3

INSTALLATION

INSTALLATION SECTION

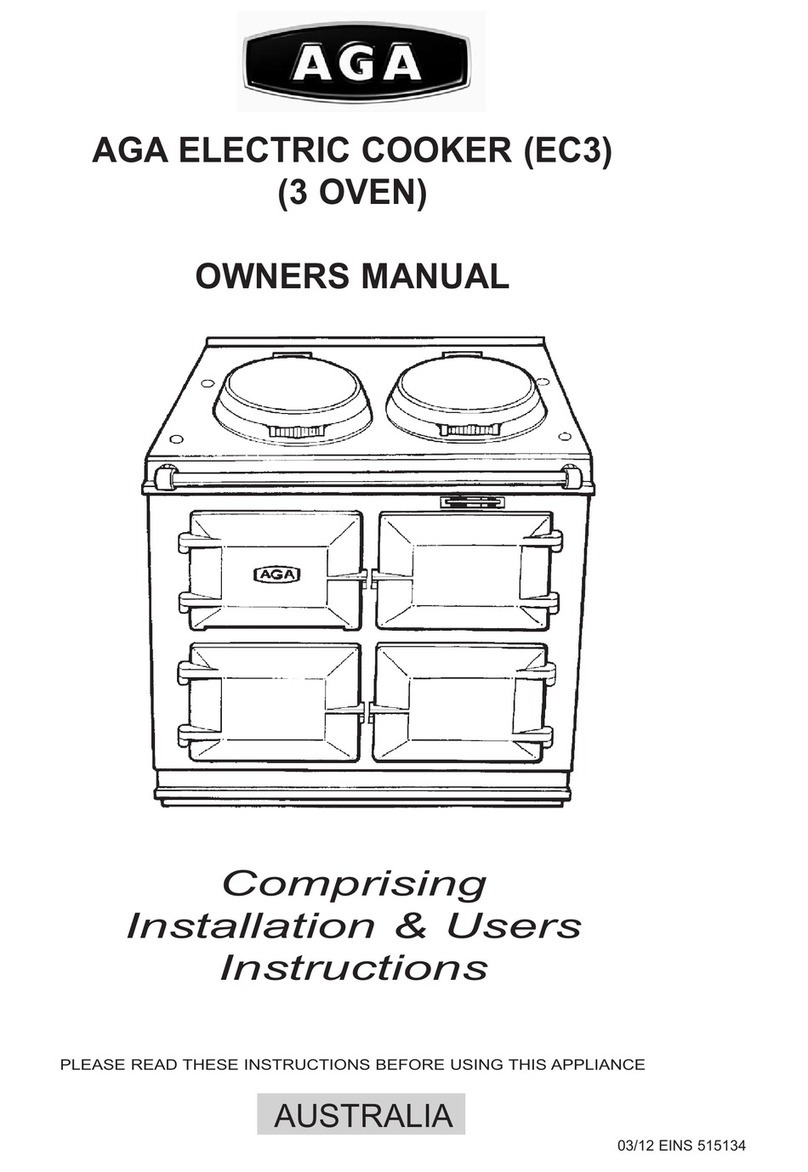

The complete cooker is floor-mounted and the space in which the appliance is to be fitted must have the following minimum

dimensions:-

A minimum clearance of 60mm is required above the raised insulating cover handle.

Side Clearance: A 3mm air gap is required each side between the cooker top plate and adjoining work surfaces that may

be fitted, this is to allow for the safe removal of the top plate should this be required at a later date.

Where cookers are fitted against side walls which protrude beyond the front of the AGA a 116mm clearance is required at

both sides for oven door access.

If the AGA is to be installed in a brick recess, then the minimum clearance should be increased by at least 10mm on either

side to allow for the walls not being square and also for the natural dimensional variations found in the castings.

In addition, a minimum clearance of 1000mm must be available at the front of the cooker to enable the cooker to be

serviced.

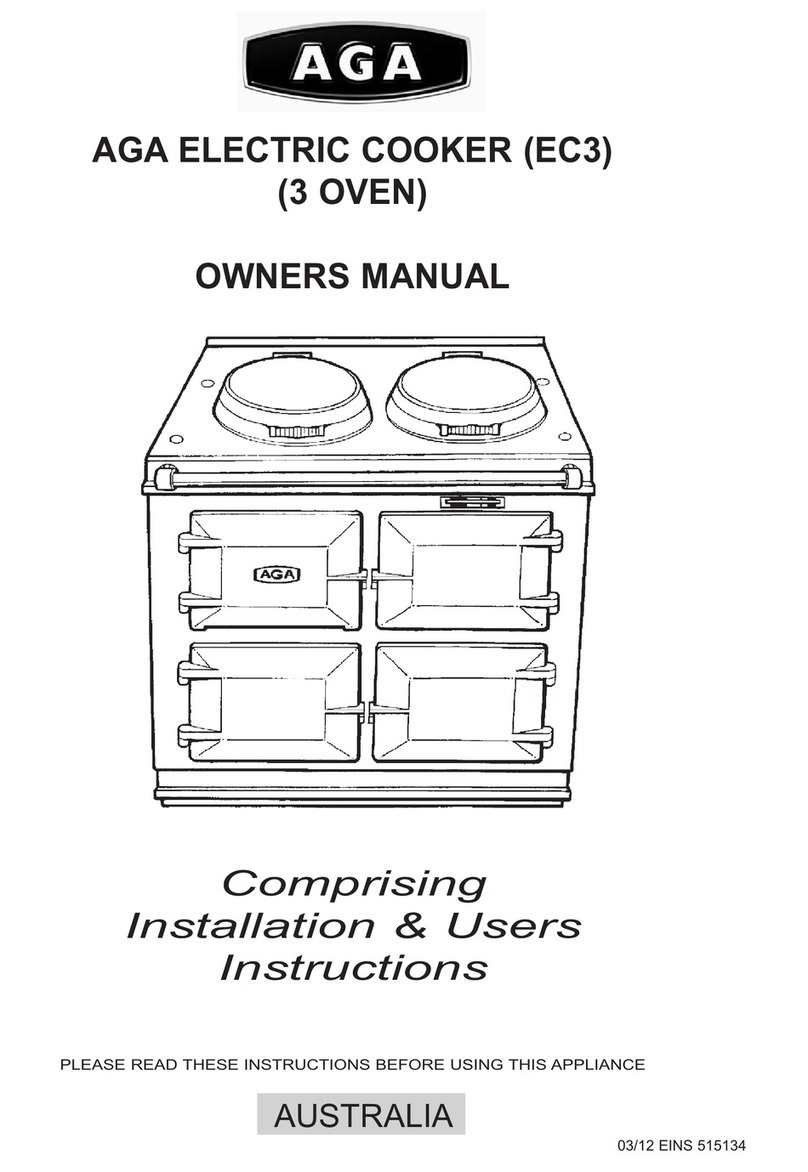

Cooker Base or Hearth

It is essential that the base or hearth on which the cooker stands should be level and be capable of supporting the total

weight of the cooker.

MODEL EC3: 477 Kg

The top of the hearth must be of non-combustible material thickness of 12mm.

The wall behind the cooker must be of non-combustible material for a minimum thickness of 25mm.

If the oven vent pipe passes through combustible material, there must be an airgap of at least 25mm around the pipe

preferably wrapped with insulation material.

The appliance oven venting pipe can be achieved up to a maximum length of 6 metres, through an outside wall or unused

flue etc. Great care must be taken in all-timber houses.

Tiling

When the cooker is to stand in a recess, or against a wall which is to be tiled, in no circumstances should the tiles overlap

the cooker top plate.

Consumer Protection

As responsible manufacturers we take care to make sure that our products are designed and constructed to meet the

required safety standards when properly installed and used.

IMPORTANT: PLEASE READ THE ACCOMPANYING WARRANTY

Any alteration that is not approved by AGA could invalidate the approval of the appliance, operation of the warranty and

could alao affect your statutory rights.

In the interests of safety and effective use, please read the following before using your new AGA appliance.

Important

This appliance may contain some of the materials that are indicated. It is the Users/Installers responsibility to ensure that

the necessary personal protective clothing is worn when handling, where applicable, the pertinent parts that contain any

of the listed materials that could be interpreted as being injurious to health and safety, see below for information.

Fire Cement - when handling use disposable gloves.

Glues and Sealants - exercise caution - if these are still in liquid form use face mask and disposable gloves.

Glass Yarn, Mineral Wool, Insulation Pads - may be harmful if inhaled, may be irritating to skin, eyes, nose and throat.

When handling avoid inhaling with skin or eyes. Use disposable gloves, face-masks and eye protection. After handling

wash hands and other exposed parts. When disposing of the product, reduce dust with water spray, ensure that parts are

securely wrapped.