2

AcraDyne Gen IV iEC Controller Manual

Table of Contents

1. Safety Information . . . . . . . . . . 3

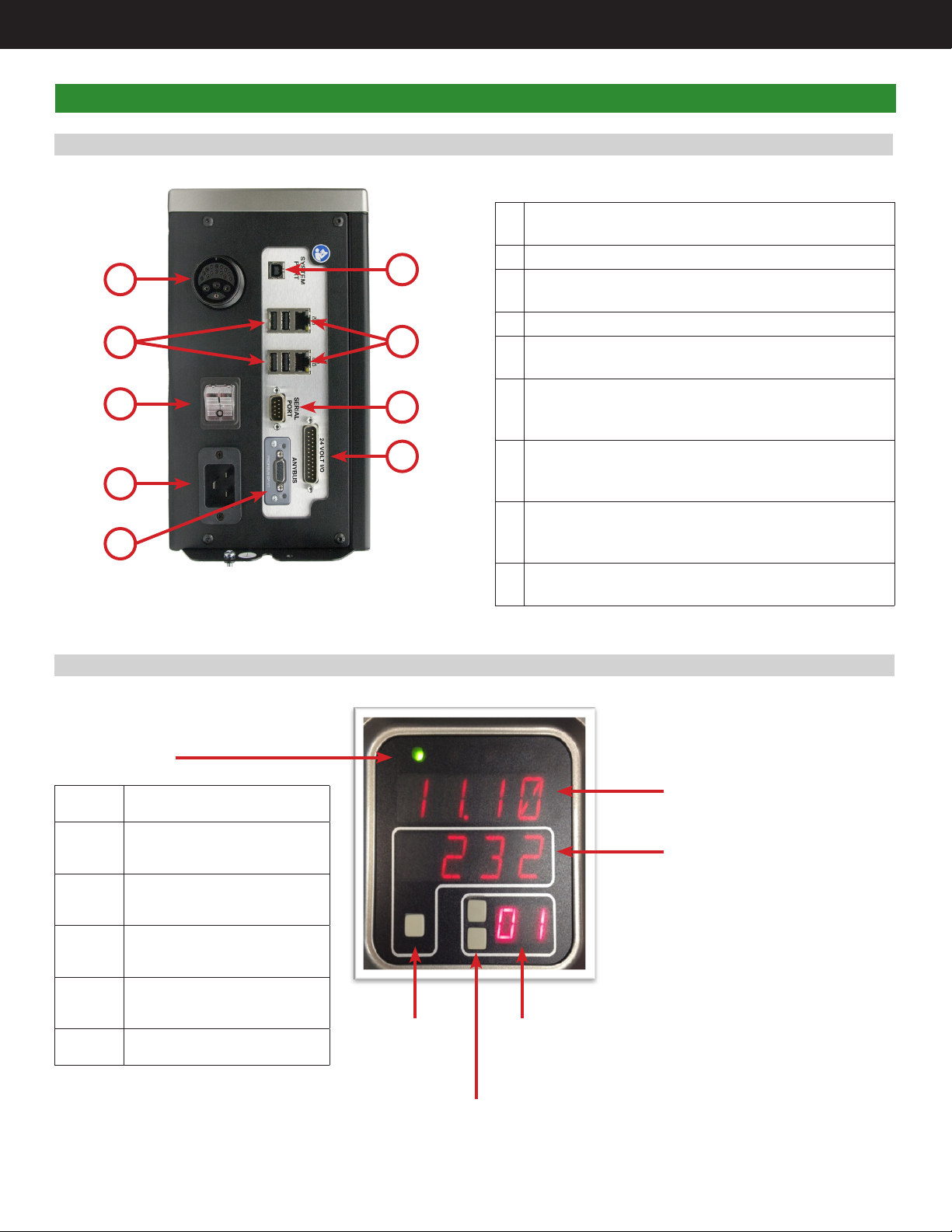

2. Controller Diagram . . . . . . . . . . 4

2.1 Bottom Panel . . . . . . . . . . . 4

2.2 Front Console LED Display . . . . . . . 4

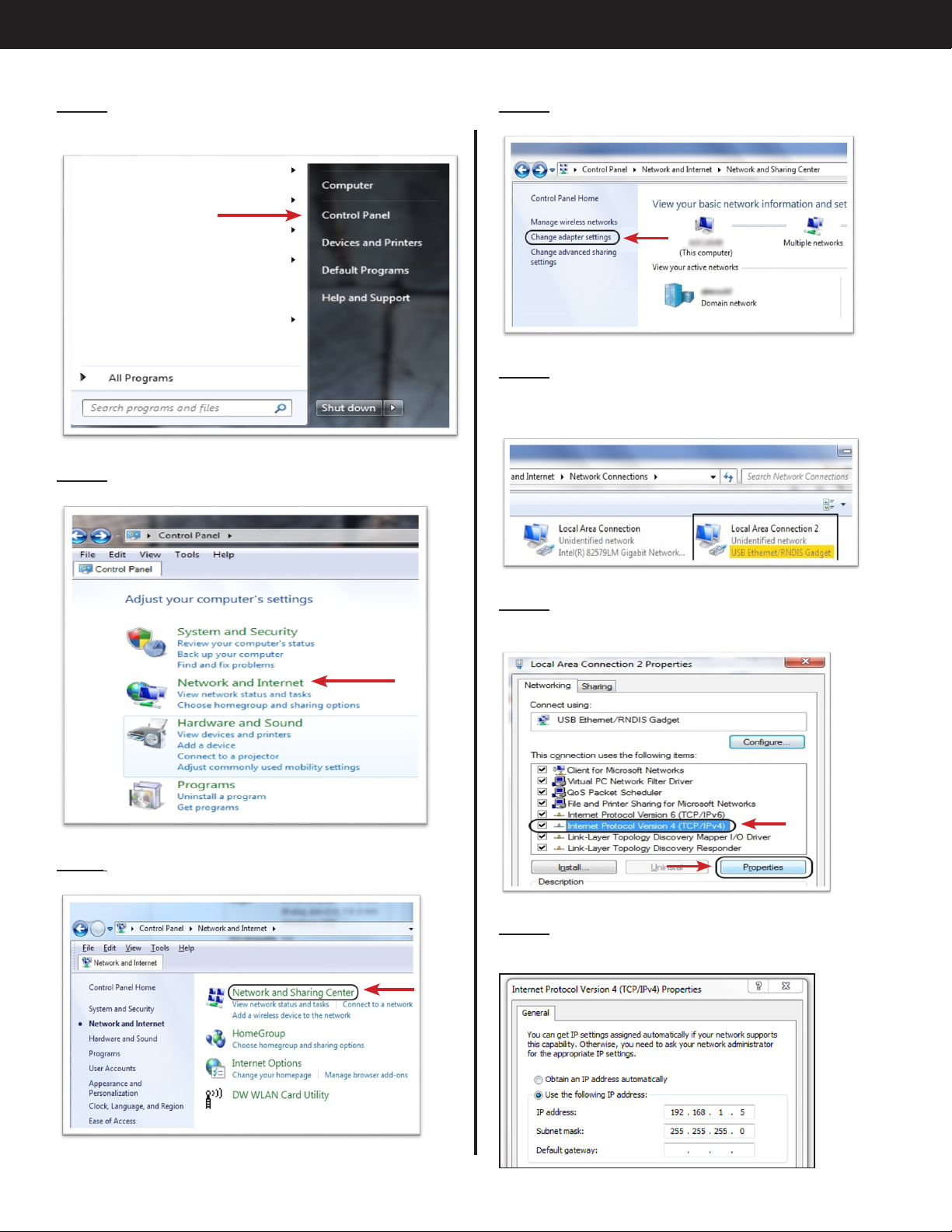

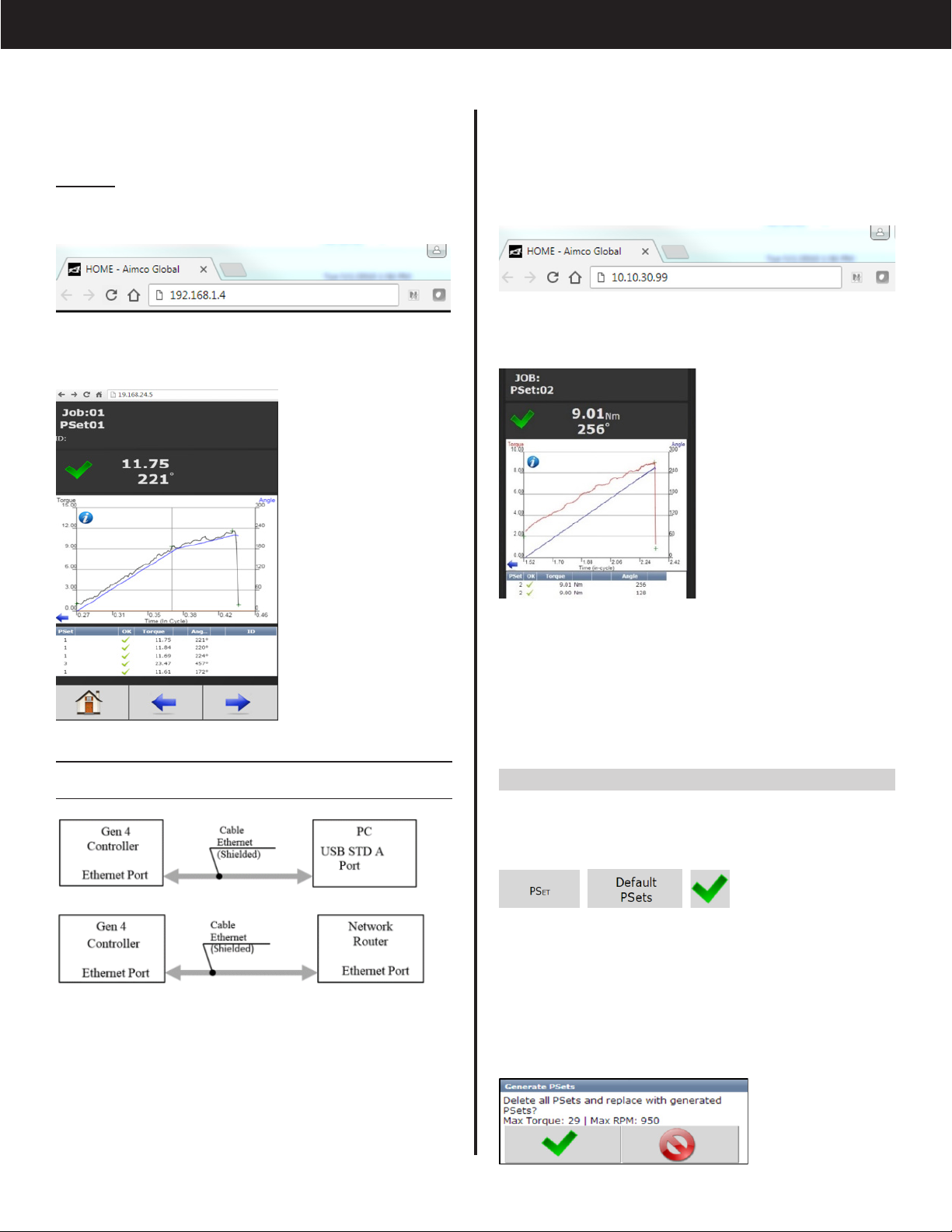

3. Initial Setup. . . . . . . . . . . . . 5

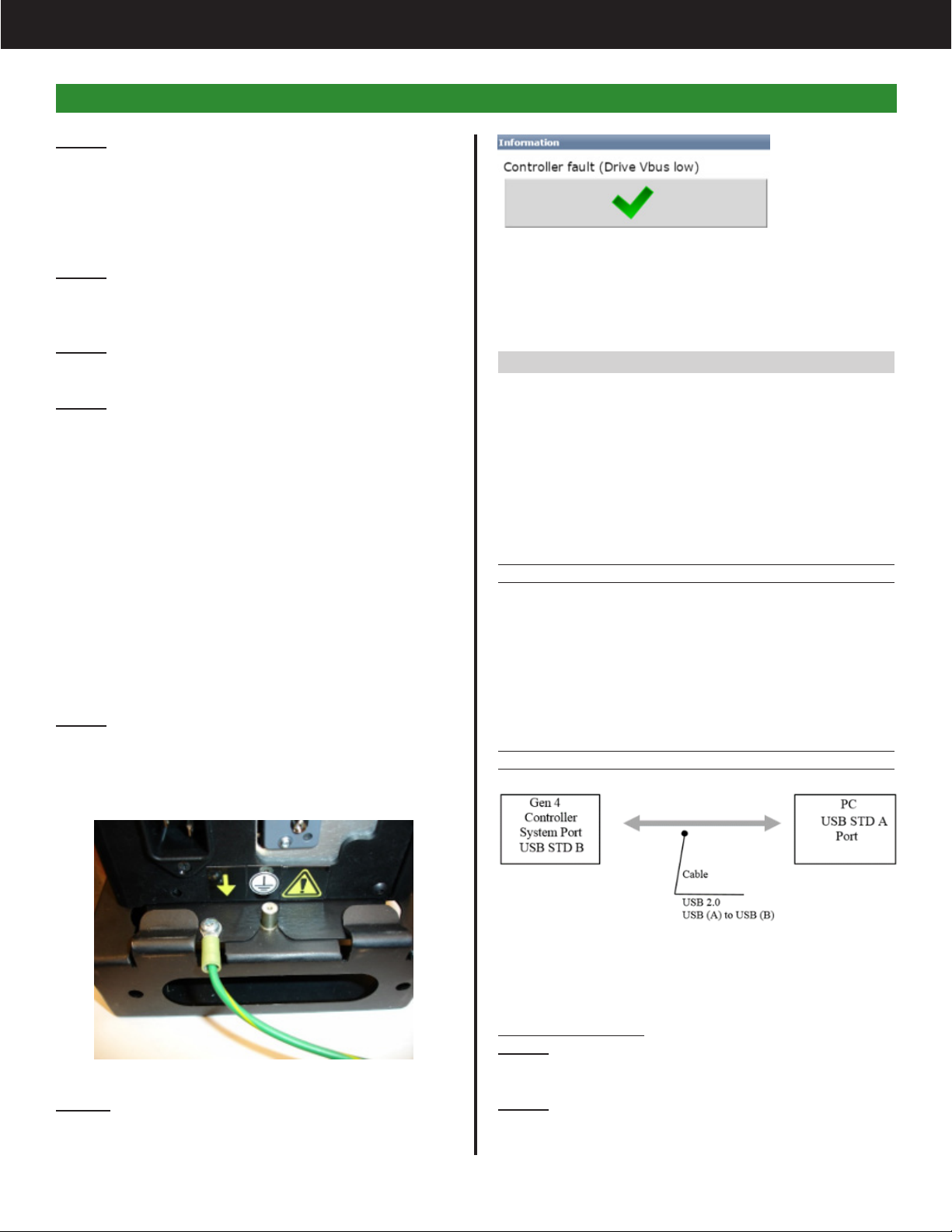

3.1 Connecting to the Controller . . . . . . 5

3.2 Quick Set Up (Default PSets from Tool). . . 7

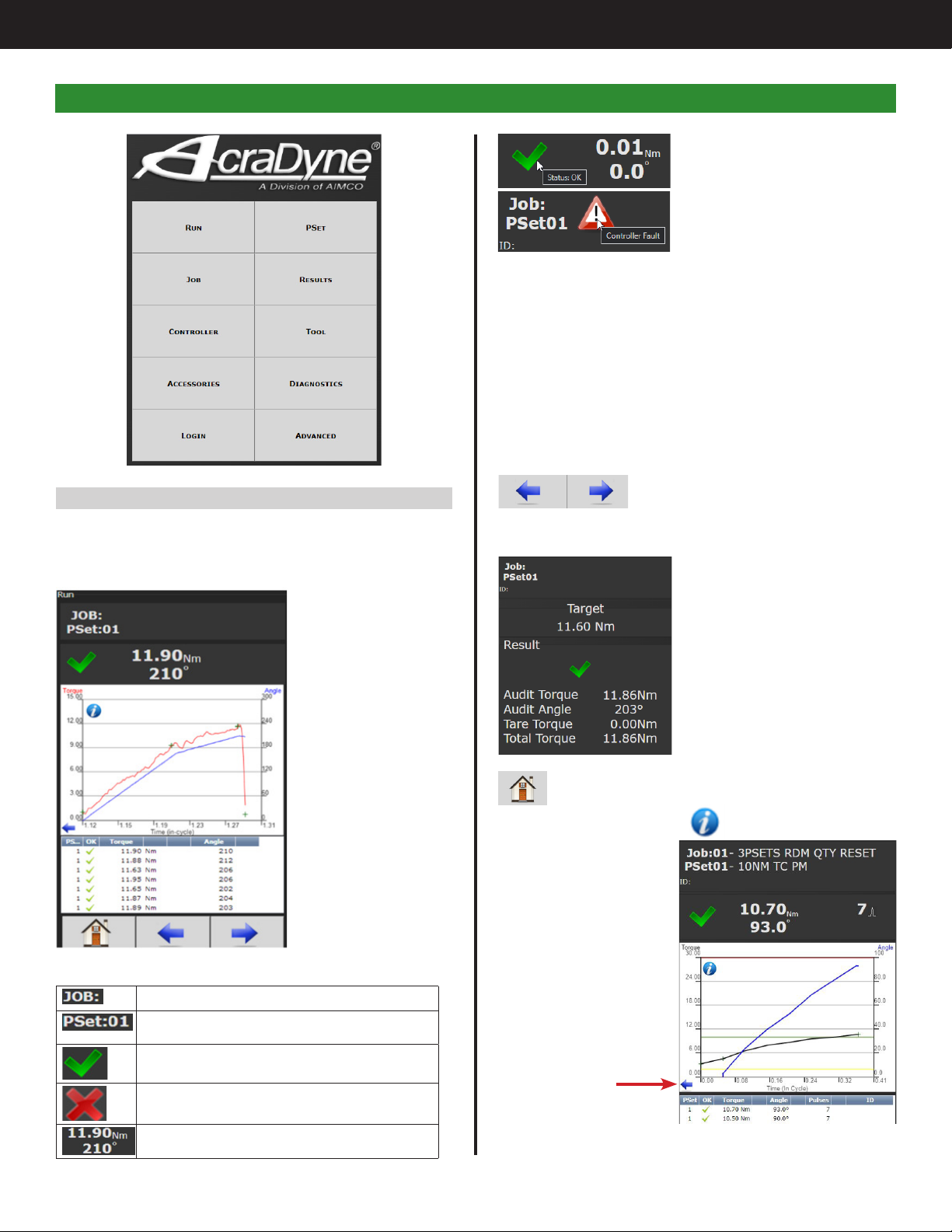

4. Home Page (Main Menu) . . . . . . . . 8

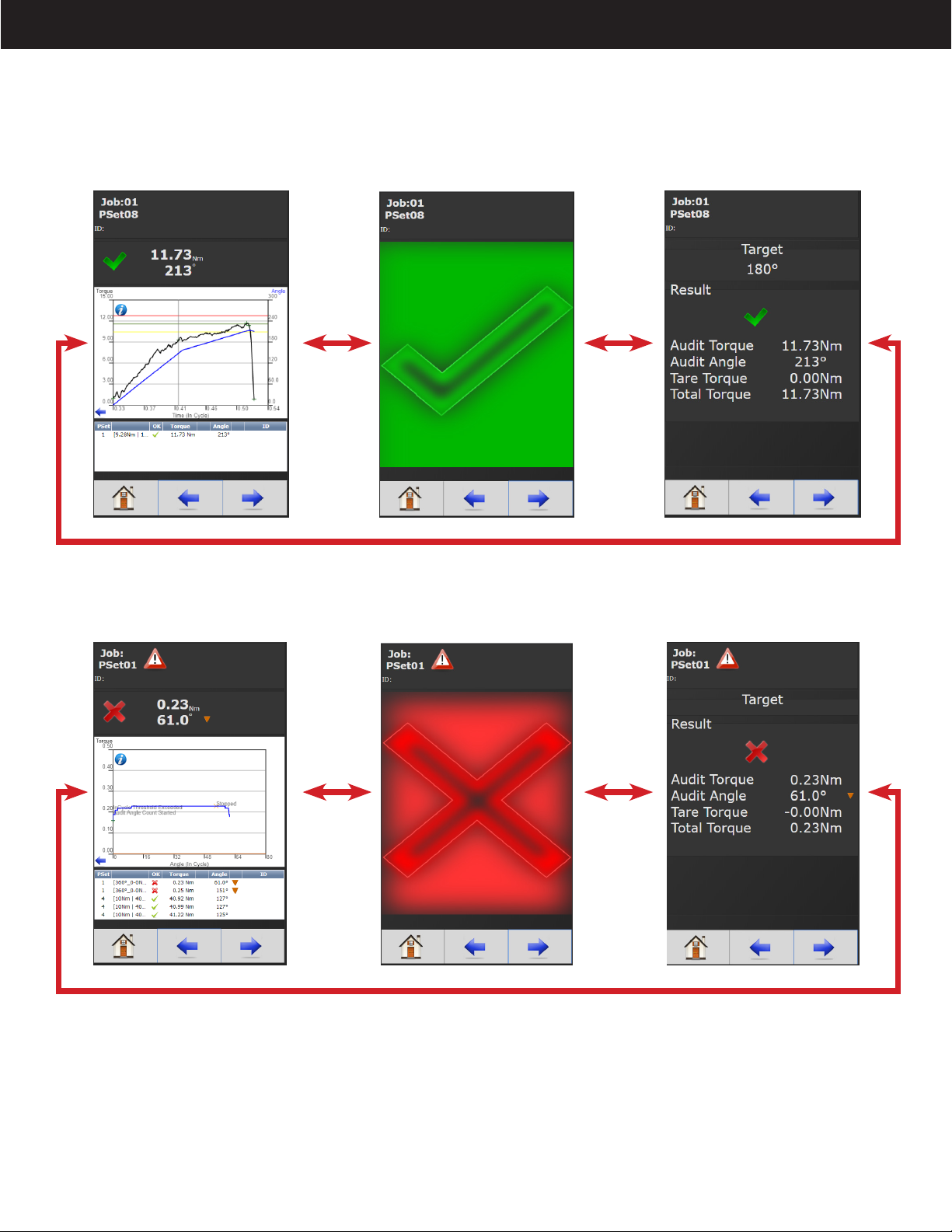

4.1 Run . . . . . . . . . . . . . . 8

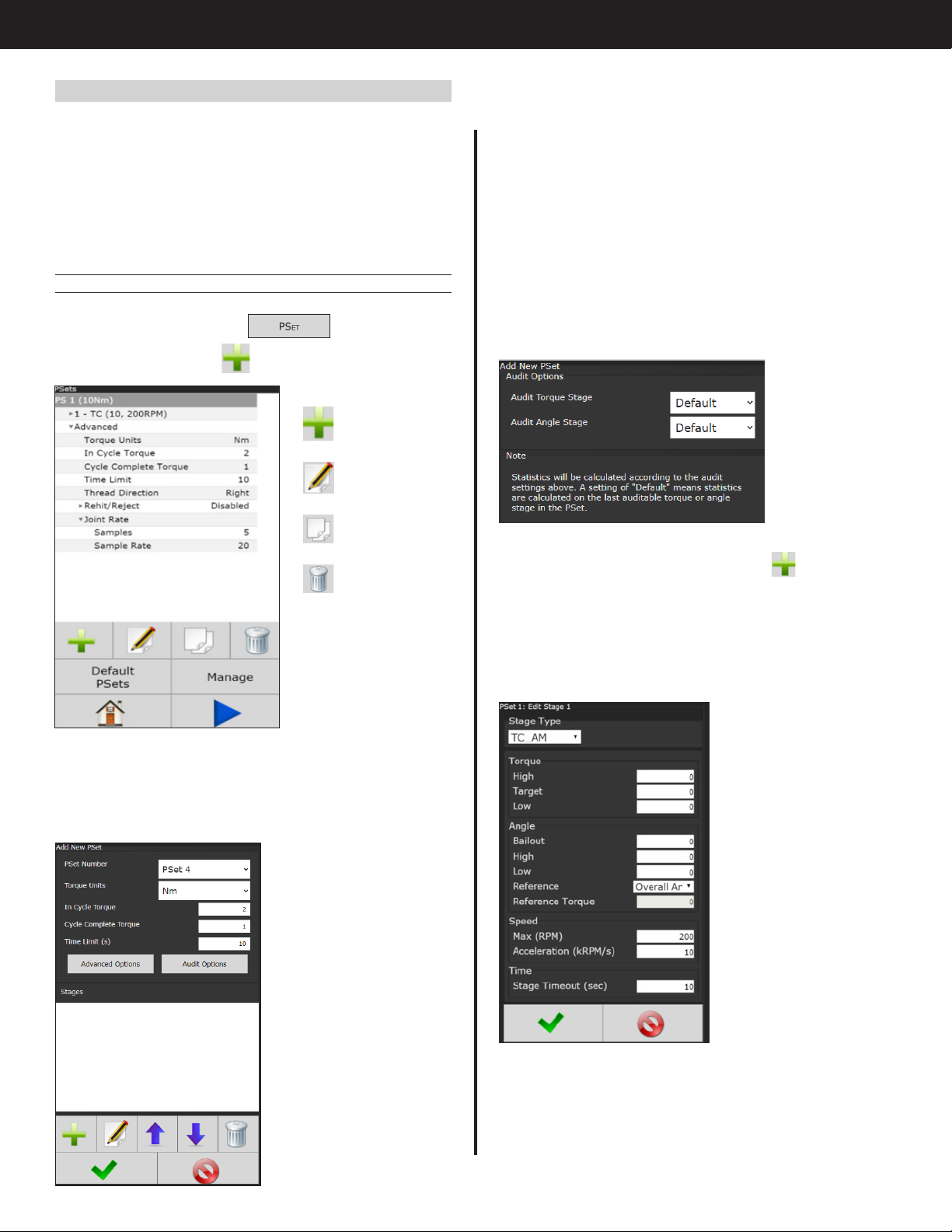

4.2 PSet . . . . . . . . . . . . . . 10

4.2.1 Add New PSet . . . . . . . . . 10

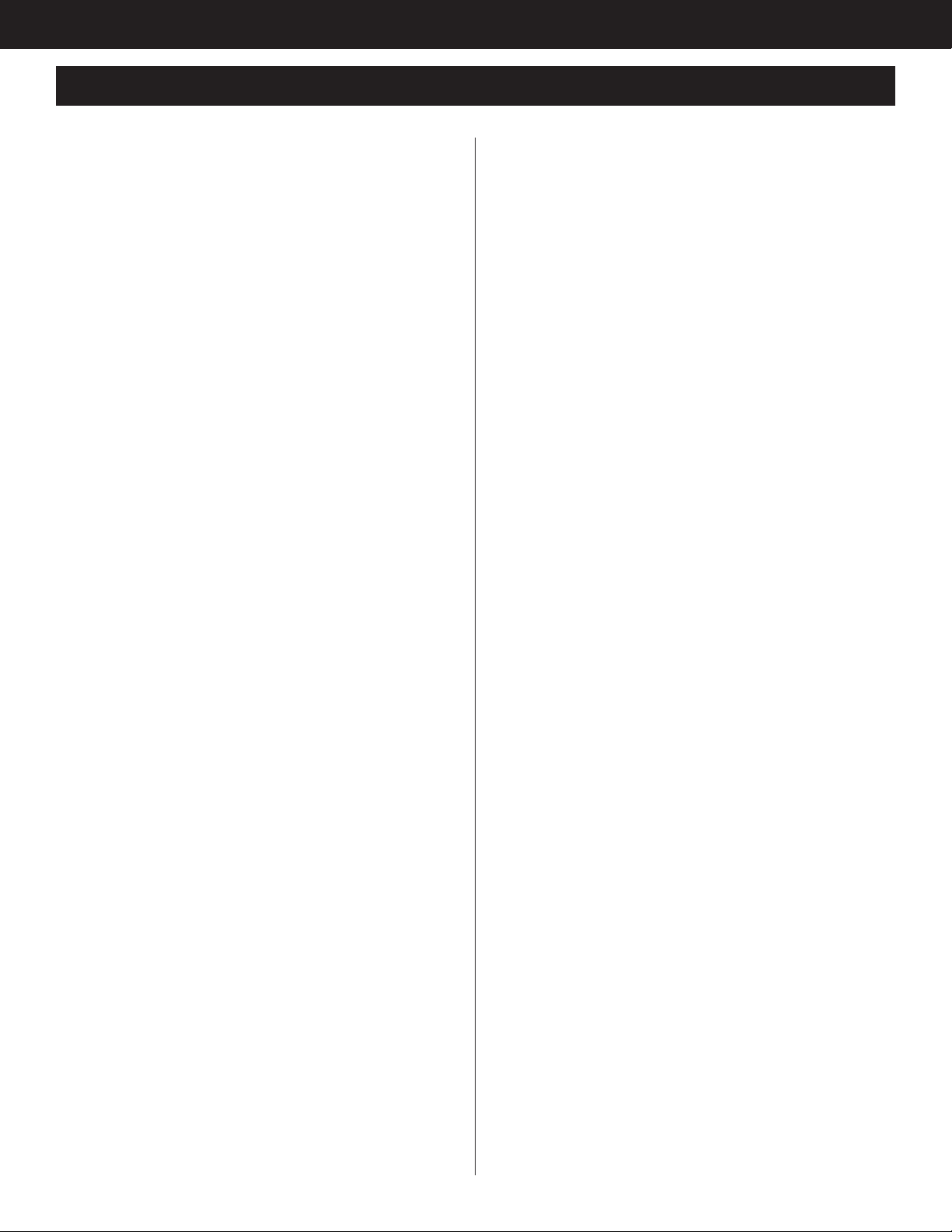

4.2.1.1 Add New Stage . . . . . . . . . 10

4.2.1.2 AcraDrive Discontinuous Drive Mode Settings 11

4.2.2 PSet Stages . . . . . . . . . . 14

4.2.2.1 TC Torque Control Stage . . . . . . 14

4.2.2.2 TC_AM Torque Control Angle Monitor Stage 15

4.2.2.3 AC_TM Angle Control Torque Monitor Stage 16

4.2.2.4 TC_AC Torque Control Angle Control Stage 17

4.2.2.5 Yield Control Stage . . . . . . . . 18

4.2.2.6 Delay Stage . . . . . . . . . . . 19

4.2.2.7 Unfasten Stage . . . . . . . . . . 19

4.2.2.8 Ergo Stop Stage . . . . . . . . . 20

4.2.2.9 Brake Stop Stage . . . . . . . . . 20

4.2.2.10 AC_TA Angle Control Torque Averaging

Stage . . . . . . . . . . . . . 21

4.2.2.11 AC_TCOMP Angle Control Torque

Compensation Stage . . . . . . . 22

4.2.2.12 AC_TCOMP Display of Torque

Compensation Value . . . . . . . 22

4.2.2.13 Sync Stage . . . . . . . . . . . 23

4.2.2.14 Thread Forming Stage . . . . . . . 23

4.2.2.15 Homing Stage . . . . . . . . . . 24

4.2.2.16 AC_TM Anti-Necking Stage . . . . . 25

4.2.2.17 Rate_Control Stage . . . . . . . . 26

4.2.3 Edit PSet . . . . . . . . . . . 27

4.2.4 Advanced Options. . . . . . . . 27

4.2.5 Default Psets . . . . . . . . . . 28

4.2.6 Manage PSets . . . . . . . . . 28

4.2.7 Multistage Rundown Evaluation and

Reporting . . . . . . . . . . . 29

4.2.8 Multiple Stage Rundown Examples . . 30

4.3 Job . . . . . . . . . . . . . . 31

4.3.1 Add New Job . . . . . . . . . 31

4.3.1.1 Advanced Options . . . . . . . . 31

4.3.2 Jobs "Enabled" Display and Button

Function . . . . . . . . . . . 32

4.4 Results . . . . . . . . . . . . . 32

4.4.1 Saving Rundown(s) . . . . . . . 33

4.5 Controller . . . . . . . . . . . . 34

4.5.1 Tool Setup . . . . . . . . . . . 34

4.5.1.1 Lock Tool On Reject . . . . . . . . 34

4.5.1.2 Buzzer . . . . . . . . . . . . . 35

4.5.1.3 Lights . . . . . . . . . . . . . 35

4.5.1.4 Start Input. . . . . . . . . . . . 35

4.5.1.5 MFB (Multi-Function Button) . . . . . 36

4.5.1.6 Disassembly . . . . . . . . . . . 37

4.5.1.7 Tubenut . . . . . . . . . . . . 38

4.5.1.8 Past Due Service Calibration . . . . . 38

4.5.2 IO . . . . . . . . . . . . . 39

4.5.2.1 Physical IO . . . . . . . . . . . 39

4.5.2.2 Physical IO Monitor . . . . . . . . 39

4.5.2.3 Anybus/Modbus TCP/Ethernet IP Inputs . 40

4.5.2.4 Anybus/Modbus TCP/Ethernet IP Outputs. 41

4.5.3 Communication Interfaces . . . . . 42

4.5.3.1 Ethernet/Second Ethernet . . . . . . 42

4.5.3.2 System Port . . . . . . . . . . . 42

4.5.3.3 Serial Port . . . . . . . . . . . . 42

4.5.3.4 Anybus . . . . . . . . . . . . 43

4.5.3.5 Spindle USB Port . . . . . . . . . 43

4.5.3.6 Serial USB . . . . . . . . . . . . 45

4.5.4 Protocols . . . . . . . . . . . 45

4.5.5 Front Panel Buttons. . . . . . . . 45

4.5.6 Power Up . . . . . . . . . . . 45

4.5.7 Bar Code Setup . . . . . . . . 46

4.5.8 Set Time . . . . . . . . . . . 47

4.5.9 Remote Connections . . . . . . . 47

4.5.10 Master Spindle Setup . . . . . . . 47

4.5.10.1 Setting up Multi-Spindle Network . . . . 47

4.5.11 Languages . . . . . . . . . . 47

4.6 Tool . . . . . . . . . . . . . . 49

4.6.1 Tool Setup . . . . . . . . . . . 49

4.6.2 Service Log . . . . . . . . . . 49

4.6.3 Button Calibration . . . . . . . . 49

4.6.4 Torque Calibration . . . . . . . . 50

4.6.5 Torque Calibration Routine . . . . . 50

4.6.6 TID Parameters . . . . . . . . . 50

4.6.7 TID Memory . . . . . . . . . . 51

4.7 Accessories . . . . . . . . . . . 51

4.8 Diagnostics . . . . . . . . . . . . 52

4.8.1 Controller Overview . . . . . . . 52

4.8.2 Controller Status. . . . . . . . . 52

4.8.3 Tool Overview . . . . . . . . . 53

4.8.4 Live Tool . . . . . . . . . . . 53

4.8.5 Indicators . . . . . . . . . . . 53

4.8.6 Identify Controller . . . . . . . . 54

4.8.7 Record Logs . . . . . . . . . . 54

4.8.7.1 Change Log . . . . . . . . . . 54

4.8.7.2 Information Log . . . . . . . . . 54

4.8.7.3 Error Log . . . . . . . . . . . . 54

4.8.7.4 All . . . . . . . . . . . . . . 54

4.8.8 System Status. . . . . . . . . . 54

4.8.9 I/O Diagnostics . . . . . . . . . 54

4.8.10 Network Diagnostics . . . . . . . 54

4.8.11 Extended Logging . . . . . . . . 55

4.8.12 Statistics . . . . . . . . . . . 55

4.9 Login . . . . . . . . . . . . . . 55

4.10 Advanced . . . . . . . . . . . . 55

4.10.1 Login Setup . . . . . . . . . . 55

4.10.2 Results Archive . . . . . . . . . 56

4.10.3 Import Settings . . . . . . . . . 56

4.10.4 Export Controller . . . . . . . . 57

4.10.5 Update Controller . . . . . . . . 57

4.10.6 Backup Restore . . . . . . . . . 57

4.10.7 Restore Factory Defaults . . . . . . 58

4.10.8 Previous Software . . . . . . . . 58

4.10.9 Calibrate Touch Screen . . . . . . 58

4.10.10 Soft Reboot . . . . . . . . . . 59

5. Barcode Reader Details . . . . . . . . 60

6. Glossary of Terms. . . . . . . . . . . 62

7. Icons Defined . . . . . . . . . . . .63

8. Stop Codes. . . . . . . . . . . . . 64

9. Error Codes. . . . . . . . . . . . . 65

10. Dual-Lever Tools Requiring Two-Handed

Operation . . . . . . . . . . . . . 67

11. 24 Volt I/O . . . . . . . . . . . . .68

12. Assignable I/O . . . . . . . . . . . 70

13. Controller Supported MIDs. . . . . . . . 82

14. Dimensions . . . . . . . . . . . . . 83

15. Specifications . . . . . . . . . . . .83

16. Tubenut Tool Setup Details. . . . . . . . 84

16.1 Overview . . . . . . . . . . . . 84

16.2 Tubenut Homing . . . . . . . . . . 84

16.2.1 Tubenut Home TID parameters. . . . 84

16.3 Setting the Tool’s Tubenut Home TID

Parameters . . . . . . . . . . . . 84

16.4 Controller Parameters Affecting

Tubenut Homing . . . . . . . . . . 84

16.5 Tubenut Pinch Detection . . . . . . . 85

16.5.1 Obstruction Detection TID Parameters . 85

16.5.2 Setting the Tool’s Tubenut Obstruction

Detection . . . . . . . . . . . 85

16.5.3 Controller Parameters Affecting

Tubenut Pinch Detection. . . . . . 85

16.5.4 Tubenut Homing Start Input Logic

Selection . . . . . . . . . . . 85

17. Troubleshooting . . . . . . . . . . . 86

18. AIMCO Warranty . . . . . . . . . . .87