Afriso EURO-INDEX DIT 01-E User manual

Read instructions before using device!

Observe all safety information!

Keep instructions for future use!

Version: 05.2011 0

ID no.: 854.001.0335

Mess-, Regel- und

Überwachungsgeräte

für Haustechnik,

Industrie und Umweltschutz

Lindenstraße 20

DE-74363 Güglingen

Telefon: +49(0)7135-102-0

Service: +49(0)7135-102-211

Telefax: +49(0)7135-102-147

Internet:www.afriso.de

Operating Instructions

Digital Tank Contents Indicator

Type: DIT 01

DIT 01 Product No.: 52122

DIT 01-E Product No.: 52123

2 DIT 01

Contents

1About this manual....................................................................................................4

1.1 Precautions ..................................................................................................4

1.2 Explanation of symbols and typeface ..........................................................4

2Safety ......................................................................................................................5

2.1 Intended use ................................................................................................5

2.2 Predictable incorrect application..................................................................5

2.3 Safe handling ...............................................................................................5

2.4 Staff qualification..........................................................................................6

2.5 Modifications to the product.........................................................................6

2.6 Usage of spare parts and accessories.........................................................6

2.7 Liability information ......................................................................................6

3Product description..................................................................................................6

3.1 Design..........................................................................................................7

3.2 Scope of delivery..........................................................................................8

3.3 Function........................................................................................................9

4Specifications ..........................................................................................................9

4.1 Approvals, tests and conformities..............................................................11

5Transportation and storage...................................................................................11

6Mounting and commissioning................................................................................12

6.1 Tank data determination ............................................................................12

6.2 Mounting the wall holder............................................................................13

6.3 Mounting the junction box..........................................................................13

6.4 Cable connection .......................................................................................13

6.5 Connecting the battery...............................................................................14

6.6 Zero balancing ...........................................................................................14

6.7 Mounting the pressure sensor....................................................................15

6.8 Entering the tank data................................................................................18

7Operation...............................................................................................................20

7.1 Switching on and off...................................................................................20

7.2 Display formats ..........................................................................................20

7.3 Correct tank data........................................................................................20

7.4 Subsequent zero balancing........................................................................21

8Maintenance..........................................................................................................21

8.1 Maintenance times.....................................................................................21

8.2 Replacing the battery.................................................................................21

9Troubleshooting.....................................................................................................21

10 Shutting down and disposal ..................................................................................22

11 Spare parts and accessories.................................................................................23

12 Warranty................................................................................................................23

13 Copyright ...............................................................................................................23

14 Customer satisfaction............................................................................................23

15 Adresses................................................................................................................24

DIT 01 3

About this manual

1 About this manual

This instruction manual is part of the product.

Read this manual before using the product.

Keep this manual during the entire service life of the product

and always have it readily available for reference.

Always hand this manual over to future owners or users of the

product.

1.1 Precautions

WARNING TERM

Type and source of the danger is shown here.

Precautions to take in order to avoid the danger are shown

here.

There are three different levels of warnings:

Warning term Meaning

DANGER Immediately imminent danger!

Failure to observe the information will result in

death or serious injuries.

WARNING Possibly imminent danger!

Failure to observe the information may result in

death or serious injuries.

CAUTION Dangerous situation!

Failure to observe the information may result in

minor or serious injuries as well as damage to

property.

1.2 Explanation of symbols and typeface

Symbol Meaning

Prerequisite for an activity

Activity consisting of a single step

1. Activity consisting of several steps

Result of an activity

• Bulleted list

Text Indication on a display

Highlighting Highlighting

4 DIT 01

Safety

2 Safety

2.1 Intended use

The DIT 01 digital tank contents indicator is exclusively suitable for

the measurement of filling levels in heating oil tanks with heights up

to 3 metres.

Any use other than the use explicitly permitted in this instruction ma-

nual in not permitted.

2.2 Predictable incorrect application

The DIT 01 digital tank contents indicator must never be used in the

following cases:

• Hazardous areas (ex)

2.3 Safe handling

The DIT 01 digital tank contents indicator represents state-of-the-art

technology and is made according to the pertinent safety regulations.

Each device is subjected to a function and safety test prior to ship-

ping.

Operate the DIT 01 digital tank contents indicator only when it is

in perfect condition. Always observe the operating instructions,

all pertinent local and national directives and guidelines as well

as the applicable safety regulations and directives concerning

the prevention of accidents.

The DIT 01 digital tank contents indicator is not a safety device.

It does not replace the function of a limit value transducer at the

heating oil tank.

The DIT 01 digital tank contents indicator may only be installed

in unpressurised heating oil tanks. A tank vent installed in ac-

cordance with the pertinent regulations as well as a limit value

transducer are required.

The cable entry point of the pressure sensor into the heating oil

tank must be significantly higher than the maximum filling level

and must be sealed with the enclosed screw connections in

such a way that no oil vapours can escape and that the pres-

sure sensor cannot move vertically

The measured values displayed, especially the litre indication

values, must not be used for billing purposes. The accuracy of

the measured values displayed depends on the accuracy of the

tank data determined and entered. Therefore, the manufacturer

cannot guarantee the accuracy required for billing purposes.

DIT 01 5

Product description

Extreme environmental conditions have negative effects on the func-

tion of the product.

Protect the DIT 01 from shocks.

Only use the digital unit in rooms.

Protect the digital unit from humidity.

2.4 Staff qualification

The product may only be mounted, commissioned, operated, main-

tained, shut down and disposed of by qualified, specially trained

staff.

Electrical work may only be performed by trained electricians quali-

fied in accordance with the local and national directives.

2.5 Modifications to the product

Changes or modifications made to the product by unauthorised per-

sons may lead to incorrect readings and are prohibited for safety

reasons.

2.6 Usage of spare parts and accessories

Usage of unsuitable spare parts and accessories may cause dam-

age to the product.

Use only genuine spare parts and accessories of the manufac-

turer (refer to chapter 11, page 23).

2.7 Liability information

The manufacturer shall not be liable for direct or consequential dam-

age resulting from failure to observe the technical instructions, guide-

lines and recommendations.

The manufacturer and the sales company shall not be liable for costs

or damages incurred by the user or by third parties in the usage or

application of this device, in particular in case of improper use of the

device, misuse or malfunction of the connection, malfunction of the

device or of connected devices. The manufacturer or the sales com-

pany shall not be liable for damages resulting from any use other

than the use explicitly permitted in this instruction manual.

The manufacturer shall not be liable for misprints.

3 Product description

The DIT 01 digital tank contents indicator consists of an electronic

pressure sensor and a microprocessor-controlled digital unit con-

tained in a sturdy plastic housing. The measured values are shown

on a 4-digit liquid crystal display (LCD). The function key F allows

you to switch on the device and select the display modes litres, cubic

6 DIT 01

Product description

metres, percentage and filling level. The device is programmed via

the two keys . A lithium battery is contained in the housing of the

digital unit. The battery is not connected when the device is shipped.

The free end of the cable is connected to the pressure sensor. The

pressure sensor and the digital unit form one unit. The pressure sen-

sor is placed in the tank from the top and is mounted either with a

connection and sealed.

The pressure sensor includes a spacer so that the measuring hole of

the pressure sensor remains above the oil sludge level.

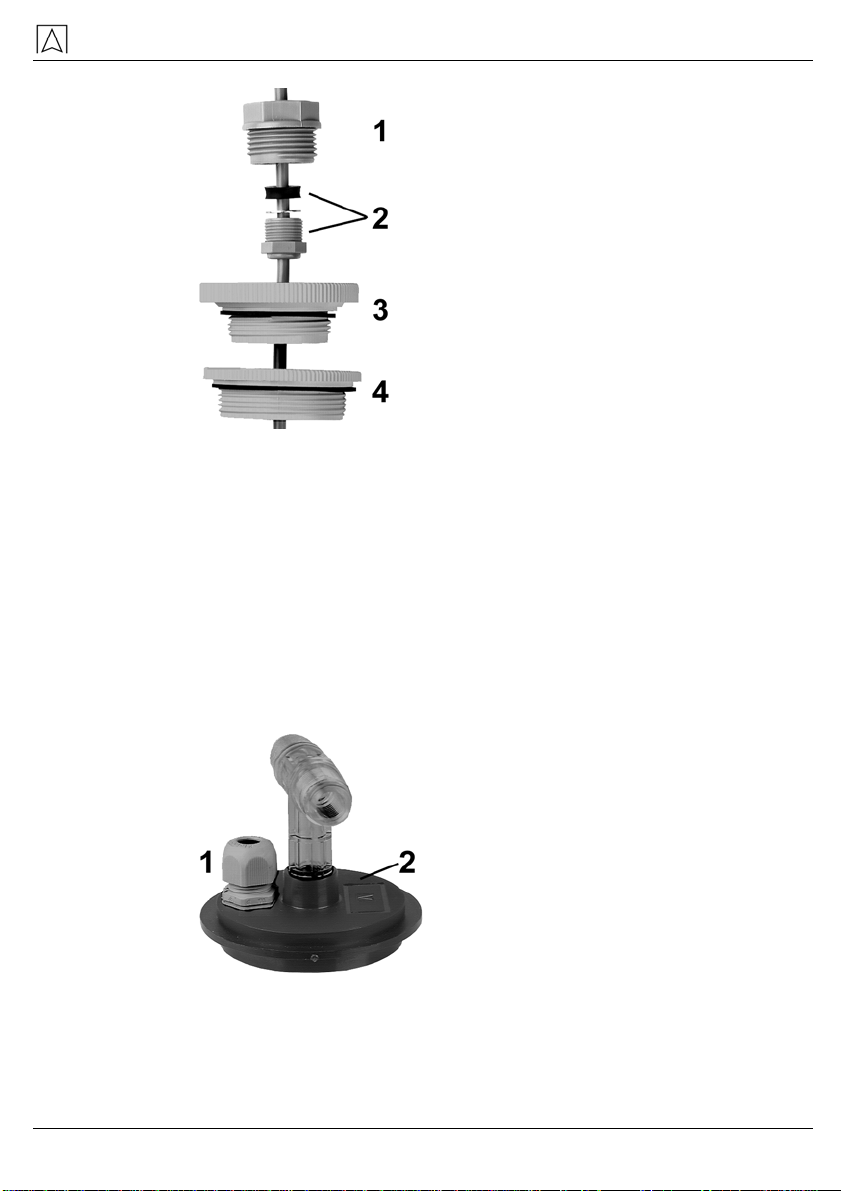

Different screw connections are shipped with the pressure sensor

which are used to mount the pressure sensor cable to the tank and

seal it.

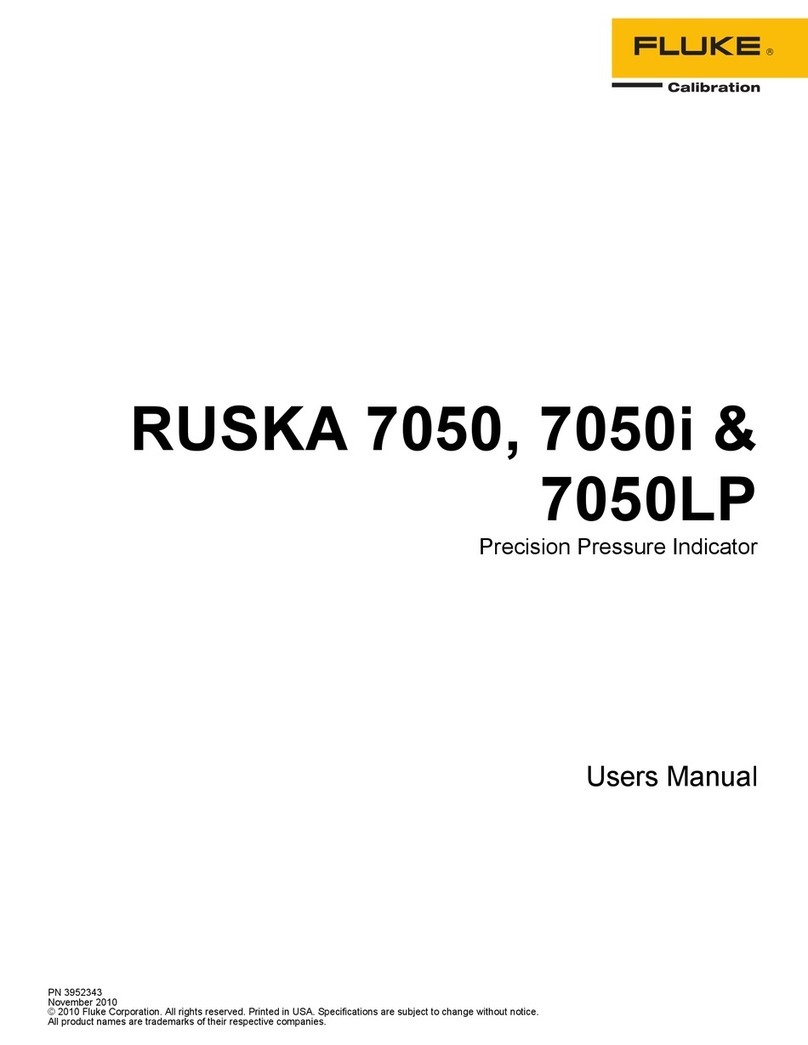

3.1 Design

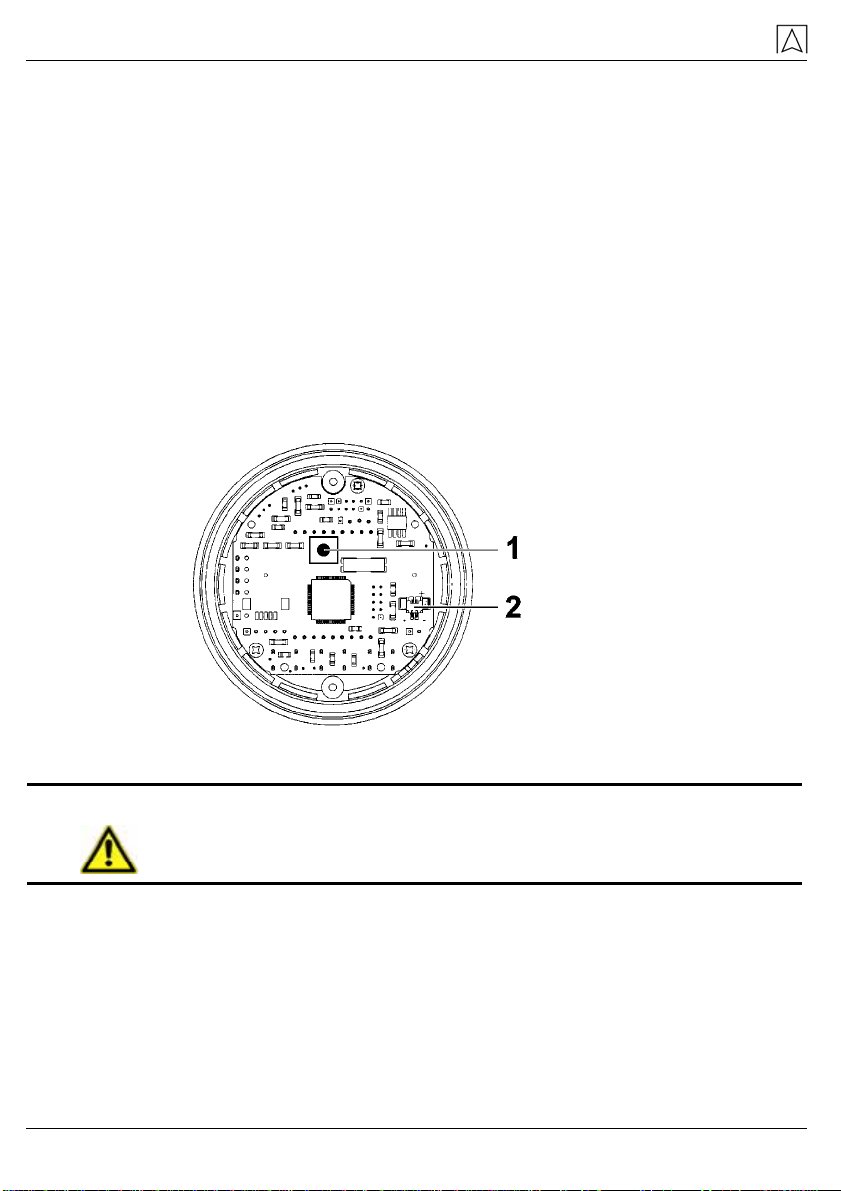

1 Display

2 Programming keys

3 PG screw connec-

tion

4 Cable

5 Function key

Fig. 1: Digital unit

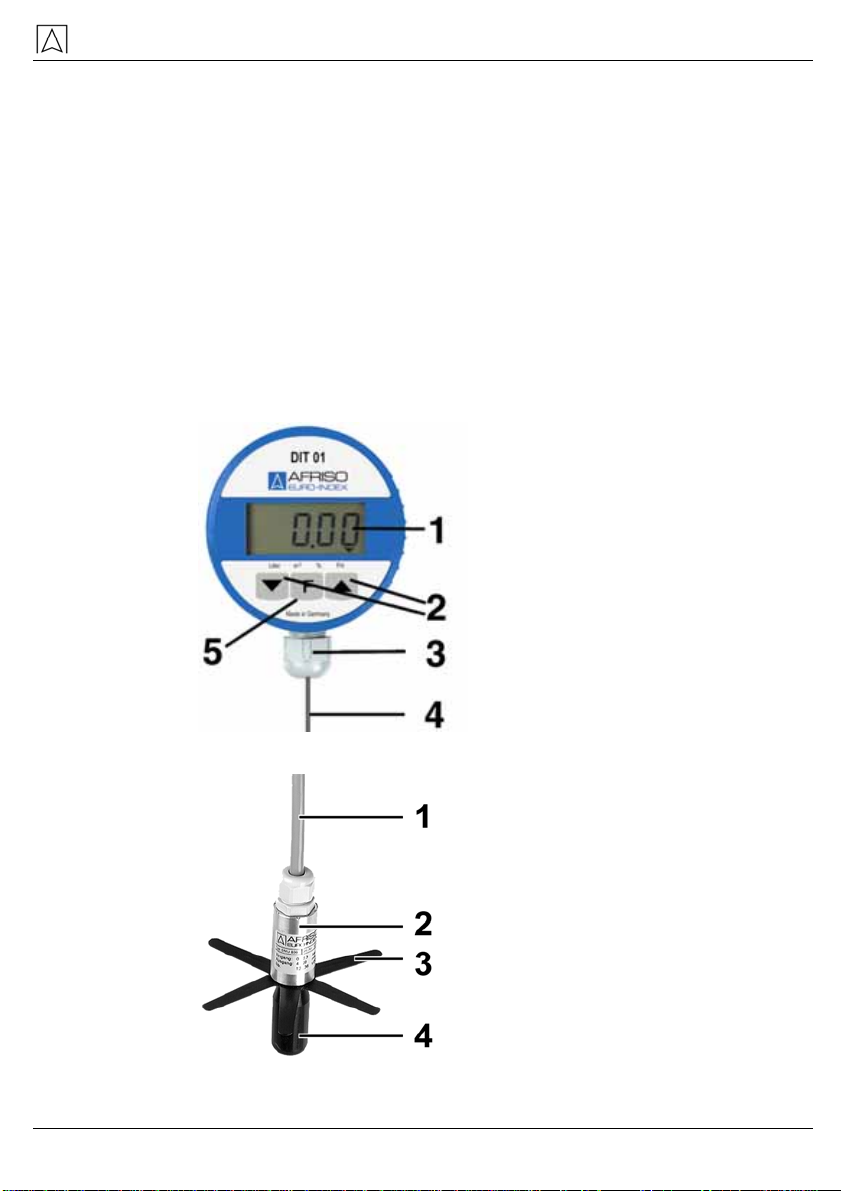

1 Cable with vent tube

2 Pressure sensor

3 Star

4 Spacer

Fig. 2: Pressure sensor with spacer

DIT 01 7

Product description

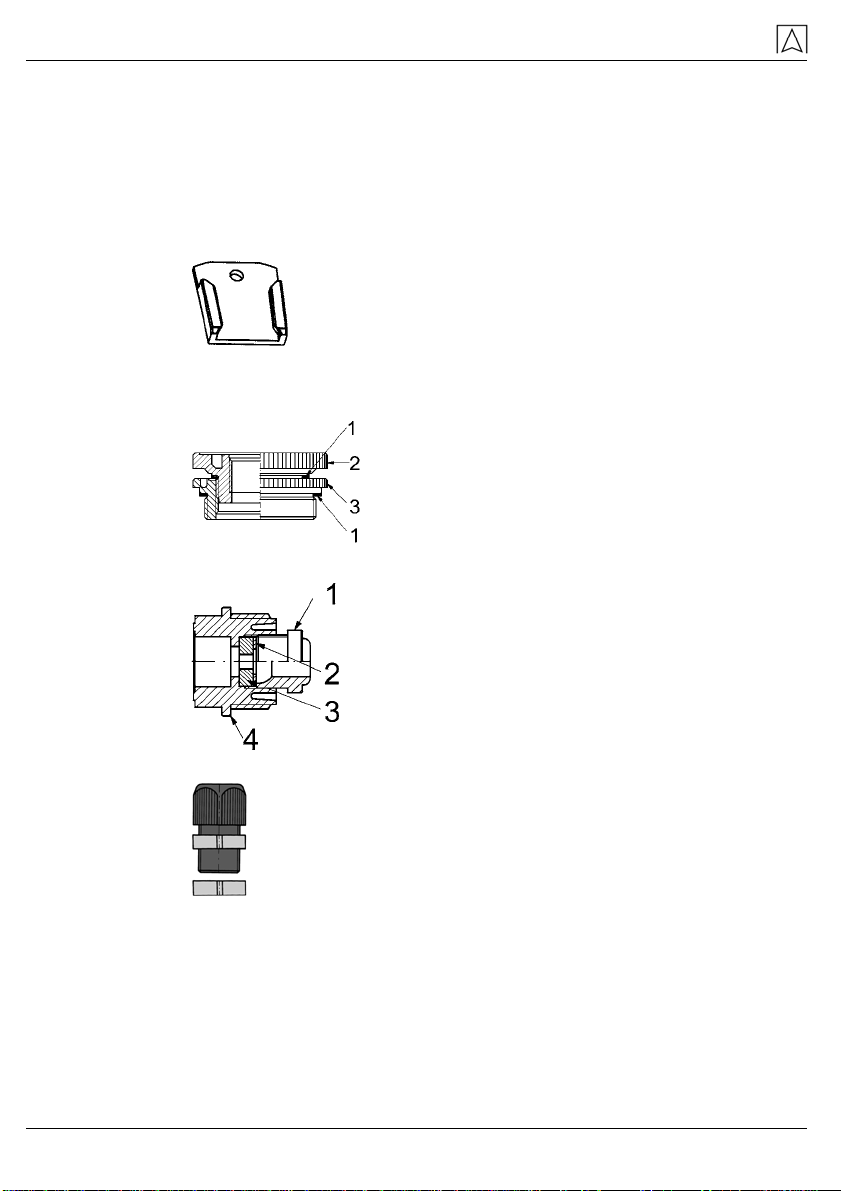

3.2 Scope of delivery

• Digital unit

• Pressure sensor with spacer

• Moisture-proof junction box

• Insulating screw joint, 4 poles

• Wall holder for DIT 01:

Screw connection DIT 01

• Connection set 2" x 1½" x 1":

1 Flat packing NBR

2 Adapter G1½ - Rp1

3 Adapter G2 - G1½

• Screw connection 1":

1 Gland

2 Washer Ø 17

3 Plug

4 Screw fitting

• Connection PG9 with hex nut:

8 DIT 01

Specifications

Connection DIT 01-E

• Euroflex combination withdrawal fitting with 3.1 m suction tube,

2 O rings (6.5 x 1.5 mm) and pressure screw:

3.3 Function

The pressure sensor is located at the lowest point of the heating oil

tank and transforms the hydrostatic pressure of the heating oil into

an electrical signal. The measuring signal is transmitted to the digital

unit via the cable. The electronic system of the digital unit uses this

signal to calculate the tank contents, which it displays in litres, cubic

metres, percentage or filling level. The display mode is selected by

means of the F function key. The tank data is entered via the two

programming keys.

4 Specifications

Table 1: Digital unit

Parameter Value

General

Dimensions (ø x L) 75 x 50 mm

Weight 380 g

Cable length 5 m

Housing material PA6 15 % glass ball reinforced

Power supply 3,6 V lithium battery

Battery life Max. 8 years (pressing the F key 1 x

per month)

Display 4-digit LCD

DIT 01 9

Specifications

10 DIT 01

Parameter Value

Resolution 14 bit

Measuring input 0-3,6 V

Accuracy* < ± 1,0 % FSO, IEC 60770

Operating temperature range

Ambient 0 °C to +45 °C

Storage -5 °C to +80 °C

Electrical safety

Protection IP 51 EN 60529

Electromagnetic compatibility (EMC)

Noise suppression According to EN 50081-1

Noise immunity According to EN 50082-1

Table 2: Pressure sensor

Parameter Wert

General

Dimensions (ø x L) 25 x 107 mm

Weight 410 g

Cable length 5 m

Pressure range 0-300 mbar

Accuracy* < ± 1,0 % FSO, IEC 60770

Temperature error < ± 2 % FSO, 0-60 °C

Material

Housing Stainless steel 1.4305

Cable Heating oil-resistant PVC

Spacer POM, PE

Additional parts coming

into contact with the me-

dium

Ceramiks, silicon, silicone glue, Viton

Operating temperature range

Medium 0 °C to +60 °C

Transportation and storage

DIT 01 11

Parameter Wert

Storage -5 °C to +80 °C

Electrical safety

Protection IP 68 EN 60529

Electromagnetic compatibility (EMC)

Noise suppression According to EN 50081-2

Noise immunity According to EN 50082-2

Accuracy of complete system*: < ± 1,5% FSO, IEC 60770

* With reference to the filling level indication in mm.

4.1 Approvals, tests and conformities

The device meets complies with the European directive Electromag-

netic compatibility (89/336/EEC and 92/31/EEC).

5 Transportation and storage

CAUTION

Damage to the device due to improper transportation.

Do not throw or drop the device.

CAUTION

Damage to the device due to improper storage.

Protect the device against shock when storing it.

Store device in a clean and dry environment.

Store device only within the admissible temperature range.

Mounting and commissioning

6 Mounting and commissioning

6.1 Tank data determination

Before the DIT 01 tank contents indicator is installed, you must de-

termine the appropriate tank data. Please document the tank data on

this page for safety reasons and to allow for subsequent checks.

Tank shape

Refer to the table below to find the appropriate code for the tank

shape. If you want a linear indication, use the code 1.

Tank shape

code Tank shape Description

1 Linear tank Rectangular tanks, upright, cylin-

ders, steel tanks welded in base

ments, all other linear measuring

applications.

2 Tubular tank Vertical cylinder

3 Ball-shaped tank Ball-shaped tank

4 Plastic battery

tank Plastic battery tanks with armour-

ing or arches

5 Oval tank Oval basement tanks, e.g glass-

fibre reinforced tanksor steel

sheet tanks

6 Plastic tank with

recess Plastic tanks with major recess

major in the centre (manufactur-

ers: e.g. Roth, Werit)

Determined tank shape code:

Tank volume

Determine the total volume of the tank facility in litres.

Determined tank volume: litres

Tank height (max. filling level)

Determine the tank height in mm.

Determined tank height: mm

Current filling level

Determine the current filling level as exactly as possible in mm.

Determined filling level: mm

12 DIT 01

Mounting and commissioning

6.2 Mounting the wall holder

Use the enclosed screw (4 x 30 mm) and, if necessary, a dowel

(6 mm) to mount the wall holder for the DIT 01 tank contents in-

dicator at the desired location.

6.3 Mounting the junction box

The provided moisture-proof junction box is not suitable for exterior

application.

1. For exterior application use the exterior junction box, refer to

chapter 11, page 23.

2. Use the enclosed screws and, if necessary, dowels, to mount

the junction box for connecting the pressure sensor cable and

the cable of the digital unit at the desired location. Make sure to

provide sufficient cable length. The digital unit must be able to

be removed from the wall holder, e.g. if you need to replace the

battery.

2. Place the digital unit into the wall holder and route the cable into

the junction box.

3. Push the connection elements required for the tank connection

(PG connection, screw connection or Euroflex) onto the pres-

sure sensor cable in the correct sequence and orientation.

6.4 Cable connection

1. Route the cable of the pressure sensor to the junction box and

connect the two cables by means of the insulating screw joint.

Make sure to connect the wires of the same colour, respectively.

Digital unit

1 White (U+)

2 Green (signal)

3 Brown (U-)

4 Yellow/black (screen)

5 Insulating screw joints

6 Pressure sensor

7

Fig. 3: Cable connection

DIT 01 13

Mounting and commissioning

4. A transparent tube can be seen at the cable end of the pressure

sensor. This tube provides the pressure sensor with atmos-

pheric pressure. Make sure not to close or bend this tube in or-

der to avoid incorrect measurements.

The junction box must be closed in such a way that it is water-

tight but not completely airtight.

6.5 Connecting the battery

1. After you have electrically connected the pressure sensor and

the digital unit, open the housing of the digital unit by turning the

upper part of the housing all the way to the stop and pulling it

up.

5. Press the miniature button (1) and keep holding it down. Plug

the 2-pole battery plug into the 2-pole socket (2) on the printed

circuit board.

Miniature

button

1

2-pole socket

2

Fig. 4: Printed circuit board

WARNING

Danger of explosion in case of short circuit of the lithium bat-

tery.

Do not short-circuit the lithium battery.

6. Release the miniature button.

6.6 Zero balancing

1. Close the housing of the digital unit by pushing the two housing

parts together.

Since the battery was connected, the digital unit was switched on.

The display switches between "Zero" and the current offset of the

pressure sensor (indication in hPa = mbar). The top left corner of the

14 DIT 01

Mounting and commissioning

display shows the arrows to indicate that you are in calibration

mode.

7. Press the keys and simultaneously to correct the offset to

the value 0.00.

When you do this, the pressure sensor must not be in the

tank.

In this state, you can zero the system any number of times.

8. Press the F key in order to exit the zero balancing mode.

An arrow is shown at the bottom of the display pointing to the

unit Litres.

6.7 Mounting the pressure sensor

The unit is zeroed.

1. Plug the star onto the sensor, observe the position of the fins at

the star.

9. Screw the star to the probe by means og the spacer.

Spacer

1 Star

2 Pressure sensor

3

Fig. 5: Mounting the pressure sensor

10. Bend the arms of the star to the front.

11. Push the probe through the tank connection thread.

Fig. 6: Pushing the probe in the tank

DIT 01 15

Mounting and commissioning

12. Move the cable in the connection until the probe tip just reaches

the tank bottom. The measuring hole of the pressure sensor

must not be immersed in the oil sludge. The oil volume below

the level of the measuring hole is not detected by the pressure

sensor.

13. Insert the withdrawal hose after you have inserted the pressure

sensor.

Fig. 7: Inserting the withdrawal hose

14. Seal the connection in the tank cover to make the connection

smell-tight and tighten the connection to prevent the cable from

moving.

Mounting with screw connection

Using a free 1", 1½" or 2" connection in the tank:

1. Insert the cable of the pressure sensor into the 1" screw con-

nection and use parts of the 2“ x 1½“ x 1 “ screw connection set

to seal it in the tank.

16 DIT 01

Mounting and commissioning

1“ thread

1 Connections elements to fixate the

cable

2

1½“ thread

3 2“ thread

4

Fig. 8: Mounting with screw connection

15. Determine the required cable length as described above.

16. Then tighten the screw connection in such a way that the cable

can no longer move and that the connection is smell-tight.

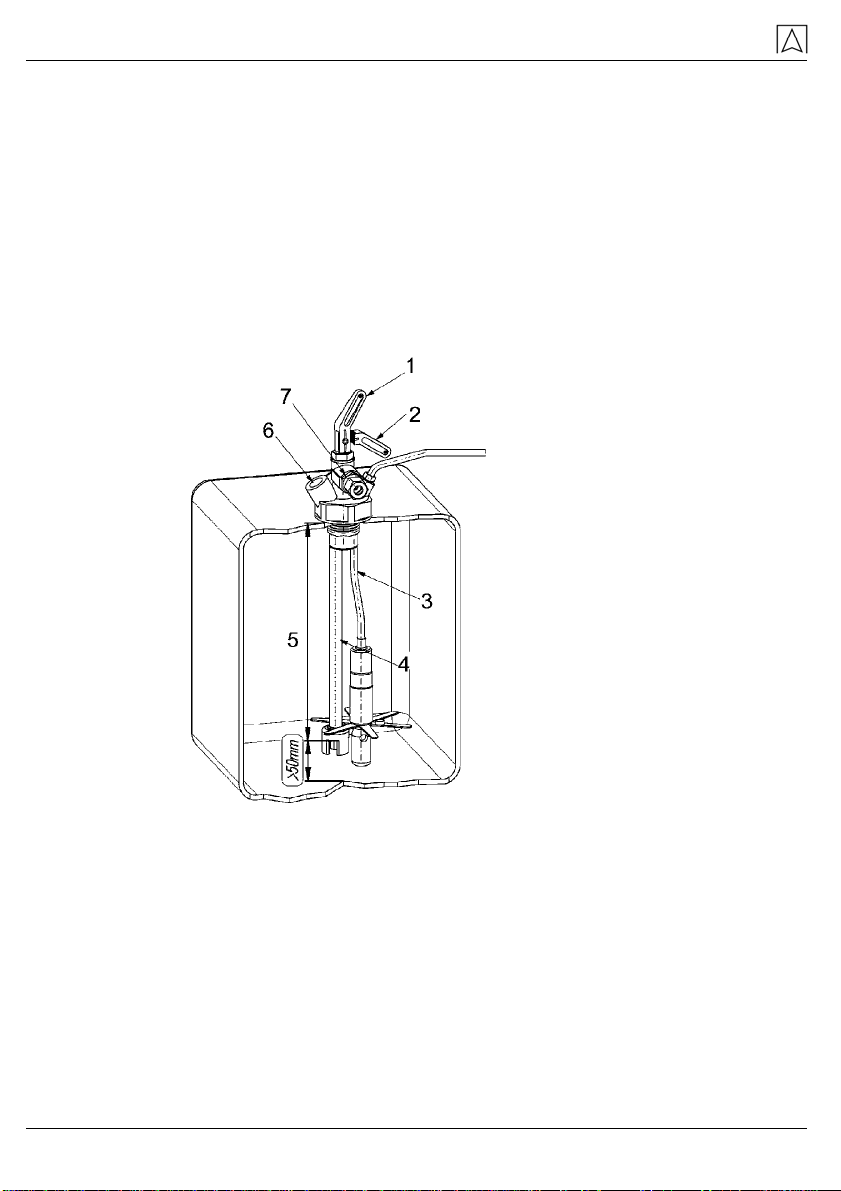

Mounting with PG 9 connection

In an installation flange with union nut, in a screw cap or in a free

blind connection:

1. Remove the installation flange, the screw cap or the blind con-

nection and drill a 15 mm hole.

Never drill directly into the tank.

When drilling, make sure that chips do not fall into the tank.

PG 9 connection

1 Installation flange

2

Fig. 9: Mounting with PG 9 connection

17. Insert the enclosed PG9 connection and fasten it with the en-

closed nut.

DIT 01 17

Mounting and commissioning

18 DIT 01

18. Insert the cable of the pressure sensor into the PG connection,

determine the required length as described above and fixate it in

a smell-tight way.

Mounting with Euroflex

1. Lower the pressure sensor into the tank.

19. Determine the required cable length as described above.

20. Tightly screw the black plastic screw (pressure screw) into the

body of the Euroflex fitting. This applies pressure to the two

O rings between the cable and the body of the Euroflex fitting,

fixates the cable and assures a pressure-tight connection.

1 Valve open

2 Valve closed

3 Measuring tube for

el. hydrostatic level

measurement

4 Suction tube

5 Tube or probe length

6 Return connection

G 3/8 IG

7 Suction connection

G 3/8 IG

Fig. 10: Mounting with Euroflex

6.8 Entering the tank data

The unit is zeroed.

The pressure sensor is installed in the tank.

Tank shape

The arrow at the bottom of the display points to the unit Litres.

The display shows the tank shape code of the currently selected

tank shape. When the unit is commissioned for the first time, the

Mounting and commissioning

DIT 01 19

display show the tank shape code 0. The 0 indicates that no

tank shape code has yet been selected.

1. Use the and keys to set the previously determined tank

shape code (see chapter 6.1, page 12).

F key to confirm the tank shape setting and continue

e of the tank facility. Press to select the digit to be

a

F key to confirm the volume setting and continue with

e bottom of the display points to the unit Per- . If

digit to be modified. Press to

ted digit in the range from 0 to 9.

cy is obtained if

21. Press the

with the tank volume data.

Tank volume

The arrow at the bottom of the display points to the unit m³.

The display shows the currently selected tank volume. If the

display shows 0000 this means that no tank volume has yet

been entered.

1. Use the and keys to set the previously determined total

volum

modified. Press to change the selected digit in the range from

0 to 9 Volumes of up to 9999 litres are entered without a comm

digit.

2. Volumes greater than 9999 litres are entered as cubic- metres

(1000 litres = 1 cubicmetre) with a comma digit. Press to

move the comma digit.

3. Press the

the tank height data.

Tank height

The arrow at th

centage. The display shows the currently selected tank height

the display shows 0000 this means that no tank height has yet

been entered.

1. Use the and keys to set the previously determined tank

height. Press to select the

change the selec

2. Press the F key to confirm the volume setting and continue with

the current filling level data.

Current filling level

The arrow at the bottom of the display points to the unit Filling

Level (FH). The display shows the filling level currently meas-

ured by the probe.

If you measure heating oil, the reading should be pretty close to the

actual filling level. If you need a greater accuracy, enter the previ-

ously determined filling level. Please note: the fuller the heating oil

tank, the greater the accuracy. The maximum accura

Operation

20 DIT 01

the tank is completely full. At levels of less than 50 %, a correction o

the value indicated is not meaningful. In order to correct the curren

filling level, you can overwrite the displayed value.

f

t

ined filling

the range from 0 to 9.

ank data are entered and the digital unit switches to

mal measuring mode.

e symbol in the top left corner of the display is no longer

7 O

7.1 Swi on the display of the digital unit. The

-

battery is not used. By pressing the F key again,

7.2 display

play points to m³.

• .

at the bottom of the display points to %.

7.3

---“. Only the current fill-

Hold down the and keys simultaneously for three seconds

to activate the "Enter tank data" mode.

1. Use the and keys to set the previously determ

level. Press to select the digit to be modified. Press to

change the selected digit in

2. Press the F key to confirm the filling level setting.

All required t

nor

Th

shown.

peration

tching on and off

Press the F key to switch

digital unit is automatically switched off approx. 2.5 minutes af

ter you press a key.

The display shows OFF.

In this mode, the

you reactivate the tank contents indicator for another 2.5 minutes

and the current filling level is displayed.

Display formats

Press the F key several times to select one of the four

formats for the filling level:

• Displaying the volume in litres.

The arrow at the bottom of the display points to litres.

• Displaying the volume in m³.

The arrow at the bottom of the dis

Displaying the volume in percent of the total contents

The arrow

• Displaying the filling level in mm.

The arrow at the bottom of the display points to FH.

Correct tank data

If the measured value exceeds the tank entered data (e.g. because

you entered incorrect tank data), the display will blink. The display

will toggle between the indicated value and “-

ing height in mm will be displayed permanently.

This manual suits for next models

1

Table of contents

Other Afriso EURO-INDEX Touch Panel manuals

Popular Touch Panel manuals by other brands

IEI Technology

IEI Technology IMK-571R Software and programming guide

Seametrics

Seametrics FT450 instructions

IEI Technology

IEI Technology IOVU-210AD-RK39 user manual

Faytech

Faytech FT32N4200W4G128GCAP manual

TCS

TCS TrainSpeed1 operating manual

Avalue Technology

Avalue Technology AID-156ST2 Quick reference guide