AFP Imaging IMAGE-VET 70 ACP Manual

Visionary Imaging

Installation, Operation

&

Service Manual

Veterinary Diagnostic X-ray Unit

With Anatomical Timer Control

AFP Imaging Corporation

250 Clearbrook Road

Elmsford, NY 10523

©AFP Imaging Corp., 2007 P/N 897-000022

1

IMPORTANT!

BEFORE INSTALLATION

These instructions describe the installation, operation and maintenance procedures for the

Image-Vet 70ACP veterinary X-ray system. One purpose of this manual is to provide the user with

instructions that will permit the equipment to run safely and efficiently. The Image-Vet 70ACP must

be used according to the procedures in the manual and never for purposes other than the ones

for which it has been designed. Please read the operation instructions, Section A of this manual

in its entirety before attempting to take any radiographs of a patient. The Image-Vet 70ACP is

intended solely for veterinary applications and for use by a qualified and licensed veterinarian or

technician. These instructions apply to all the versions of the Image-Vet 70ACP X-ray equipment

as well as various accessories that may be provided. For this reason, the description of some

parts may not correspond or be applicable to your equipment.

The manufacturer or its representative shall provide authorized service to meet the stated

performance standard information as required for the timer or tubehead.

No part of this manual may be reproduced, stored in a retrieval system or transmitted in any form

or by any means, I.E. electronic, mechanical, photocopying, translation, or otherwise, without the

prior written permission of AFP Imaging Corp., © AFP Imaging Corporation, 2007.

All information, specifications and illustrations contained herein are subject to change.

AFP Imaging Corp. has a company policy of continual development. Therefore, it reserves the

right to make changes without prior notice.

AFP’s limited warranty obligations apply to, but are not limited by the following conditions:

1) Damage incurred due to improper wiring or connections are excluded.

2) The installation must be carried out by authorized personnel.

3) The installation must be completed in accordance with the diagrams supplied by

the manufacturer.

4) An independent earth ground wire is required for electrical safety with main power input

wiring.

Important: An electrical source must be provided with + or - 3%

regulation which includes a fuse or circuit breaker rated for 120/220 VAC,

15 Amps.

2

ABOUT THIS PRODUCT...

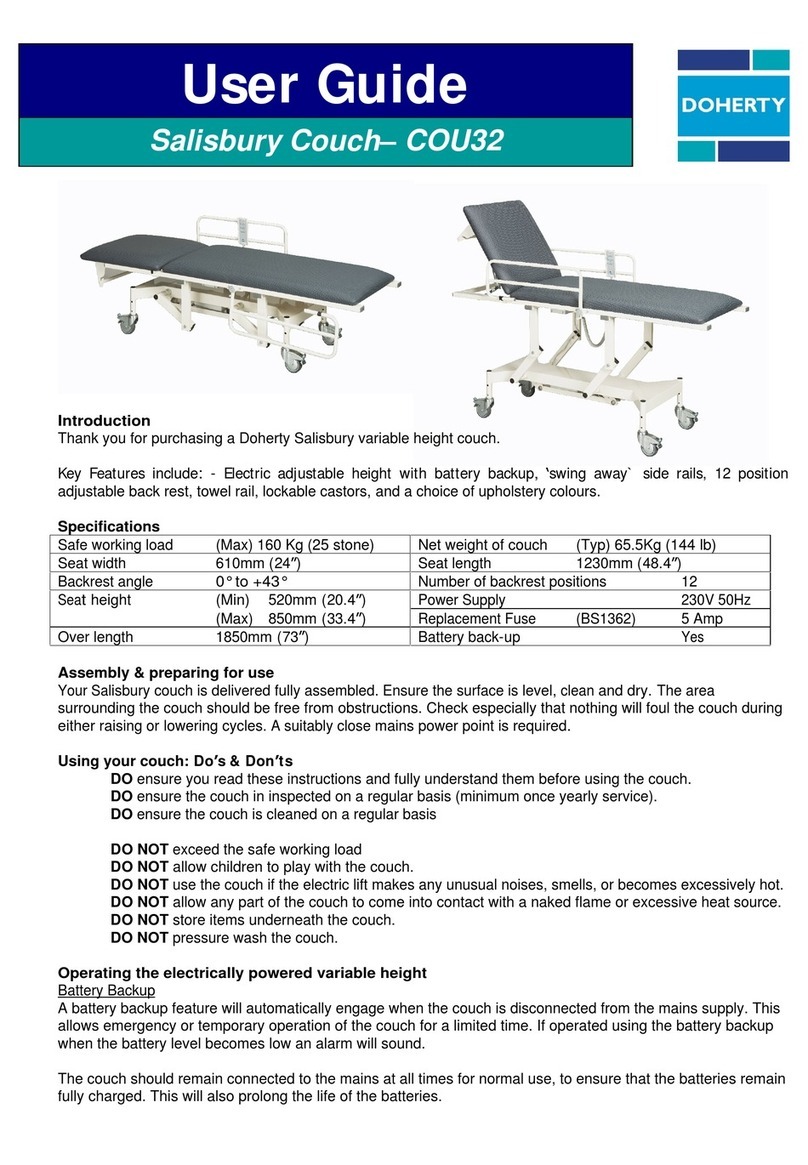

Performance

The Image-Vet 70ACP X-ray system is designed for use in veterinary dental

radiography. It is an AC type X-ray system that houses both the high voltage

transformer and tube insert in a compact tubehead assembly. This assembly is

supported by a spring loaded articulating arm that is balanced to provide smooth

movement and positioning of the tubehead in a variety of positions.

The positioning arm is atttached to a pivoting extension arm that, in turn, is

attached to a wall mounted plate. A remote exposure control providing voltage

to the tubehead is wall mounted and provides for precisely timed exposures.

The system provides for X-ray exposures on a variety of media from film to

CCD or CMOS digital sensors to PSP (Photo Stimulated Phosphor) plates.

The system is designed and manufactured to perform in accordance

with the manufacturer's certification, which is based upon FDA

regulations for X-ray sources and International IEC standards.

Performance qualification criteria is available from the manufacturer.

This device is for veterinary use only and is not certified for human application.

Disposal

The Image-Vet 70ACP Intraoral X-ray System, (except for the

tubehead), may be disposed of by any means appropriate for the

discard of electro-mechanical devices.

The Image-Vet 70ACP X-ray tubehead contains mineral oil, which is classified as a special

by-product. Therefore, when the tubehead is to be taken out of service, it should be sent

back to the manufacturer or given to a firm authorized to dispose of the mineral oil.

3

REVISION RECORD

Title: Image-Vet 70ACP Installation, Operation & Service Manual

Document Number: 897-000022

Revision Effective Date Description

01 August, 2004 Initial Release

02 November, 2004 Full Revision

03 May, 2007 Partial Revision

INSPECTION RECORD

Inspection Effective Date Description/Notes

01

02

03

04

05

4

SECTION A: OPERATORS MANUAL

Image-Vet 70ACP

TABLE OF CONTENTS:

A1. WARNINGS 5 - 6

A1.1. Ambient conditions 7

A1.2. Purpose of the equipment 7

A1.3. Improper use 7

A1.4. Protection against radiation 7

A1.5. Compliance with current standards and regulations 8

A2. DESCRIPTION OF THE Image-Vet 70ACP 9 - 10

X-RAY EQUIPMENT

A2.1. Nameplates 11

A3. USE OFTHE Image-Vet 70ACP 12

A3.1. Patient’s position 12

A3.2. Positioning the X-ray tubehead 12

A3.2.1. Bisector technique 12

A3.2.2. Interproximal radiographs 12

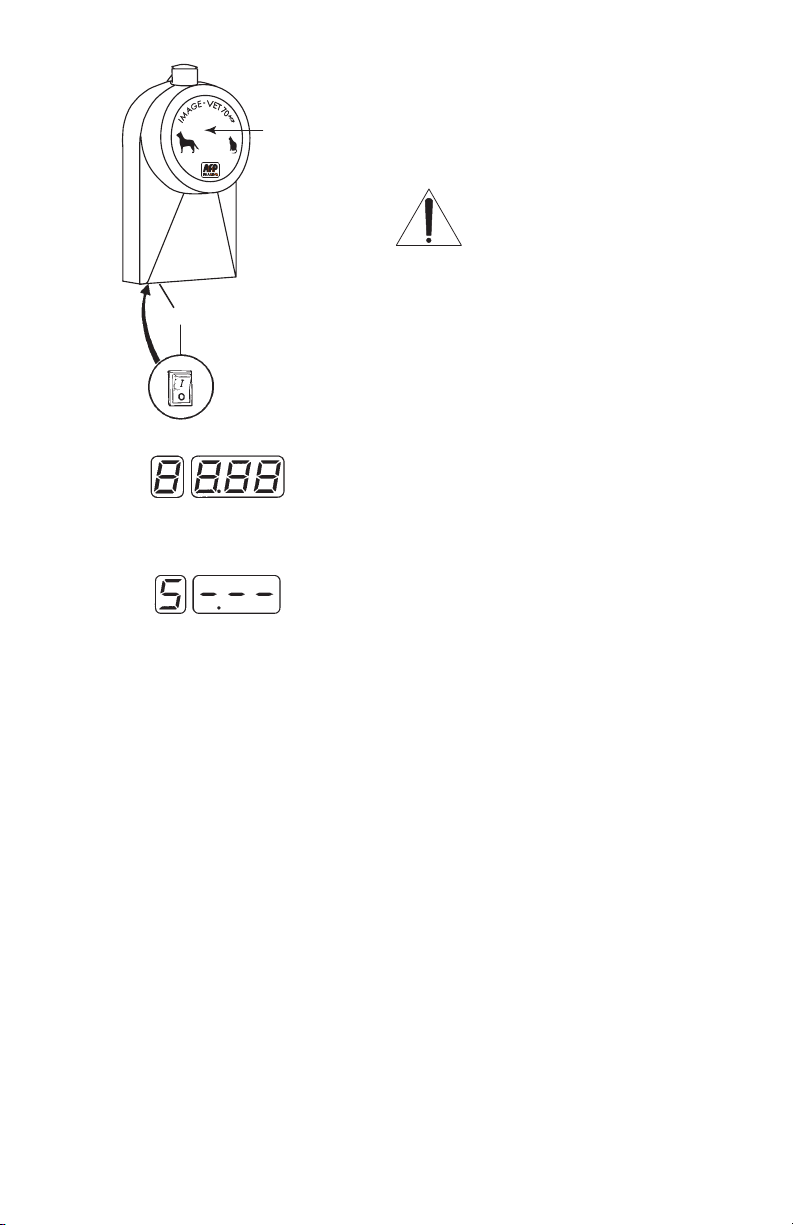

A3.3. Turning on the X-Mind control 13

A3.3.1. Display status 13

A3.4. Factory settings 13

14

A3.5. Setting the exposure time 15

A3.5.1. Exposure time chart 16

A4. DEVELOPING THE FILM 18

A5. CLEANING AND DISINFECTION 19

A5.1. Cleaning and disinfection instructions 19

A6. MAINTENANCE 20

A6.1. Periodic maintenance 20

A6.2. Malfunction and error messages 20 - 21

A7. SPECIFICATIONS 22 - 23

A8. FUSES 23

B1. - 6. SECTION B: INSTALLATION MANUAL 25 - 50

5

�

C US

12

A1. Warning Symbols & Labelling

Pay careful attention to the symbols contained herein and on

the equipment.

Certain instructions are preceded by Warning! with a triangle at

the side. Whenever this symbol appears, carefully read the

relevant paragraph before performing any operations. See symbol #2

Definitions of symbols used:

1) Degree of protection when coming directly or

indirectly into contact with live electrical parts.

(Class I, Type B)

2) CAUTION! Consult the technical documentation

provided.

3) Earth ground connection

4) Alternating current

5) On

6) Off

7) Source of radiation

8) Radiation exposure control

9) Ionizing radiation warning

10) Equipment which conforms with the EEC Directive

93/42 standards

11) I.M.Q. kite mark

12) CSA Mark

6

Before leaving the operatory, turn the main switch to the “Off” position.

The equipment is not liquid-proof. Do not immerse components.

The equipment is not suitable for use in the presence of flammable anaesthetic gas based on

oxygen and nitrous oxide.

WARNING!

If electrical equipment which does not comform with local codes for shield-

ing and isolation and/or FCC Part 15 of the FCC rules for class A computing

devices is used in operatories and/or nearby, interferences and/or distur-

bances may arise thus causing the X-ray equipment to malfunction.

In this case, DISCONNECT the X-ray equipment before using any other instrument or device.

The limited warranty will be voided if the following precautions are not taken:

· Assembly, servicing and modifications to the equipment should only be carried out by AFP Corp.

authorized technicians.

· Observe the conditions specified in the limited warranty certificate itself.

· The electrical supply wiring in the room where the equipment is installed must conform with the

National Electrical Council (NEC) specifications or other local electrical codes ( i.e. the regulations

concerning the electrical wiring to be used in operatories).

· The room where the X-ray equipment is installed must conform with the regulations, concerning

protection against radiation, in force in the locality where the equipment is used.

Assembly, repairs, modifications, adjustments and any other operations which involve gaining ac-

cess to the inside of the equipment must only be carried out by AFP Corp. authorized technicians

or representatives.

7

A1.1. Ambient conditions

The place where the equipment is to be installed should satisfy the following conditions:

a) Temperature between 50° and 105° F (10° and 40° C)

b) Relative humidity from 30 to 75%

c) Atmospheric pressure from 700 to 1060 hPa.

A1.2. Purpose of the equipment

The Image-Vet 70ACP veterinary dental X-ray system is designed for radiographic diagnosis

in the field of veterinary dentistry. Operation of this equipment must be under the direction or

supervision of a licensed veterinarian.

WARNING!

The Image-Vet 70ACP X-ray tubehead contains mineral oil, which is

classified as a special by-product. Therefore, when the tubehead is to be

taken out of service it should be sent back to the manufacturer or given to

a firm authorized to dispose of the mineral oil.

A1.3. Improper use

The Manufacturer declines all responsibilities if:

Installation, adjustment, repairs and modifications are carried out by persons who have not been

authorized by AFP Corp.

The electrical system which serves the X-ray equipment does not conform with local electrical

codes.

The equipment is not used as outlined in this manual.

A1.4. Protection against radiation

WARNING!

X-rays are harmful if improperly used. Therefore, the instructions contained herein must be strictly

observed. After installation, the installer should perform a radiation test emission procedure to

check the equipment for proper operation.

8

All instuctions concerning operations during which

X-rays are emitted will be preceded by this symbol

to remind the user of the precautions to be taken,

as recommended by local regulations.

General precautions for protection against X-rays.

• OperatorcontrolX-rayemissionfromadistanceof

at least 6 feet from the focal spot of the X-ray.

• Reducetheradiationleveltowhichpatientsand

operating personnel are exposed.

• DuringX-rayemissions,onlytheoperating

personnel and the patient should be present.

• Theveterinarianshouldwearaprotectiveapron,

etc., when necessary.

A1.5 Compliance with current USA and International standards and

regulations

CDRH/FDA

The components of this device have been certified by the

manufacturer to be in compliance with FDA regulations as per 21

CFR SUBCHAPTER J as ammended, for veterinary applications.

This model is not for human use.

International X-ray Standards

CEI 62-5+A11+A12+A13+Amend.2

General safety regulations concerning electrical medical

equipment.

CEI 62-67

Safety standards for X-ray tubeheads.

CEI EN 60601-1-2

Additional safety regulations concerning electro-magnetic

compatibility: Recommendations and testing.

CEI EN 60601-1-3

General safety regulations.

General recommendations for protection against X-rays when the

equipment is used for diagnostic purposes.

CEI EN 60601-1-4

General safety regulations for SW logic programmable equipment.

CEI EN 60601-2-28

Specific safety regulations for X-ray equipment and tube assemblies

for medical diagnostics.

9

EXPOSE

S

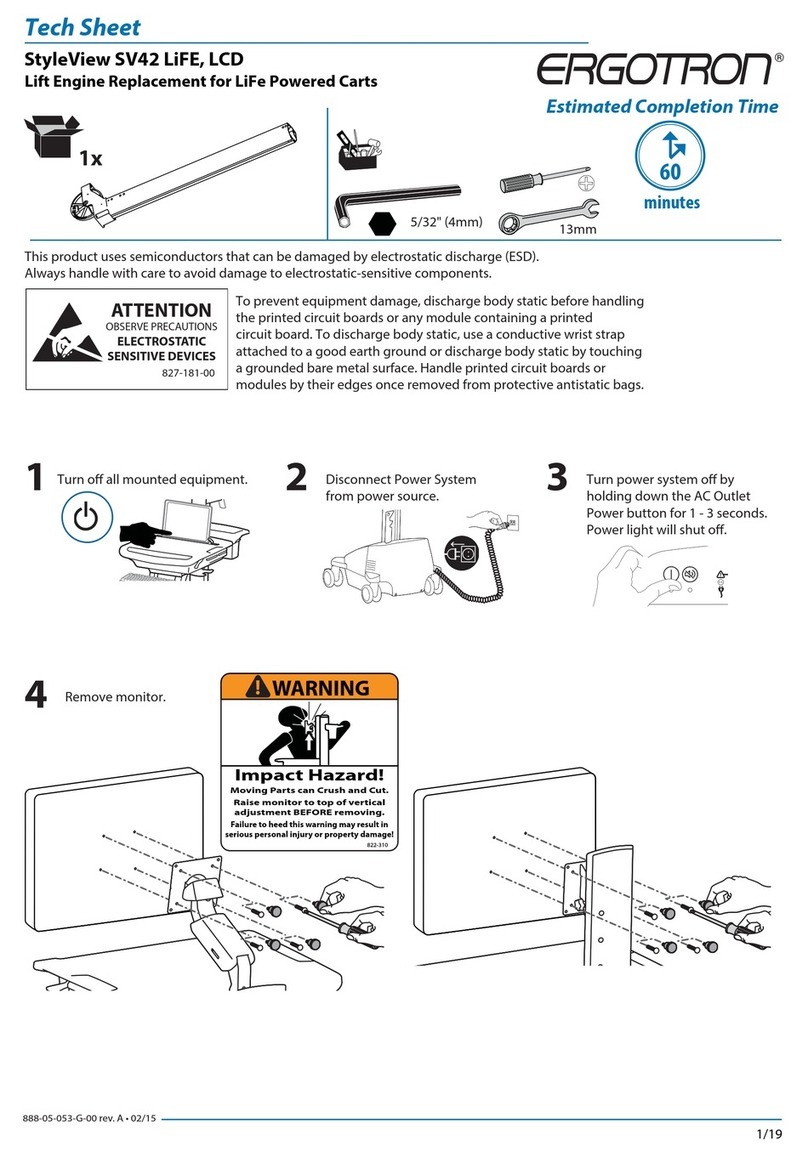

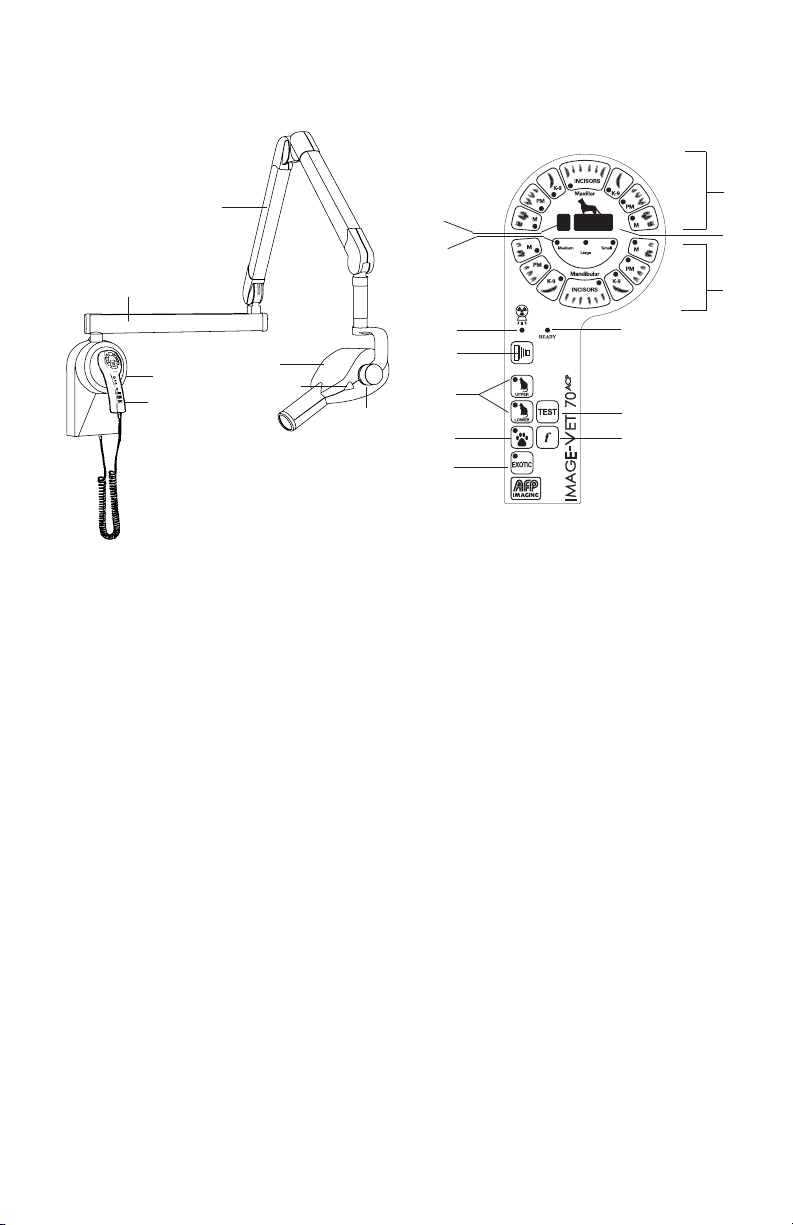

1. Description of the X-ray

system

a) X-ray Tubehead/Tubehead

Assembly

b) Dial, angulation

c) Timer/Wall-mount pivot assembly

d) Hand held control

e) Double-jointed scissors arm

f) Extension arm

g) Focal spot location

(Wall mounting plate

not shown)

2. Description of the hand held

X-Mind control unit

a) Display, Film sensitivity (1 to 9) or

Xray tubehead selected (A or B)

b) Patient’s jaw size selection

c) Warning light, X-ray emissions

d) Button, Exposure start

e) Upper and lower cat selections

f) Paw select

g) Exotic select

h) Upper dental arch (for dogs)

i) Exposure time display

j) Lower dental arch (for dogs)

k) “Ready” light, pre X-ray emission

l) Service test control

m) Film/Sensor sensitivity level

(Scroll button)

A2. Description of the Image-Vet 70ACP X-ray equipment

a

c

d

e

f

b

g

12

c

d

e

f

i

j

a

b

m

l

k

h

g

10

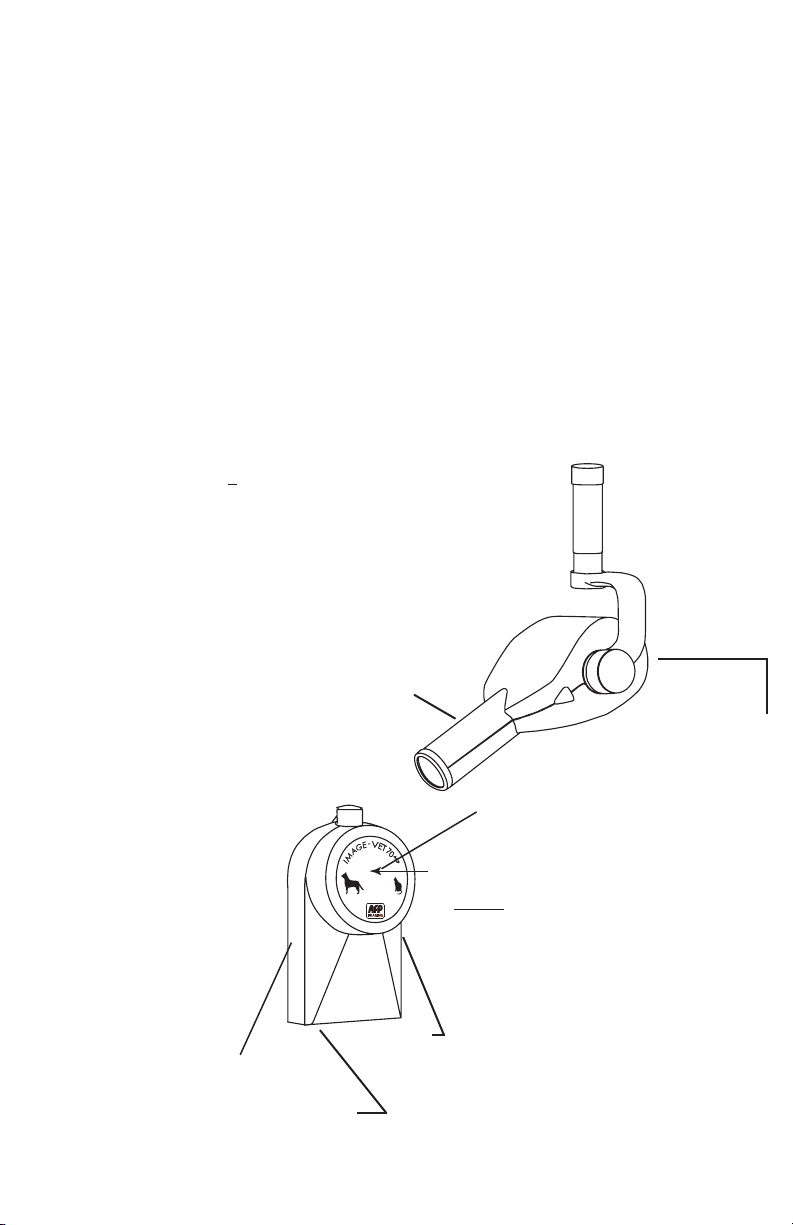

X-RAY EMISSION

SWITCH

WARNING LABEL

MAIN ON/OFF

SWITCH

IDENTIFICATION/CERTIFICATION

LABEL (TIMER CONTROL)

IDENTIFICATION/CERTIFICATION

WARNING LABEL (TUBEHEAD)

HAND CONTROLLER

ATTACHES HERE

Double-jointed scissors arm

This is a double-jointed arm which carries the

X-ray tubehead. It can be extended or retracted

and moved up and down while keeping the tube-

head balanced in the position it has reached. An

additional extension arm is attached to the arm

which is available in three different lengths: 15.75

in (40 cm), 23.6 in (60 cm) or 34.25 in (87 cm).

Micro-processor X-Mind control

panel

The microprocessor-based control system is used

to automatically set the exposure time from a

minimum of 0.02 s to a maximum of 1.28 s. The

electronic controller automatically determines

the exposure time according to the changes in

the electrical supply and in relation to the rated

voltage (in the range of + 10%).

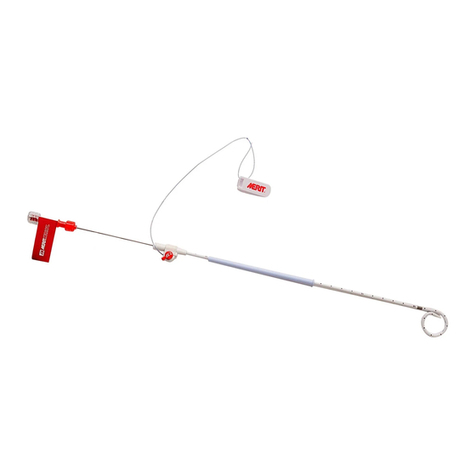

X-ray tubehead with collimator

The X-ray tubehead is self-contained and due

to its operating characteristics, the exposure

time can be reduced so that less radiation

is absorbed by the patient. Moreover, the

tubehead is provided with a positioning cone

capable of operating at a minimum skin/focus

distance of 7.88 in (20 cm); the maximum

diameter of the X-ray beam is 2.36 in (6 cm).

The X-ray tubehead is attached to the arm in

such a way as to permit unlimited rotation. With

this arrangement it can be rotated 360° on its

horizontal plane while the rotary movements on

the vertical plane are limited by the positioning

cone.

POSITIONING CONE

11

A2.1. Nameplates

(1) X-ray tubehead nameplate

The name plate is located on the back of the

tubehead. The following details are given on

the name plate:

· Manufacturer

· Name of equipment

· Serial number

· Tube insert number

· Specifications

· Month and Year of manufacture

(2) X-Mind control unit nameplate

This plate is located on the left side of the controller.

The following details are given:

· Name of equipment

· Serial number

· Specifications

· Month and Year of manufacture

(3) X-Mind control warning nameplate

The nameplate is on the right side of the timer.

(4) Scissors & Extension Arms

These nameplates contain:

· Model number

· Serial number

1

2

3WARNING:

THIS X-RAY UNIT MAY BE DANGEROUS TO

THE PATIENT AND OPERATOR UNLESS

SAFE EXPOSURE FACTORS AND OPERAT-

ING INSTRUCTIONS ARE OBSERVED.

ELECTRICAL SHOCK HAZARD - DO NOT

REMOVE PANELS.

RISK OF EXPLOSION - DO NOT USE IN

PRESENCE OF FLAMMABLE

ANESTHETICS. FOR CONTINUED PROTEC-

TION AGAINST RISK OF FIRE, REPLACE

ONLY WITH SAME TYPE AND RATING

OF FUSE.

DANGER:

RISQUE D’ EXPLOSION - NE PAS EMPLOY-

ER IN PRESENCE D’ ANESTHETIQUES

INFLAMMABLES.

POUR ASSURER PROTECTION CON-

TINUE CONTRE LE RISQUE D’ INCENDIE.

UTLISER UNIQUEMENT UN FUSIBLE DE

RECHANGE DE MEME TYPE ET DE MEMES

CARACTERISTIQUES NOMINALES.

4

Model:

S/N:

12

90˚

A3. Basic applications of the Image-Vet 70ACP

A3.1. Basic patient position

The patient should be positioned on the table in whatever position that is

appropriate for the radiograph to be taken.

A3.2. Positioning the X-ray tubehead assembly

Position the tubehead by moving the double-jointed scissors arm so as to

bring the collimator into contact with the patient’s skin at the point where the

radiograph is to be made. The X-ray tubehead is set to the correct position

by using the bisecting angle technique

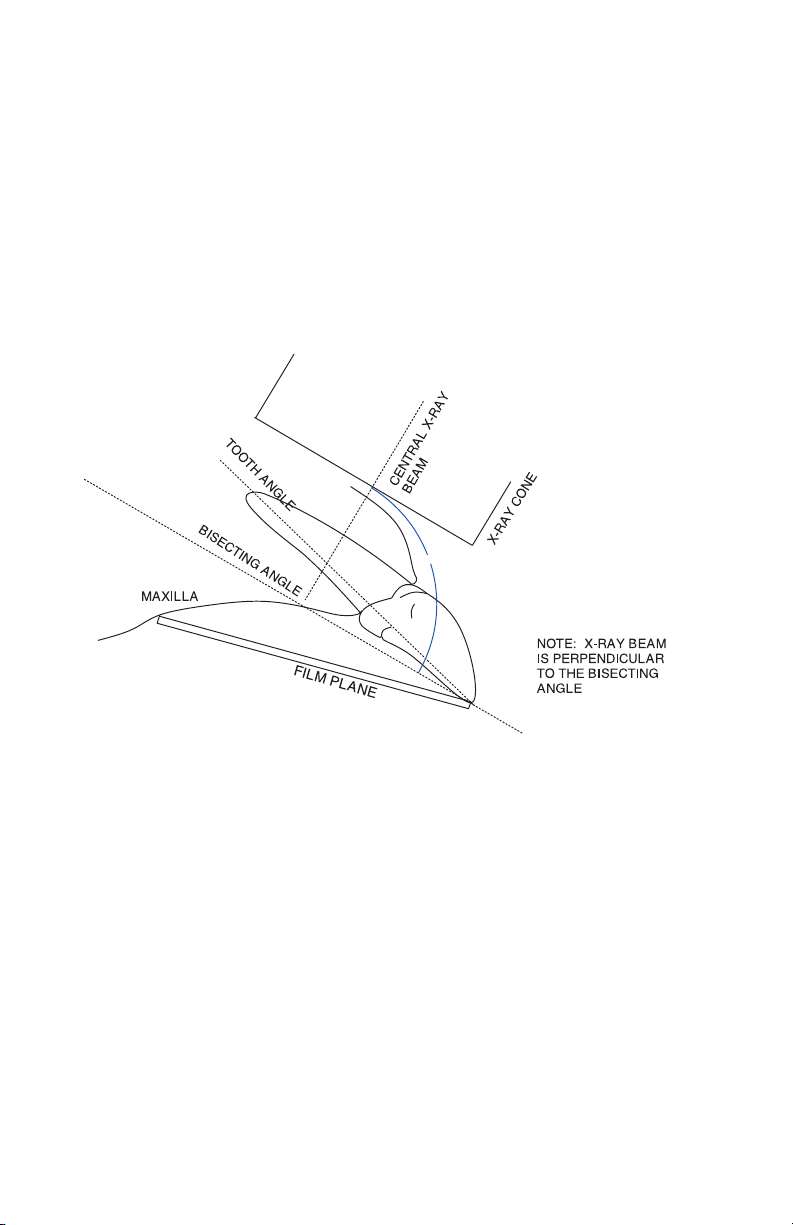

A3.2.1. Bisecting angle technique

a) Vertical incidence angle of the main beam:

In order to obtain a precise image of the tooth, the main beam must be

perpendicular to the bisector of the angle created between the longitudinal

axis of the tooth and of the film. Having positioned the tube head and the

film, as said above, an average incidence angle can be used for each area.

The incidence angle of the main beam can be determined by using the

graduated scale located on the bracket of X-ray tube. The diagram at the

side shows an example of positioning the X-ray cone using the bisecting

technique.

A3.2.2. Interproximal radiographs

To carry out this type of radiograph, the tubehead must be perpendicular

to the surface of the film.

13

EXPOSE

A3.3. Turning on the X-Mind control

Use the main switch (a) to turn ON the control

unit. The green light built into the switch will

come ON to indicate that power is being

delivered to the control unit.

IMPORTANT

Each time the unit is turned ON,

the equipment runs a test which

lasts 10 seconds. During this time,

no radiographs will be produced.

All the indicator lights come on and “8 8.88”

will be temporarily shown on the display.

A3.3.1. Display status

After the equipment is turned on and the initial test

has run, the display shows the selected sensitivity

for the film.

A3.4. Factory settings

Factory settings are determined

when the equipment is installed and

can only be modified by AFP Imaging Corp.

authorized technicians.

Always prepare before exposure with

appropriate protective shields, aprons

or equivalent devices to protect from

unnecessary radiation.

a

14

Typical Wall Mounting

Typical Mobile Mounting

15

EXPOSE

S

A3.5. Setting the exposure time

To set the radiation exposure time, the following

operations must be carried out:

· Press the key corresponding to the type of dog

tooth being radiographed. Otherwise press the key

for upper or lower cat jaw radiographs or the ones

for paw or exotic radiographs. The light built into

the key that has been pressed will light-up.

· Press the key which corresponds to the jaw or

part size of the patient. i.e.

a Small or light jaw

b Medium or average jaw (default)

c Heavy or dense jaw

· Set the sensitivity level for the film used (see page

16) by using the (f) key.

WARNING!

The green Ready light comes on to

indicate that the equipment is ready

for emitting X-rays.

· Move to a shielded or safe location

before exposure. Use caution in

the area where the X-rays are to be

emitted. Press the exposure control button

and hold it down. The yellow light will come on

together with an audible warning device which will

continue sounding until the X-ray emission has

been completed.

IMPORTANT!

SAFETY FEATURE

The exposure control button must be

held down during the entire exposure!

If the button is released prematurely,

X-ray emission is interrupted and the

radiograph may be underexposed.

Film Sensitivity

Select

X-Mind Hand Held Selector

X-ray Exposure

Start

16

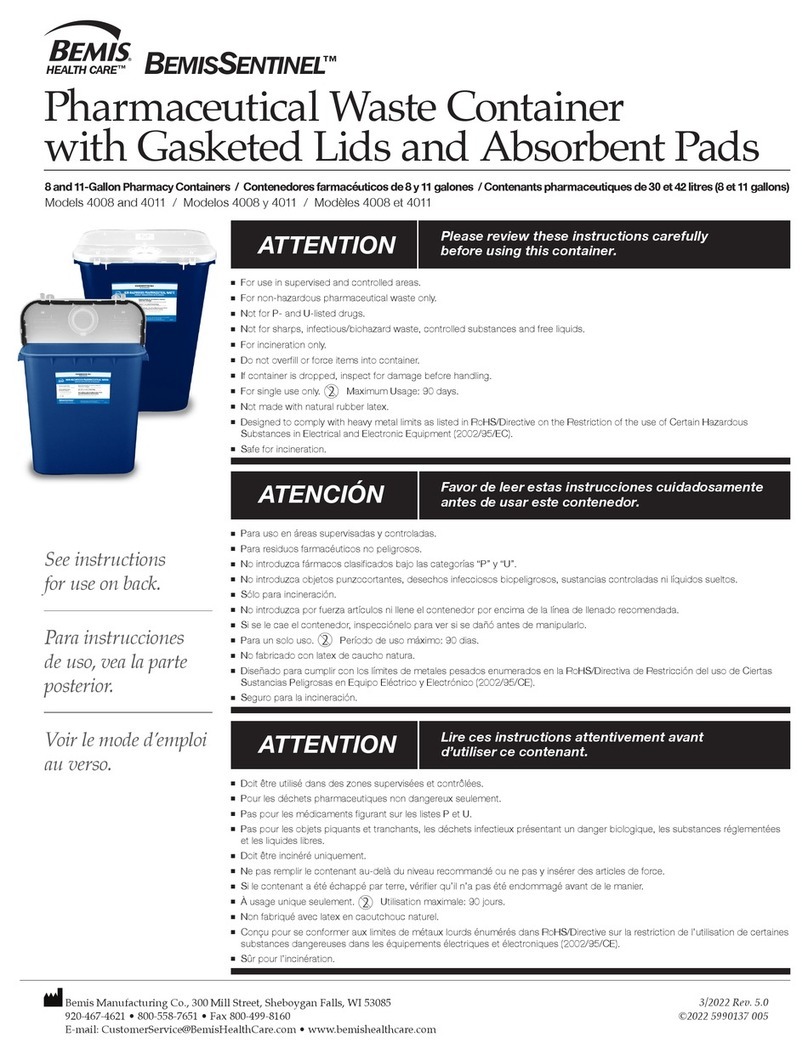

Tooth Selections Small Medium Large

Patient Patient Patient

UPPER INCISORS 0.10 0.12 0.13

UPPER CANINES 0.22 0.25 0.28

UPPER PREMOLARS 0.17 0.20 0.23

UPPER MOLARS 0.17 0.20 0.23

LOWER MOLARS 0.13 0.15 0.17

LOWER PREMOLARS 0.13 0.15 0.17

LOWER CANINES 0.17 0.20 0.23

LOWER INCISORS 0.08 0.10 0.12

CAT (UPPER) 0.13 0.15 0.17

CAT (LOWER) 0.08 0.10 0.12

PAW 0.30 0.35 0.40

EXOTIC 0.08 0.10 0.12

A3.5.1. Exposure time chart

This chart shows the exposure time (in

seconds) for radiographs with a film

sensitivity of 4and the equipment running

at the rated voltage.

The first column indicates the type of teeth

or radiograph.

The second column indicates the exposure

time for animals with light jaws, the third

the exposure time for animals with medium

or average jaws, and the fourth that for

animals with large or dense jaws. Small,

Medium and Large Patient settings also

apply to parts radiographed with the PAW

and EXOTIC settings.

Selecting film sensitivity with the key:

NOTE: A setting of 2 - 3 for film sensitivity is a good range for

Kodak Insight (F) speed film OR the EVA-Vet Digital Imaging

System. A setting of 6 - 8 for film sensitivity is a good range for

Kodak Ultra-Speed (D) speed film.

17

EXPOSE

S

NOTE: All upper and lower tooth selections are for

dogs only. Due to the relatively small dentition of cats,

only the selection for any upper or maxillar feline tooth

(CAT UPPER) or any lower or mandibular feline tooth

(CAT LOWER) is needed. The PAW setting is for any

paw that can be rediographed within the field size of

the cone. The EXOTIC setting is for bird wings, small

animal extremities, etc., that can be radiographed

within the field size of the positioning cone.

The above chart shows the amount of exposure

time variation for the different film sensitivity values

Radiograph-film correction chart

Sensitivity Standard Variation

coefficient

1 0.500 - 50 %

2 0.630 - 37 %

3 0.800 - 20 %

4 1.000 0%

5 1.250 + 25 %

6 1.600 + 60 %

7 2.000 + 100 %

8 2.500 + 150%

9 3.200 +220%

18

A4. Film developing

A4.1 Automatic Processor

Automatic film processors designed for processing dental films with RP type chemicals (such as

the AFP 810 Plus or 810 Basic) control all of the processing parameters (such as temperature,

time, washing and drying) automatically. When set up and maintained properly, they will develop

the images with very little attention required by the operator.

A4.2Manual Hand Tank Processing

In order to obtain good quality images, the film must be developed by carefully following the

instructions below:

1.) Remove the film from the package in a dark room taking care not to damage it with

fingerprints or scratches. Use holder clips as required.

2.) Immerse the film in the developer and shake it for a few seconds then leave it for 5

minutes at a temperature of 68°F (20°C), 6 minutes at 66°F (18°C) or 4 minutes at

72°F (22°C).

3.) Rinse in running water for approx. 20 seconds. Immerse the film in the fixing agent,

shake it for a few seconds and leave it there for at least 5 minutes.

4.) Wash the film in running water. This operation and the ones that follow can be

performed outside the dark room. Dry the film in the open air away from dust.

5.) The slightest amount of fixer will contaminate the developer solution. Never move a

film from the fixer solution back into the developer solution.

It is extremely important to use fresh chemicals dispensed in the correct proportions. Do not add

developer to make the baths stronger as this increases contrast but reduces detail.

POSSIBILITIES

DEFECTIVE EXPOSURE DEVELOPING STATE OF THE POSITION

IMAGES TIME TIME BATHS

Underexposed Too short Too short Cold

Overexposed Too long Too long Hot

Lack of detail Too short Cold or depleted

Blurring or Patient moved during

double image exposure

Distorted Film bent during

exposure

Not centered incorrect angle

Teeth elongated Incidence angle of

center beam too

horizontal

Teeth shortened Incidence angle of

central beam too vertical

Too light or Fixing time

transparent too long

Not transparent Fixing time

enough too short

Table of contents