7

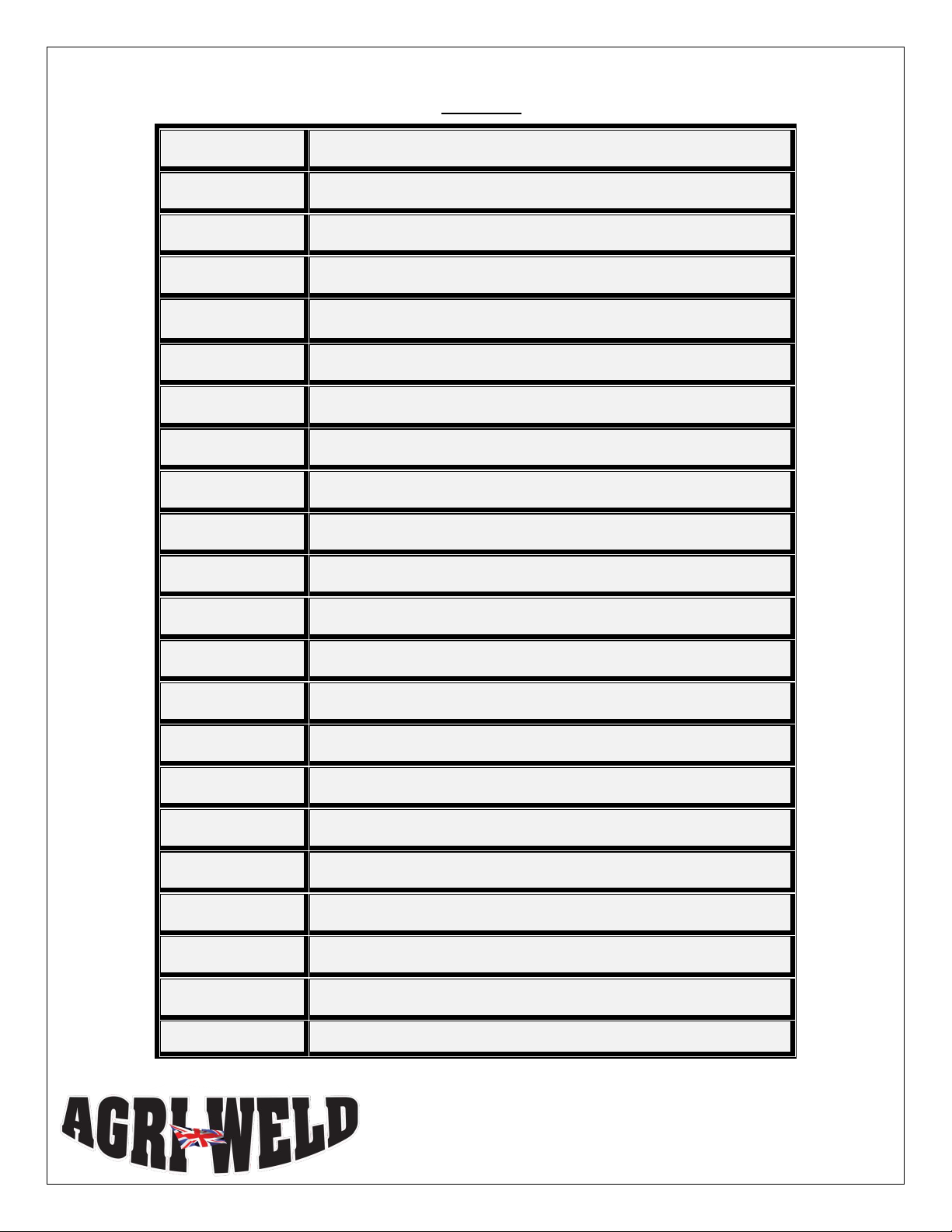

BOLT-ON BRACKETING TO SUIT YOUR FORKLIFT/LOADER

Your Cereal Mixer Bucket will be delivered already fitted with the correct bolt-on, width

adjustable bracketing or 3-point linkage attachments, hydraulic fittings and hydraulic

hose to fit your forklift/loader.

If for any reason the fittings are lost or damaged they must be replaced with the

following specification of fitting;

QUICK-HITCH brackets or LOADER BRACKETS and brackets to fit 3-point linkage, require

the following ‘U’ Bolt fittings;

8 X M16 X 120mm square Bolts

16 X M16 Nylock nuts/washers

For your own safety and the safety of others, always use the correct fittings to attach

bolt-on bracketing to the rear of the unit. Always place the unit on the ground and turn

off the forklift/loader before attempting any changes.

CREATING OFFSET (Before connection to forklift/loader)

The bracketing on your mixer bucket may require off-setting prior to use to enable you

to discharge outside the loader wheels. Please follow the procedure below;

1. Take note of the dimension between the brackets for re-positioning correctly.

2. Slacken all 16 Nylock nuts and reposition the bracket by sliding it across the steel

frame to the create the required offset (It is important to maintain the correct

spacing between the brackets and that on tightening up the bolts make sure

that the brackets remain square to the bracket mounting frame and are at the

correct centres).

3. RE-TIGHTEN THE M16 NYLOCK NUTS. EACH TIME THE BRACKETS HAVE BEEN

REPOSITIONED ONCE, IT IS RECOMMENDED TO REPLACE THE NYLOCK NUTS WITH

NEW ONES. ALWAYS ENSURE THEY ARE ALL THOROUGHLY TIGHTENED.

CONNECTION TO FORKLIFT/LOADER

Stand the Cereal Mixer Bucket in an area free from obstruction to allow you to drive the

forklift/loader towards the bracketing.

For Quick Hitch bracketing, connect as you would with any other attachment and the

type of bracketing fitted to the rear of the bucket. Locate any locking pins securely.

Attach the hydraulic hoses, pipes and fittings to your tractor/forklift/loader while it is

turned off. The hoses should be marked FEED and RETURN.

FEED is to drive the auger forwards to discharge.

RETURN will reverse the auger.