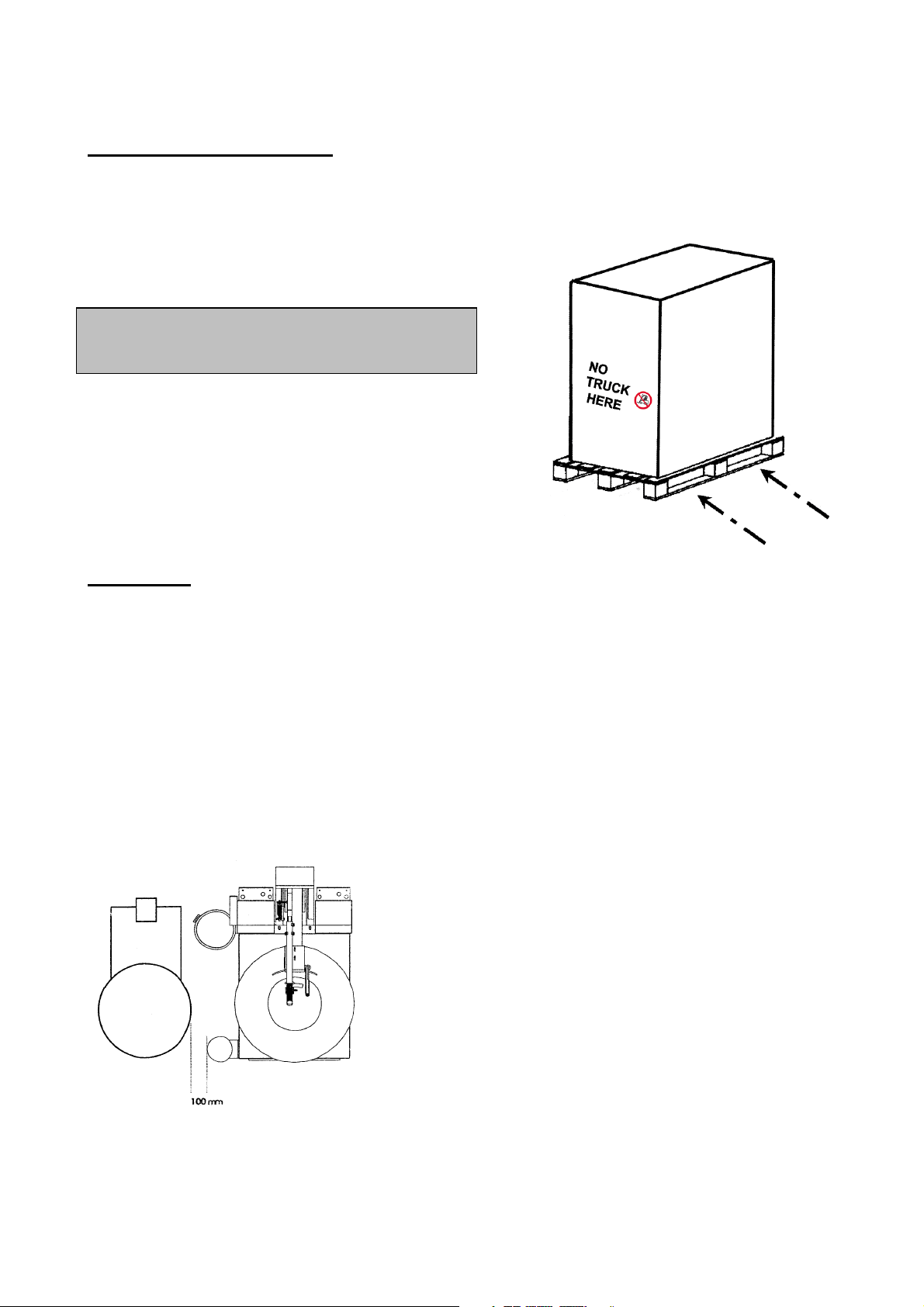

Transport and Handling

This machine has to be transported with a pallet stacker or a fork-lift truck according to the

below instructions.

Place the machine close to the place of use.

Remove the bolts holding the machine to the pallet.

Unpacking

Remove the wrap folio and cut the tape holding the Bead Breaker’s arm down.

Check that the contents correspond to the order.

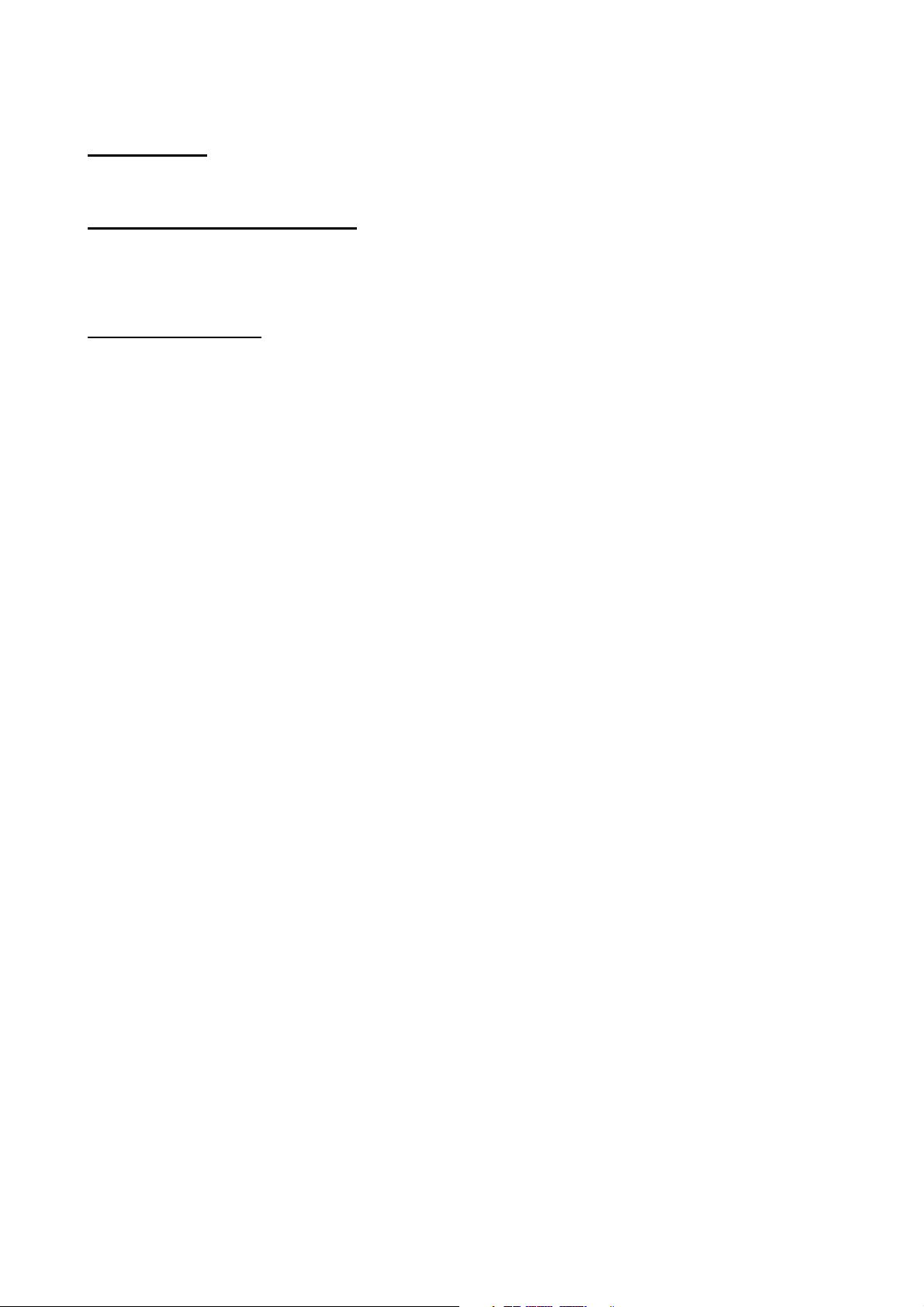

Place the machine on an even floor at a distance of approx. 100 mm from the wheel

turning plate and the Bead Breaker’s rotation plate. Please see the below illustration.

If the Bead Breaker is equipped with a wheel turning plate with swinging support arm the

distance should be approx. 400 mm.

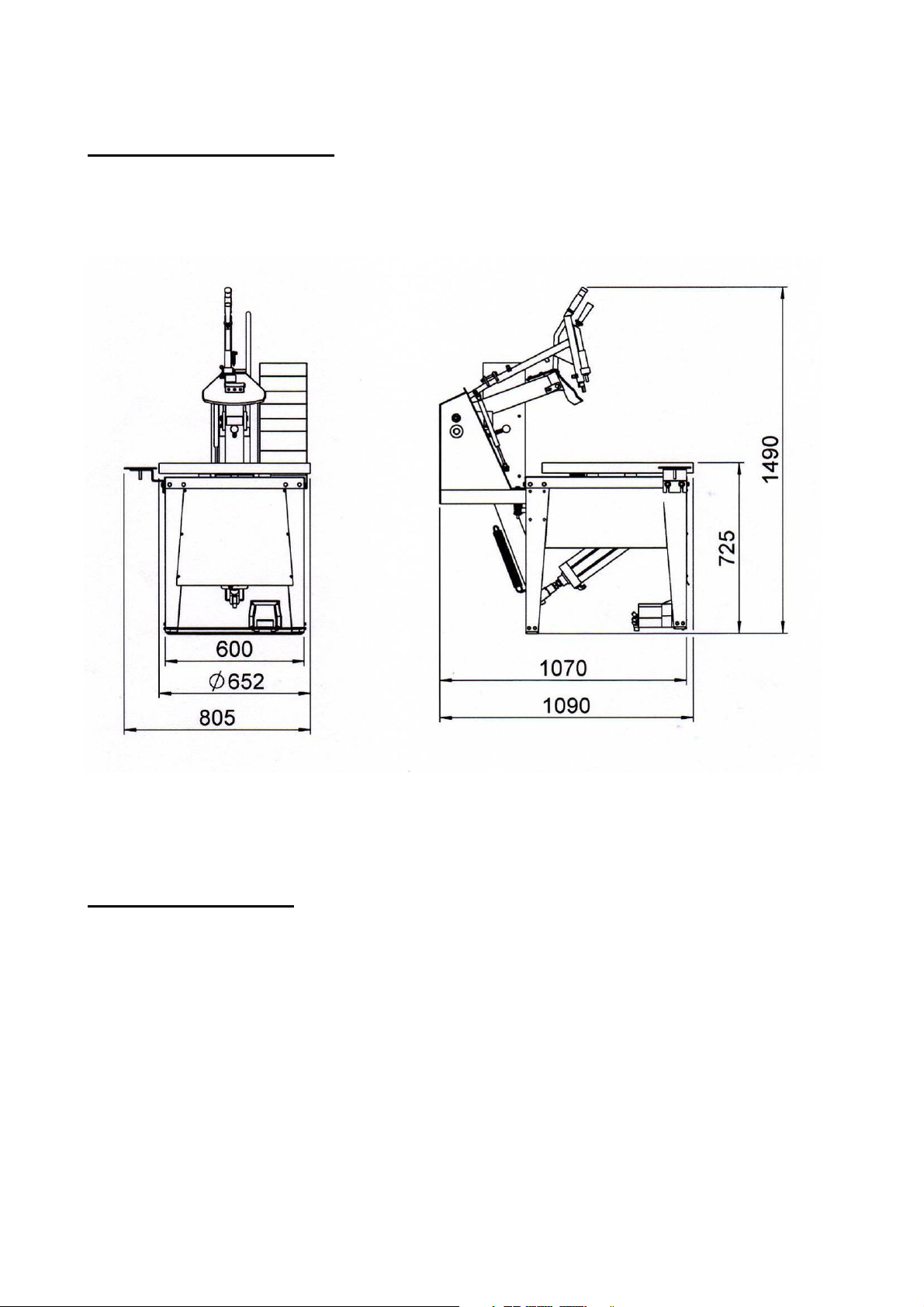

Tyre Changer Bead Breaker BBRT 700 / 900

Fasten the machine to the floor with 4 expansion bolts.

K

EEP A SAFETY DISTANCE OF MIN

.

2

M WHEN

THE FORK

-

LIFT TRUCK IS LOWERED

!