2

Table of Contents

Safety Precautions ................................................................................................................................................. 3

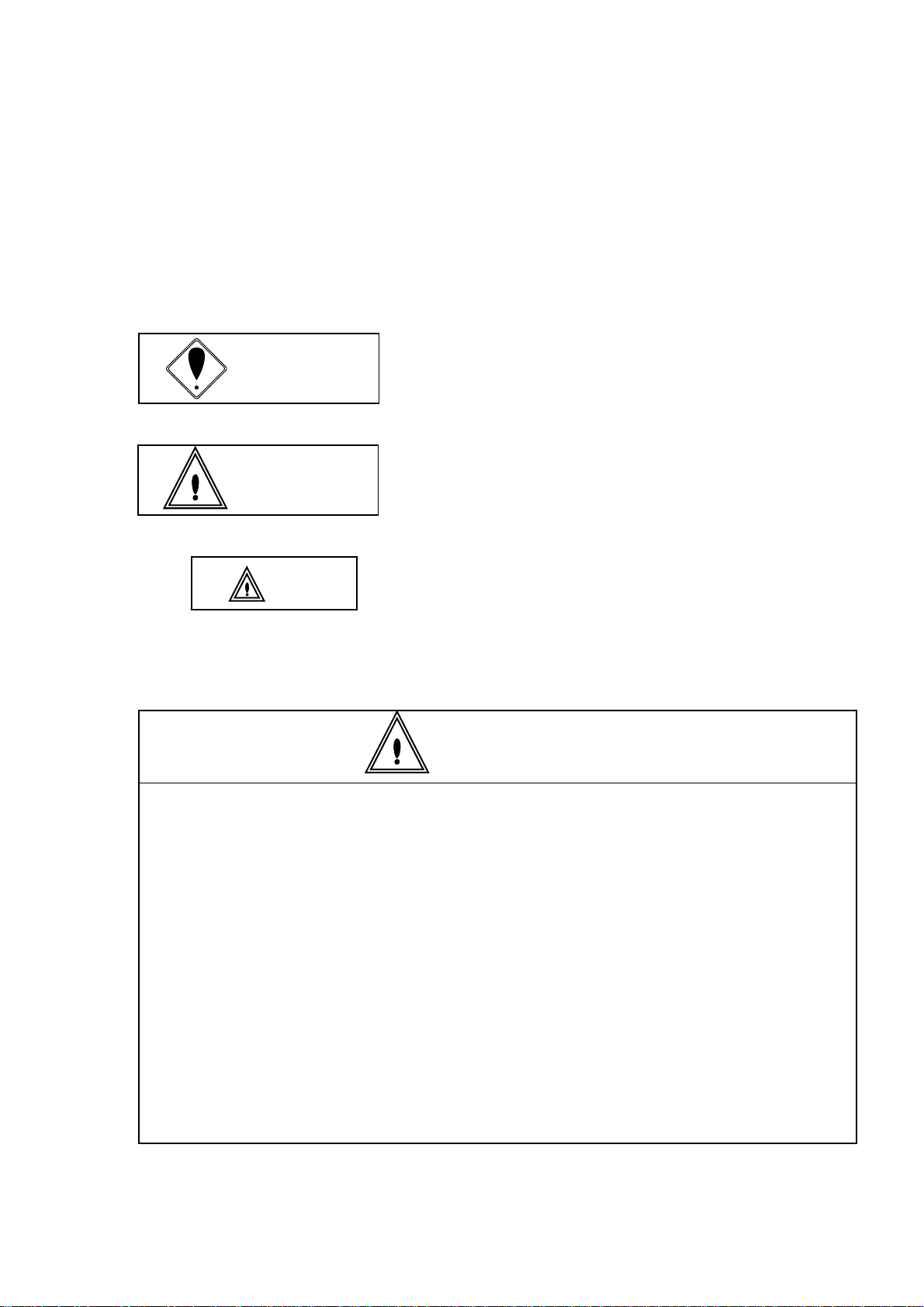

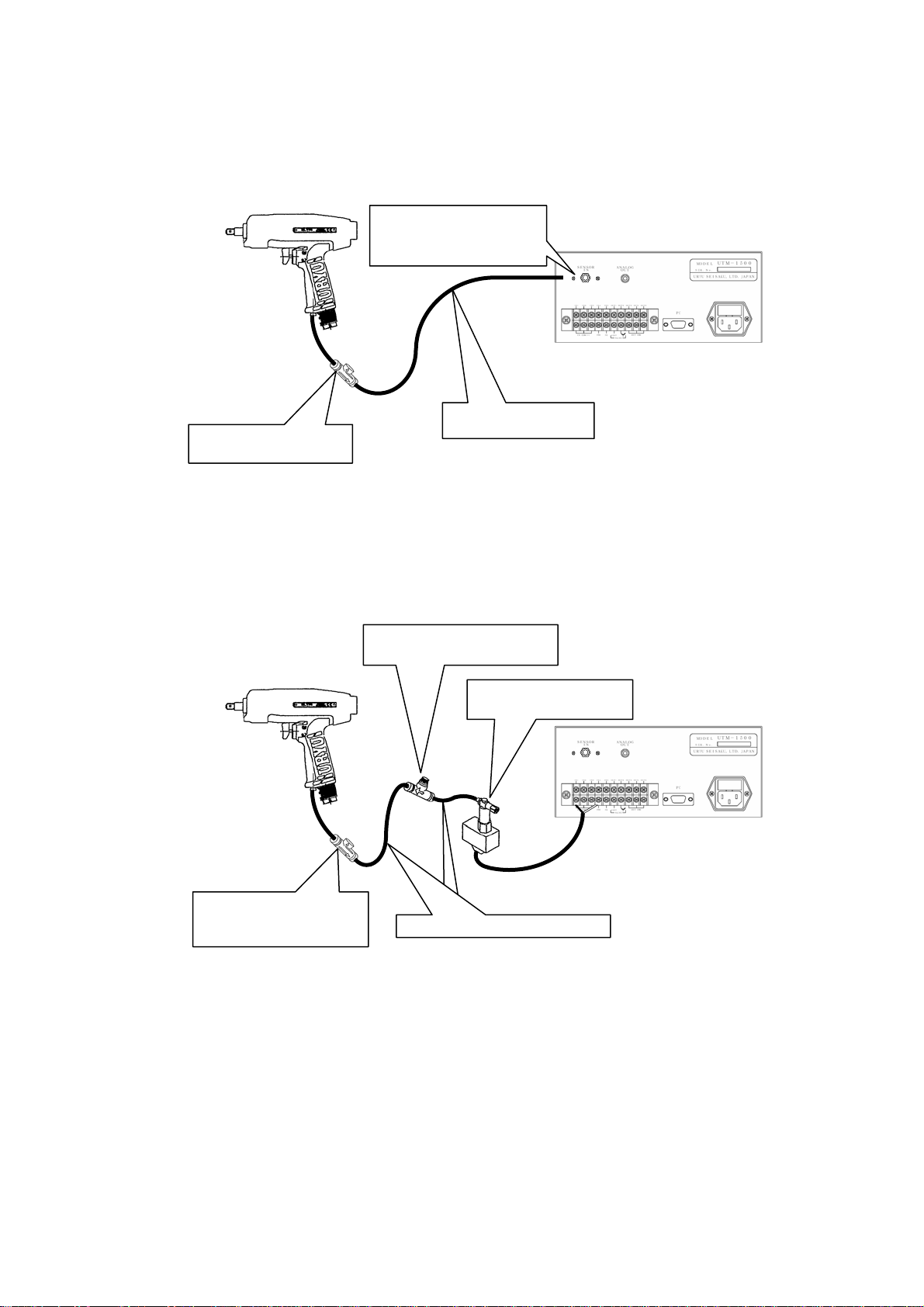

(1) Shut-off Tool (TM)..................................................................................................................................7

Exterior Features................................................................................................................................................. 11

(1) Front Side.............................................................................................................................................11

(2) Back Side..............................................................................................................................................13

Functions.............................................................................................................................................................. 14

Settings................................................................................................................................................................. 15

SET UP............................................................................................................................................................... 16

AUTOMATIC SET UP (automatic setting) ........................................................................................................ 25

TIMER .................................................................................................................................................................. 26

TERMINAL ALLOCATION(Terminal Block Input/Output Alternatives)................................................... 28

(1) Choice among terminal block input alternatives.......................................................................................28

(1) Choice among terminal block output alternatives.....................................................................................29

WIRING DIAGNOSIS(Terminal Block Wiring Diagnosis)........................................................................... 30

(1) Input Wiring Diagnosis .......................................................................................................................30

(2) Output Wiring Diagnosis ....................................................................................................................30

MEMORY........................................................................................................................................................... 31

BAUD RATE(transmission speed)............................................................................................................... 31

Tool Management(tool management)........................................................................................................... 32

(1) TOOL........................................................................................................................................................32

( 2 ) OUT SET.........................................................................................................................................32

( 3 ) CUMULATIVE COUNT .................................................................................................................34

Pressure Value Setting ........................................................................................................................................ 35

( 1 ) In the case of Shut-off Tool (TM).........................................................................................................35

( 2 ) In the case of TM Type Tool ................................................................................................................35

( 3 ) In the case of Standard Tool................................................................................................................35