™

© 2012 AIC WAIKATO LLC 608-526-6882

5

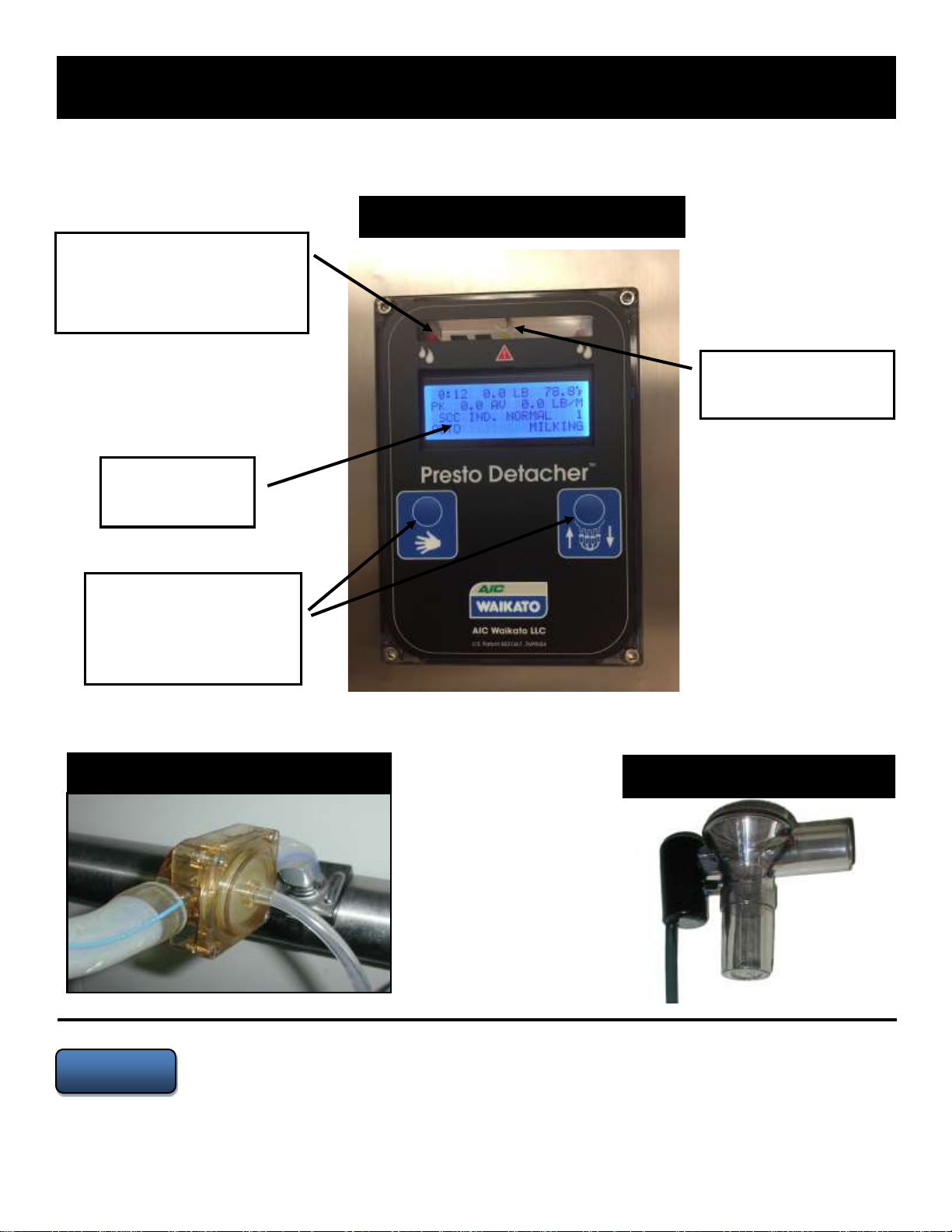

Presto Control Outputs:

‘’

‘’

Power Requirement Calculation:

WARNING

Power Supplies and AC Power Source

In all cases, follow local electrical codes and

safety regulations at all times. It is

recommended the power source be 220/240 volt

and that the power supply be wired to a

dedicated circuit in the incoming power panel.

There should be no additional equipment

hooked to the AC power lines feeding the

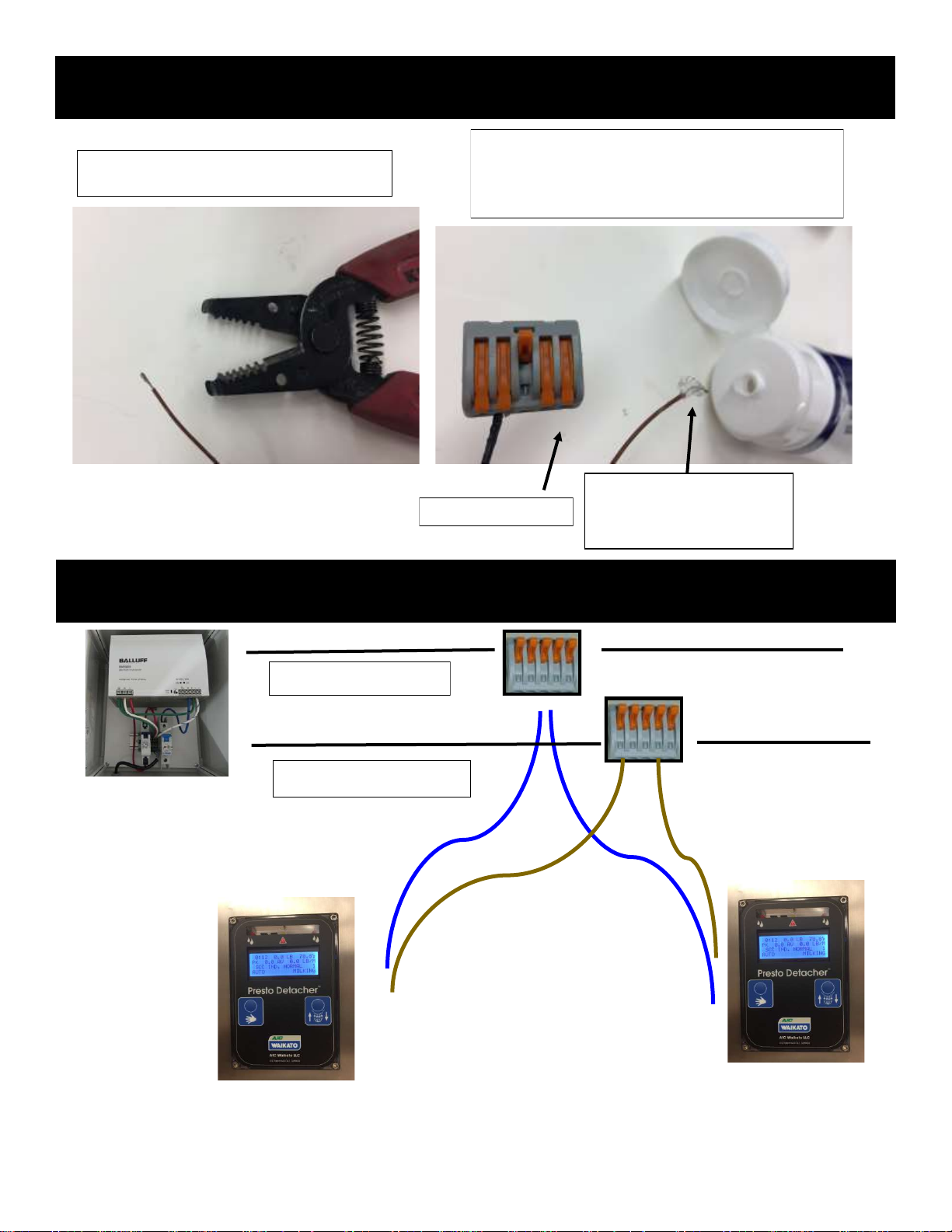

power supply. When two or more power

supplies are used in the same installation, the

negative outputs must be tied together by

adding an 14 gauge jumper wire tying the

negative DC outputs together of each power

supply. This establishes a common reference

plane, enabling communications to function.

(When using two power supplies see the

following Parlor Wiring Schematic for more

than 18 stalls)

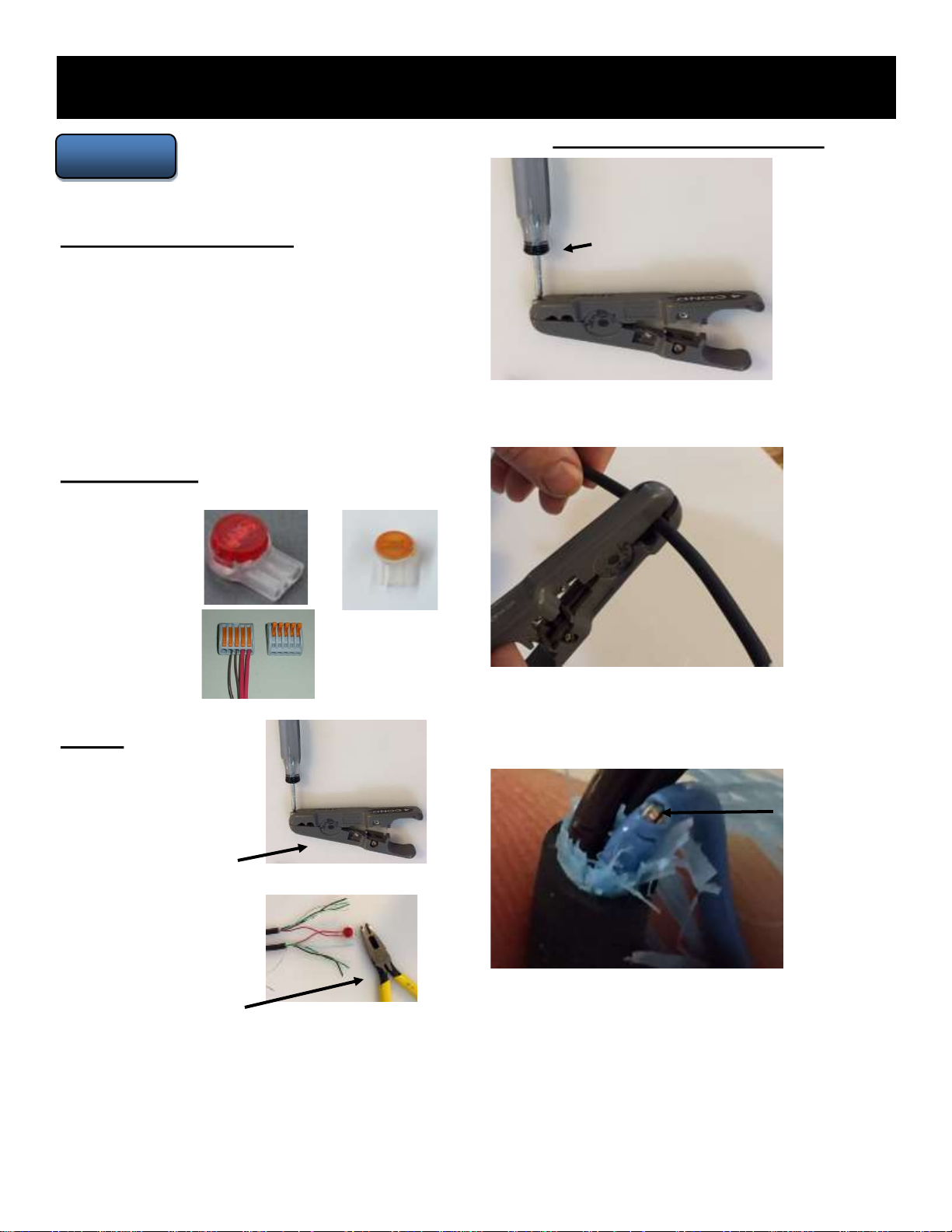

Step 1:

Step 2:

Step 3:

’

Step 4:

CAUTION

Ensure that the existing power supplies are of adequate power rating.

Agricultural Instruments is not responsible for damages or losses

incurred by poorly functioning power supplies. Solid connections are

absolutely necessary to assure no electrical problems will occur.

WARNING