AFS L-SINGLE User manual

INSTRUCTIONS FOR USE

Preparation

1. Start by removing the cellophane wrapping from the filter cartridge.

2. Carefully inspect the bottom of the filter housing where the paper is looking for any tears or imperfections that

could result in a rupture. Any questionable defects should be addressed with AFS for a replacement prior to use,

or use a secondary backup filter (as outlined below)

3. (Optional): For best results poke a small hole in the filter lid and place in a vacuum oven at 100˚F for 30-60

minutes prior to use. This helps eliminate any humidity/moisture that may have accumulated in the media.

4. Peel foil lid away from cartridge and discard.

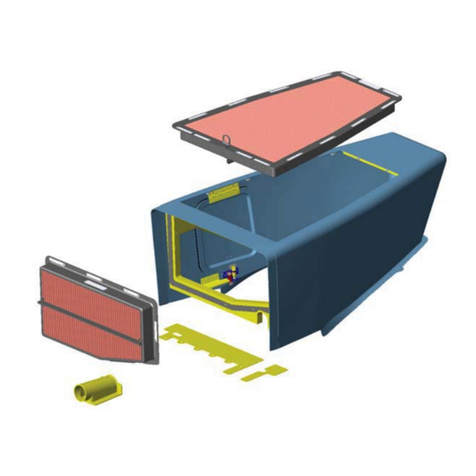

5. Place filter cartridge into filter housing.

6. Using a seal/bearing punch (available at most automotive stores/harbor freight) firmly press the filter media to

ensure a tight packing in case pack was disrupted during the shipping process.

*** Important! Do not skip this step. Failure to pack will cause channeling which could result in poor filter

performance and possible filter paper rupture. ****

Installation

7.

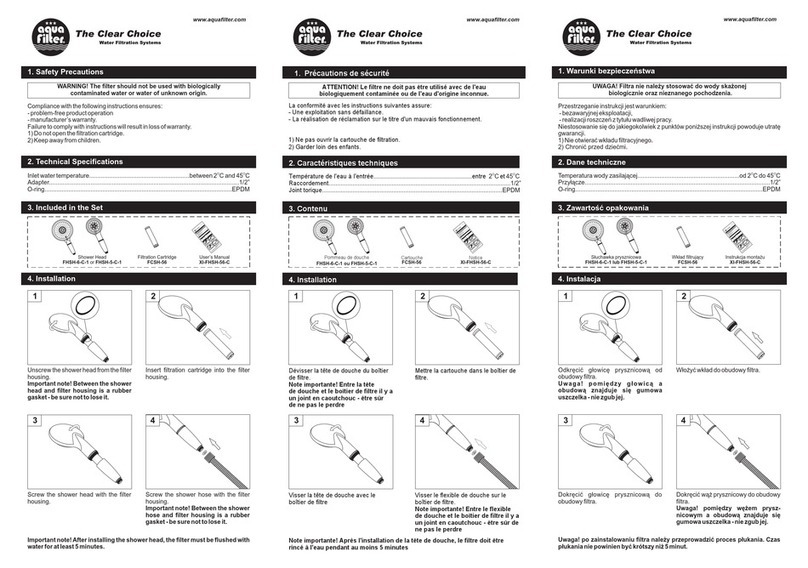

a. For internal systems provided by the OEM attach the filter housing to the flange using the 2.5” tri-

clamp. The filter cartridge itself acts as the gasket. Tighten bolts to 10ft/lbs.

Place entire assembly back into column and follow reassembly procedures per manufacturers’

instructions.

b. For external systems running inline, assemble the base of the filter housing by installing the 2.5” -> 1.5”

reducer using a gasket and clamp. The base of the filter housing is the side closest to the screen plate.

Tighten bolts to 4ft/lbs.

Install another 2.5”->1.5” cap reducer onto the top of the filter housing using the filter itself as the

gasket. Tighten bolts to 10ft/lbs.

Place inline assembly within the flow path of your extraction system using standard 1.5” tri-clamp

connections. For best results/control place the assembly directly below a ball valve.

*Please note, inline housings are not equipped with pressure relief valves or other safety related

components. Please ensure your system has adequate protection for where housing is located. Do not

place between two ball valves or closed cylinders without adequate protection.

Operation

8. Operate the extraction system as normal with the fill/soak process (see manufacturer’s recommended operating

procedures).

9. When it comes time for the solution to pass through the filter housing it will require Nitrogen or Argon assist (do

not use compressed air). Set the pressure on the nitrogen regulator to no more than 60psi.

10. Connect the nitrogen line to the top of the materials column and fill the head space with nitrogen.

11. Activate the recovery pump as with a normal operation. The combination of the nitrogen pressure above the

filter and the vacuum pressure below the filter will cause the solution to flow through the media. Depending on

media type and solution viscosity flow may vary. It is recommended to suspend the addition of heat to the

collection vessel until ample solution has passed through the filter allowing a liquid solution to pool in the

collection vessel. This will help prevent burning of extract materials if evaporation/recovery is happening at a

rate faster than the flow through the filter.

12. Once the solution is finished passing through the filter (as observed by sight glasses when available), you may

vent off the nitrogen from the system to keep it from circulating through the system and being recovered into

the recovery tank.

Disposal

13. Once the run is complete, remove the filter cartridge from the housing assembly and discard.

*Some contents of filters may cause irritation if handled. Wear appropriate protective gloves and eye wear when

handling. Do not remove contents of filters as some contents may be harmful to respiratory system. In case of

accidental spillage, use appropriate respiratory masks. Do not eat contents. Not intended for internal use.

*Prop 65: May contain chemicals known to the state of California to cause cancer, birth defects, or other reproductive

harm.

(Optional) Secondary Backup Filtration

For added safety against a rupture condition a secondary filter may be used. Secondary filters will slow the flow/recovery

rate, however they provide a secondary layer of protection in case the initial filter paper layer of the AFS filter should fail.

AFS filters have been tested to 120psi head pressure without failure; however other varying conditions could contribute to

membrane failure. Inexperienced with AFS/CRC it is recommended to use secondary filtration layer.

OEM or inline housings can accomplish a secondary filter backup by placing a secondary 2.37”(69mm) quantitative filter

paper into the OEM housing. Then place Dash# 035 O-ring (9452K123) into the OEM housing on top of the filter paper.

Make sure the o-ring is seated fully into the base or it will roll to the side when the AFS filter is inserted. Next slide the AFS

filter into the OEM housing. As you tighten the tri-clamp seal into your extraction unit it will force the AFS filter to seat

securely into the housing sealing against the o-ring.

Opt 2.

Inline housings have a secondary tri-clamp on the bottom of the housing where a secondary sintered stainless filter may be

used as a backup filter in case the primary filter paper were to rupture. Using a secondary process will slow the

flow/recovery process, however add extra security in case of rupture.

*Notice*

There are many factors that can affect the tensile strength of the filter paper in the base of the housings, and mistreatment of the filters can

result in rupture of the filter membrane causing media to become infused into the extracted products. These include incorrectly packing before

use causing channeling, physical damage to filter membrane, excessive head pressure, and aqueous (water) reagents [too much water moisture

will weaken the membrane; use dried or heavily frozen materials to ensure no water contamination]. Due to so many varying factors, and lawful

limitation on purchasing of extract, AFS will not be responsible for product loss due to media contamination. It is the extractor’s responsibility to

ensure adequate due diligence and product knowledge when using AFS filters. If you are uncertain use a secondary/backup filter.

This manual suits for next models

3

Table of contents

Other AFS Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Puretec

Puretec CFS Series user guide

Puretec

Puretec MaxiPlus MPB202B user guide

Aqua Medic

Aqua Medic ECO Runner 3700 Operation manual

Oase

Oase BioTec ScreenMatic Series operating instructions

AMI

AMI AAA-RO-200 MANUAL FOR INSTALLATION, OPERATION AND MAINTENANCE

Maico

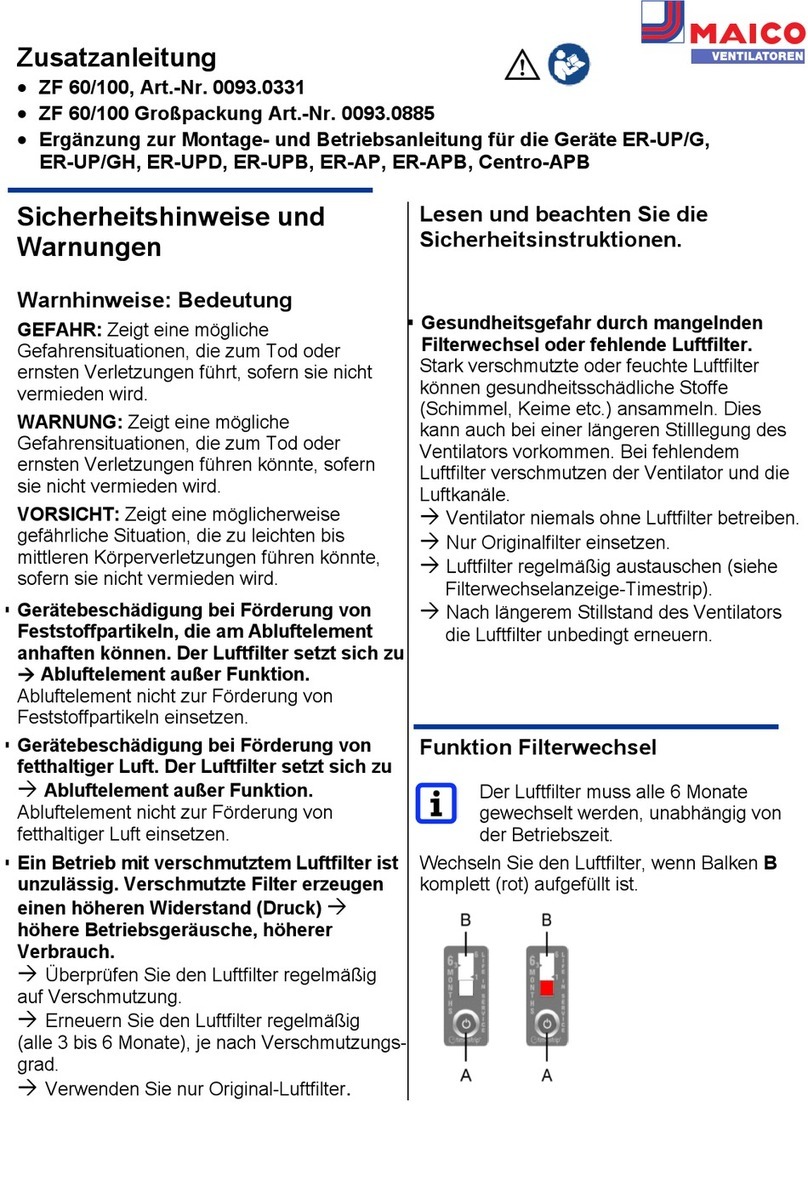

Maico ZF 60/100 Supplementary instructions