Afriso EURO-INDEX Unitop AdBlue User manual

Version: 03.2017.0

ID: 900.000.0129

Lindenstraße 20

74363 Güglingen

Telefon+49 7135 102-0

Service+49 7135-102-211

Telefax +49 7135-102-147

www.afriso.com

Copyright 2017 AFRISO-EURO-INDEX GmbH. All rights reserved.

EN

Operating

instructions

Pneumatic level indicator

Unitop

Unitop AdBlue®

2

About these operating instructions

EN

Unitop

1 About these operating instructions

These operating instructions describe the pneumatic level indicator "Unitop"

(also referred to as "product" in these operating instructions). These operat-

ing instructions are part of the product.

• You may only use the product if you have fully read and understood these

operating instructions.

• Verify that these operating instructions are always accessible for any type

of work performed on or with the product.

• Pass these operating instructions as well as all other product-related doc-

uments on to all owners of the product.

• If you feel that these operating instructions contain errors, inconsisten-

cies, ambiguities or other issues, contact the manufacturer prior to using

the product.

There operating instructions are protected by copyright and may only be

used as provided for by the corresponding copyright legislation. We reserve

the right to modifications.

The manufacturer shall not be liable in any form whatsoever for direct or con-

sequential damage resulting from failure to observe these operating instruc-

tions or from failure to comply with directives, regulations and standards and

any other statutory requirements applicable at the installation site of the prod-

uct.

3

Information on safety

EN

Unitop

2 Information on safety

2.1 Safety messages and hazard categories

These operating instructions contain safety messages to alert you to poten-

tial hazards and risks. In addition to the instructions provided in these oper-

ating instructions, you must comply with all directives, standards and safety

regulations applicable at the installation site of the product.Verify that you are

familiar with all directives, standards and safety regulations and ensure com-

pliance with them prior to using the product.

Safety messages in these operating instructions are highlighted with warning

symbols and warning words. Depending on the severity of a hazard, the

safety messages are classified according to different hazard categories.

NOTICE

NOTICE indicates a hazardous situation, which, if not avoided, can

result in equipment damage.

4

Information on safety

EN

Unitop

2.2 Intended use

Unitop 3000 part no. 28000

This product may only be used for measuring the level of the following media:

• Fuel oil EL as per DIN 51603-1

• Diesel fuel as per EN 590

• Fatty acid methyl ester (FAME) as fuel oil as per EN 14213

• Fatty acid methyl ester (FAME) as biodiesel as per EN 14214

• Flammable liquids of danger class A III and non-flammable liquids with

the following prerequisites:

- The vapours of the liquids do not attack plastic materials (PA, PS, PE),

Cu, Zn and Sn alloys and elastomers.

- The liquid does not belong to danger classes AI, AII or B.

- Cinematic viscosity < 300 mm²/s.

Unitop AdBlue®part no 28042

This product may only be used for measuring the level of AdBlue®as per DIN

70070 with a specific weight (density) = 1090 kg/m³. The term AdBlue® des-

ignates the same as "NOx reduction agent AUS 32" and "urea solution 32.5

%").

Any use other than the application explicitly permitted in these operating

instructions is not permitted and causes hazards.

Verify that the product is suitable for the application planned by you prior to

using the product. In doing so, take into account at least the following:

• All directives, standards and safety regulations applicable at the installa-

tion site of the product

• All conditions and data specified for the product

• The conditions of the planned application

In addition, perform a risk assessment in view of the planned application,

according to an approved risk assessment method, and implement the

appropriate safety measures, based on the results of the risk assessment.

Take into account the consequences of installing or integrating the product

into a system or a plant.

When using the product, perform all work and all other activities in conjunc-

tion with the product in compliance with the conditions specified in the oper-

ating instructions and on the nameplate, as well as with all directives, stand-

ards and safety regulations applicable at the installation site of the product

5

Information on safety

EN

Unitop

2.3 Predictable incorrect application

The product must never be used in the following cases and for the following

purposes:

• Hazardous area (EX)

- If the product is operated in hazardous areas, sparks may cause defla-

grations, fires or explosions.

• Level measurement of liquids not specified above.

• Use of the measurement result for billing purposes.

2.4 Qualification of personnel

Only appropriately trained persons who are familiar with and understand the

contents of these operating instructions and all other pertinent product doc-

umentation are authorized to work on and with this product.

These persons must have sufficient technical training, knowledge and expe-

rience and be able to foresee and detect potential hazards that may be

caused by using the product

All persons working on and with the product must be fully familiar with all

directives, standards and safety regulations that must be observed for per-

forming such work.

2.5 Personal protective equipment.

Always wear the required personal protective equipment. When performing

work on and with the product, take into account that hazards may be present

at the installation site which do not directly result from the product itself.

2.6 Modifications to the product

Only perform work on and with the product which is explicitly described in

these operating instructions. Do not make any modifications to the product

which are not described in these operating instructions.

6

Transport and storage

EN

Unitop

3 Transport and storage

The product may be damaged as a result of improper transport or storage.

NOTICE

DAMAGE TO THE PRODUCT

• Verify compliance with the specified ambient conditions during transport or

storage of the product.

• Use the original packaging when transporting the product.

• Store the product in a clean and dry environment.

• Verify that the product is protected against shocks and impact during trans-

port and storage.

Failure to follow these instructions can result in equipment damage.

7

Product description

EN

Unitop

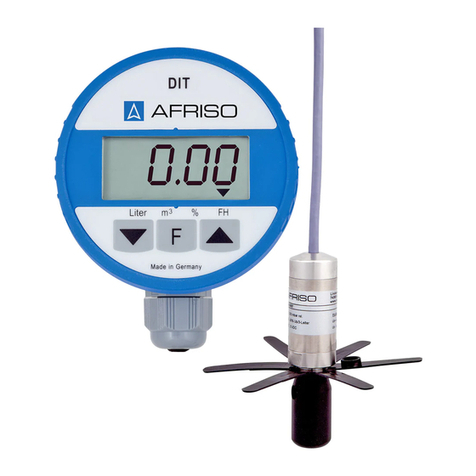

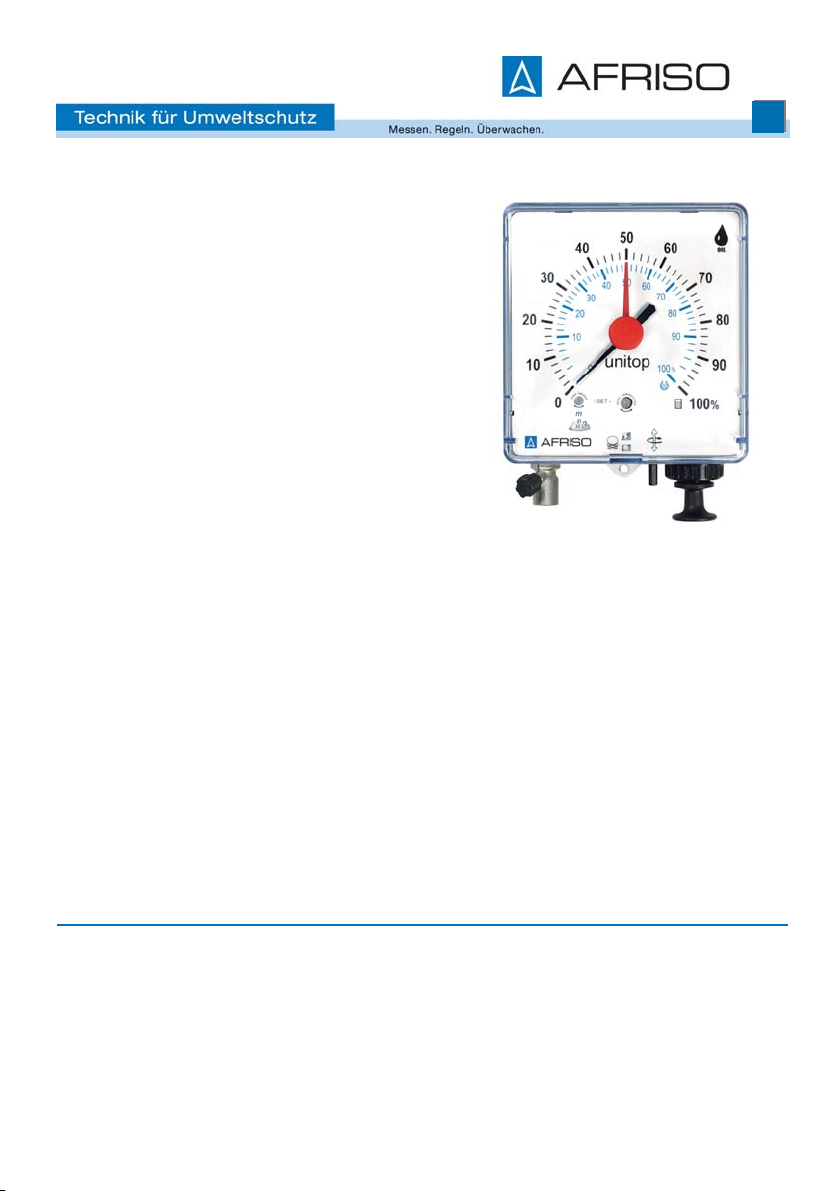

4 Product description

The product measures the hydrostatic pressure at the tank bottom to deter-

mine the level. The hydrostatic pressure depends on the level and the density

of the stored liquid. The pressure is measured approximately 20 mm above

the tank bottom and indicated on the dial.

Pneumatic pressure is generated in the pressure line by pulling out and push-

ing back the pump plunger. The pressure line consists of the measuring line

(from the measuring instrument to the tank) and the vertical line (inside the

tank). The pneumatic pressure displaces the liquid from the vertical line.

When the pneumatic pressure is equal to the hydrostatic pressure acting at

the tank bottom, the liquid is fully displaced from the vertical line. Bubbles

start to escape at the lower end of the vertical line. In this condition, the

pointer has reached the maximum deflection and remains at the indicated

value.

The product enables consumption monitoring and timely re-fuelling. The tank

lorry driver can use the product to verify prior to filling whether the ordered

volume fits into the tank.

It is recommended to use the mounting kit Pneumofix type 2, see chapter

"Spare parts and accessories".

8

Product description

EN

Unitop

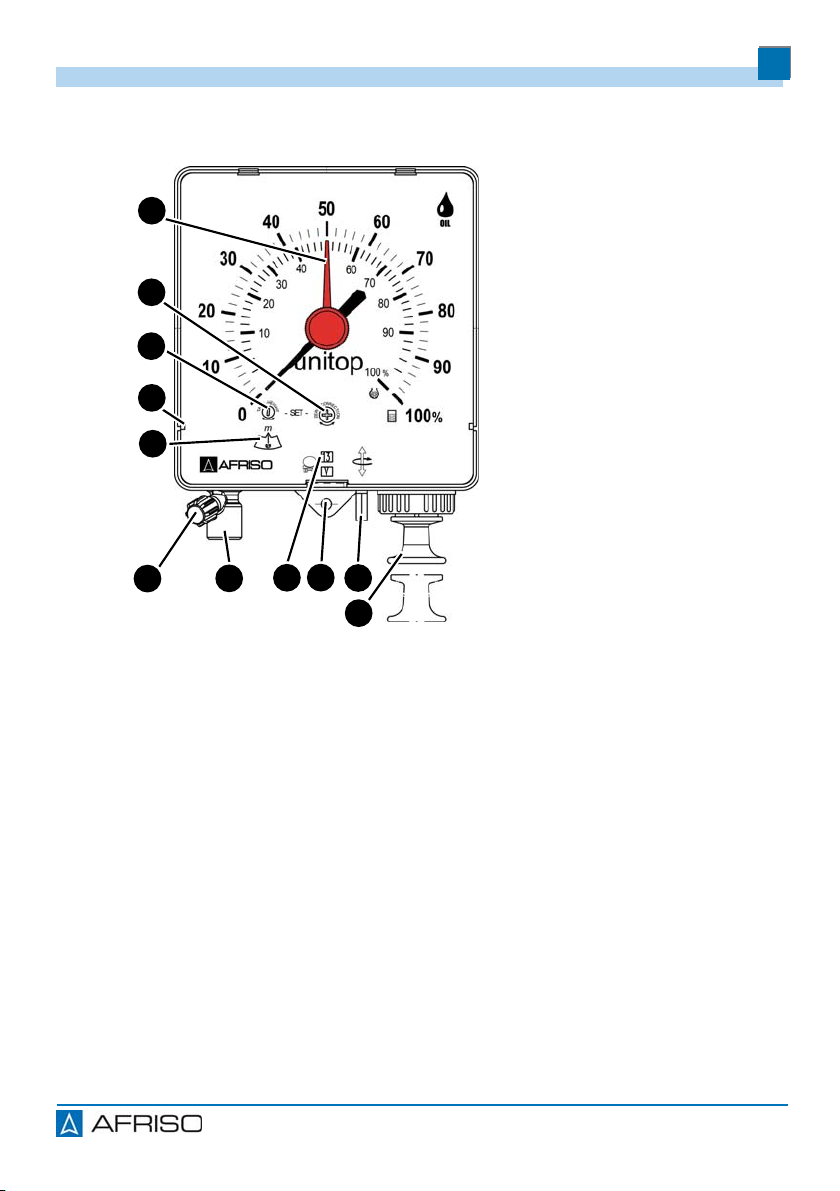

4.1 Overview

A. Red reference pointer

B. Adjustment screw for zero

correction

C. Adjustment screw for

measuring range

D. Support for additional

slide-in scale

E. Adjustment scale for

measuring range

F. Vent cap

G. Connection for measuring

line

H. Manual date indicator

I. Lug

J. Adjustment pin for date

indicator

K. Pump plunger

A

D

C

B

GH

E

IJ

K

F

9

Product description

EN

Unitop

4.2 Dimensions

166 mm

205 mm

281 mm

10

Product description

EN

Unitop

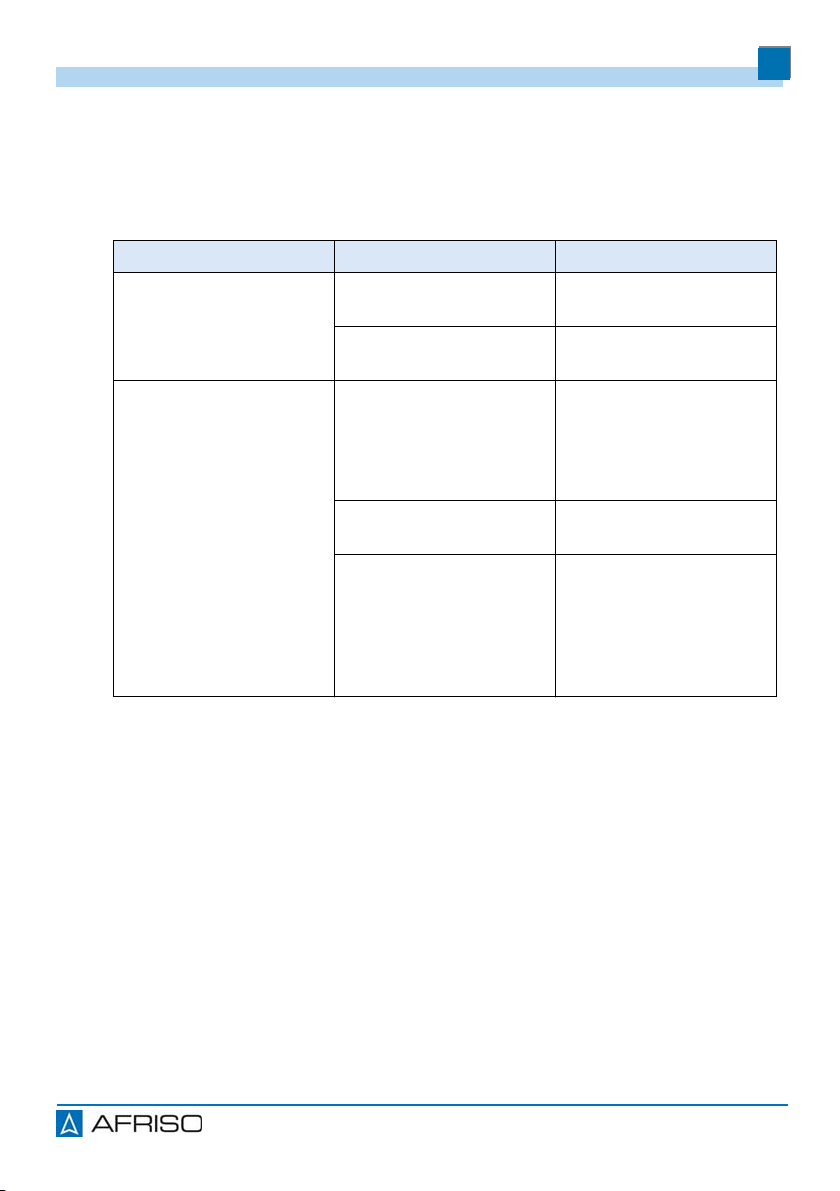

4.3 Technical specifications

Parameter Value

General specifications Unitop 3000 Unitop AdBlue®

Dimensions housing (W x

HxD) 155 x 166 x 73 mm

Weight 0.6 kg

Housing Plastic, ABS

Window Plastic SAN

Measuring system Brass

Measuring range

Fully adjustable 900 to 3000 mm tank

height 700 to 2300 mm tank

height

Measuring accuracy ±2 % of full scale value

Indication Standard: 0-100 % liquid level for rectangular and

cylindrical horizontal tanks, additional scales with

litre indication for standardised tanks and special

additional scales

Operating temperature range

Ambient -5/+55 °C

Storage -5/+55 °C

Vertical line (wetted)

Material The vertical line must consist of a material that is

neutral with regard to the medium

For example, for fuel oil EL, diesel fuel and FAME:

Pneumofix line (PVC), copper pipe or oil-resistant

Perbunan-N hose with weight as spacer

Inside diameter 4 mm for fuel oil EL, L, M, diesel fuel, FAME, liq-

uids with a kinematic viscosity up to 90 mm²/S

6 mm liquids with a kinematic viscosity up to

190 mm²/S

8 mm liquids with a kinematic viscosity up to

300 mm²/S

Measuring line

11

Product description

EN

Unitop

Length Max. 50 m

Version - Copper pipe 6 mm (outside Ø) x 1 mm

- PVC hose 4 mm (inside Ø)x1mm

- PE hose 4 mm (inside Ø)x1mm

Approved media Unitop 3000 Unitop AdBlue®

Medium Fuel oil EL or diesel fuel

(density = 0.84 g/cm³ at

+15°C)

AdBlue®

Parameter Value

12

Mounting

EN

Unitop

5 Mounting

5.1 Mounting the product

Verify that the housing is accessible and easy to oversee at all times.

Verify that the housing is protected against water and splash water.

Verify that the housing is not mounted in a humid room.

Verify that the ambient temperature is not exceeded at the housing.

Verify that the housing is protected from direct sunlight.

1. Drill two holes at the same height at a distance of 13 cm.

- Use the enclosed drilling template.

2. Insert the enclosed dowels.

3. Screw in the screws up to approx. 1.5 cm.

4. Fit the product onto the screws and slightly pull it down.

- The lug is flush with the wall.

5. Fasten the product to the wall by means of the third screw.

5.2 Adjusting the measuring range and calibrating the zero point

The measuring range and the zero point must be accurately adjusted for the

product to operate with maximum measuring accuracy.

Verify that the measuring

line has not yet been con-

nected or open the vent

cap (A). The system must

be unpressurised.

A

13

Mounting

EN

Unitop

1. Determine the measuring

range.

- Fuel oil EL and diesel

fuel: Measuring range =

tank height.

- Other liquids: See table

"Determining the meas-

uring range"

1. Open the window (A) by

means of a screwdriver.

2. Adjust the measuring

range (B) by means of an

Allan key.

3. Slightly tap at the side of

the housing

4. Correct the zero point (C)

by means of a screw-

driver.

5. Set the pointer to "0" by

means of a screwdriver.

Do not turn to the right or

left by more than 1 turn.

6. Insert the additional scale,

if applicable.

7. Close the window (A).

A

C

B

14

Mounting

EN

Unitop

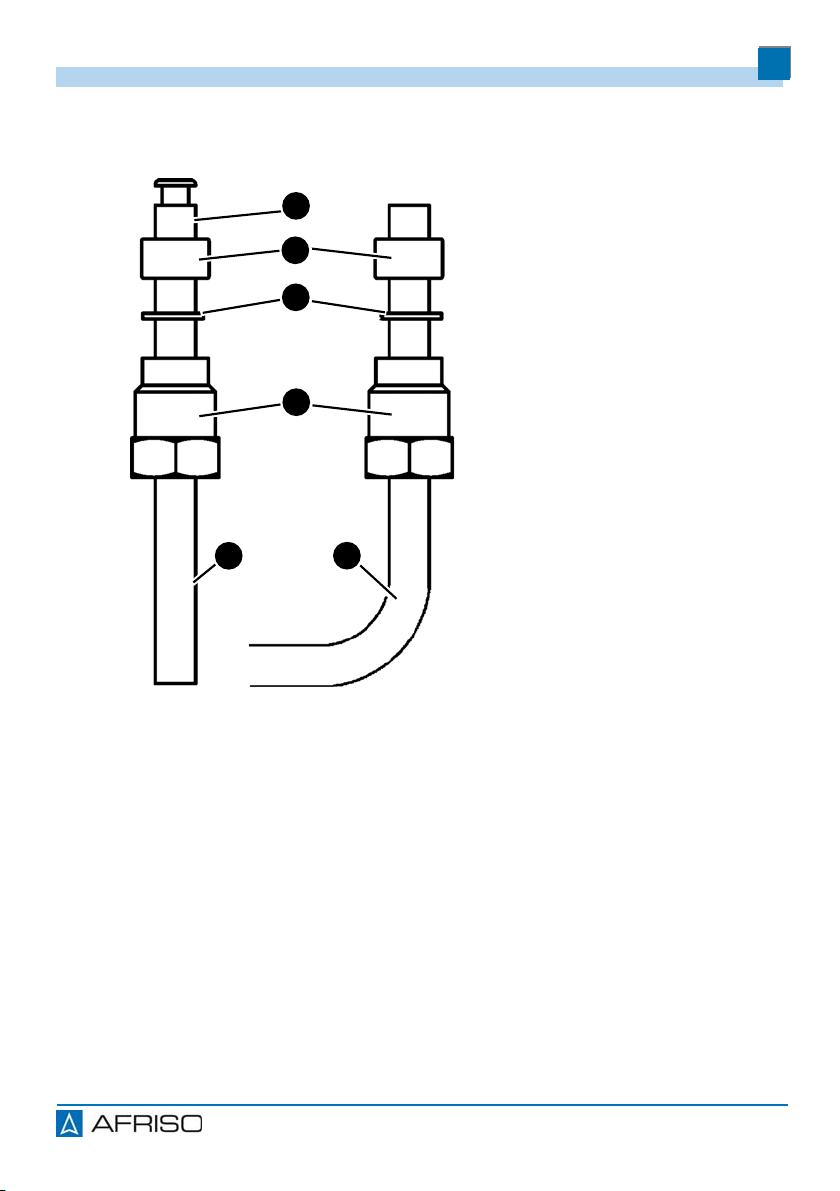

5.3 Mounting the line

If no connection thread is available on the tank, several lines can be con-

nected via the combination fitting "Euroflex 3" to a single G1 connection

thread.

1. Mount the vertical line in the tank in such a way that the lower end of the

vertical line is approximately 20 mm above the lowest point of the tank bot-

tom.

2. Install the measuring line with a steady gradient towards the tank, avoid

bends.

3. Push the screw connection onto the measuring line.

A. Unitop

B. Measuring line

C. Standpipe

D. Condensate trap

A

C

B

D

15

Mounting

EN

Unitop

If the measuring line does not have a steady gradient to the tank or if conden-

sate can collect in the measuring line, use a condensate trap.

1. Push the measuring line into the connection piece all the way to the stop.

2. Slightly tighten the compression screw.

3. Connect the vertical line and the measuring line.

A. Hollow rivet

B. Seal

C. Washer

D. Compression screw

E. Hose

F. In-line

A

B

D

C

F

E

16

Operation

EN

Unitop

6 Operation

Precise measurements are not possible during filling of the tank. The

pointer does not provide a stable reading during filling.

Verify that the vent cap is closed.

The product provides semi-permanent indication. The pump closes off the

measuring line when it reaches the upper dead end. The pointer stays tem-

porarily at its last reading and then drops back very slowly. As a result of this,

the gauge mechanism is protected by an air cushion.

1. Pull out the pump plunger all the way to the stop.

2. Then release the pump plunger.

3. Repeat the pumping procedure until the indicated value no longer

changes.

4. Read the level on the scale.

- If the measuring line has been installed airtight, the pointer of the gauge

will continue to show the last reading for a long period of time. In order

to obtain an accurate reading, always operate the pump before a read-

ing is taken.

The red reference pointer can be adjusted manually, for example to the level

after the last filling. The red reference pointer lets you compare the current

level to a previous level for consumption monitoring. The date indicator can

be adjusted manually, for example, in order to mark the date of the most

recent tank filling.

6.1 Setting the day

1. Push the adjustment pin to the top and turn it.

6.2 Setting the month

1. Push the adjustment pin down and turn it.

6.3 Use in flood hazard areas

The product is suitable for use in flood hazard areas; it is watertight up to 10

m water column (1 bar pressure).

The product does not have to be replaced after a flood.

17

Maintenance

EN

Unitop

7 Maintenance

7.1 Maintenance intervals

Perform a function test at least once per year.

When Activity

Water in condensate

trap Drain the condensate trap.

During tank mainte-

nance and/or tank

cleaning

Verify correct operation of the product and have

the product re-adjusted, if necessary.

18

Troubleshooting

EN

Unitop

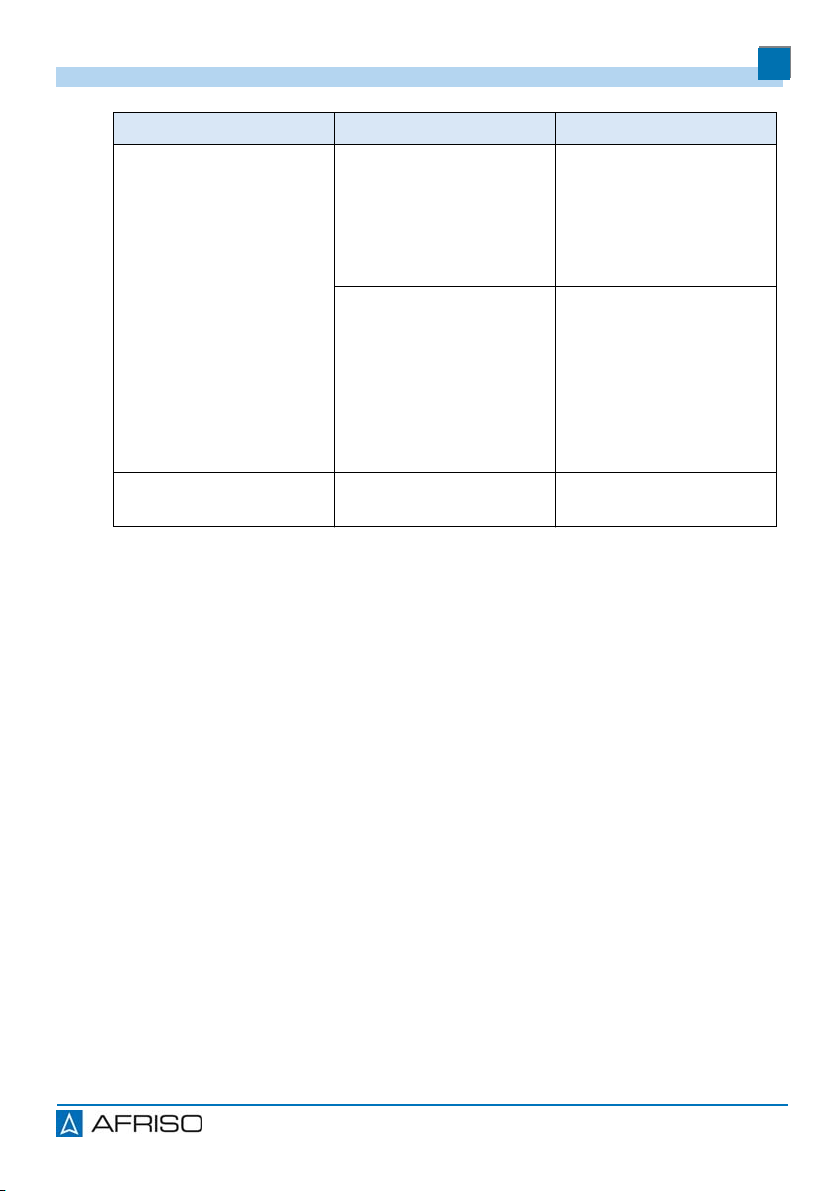

8 Troubleshooting

Any malfunctions that cannot be removed by means of the measures

described in this chapter may only be repaired by the manufacturer or by

qualified persons.

Problem Possible reason Repair

Pointer does not move

when pump is operated

or drops back very

quickly

Connections or lines

have a leak. Seal the connections

and lines.

Tank is being filling. Measure the level after

filling the tank.

Pointer goes beyond

100 % or pump plunger

does not fully return.

Measuring line clogged

or bent. Make sure there are no

bends in the measuring

line.

Install a condensate

trap.

Condensate trap full. Drain the condensate

trap.

Measuring range not

correctly adjusted. Verify and correct the

adjusted values (see

chapter "Adjusting the

measuring range and

calibrating the zero

point").

19

Troubleshooting

EN

Unitop

Problem Possible reason Repair

Incorrect indication Incorrect measuring

range

adjusted.

Verify and correct the

adjusted values (see

chapter "Adjusting the

measuring range and

calibrating the zero

point").

Incorrect zero adjust-

ment. Remove the pressure

from the system by

opening the vent cap.

Correct the zero point,

see chapter "Adjusting

the measuring range

and calibrating the zero

point".

Other malfunctions - Contact the AFRISO

service hotline.

20

Decommissioning, disposal

EN

Unitop

9 Decommissioning, disposal

Dispose of the product in compliance with all applicable directives, standards

and safety regulations.

1. Dismount the product (see chapter "Mounting", reverse sequence of

steps).

2. Dispose of the product.

10 Returning the device

Get in touch with us before returning your product.

11 Warranty

See our terms and conditions at www.afriso.com or your purchase contract

for information on warranty.

This manual suits for next models

1

Table of contents

Other Afriso EURO-INDEX Touch Panel manuals

Popular Touch Panel manuals by other brands

Contro l4

Contro l4 C4-TSWM7-E-B Technical specifications

Contro l4

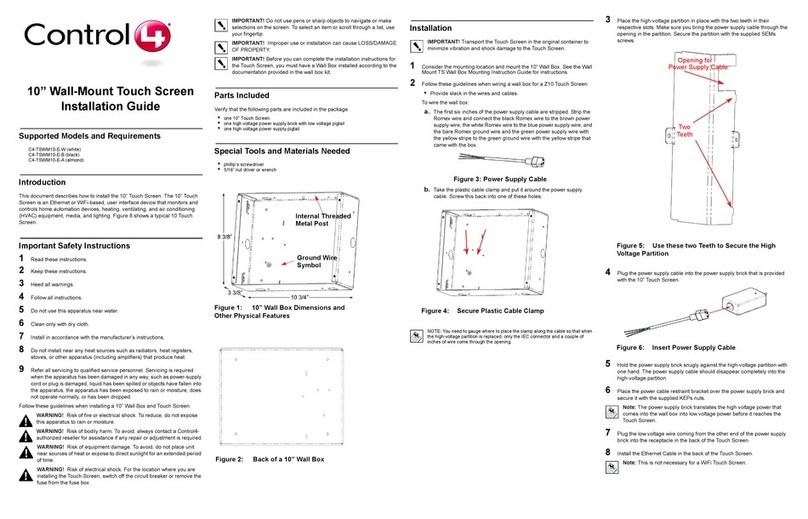

Contro l4 C4-TSWM10-E-W installation guide

Saia Burgess Controls

Saia Burgess Controls PCD7.D412DTPF manual

EL GENS

EL GENS LPC P-cap Series user manual

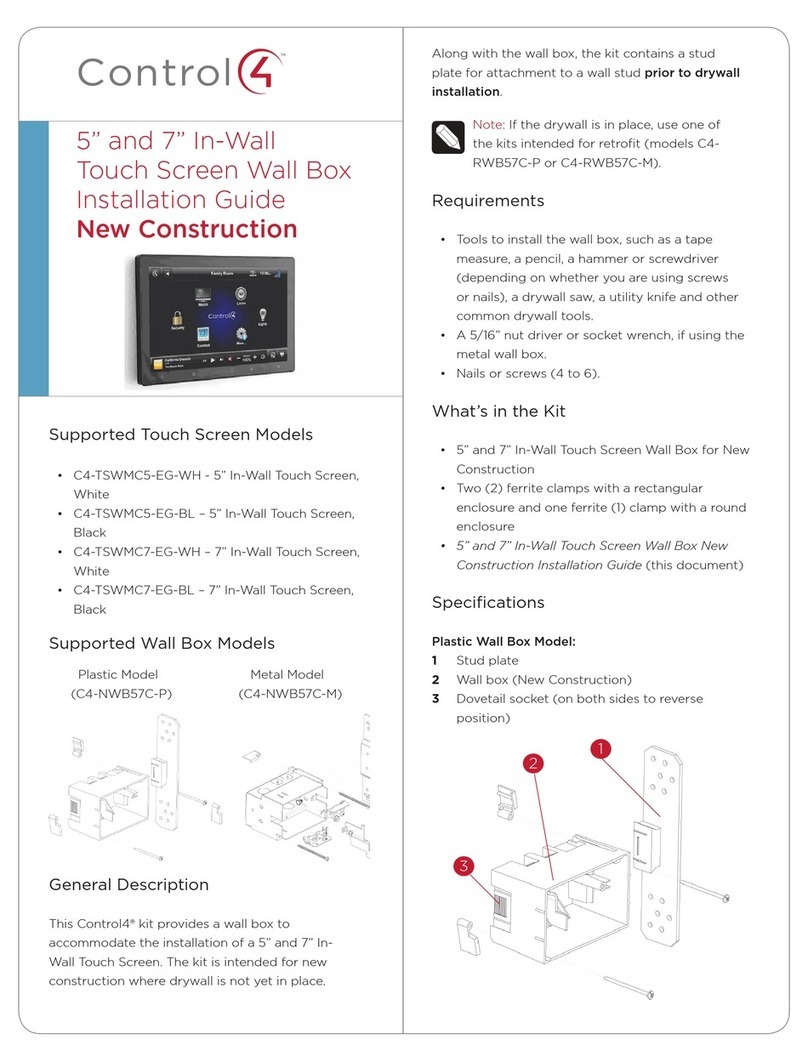

Contro l4

Contro l4 C4-TSWMC5-EG-WH installation guide

Contec

Contec IPC-PT/MV10 Series Software manual