Agilent Technologies 34450A Installation and operating instructions

Other Agilent Technologies Multimeter manuals

Agilent Technologies

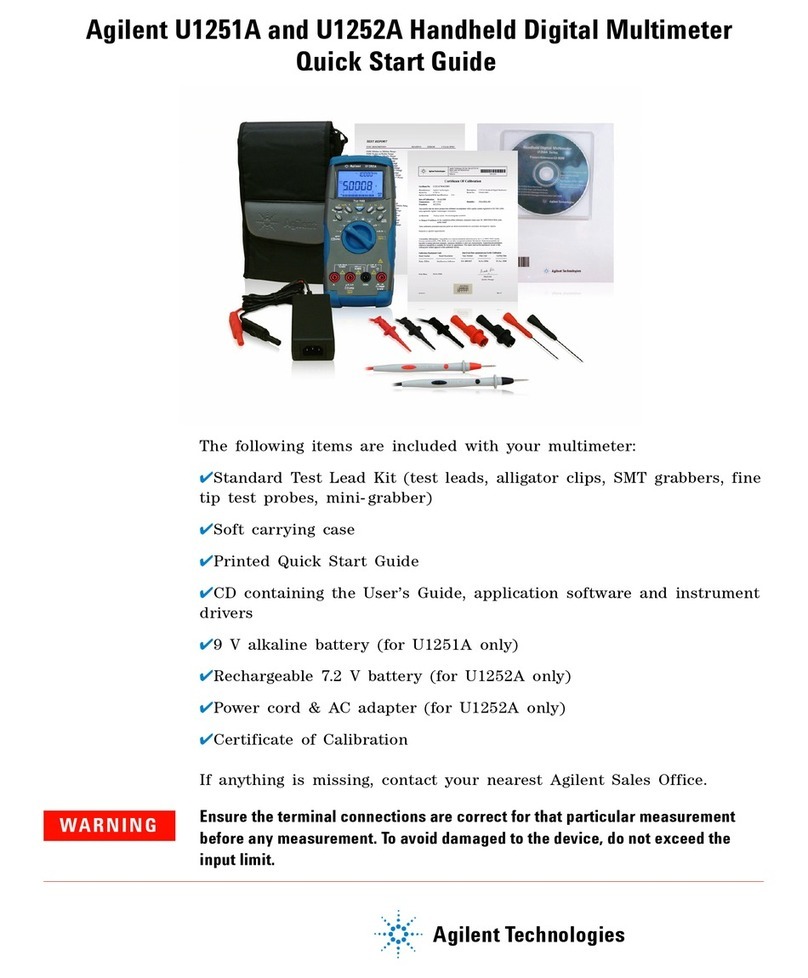

Agilent Technologies U1251A User manual

Agilent Technologies

Agilent Technologies U1251A User manual

Agilent Technologies

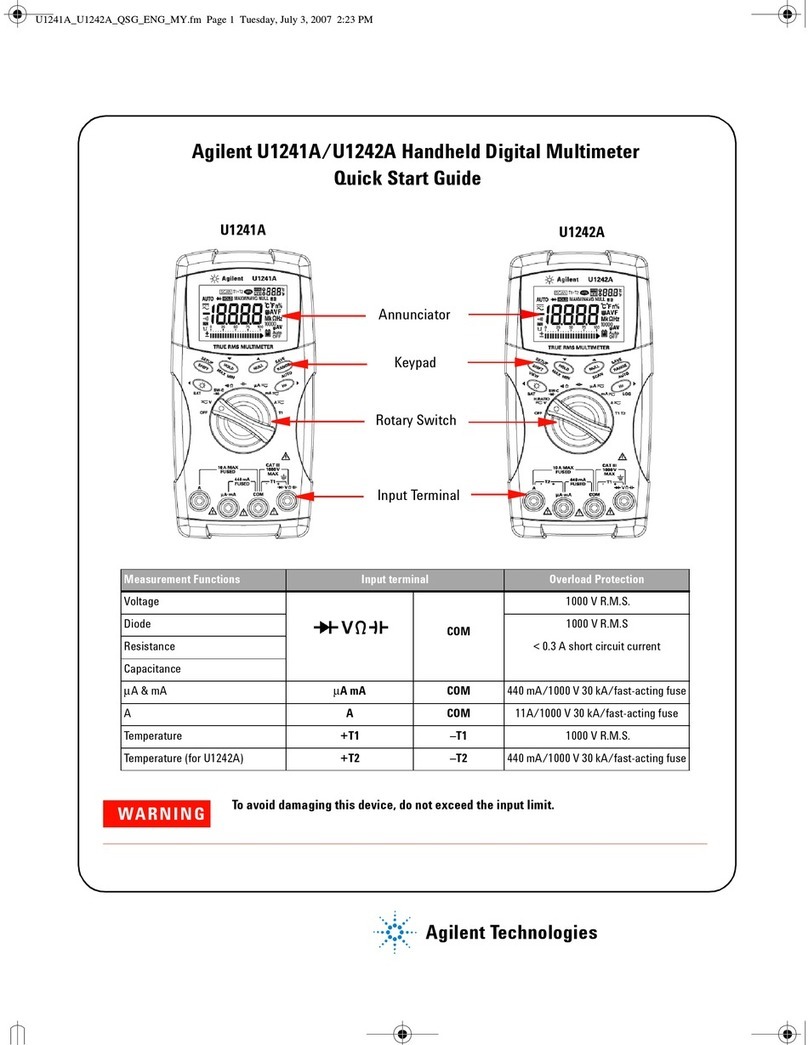

Agilent Technologies U1241B User manual

Agilent Technologies

Agilent Technologies L34410A User manual

Agilent Technologies

Agilent Technologies U3606B User manual

Agilent Technologies

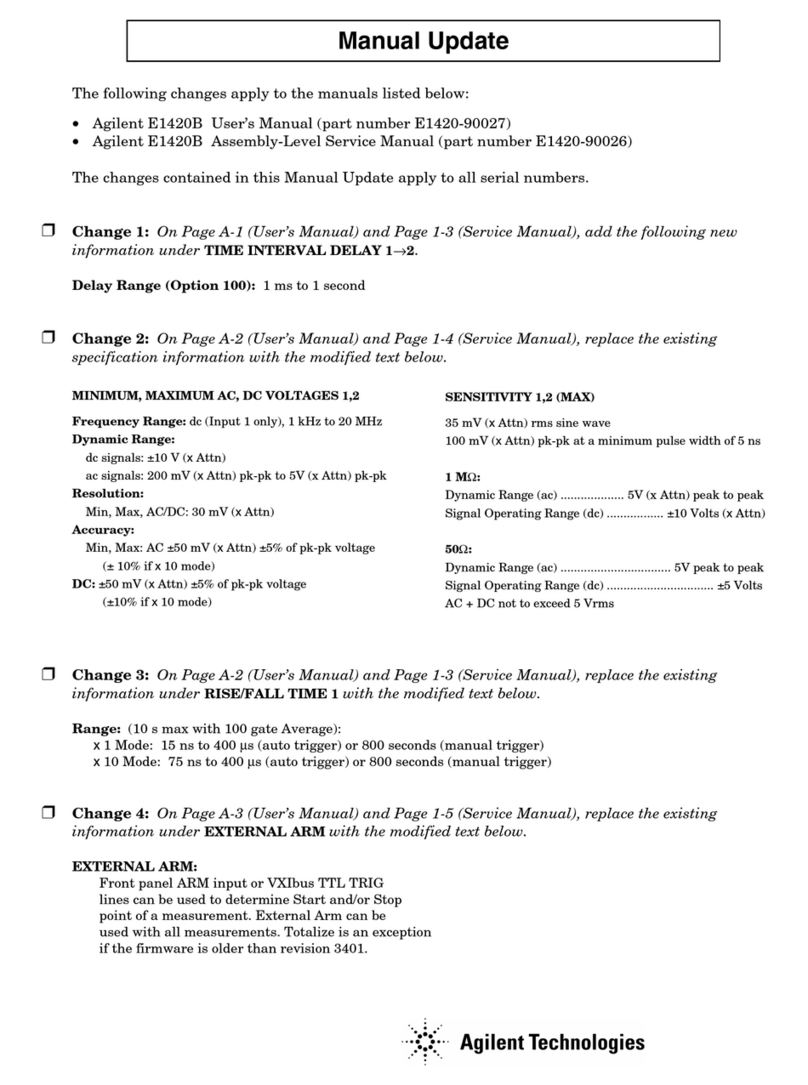

Agilent Technologies E1420B Technical manual

Agilent Technologies

Agilent Technologies 34410A User manual

Agilent Technologies

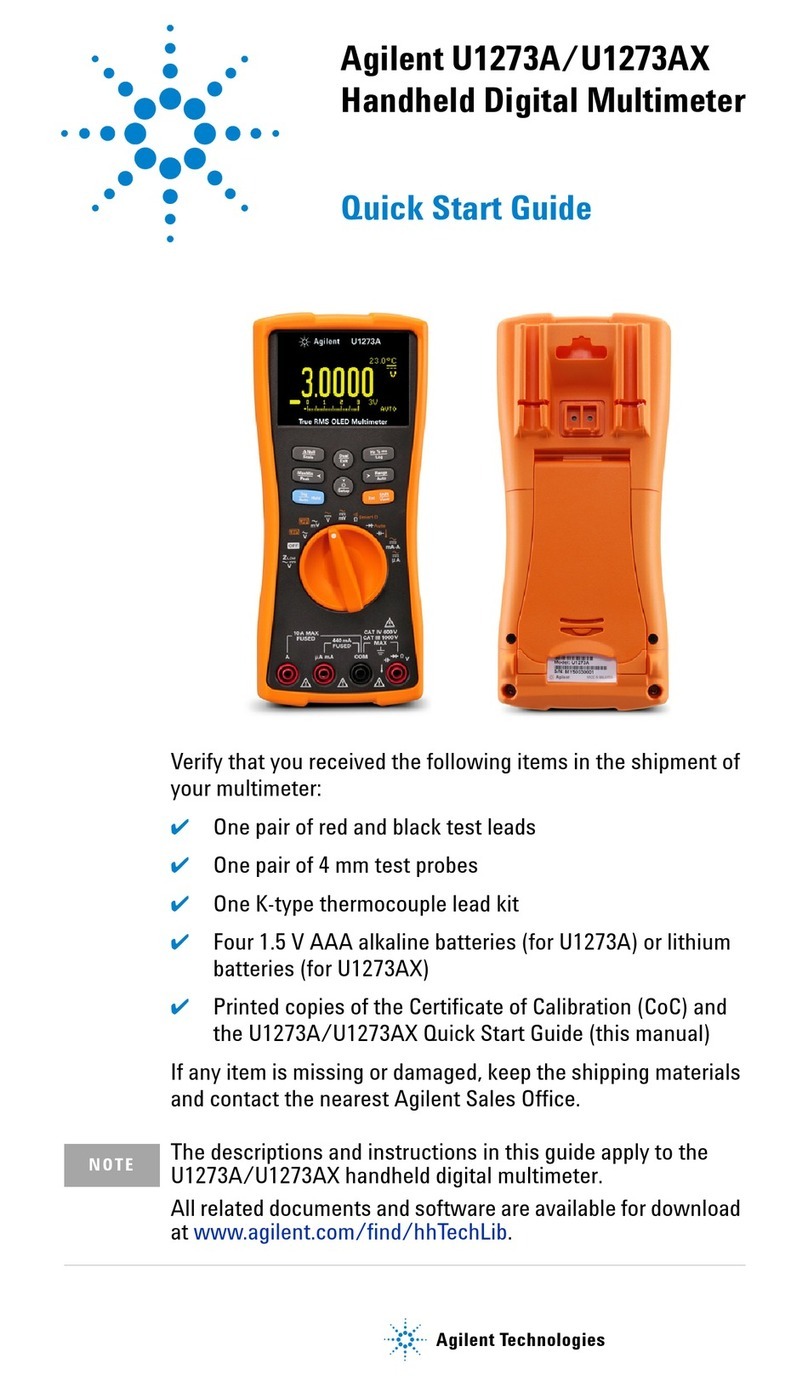

Agilent Technologies U1273A User manual

Agilent Technologies

Agilent Technologies Agilent E1412A User manual

Agilent Technologies

Agilent Technologies U1241B Manual

Agilent Technologies

Agilent Technologies 34401A User manual

Agilent Technologies

Agilent Technologies 3457A User manual

Agilent Technologies

Agilent Technologies U1253A Manual

Agilent Technologies

Agilent Technologies U1253B User manual

Agilent Technologies

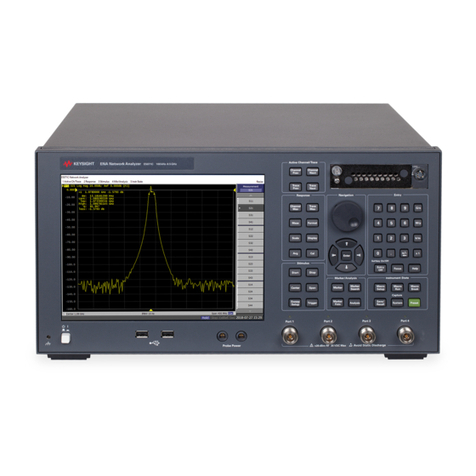

Agilent Technologies E5071C Installation and operating manual

Agilent Technologies

Agilent Technologies 34405A User manual

Agilent Technologies

Agilent Technologies 34410A User manual

Agilent Technologies

Agilent Technologies 34405A Manual

Agilent Technologies

Agilent Technologies U3402A User manual

Agilent Technologies

Agilent Technologies U3402A Manual

Popular Multimeter manuals by other brands

Somogyi Elektronic

Somogyi Elektronic home SMA 92 instruction manual

Gossen MetraWatt

Gossen MetraWatt METRAmax 6 operating instructions

PeakTech

PeakTech 4000 Procedure of calibration

YOKOGAWA

YOKOGAWA 90050B user manual

Fluke

Fluke 8846A Programmer's manual

Tempo Communications

Tempo Communications MM200 instruction manual