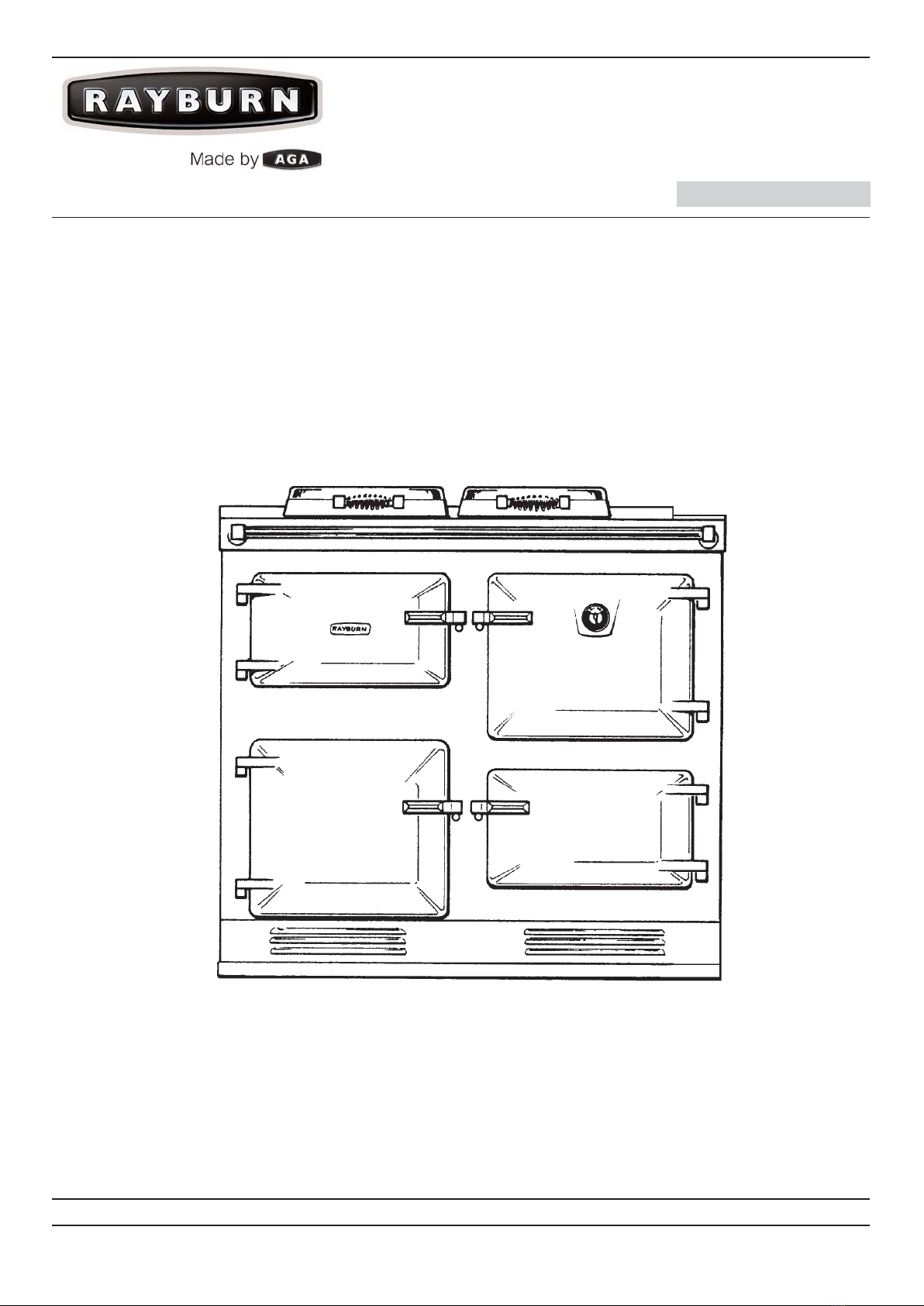

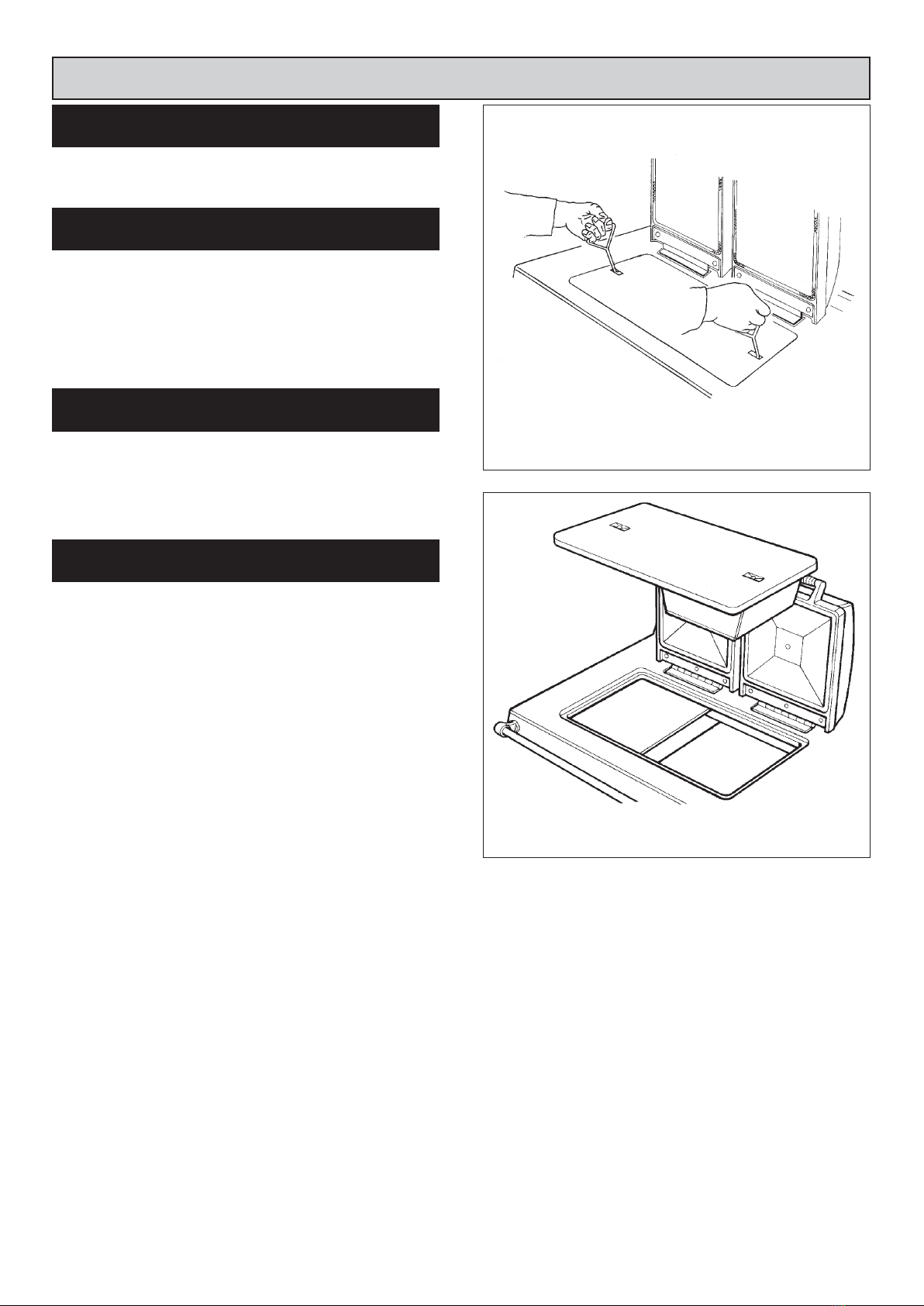

CONDENSATE TRAP SERVICE

Unscrew condensate trap base and check for excessive

deposits. If levels are acceptable wash out any deposits

and replace. (See Fig. 7)

COMBUSTION ANALYSIS

Check that the CO2/CO levels are within tolerances shown

in Fig. 1.

To check the levels at full rate, turn the boiler knob fully

clockwise.

To check the levels at the low rate, turn the boiler knob to

the first segment on the dial.

If these levels are within the tolerance, no further action is

required with the boiler.

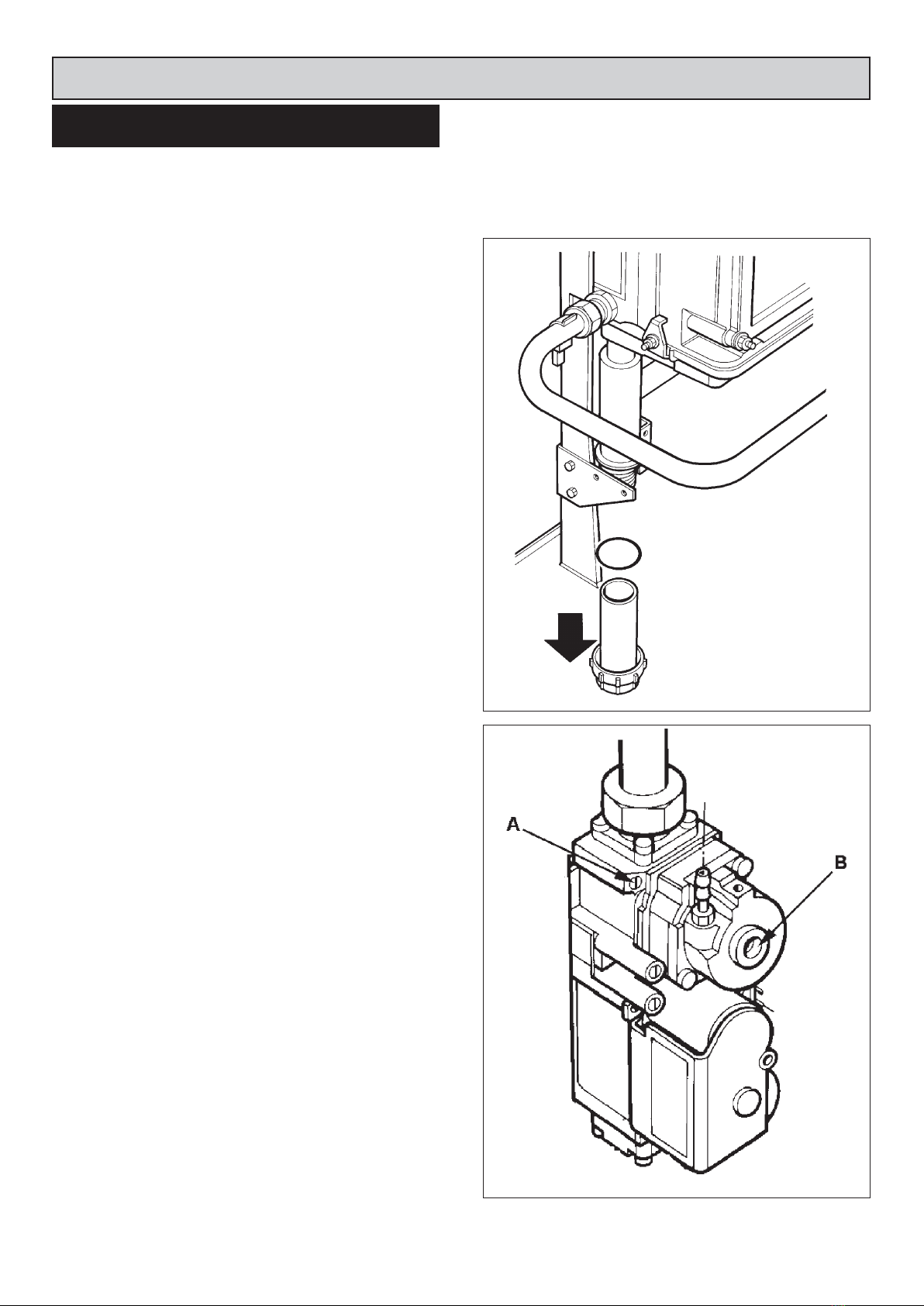

If levels are not within tolerance check for possible causes

e.g. blocked flue, faulty fan etc. If no other fault can be

detected, the gas valve needs to be adjusted manually.

To do this, turn the boiler knob fully clockwise to create the

highest possible demand.

Check that CO2/CO levels are within stated levels (See

Fig. 1). If the valve are found to be inconsistent with these,

turn the gas valve regulator A (See Fig. 8) in the

appropriate direction. Turning clockwise will decrease the

CO2; turning anti-clockwise will increase the CO2. Please

note that due to the sensitivity of the screw, only small

adjustments will be necessary.

Once adjustment has been made, wait until CO2level

stabilises and recheck the combustion. Repeat the above

steps as necessary.

Check that CO2levels are within stated levels at minimum

rate, turn knob to first segment on the display.

Using the method detailed above, run the boiler at its

minimum output. Wait for the boiler to stabilise and

perform the combustion analysis, check the results

against those in the Technical Specification Fig. 1. in the

Installation Instructions.

If the valves are found to be inconsistent with these, turn

the gas valve regulator B (See Fig. 8) in the appropriate

direction. Turning clockwise will increase the CO2; turning

anti-clockwise will decrease the CO2. Please note that due

to the sensitivity of the screw, only small adjustments will

be necessary (1/8 of a turn).

NOTE: Unscrew cap and adjust accordingly.

Once adjustment has been made, wait until the CO2level

stabilises and recheck the combustion. Repeat the above

steps as necessary.

After completion of calibration, recheck the CO2at

maximum output. It is also advisable to check the gas

capacity at the metre against the figures given in the

technical specification in Fig. 1.

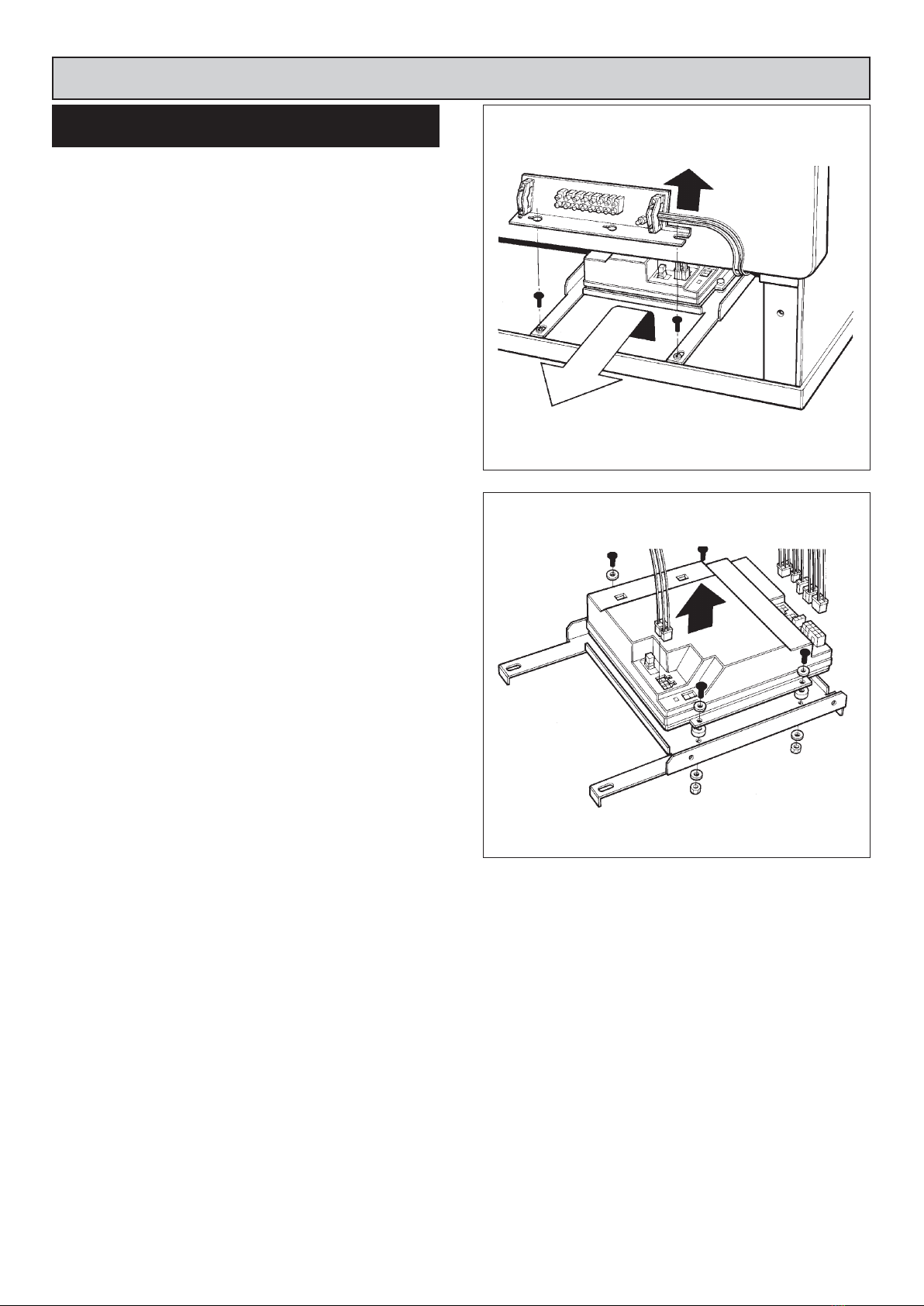

Boiler Servicing

BOILER SERVICE

FIG. 7 DESN 515015

FIG. 8 DESN 515016

7