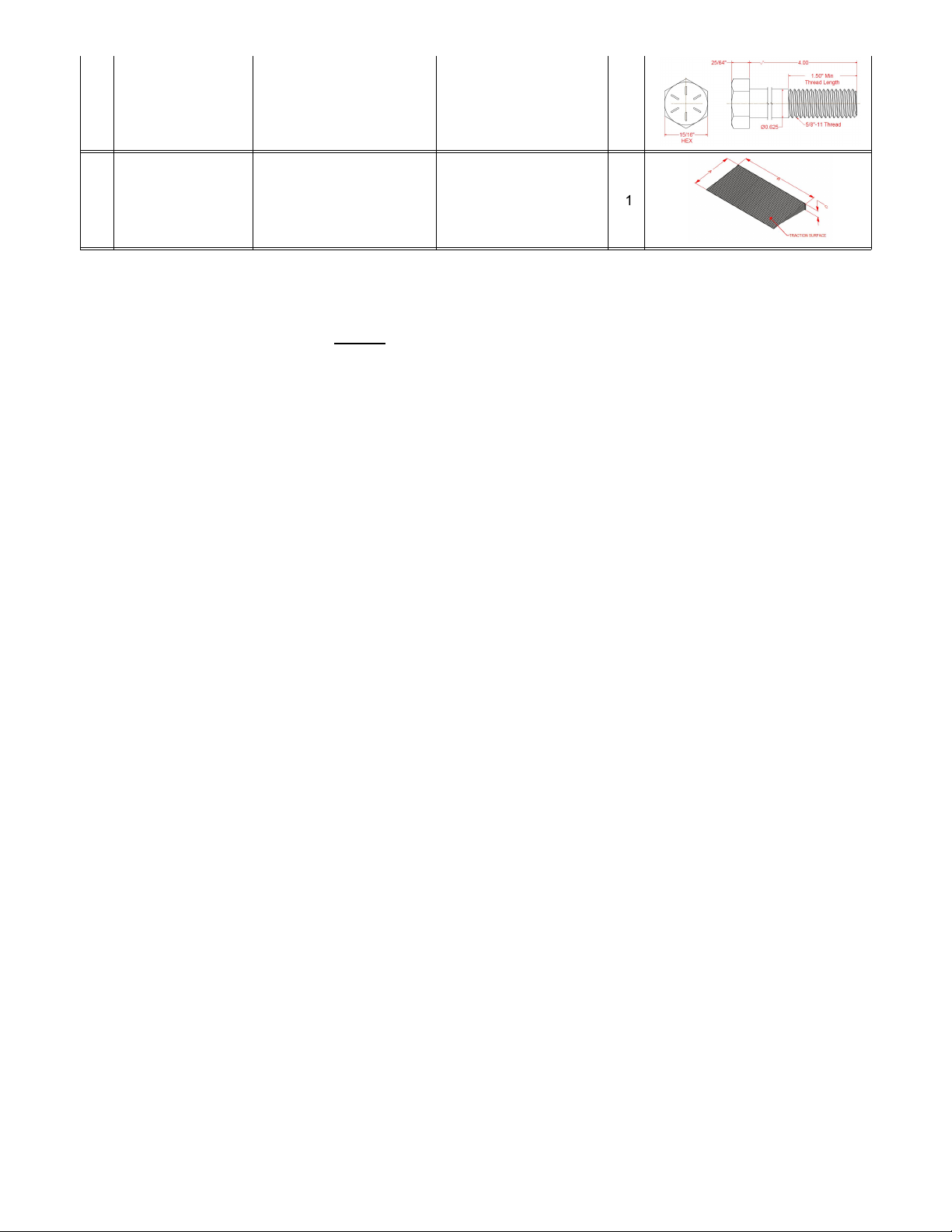

MW82.5x 0.625xX

Wheel Kit - Bolts

5/8"-11x4"

2

27

6000111

A16B33C2.75

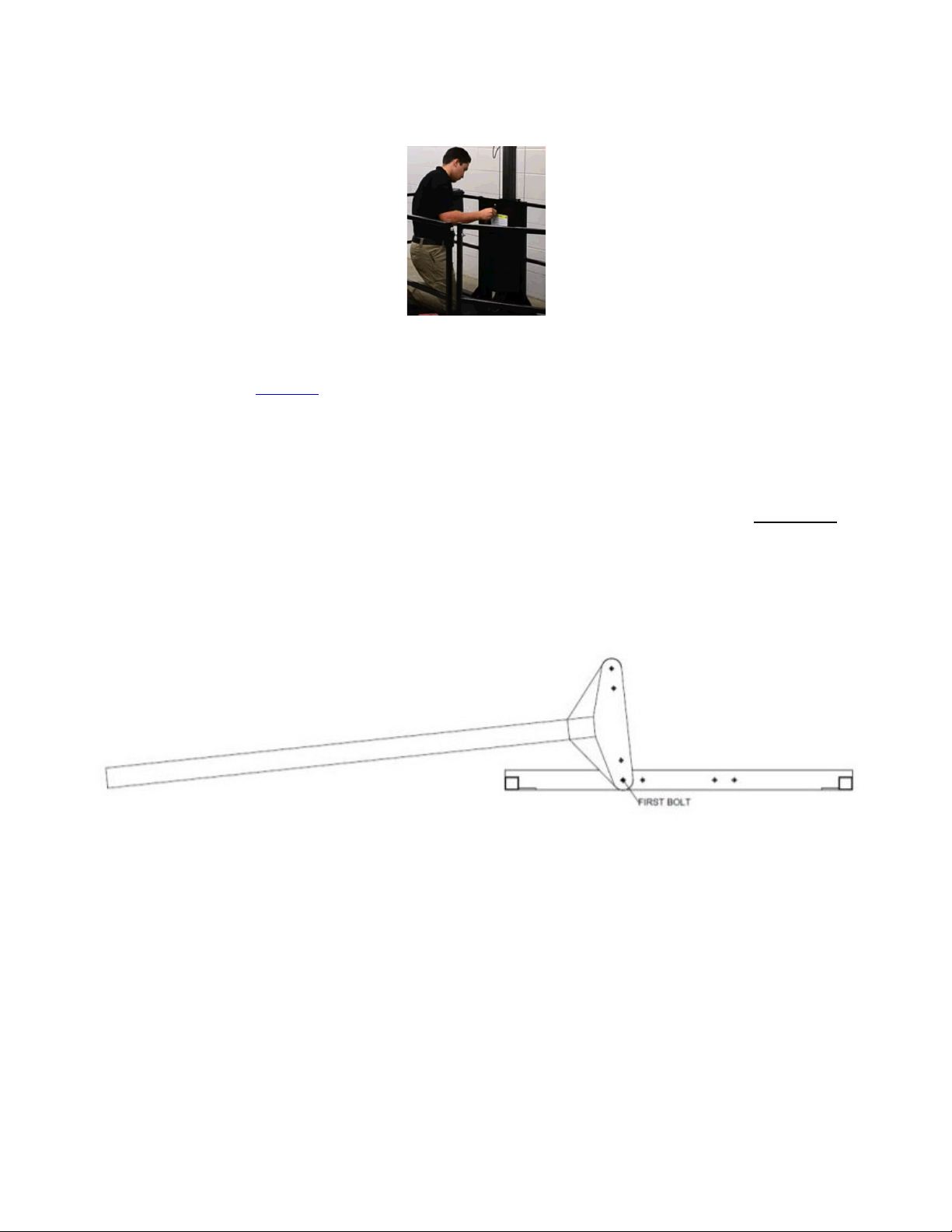

Left Side Ramp

A16"xB33"xC2.75", Gloss

Black

1

5. Prepare to Install Your Lift

5.1. We Are Here To Help:

We would much rather have you call us for help than have you assemble or install your lift

incorrectly. Your lift's serial number is

E9997B

. If you have questions or problems during assembly please call Customer

Support at (USA) 434-515-2321 (Provide your Serial Number 'E9997B' and contact information when you call).

5.2. Receiving Your Lift:

If damage has occurred during shipping immediately document it with photographs and notify our

Shipping Department at (USA) 434-207-8444 (Provide your Serial Number 'E9997B' and contact information when you

call). Check your lift for damage before signing the papers with the delivery man, when applicable. If there is damage, note

it on the delivery paperwork appropriately and notify Affordable Lifts.

If damage is found after the delivery papers are

signed, we will not be able to file a claim for the damage with the shipping company on your behalf.

5.3.

We recommend that at least two adults work together to assemble this lift. Some parts of your lift are quite heavy and

having two or more people assemble your lift reduces the risk of injury. Affordable Lifts is not responsible for injuries that

occur while assembling or utilizing your lift.

5.4.

Most customers prefer their lift be oriented for straight-through travel. This means entering one side of the lift (right or left)

going up and then continuing out the other side (right or left). Sometimes this is not practical. If you are using a wheelchair

or walker, remember to allow adequate space to navigate onto and off of your lift's Platform.

5.5.

We recommend that if possible, the Column side of the lift be installed closest to a nearby wall. If bracing is desired, then

this positioning will make bracing easier.

5.6. Before you begin:

!"

The installation site should be flat and level, or you should be prepared to use steel or plastic shims to level

your lift.

!"

The installation site should be clear of debris and as accessible as possible.

!"

Your lift weighs approximately 450 lbs and it has a Platform weight capacity of 500 lbs. Be sure that the floor of your

installation location can support this combined weight.

!"

The lift should sit on a solid surface (concrete, asphalt, solid flooring, etc) or substantial pavers. Anchoring on asphalt

installation requires inserting steel anchors into an epoxied hole.

!"

Pinch point protection should already be installed.

!"

If you remove a section of a landing railing then, if the landing is high enough you should install a safety gate in its place.

!"

Children and pets should be excluded from the area during assembly and installation.

6. The Wheel Kit

6.1.

Your lift was shipped with a detachable Wheel Kit. We will discuss the Wheel Kit now because you may choose to use it

in the next steps.

The Wheel Kit consists of two 8" wheels and their axle bolts. These wheels allow the lift to be tilted backwards and wheeled

over a smooth hard surface.

Here is a photo of the Wheel Kit after installation:

While this is an easy way to move the lift, it is still a two person operation.

These wheels should always be removed prior to actually using the lift.

6.2. Wheel Kit Installation or Removal:

1.

Locate the wheel mounting points on the back of the Base. Use a pry bar to lift the corner of the base up about 1".

2.

Place the bolt through the wheel as shown in the photo above.

3.

Use a wrench to secure the wheel by tightening the bolt.

4.

Reverse this process when removing the Wheel Kit.

6.3. Using The Wheel Kit:

1.

With one person at the back of the lift and one person at the front, tilt the lift backwards so that it is balanced on its

wheels.

2.

Carefully move the lift along a flat, hard surface to its desired position.

3.

Remove and store the Wheel Kit once the lift is in place.

7. Unpack Your Lift

7.1. Keep in Mind:

As you unpack,

watch out for any shipping damage

. If you sign for a damaged lift without noting

shipping damage you will not be able to make a claim later.

7.2. Small Parts:

Look inside the grey Controller Storage Box to see what small parts and paperwork it contains.

7.3. Unbolt the Platform:

Use a wrench to unbolt the Platform from the pallet and slide it forward off the pallet to one side.

7.4. Move the Base:

Lift up the Armed Base from the pallet and move it off to one side.

7.5. Unpackage the Column:

Your lift's Column is packaged separately. Remove any column packaging and check to make

sure that your Column

tube

is 3" x 3" x 78.0".

7.6. Weather:

Electrical components should be protected from weather until properly installed. For example, do not leave

your Hoist Assembly upside down where water can accumulate in it and damage the motor.

8. Remove Safety Guard

8.1.

Remove the Safety Guard from in front of the Collar. You will reattach it after finishing the next several steps. Be sure to

not lose the four acorn nuts.

9. Connect the Armed Base, Column and Hoist Assembly

Here is a video of this step:

Click here

9.1. Assembly Location Versus Final Location:

Assembly is easiest if you have ready access to all sides of the lift. So we

often do most of the assembly two or three feet from the final position and then move the lift to its final position towards the

end of the assembly process.

9.2.

The Armed Base has four anchor pads. Be sure that these pads are positioned on the floor side of the base.

9.3.

Lower the Column over the Base so that the Column flanges straddle the back beam of the Base.

It is

IMPORTANT

that

the smaller, shorter Column flange is on the inside of the base (towards the side with the base arms).

When looking

straight along the Column beam ensure that it is parallel with the back beam of the base.

Failure to make the Column

parallel with the Base will make bolt hole alignment difficult, and bolt insertion impossible.

9.4.

Line up the bottom hole in the flange with the end hole of the four (4) hole pattern in the Base. In the case of the

illustration below, the BOTTOM hole of the flange must be aligned with the LEFT most hole in the Base.

9.5.

Insert a ½-13 x 4.5" Hex head bolt through the bottom hole.

Insert the bolt from the arm side of the Base.

Do not put

the washer on the bolt head end of the bolt. By design, the holes are snug on the bolt. It will probably be necessary to tap

the bolt through the beams. Do not beat on the bolt if the holes are not aligned. Doing so will only ruin the bolt.

9.6.

Install a washer and nylock nut together on the bolt.

DO NOT TIGHTEN.

This bolt will serve as a pivot point when you

later set the Column upright.

9.7. Prepare To Attach The Hoist Assembly:

To attach the Hoist Assembly you may proceed one of two ways. For most

assembly situations the first set of steps is easiest. Each step is described in detail further below.

1.

Pivot the Column to its vertical position.

2.

Insert the remaining 3 flange bolts

from the arm side of the Base

and tighten all 4 flange bolts to secure the Column.

3.

Place the Hoist Assembly on the top of the Column.

OR

1.

Place the Hoist Assembly on the top of the Column.

2.

Pivot the Column to its vertical position.

3.

Insert the remaining 3 flange bolts and tighten all 4 bolts to secure the Column.

Here are more detailed explanations of each of the above steps. Depending

on your situation you may choose to do them in different orders, as outlined

above.

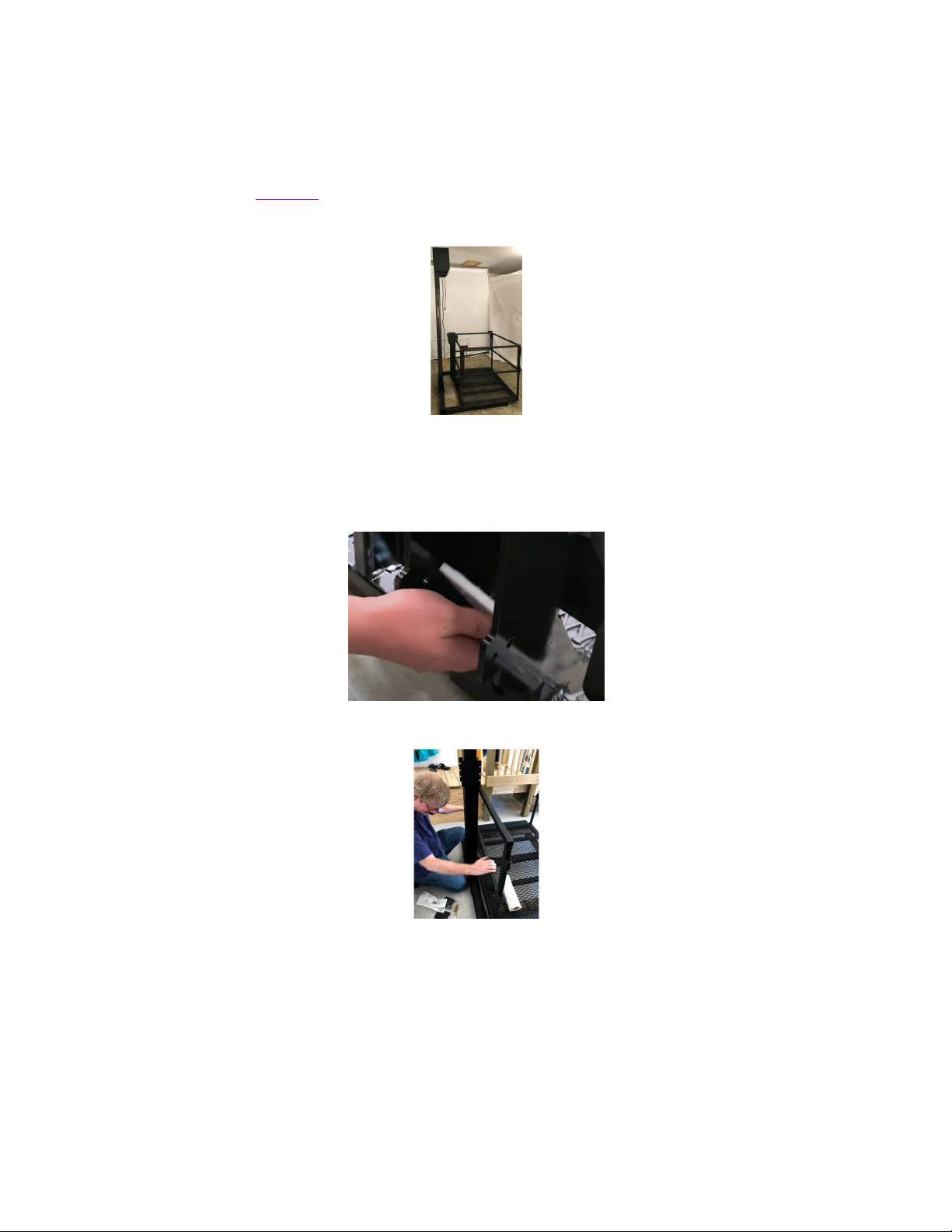

9.8. Pivot the Column to Its Vertical Position:

For tall lifts, please take extreme caution during this step. Depending

on its length your Column could weigh over 200 pounds.

Consider obtaining scaffolding, ladders, or other equipment so that you can safely do some of these steps. If you are not

sure you can complete these steps, we recommend hiring a local handyman. Before doing this first step you may wish to

move the Platform onto the end of the base arms to secure the base, as shown below.

Note that the drawing below does not show any Hoist Assembly on the upper end of the Column.

Be careful around the lift at this point. Especially if the lift is not on a level surface or you try to move it. Without the

weight of the Platform, the lift is top heavy and not very stable. This is even more true once the Hoist Assembly is mounted

on the Column top.

9.9. Insert Remaining 3 Flange Bolts:

Insert the remaining 3 bolts holding the Column to the base.

Insert the bolt from the

arm side of the Base.

Do not put the washer on the bolt head end of the bolt. It goes on the other end. Tighten all four

bolts to 80 ft/lbs.

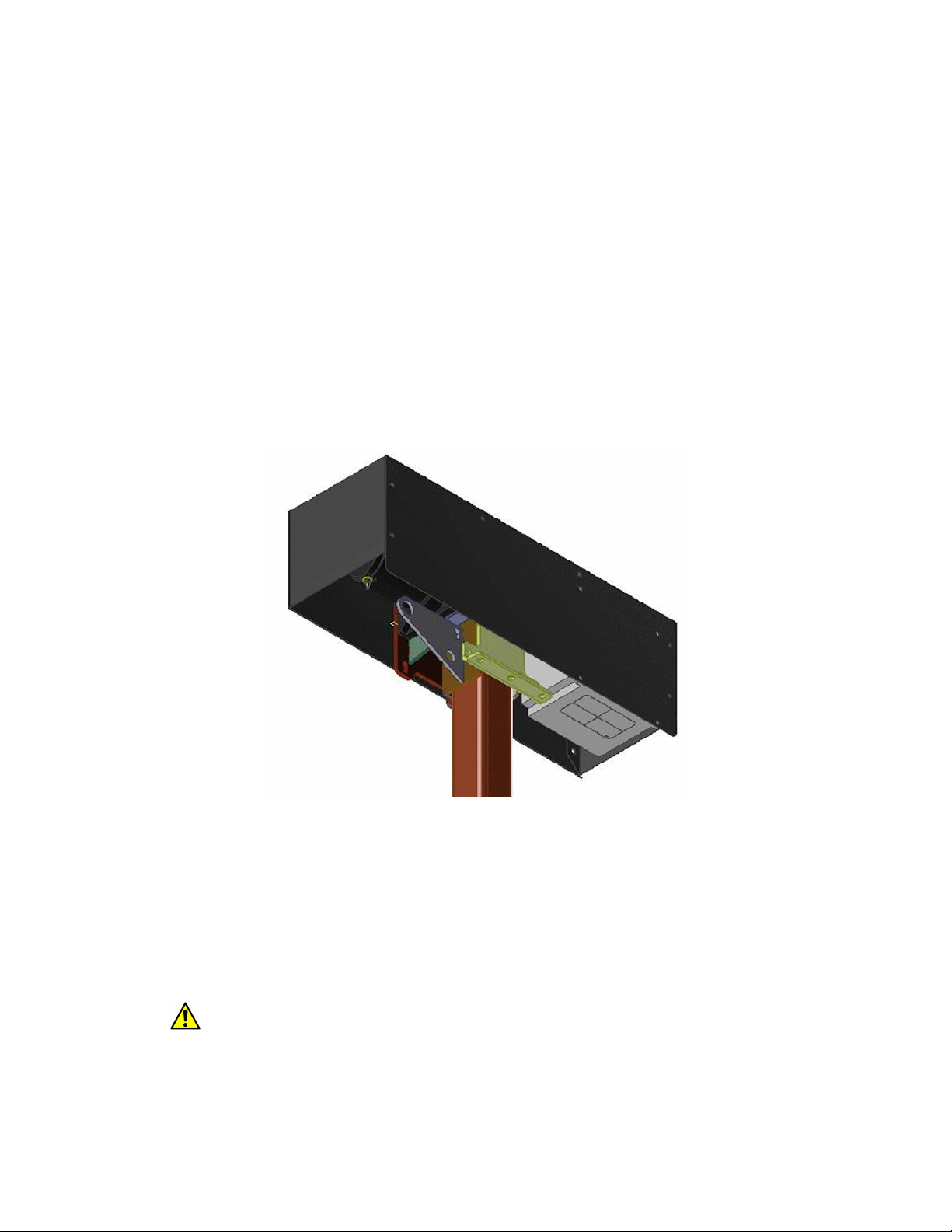

9.10. Place Hoist Assembly Onto The Column:

There are two ways to do this. For most assembly situations the first set of

steps is easiest.

Use Caution When Handling the Hoist Assembly.

!"

The Hoist Assembly is a heavy object. Use care when lifting.

!"

The electrical cables are easily damaged.

1.

Lean the top of the Column down onto a solid support. This solid support could be the intended landing. Make sure both

ends of the Column are secure and will not slide.

2.

Slide the Hoist Assembly onto the end of the Column, oriented so that the hoist cable will run down the front of the

Column.

3.

Carefully set the lift upright on its base.

OR

1.

With the Column upright, use a scaffold, deck or other structure to safely access the top of the Column. You may wish to

temporarily lean the Column slightly or rotate the base to position the Column's top nearer to your landing.

2.

Carefully lower the Hoist Assembly onto the Column, oriented so that the hoist cable will run down the front of the

Column.

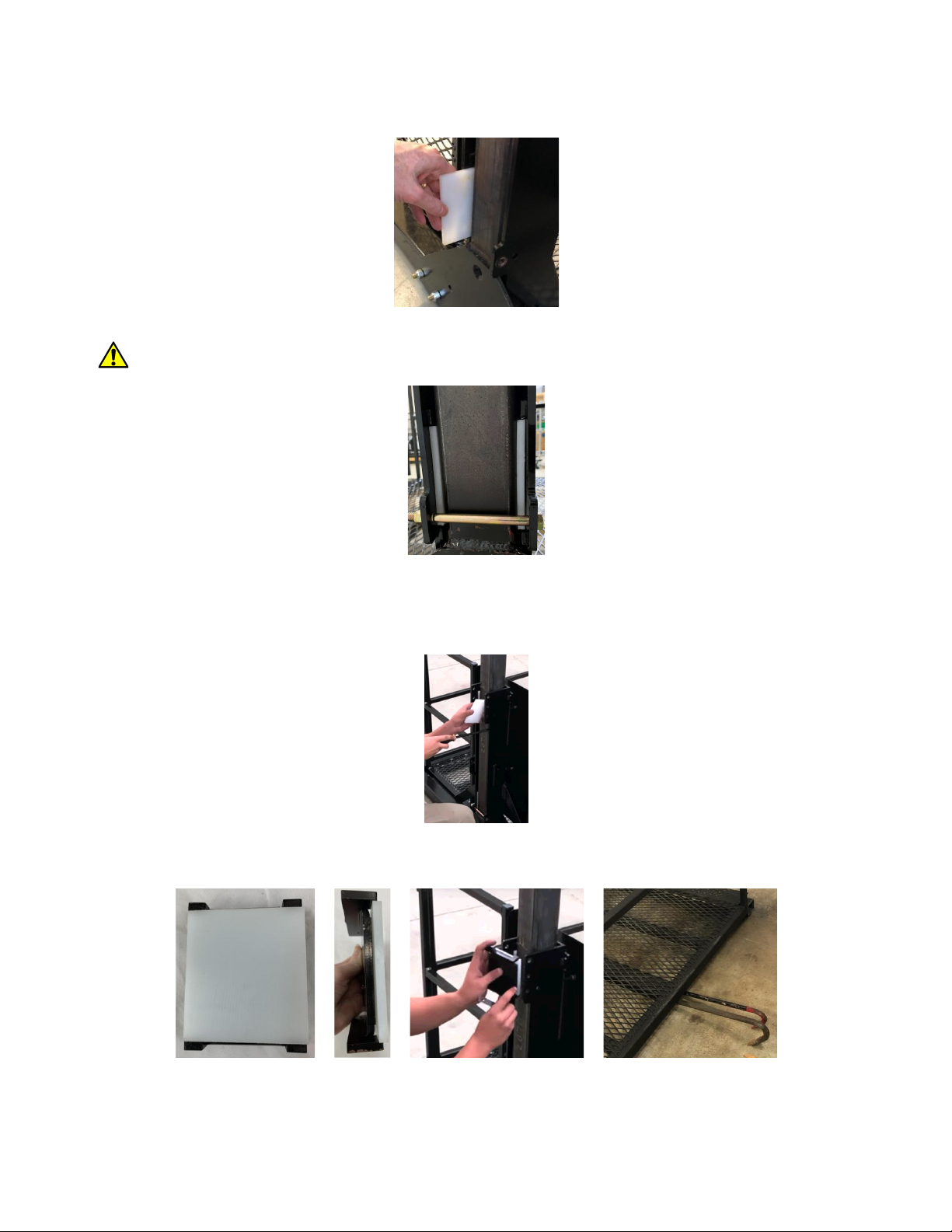

10. Attach the Platform to the Column

Here is a video of this step:

Click here

10.1.

Line up the Platform and Collar. Move the Collar to about a foot away from the Column.

10.2.

Clean all plastic Slip Pads of dirt and debris. Ensure that they remain clean throughout the assembly process. You have

five Slip Pads that are have a common size (Part Number 6000014) and one Slip Pad that is a unique size (Part Number

6000013). The unique Slip Pad will be installed last. Take one of the common-sized Slip Pads and put a little grease or

petroleum jelly on one side of the pad. Use the grease to stick the Slip Pad to the inside front of the Collar between the pad

retainer rails near the bottom of the Collar.

10.3.

Slide the Platform back so that the Collar surrounds the Column.

10.4.

Ensure that the Slip Pad you just installed has not fallen out of position. Now insert a common-sized Slip Pad into each

of the two pockets found along either side of the

lower

Collar. If the fit is a bit tight you may need to tap the Slip Pad with a

hammer and screwdriver, jiggle the Platform or use a screwdriver to widen the opening.

Note:

There is no back side Slip Pad for the lower Collar.

10.5.

Loosely

secure the lower Collar bolt and lock nut.

If you over tighten then the Platform will not descend properly under its own weight.

10.6.

Insert a common-sized Slip Pad into each of the two pockets found along either side of the

upper

Collar. If the fit is a bit

tight you may need to tap the Slip Pad with a hammer and screwdriver, jiggle the Platform or use a screwdriver to widen the

opening. After this step you should have only one Slip Pad left to install.

Note:

The front side of the Collar does not get a Slip Pad.

10.7.

Position the remaining Slip Pad on the Backer Plate and insert the Backer Plate into the Column as shown below. You

may need to lift the front of the Platform slightly to bring the top of the Collar closer to the Column to make this step easier.

10.8.

Install the Upper Limit Switch Actuator Spring (a silver L shaped piece of sheet metal with holes on one side) and

secure the Backer Plate as shown in the photos below. The Slip Pad must be against the Column.

The Upper Limit

Switch Actuator Spring is critical and prevents your Upper Limit Switch from being crushed.

There is no top or

bottom end for the Backer Plate. Tighten the three bolts used here.

10.9.

It is critical that the lower Collar adjustment bolt is adjusted properly. All Collar bolts have nylock nuts. The lowest

Collar bolt does not need to be tight to work properly. If the lowest Collar bolt is too tight, the Platform may bind on the

Column and may not descend as the hoist unspools the synthetic rope. If this happens, the hoist may produce several

inches (or feet) of slack, and the Platform may then fall until the slack is used up, or the Platform will fall until the anti-fall

device locks up and stops the platform. Either condition is undesirable.

Later in the installation process we will adjust the single bolt on the back, near the bottom of the Collar so that side to side

wobble is minimized and the unit descends smoothly with no weight on the Platform.

11. Safety Backup System

EVERY LIFT MUST HAVE A SAFETY BACK UP SYSTEM. NEVER OPERATE THE LIFT WITHOUT AN

OPERATIONAL SAFETY BACK UP SYSTEM.

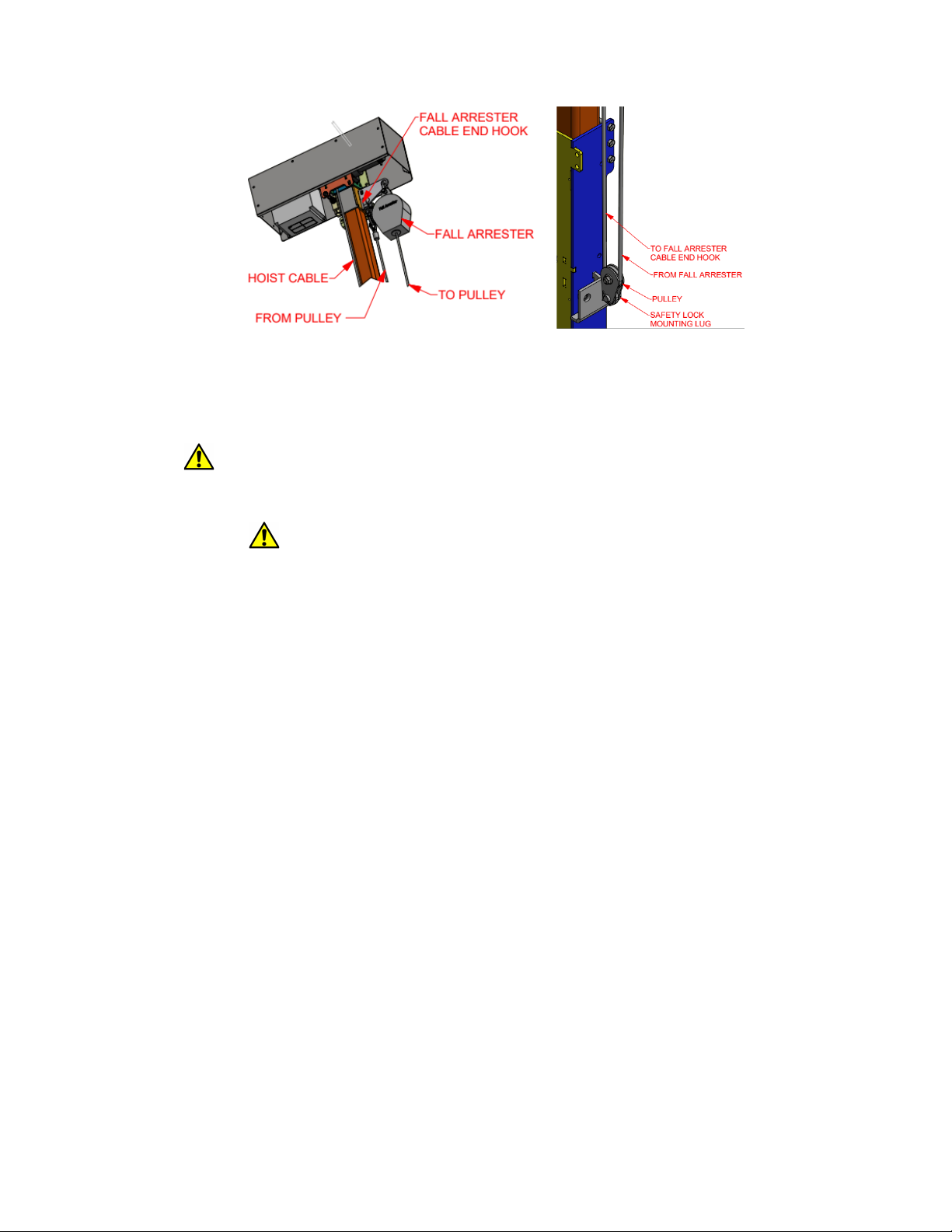

Your lift is equipped with a Self Retracting Lifeline (SRL). See below:

11.1. Installing your SRL:

Your SRL color, model and its cable or strap may be different from what is shown here. Your SRL

should be inspected yearly for wear and tear.

Here is a video of one way to install the Safety Backup System:

Click here

The SRL should always retract smoothly and completely when the Platform is at the upper station. If this

does not happen, do not allow anyone to use the lift and call Customer Support at (USA) 434-515-2321 (Provide

your Serial Number 'E9997B' and contact information when you call).

1.

Always use gloves when touching wire rope.

2.

Secure the carabiner at the top of the SRL body through the outer hole on the Hoist Head.

3.

With the wire rope running through the pulley, attach and secure the SRL cable pulley to the Safety Lock Mounting Lug

on the right side of the Column midway down. Do so by inserting the pulley's carabiner or bolt through the holes at the

bottom of the pulley. See the photo below.

4.

Attach the SRL’s cable hook to the inner hole on the Hoist Head.

5.

Test the SRL by using a

gloved hand

to sharply pull the cable down from the SRL body. It should engage and lock. Let

the cable retract slowly.

12. Electrical Power

12.1. Warning:

When the hoist is connected to electrical power, anyone with a Controller can cause it to activate.

Before plugging in the lift or working on any part of the lift always be sure that no one is pushing any buttons on any hand

held Controller.

12.2. Controller Access:

Controllers should always be kept away from children or those who should not operate the lift

without supervision. The Controller Storage Box has a hasp and can be locked using a customer supplied lock.

12.3. Power Source:

!"

You have an AC motor that requires 120 volt AC power.

!"

Your lift should never require more than 15 amps of electrical power.

!"

Avoid plugging your lift into any circuit that cannot support at least 20 amps or is shared with heavy machinery that

might, together with the lift, trip the circuit breaker.

!"

GFI protected electrical outlets must be used in all locations that might be exposed to water.

!"

You may use an extension cord to bring power to your lift, but it must be 12 gauge or thicker.

!"

Be sure that electrical power cords will not be crushed, punctured or have their insulation worn through.

!"

When installing your lift anywhere where the power cords may be exposed to water you must use weatherproof

extension cords and weatherproof extension cord connectors.

12.4. Plug in the hoist motor power cord into a suitable outlet.

12.5. Power Cord:

Consider using a zip tie to secure any excess power cord out of the way so that it will not rub or chaff.

13. Connect Your Synthetic Rope

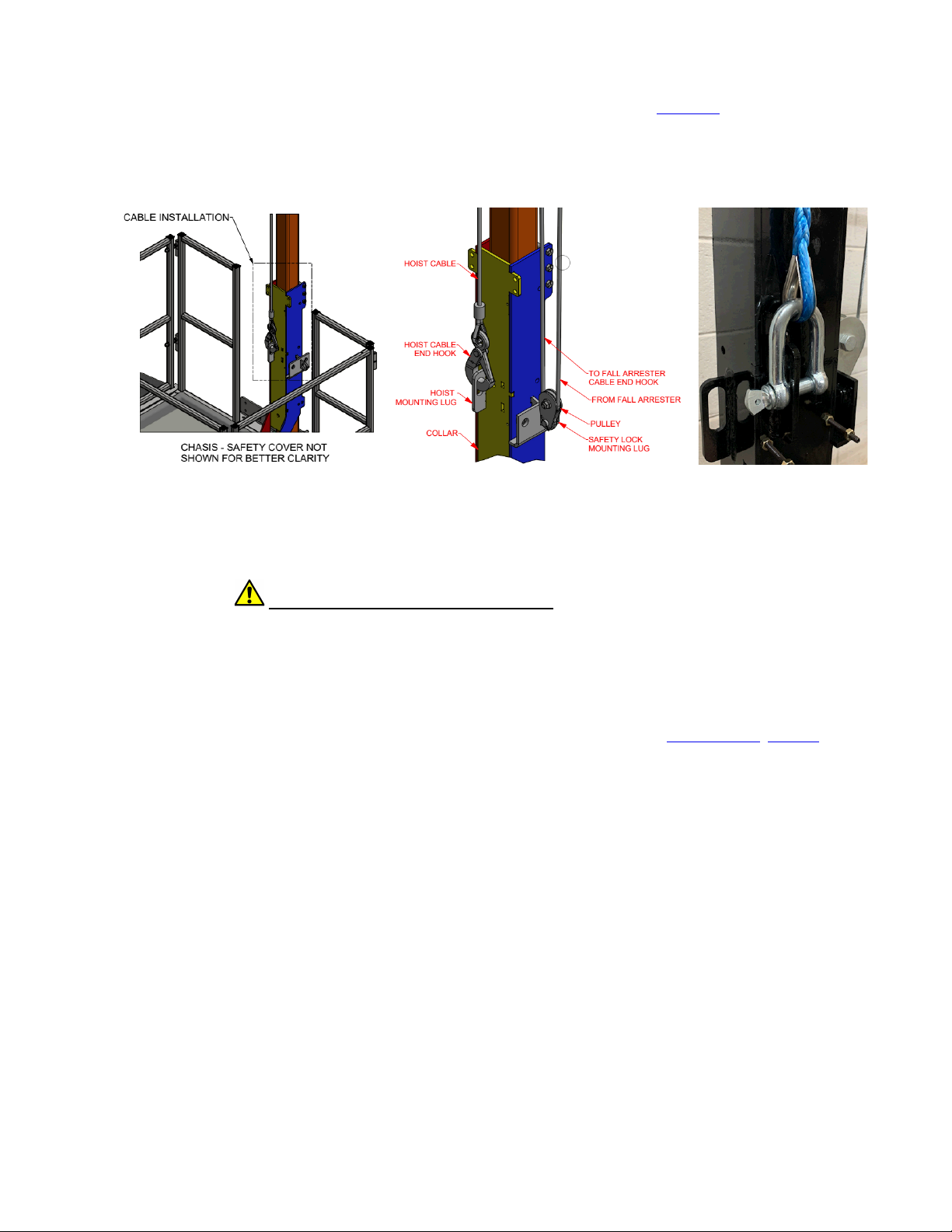

13.1. Attaching the Synthetic Rope:

Here is a video of attaching your lift's synthetic rope:

Click here

1.

Connect your hoist motor to electrical power.

2.

While lightly pulling your synthetic rope, use your Controller to unspool enough synthetic rope to reach slightly past the

hoist mounting lug.

3.

While keeping slight tension on the synthetic rope, securely connect the hook or carabiner to the hoist mounting lug on

the

front

of the Collar.

4.

Use your Controller to take up any slack in the synthetic rope.

5.

Ensure that the synthetic rope does not contact any bolts, studs, brackets, etc.

6.

Proceed to the next step to test your lift.

14. Test Your Lift

14.1. Take a Test Run:

with no one on or under the lift's Platform.

Now that your lift is positioned and plugged into your power source, on your tethered hand held Controller push the “Up”

button to tighten any loose synthetic rope. Then go up several inches and all the way back down again. Be sure to not go

up more than several inches. The motor should turn off when you reach the ground. After you successfully do this several

times you may send the Platform higher, but remember that you have not yet installed your Upper Limit Switch.

Do not

allow your Collar or Actuator Spring to collide with your Hoist Assembly.

14.2. Troubleshooting:

If you run into any issues during testing you may wish to consult the

Troubleshooting Section

at the

end of this document.

15. Adjust Your Lift’s Maximum Height

15.1. Upper Limit Switch:

Your lift has an Upper Limit Switch that automatically stops the Platform at a preset station height.

This is an important safety feature.

You can set this height easily using the 1/8" allen wrench supplied with the lift, taped

on to the Upper Limit Switch bracket.

The switch is clamped onto the column as shown below. Please note that the Upper Limit Switch must be actuated by the

Actuator Spring shown in the photo.

You will damage the Upper Limit Switch if the Actuator Spring is not properly

installed.

15.2. Attach And Adjust the Upper Limit Switch:

To see a video of this step

click here

1.

Do NOT stand on the Platform while doing this.

2.

Place the Upper Limit Switch bracket onto the Column as you see below. The switch goes on the back of the Column.

The plunger faces downward. Slide the Upper Limit Switch up or down on the Column until the bottom of its mounting

bracket is 33” above your landing height.

3.

Slide the Upper Limit Switch downward until the switch touches the Actuator Spring and also makes a click sound.

4.

Using a 1/8" allen wrench, tighten the set screw in the bracket holding the Upper Limit Switch.

5.

Raise or lower the Upper Limit Switch to make the Platform stop higher or lower.

6.

Note that landings are not always level, nor are their edges always square.

7.

Tip:

If your Upper Limit Switch is at a good height and you find you need to temporarily move it, first mark its current

position on the Column for later reference.

15.3. Attach The Upper Limit Switch Rain Guard:

1.

If the lift is exposed to severe weather, a Rain Guard (PN 6000144) should be used to prevent water from entering the

switch.

2.

The photos below show a Rain Guard installed over the switch.

3.

To install the Rain Guard, loosen the Upper Limit Switch set screw, slide the Rain Guard tab down between the Column

and the Upper Limit Switch mounting bracket, as in the photo below. Then tighten the Upper Limit Switch set screw.

16. Anchoring The Armed Base

16.1.

Depending on local building codes, anchoring the armed base of a lift of this height may be optional. But we do

recommend it to keep your lift from shifting over time.

NOTE: If you use shims then you must also anchor your base to

prevent it from shifting off of your shims.

16.2.

Here is how to anchor your Armed Base:

1.

Be sure the Armed Base is

exactly

where you want it long term.

Run your Platform up and down its full travel

to check for any collisions.

You may even want to initially anchor your Platform at only two points so that you can later

easily adjust the base location and use the other anchor points.

Once anchored at all points, your lift's location will

be very difficult to adjust.

2.

Make sure the gates are properly aligned, working and properly interacting with the landing railings.

3.

For the measurements below please remember that many walls are not truly vertical. If you are placing your Column

near a wall use a plumb bob to determine the vertical plane of the wall and any obstructions.

4.

Use a plumb bob to determine the vertical plane of a landing's edge. Remember that many landings are not square and

many landings are not level.

5.

Be sure to also consider water spigots, electrical outlets and other items that might obstruct the path of the Collar or the

Platform itself.

6.

If you will use your Platform's left opening at an upper landing, then

the left side of your Column should be 25.0"

from the edge of that landing

. This number includes a 0.5" (1/2") gap between the edge of your Platform and your

landing.

7.

If you will use your Platform's right opening at an upper landing, then

the right side of your Column should be 25.0"

from the edge of that landing

. This number includes a 0.5" (1/2") gap between the edge of your Platform and your

landing.

8.

If your Platform's front side passes by an obstruction, then

the front side of your Column should be at least 37.75"

from that obstruction

. This number includes a 1" gap between the edge of your Platform and that obstruction.

9.

For the Collar to ascend and descend without hitting any obstruction the back side of the Column must be

at least 1.75"

from a vertical plane that includes any obstruction in the Collar's path.

10.

There are four anchor pads built into the Armed Base. Each has a 0.5" (1/2") pre drilled hole.

11.

Decide on what diameter and length anchors to use based on your floor material. We recommend anchors at least 3"

long.

12.

Drill the anchor holes. Consider drilling deep enough so that the anchors can be hammered down into the floor if the lift

is ever removed.

13.

Insert and tighten the anchors. If you elevate the Platform in order to do this, make sure the Platform is secure before

you work under it.

17. Finalize Column Bracing

17.1.

For your particular lift you do not have to anchor the top of the lift to a strong structure. However many people prefer to

do so as this minimizes any Platform "bounce".

17.2. Back Flange Brace:

Your Hoist Assembly has a Back Flange with 3/8” diameter holes (three vertical and two

horizontal) that can be used for bracing the lift’s Column. They are visible in the drawing below. On your lift this flange is

located approximately 76" from the ground.

Connect your brace to a strong structure using steel angle iron or equivalent.

18. Reinstall Safety Guard

18.1.

Now that all of your wires and hoist rope have been installed, re-attach your Platform's Safety Guard to the Collar using

the four acorn nuts you removed earlier. Be sure to reinstall it so that the nameplate sticker is visible and right side up.

19. Platform Gates

19.1. Platform Gates:

Each gate comes pre-attached to the Platform, hinged on the side specified in your Order. Gate and

latch styles may vary.

For most lift configurations you can easily detach a gate and reverse its swing direction.

19.2. Safety:

It is important that all gates shut easily and securely, and that all gates be shut and latched before using

the lift.

Unsecured gates can catch on items as the Platform moves and severely damage the lift, or people could

fall off of the Platform and be injured or killed.

Other manuals for KCSPM3648

1

This manual suits for next models

1

Table of contents

Other AFFORDABLE LIFTS Lifting System manuals

Popular Lifting System manuals by other brands

TradeQuip

TradeQuip 1030 owner's manual

NAUSICAA

NAUSICAA Weighing System user manual

Faraone

Faraone ELEVAH 70 Use and maintenance instructions

TECALEMIT

TECALEMIT TEC 3000X Installation, operation and maintenance instructions

WERTHER INTERNATIONAL

WERTHER INTERNATIONAL 280AZ manual

Pro-Lift

Pro-Lift T-5500 Operating instructions & parts manual