2

1.0 General safety precautions

IMPORTANT - Please study all the instructions

before installing and commissioning the lter.

Please keep manual for future reference.

Instruct all users in the function and operation of the

product.

Maintenance, replacement of lter cartridges should

only be done in accordance with section 4 in this

manual.

Power cables and pneumatic air hoses should be repla-

ced at once, if they are damaged. This should only be

done by trained electrician and ventilation tter.

Do not dismantle any factory-mounted parts, since it

impedes the commissioning of the equipment.

All electrical installations must be carried out by an

authorised electrician.

1.1 Danger

It is dangerous to dismantle the lter while in operation.

When installing or servicing of the lter make sure that

the power is disconnected.

1.2 Field of application

GeoFilter GFO-XT is used for ltration of oil saturated air

or fumes from polluting industrial processes such as ma-

chining, cutting and metal working involving cutting oil.

The GeoFilter GFO-XT comes with lter cartridges of

dierent pleated textiles with or without coating

(minimum ltration eciency of 99,90% according to

BIA-test - see section 1.3.)

1.3 Technical data

Model No. of

cartridges Filter area [m²] Max. Air ow

GFO-XT-3 3 14,7 m² 1.800 m³/h

GFO-XT-6 6 29,4 m² 3.600 m³/h

GFO-XT-9 9 44,1 m² 5.400 m³/h

GFO-XT-12 12 58,8 m² 7.200 m³/h

Model Dimensions

(HxBxD) mm.

Inlet Outlet

GFO-XT-3 2032x325x927 Ø250mm Ø250mm

GFO-XT-6 2032x625x927 Ø315mm Ø315mm

GFO-XT-9 2032x925x927 Ø400mm 2xØ315mm

GFO-XT-12 2032x1225x927 Ø500mm 3xØ315mm

Temperature surroundings -10°C - +65°C

Relative humidity must be below <90%

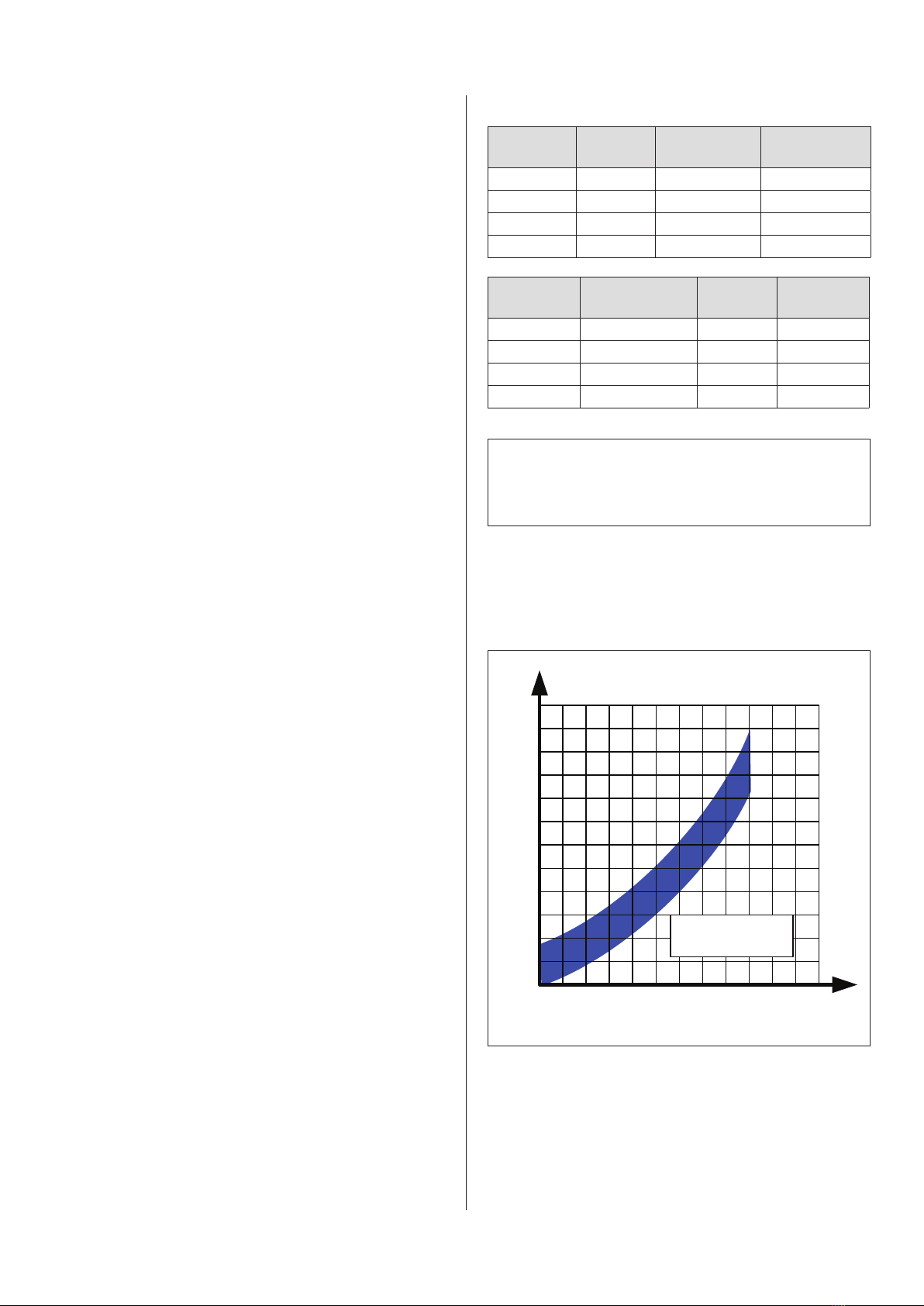

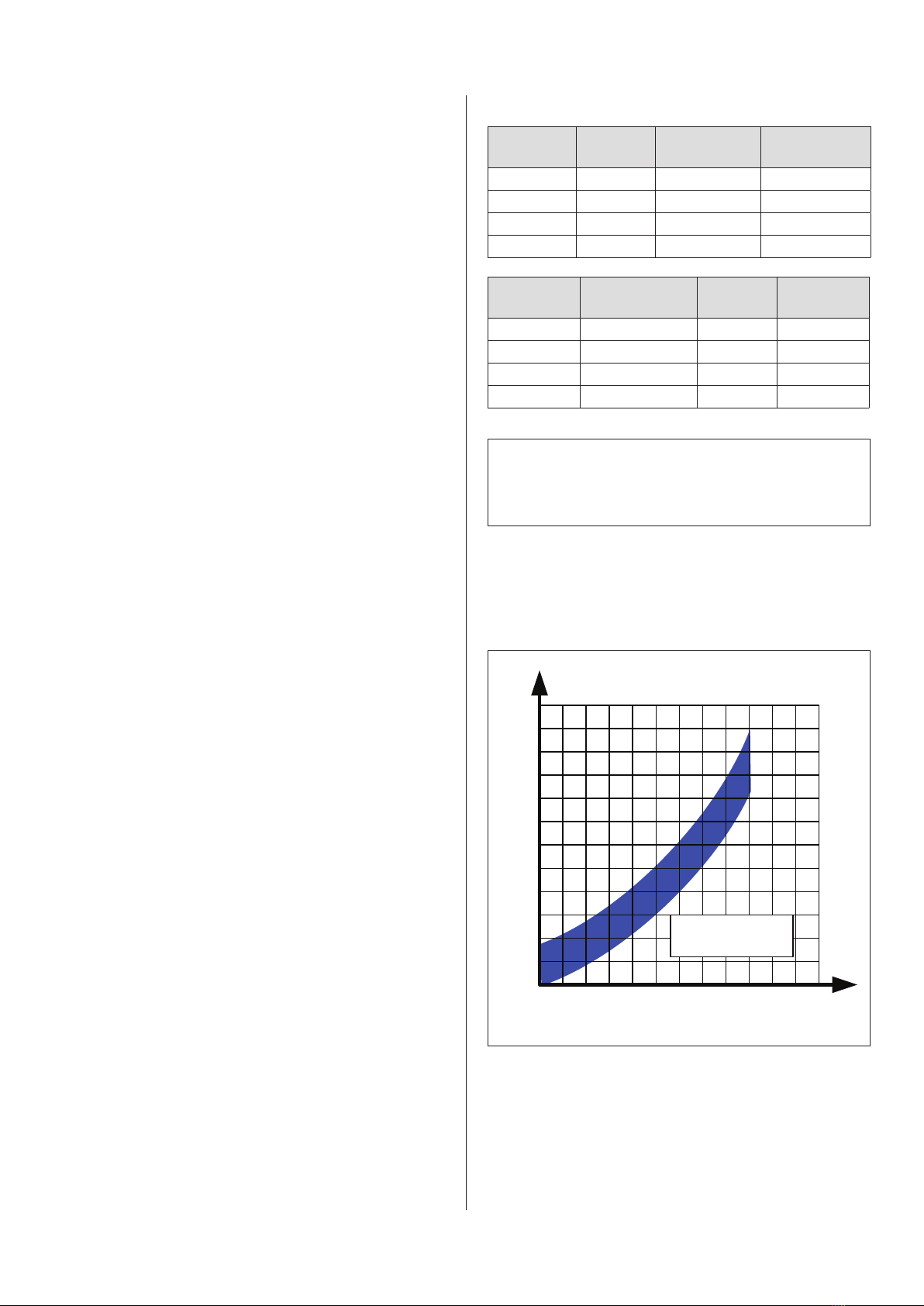

The pressure drop in the lter will vary depending on

the load and how dirty the lter cartridges are. The lter

cartridges must be replaced, when the pressure drop

exceeds 1.200 Pa.

Table of content

1.0 General safety precautions.................. 2

1.1 Danger ................................. 2

1.2 Field of application . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Technical data............................ 2

1.4 Construction ............................. 2

2.0 Installation. .............................. 3

2.2 Test Run - adjusting ....................... 3

3.0 User instruction........................... 3

4.0 Maintenance............................. 3

4.1 Replacing lter cartridges................... 3

4.2 Trouble shooting ......................... 4

6.0 Declaration of conformity ................... 4

1.4 Construction

Cabinet: Sturdy frame/cabinet, made of galvanised

steel plate (corrosion class lll), with lter cone and

deector in the inlet.

150

400

Airflow [m³/h]

Pressure drop [Pa]

800 1200

300

450

600

750

900

1050

1200

1350

1500

1650

GFO filter

200 600 1000 1400 1600 1800 2000 2200

Lower curve = clean filter

Upper curve = dirty filter