Rev 05/202

Direct Service Done Right

Since 1948, Nystrom has been the go-to manufacturer of specialty building products providing a wide range of floor, roof, wall,

ceiling, and stair access products that create safer, more accessible buildings. We offer hassle-free services including access to

technical experts, REVIT tools for BIM, HPDs for LEED v4, 3-part specifications and AIA-accredited continuing education courses.

Installation, Operation

+ Maintenance Manual

1

SEISMIC ALUMINUM HEAVY-DUTY FLOORING

SYSTEM – RECESSED BLOCKOUT APPLICATION

MODEL(S): PTX/PTXw

PTX Floor to Floor System – 2” Through 12” Sizes

GENERAL DESCRIPTION

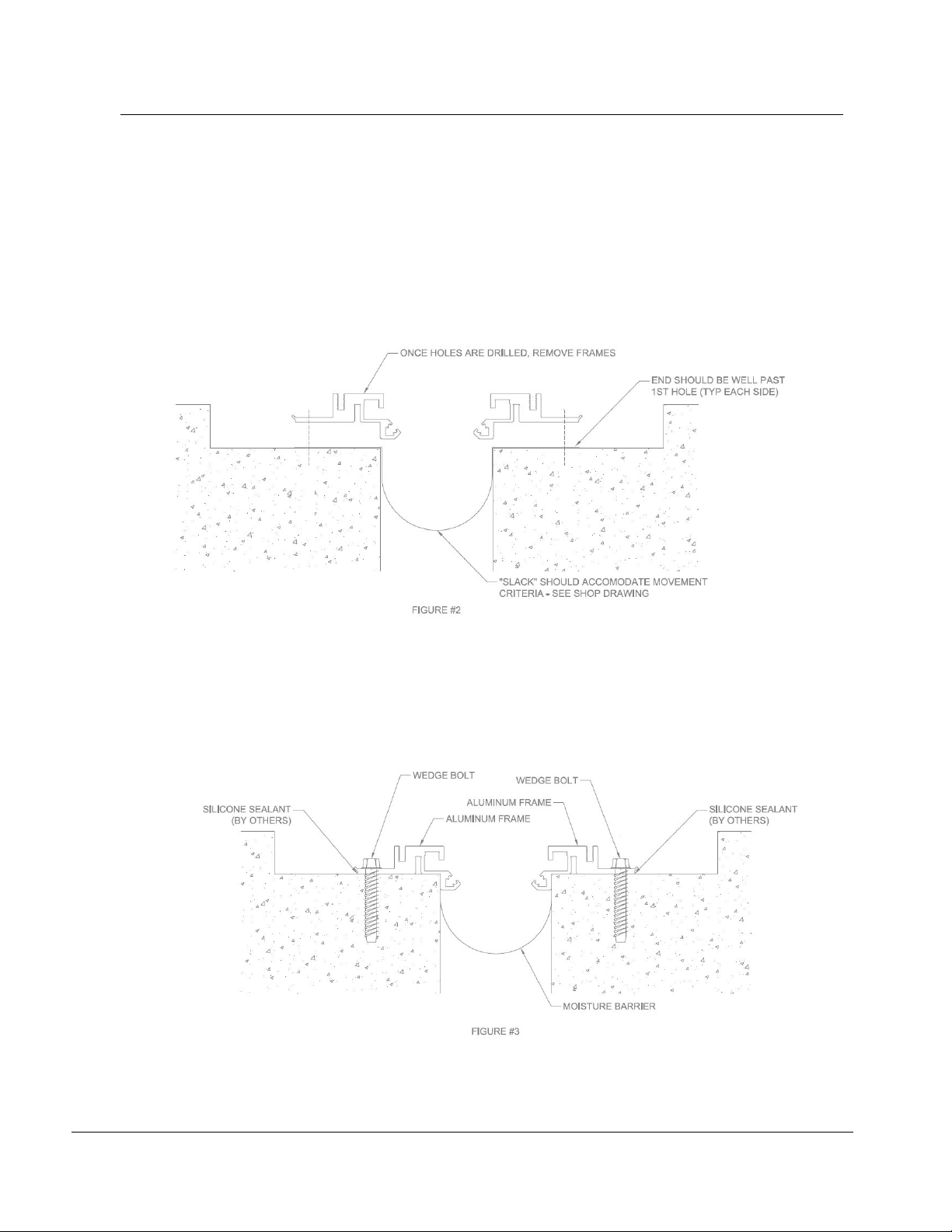

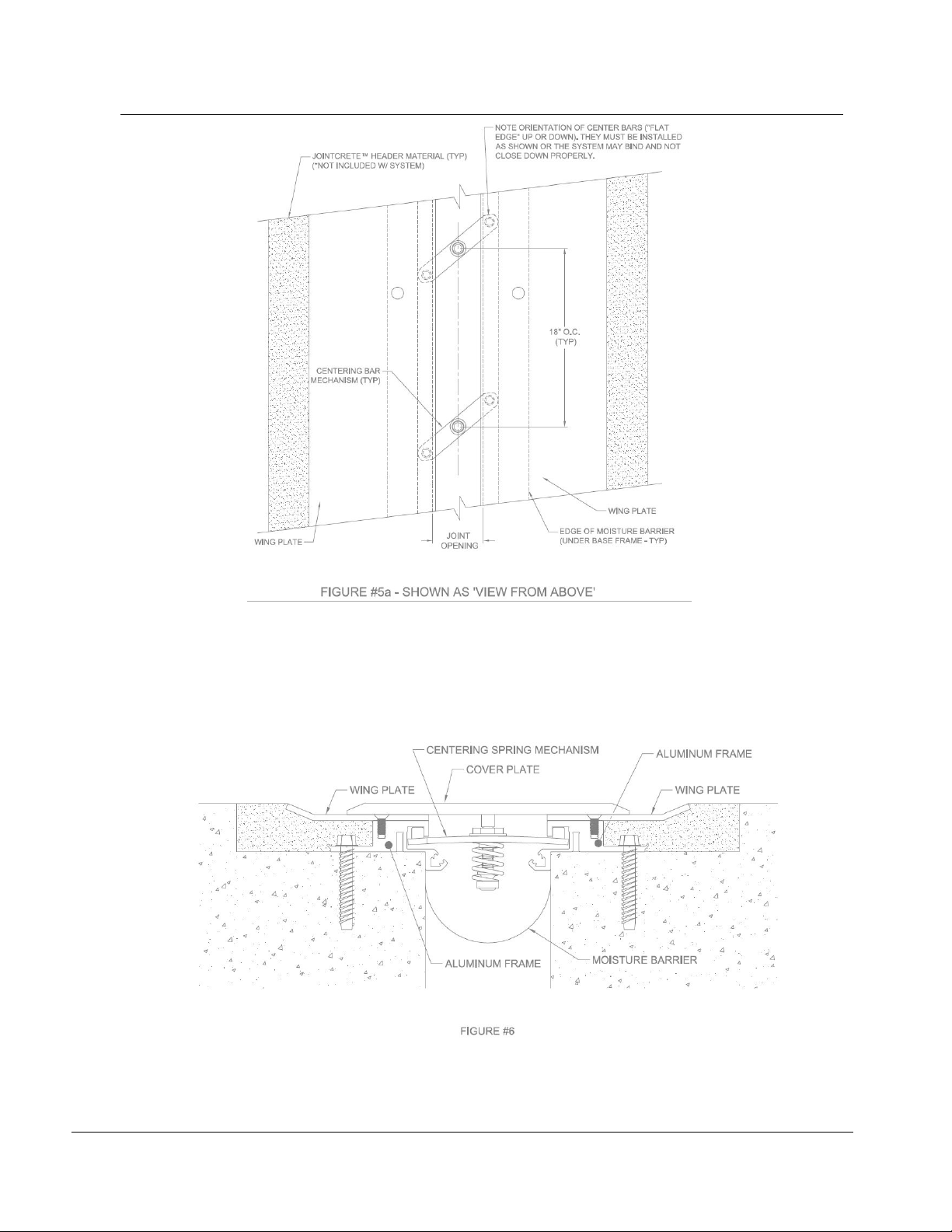

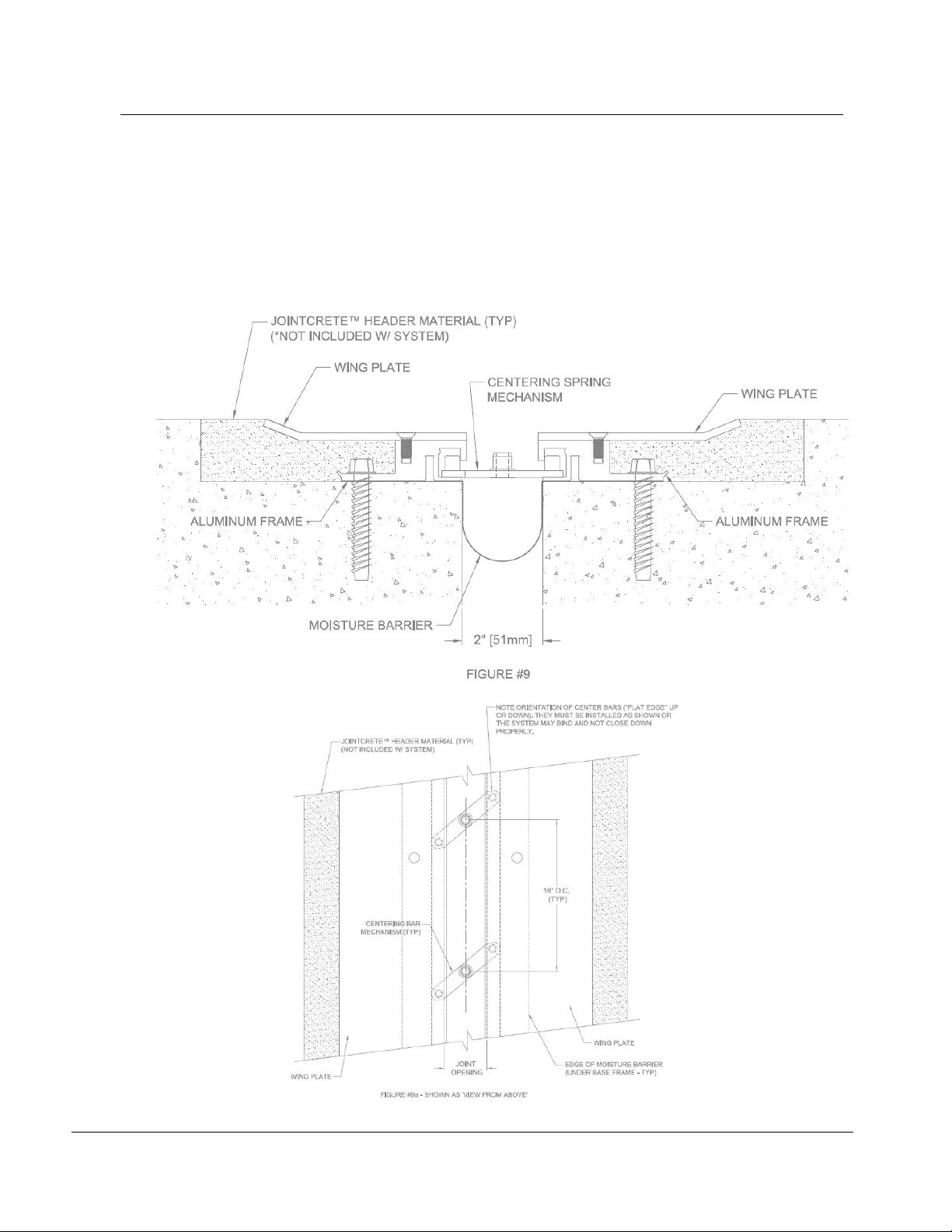

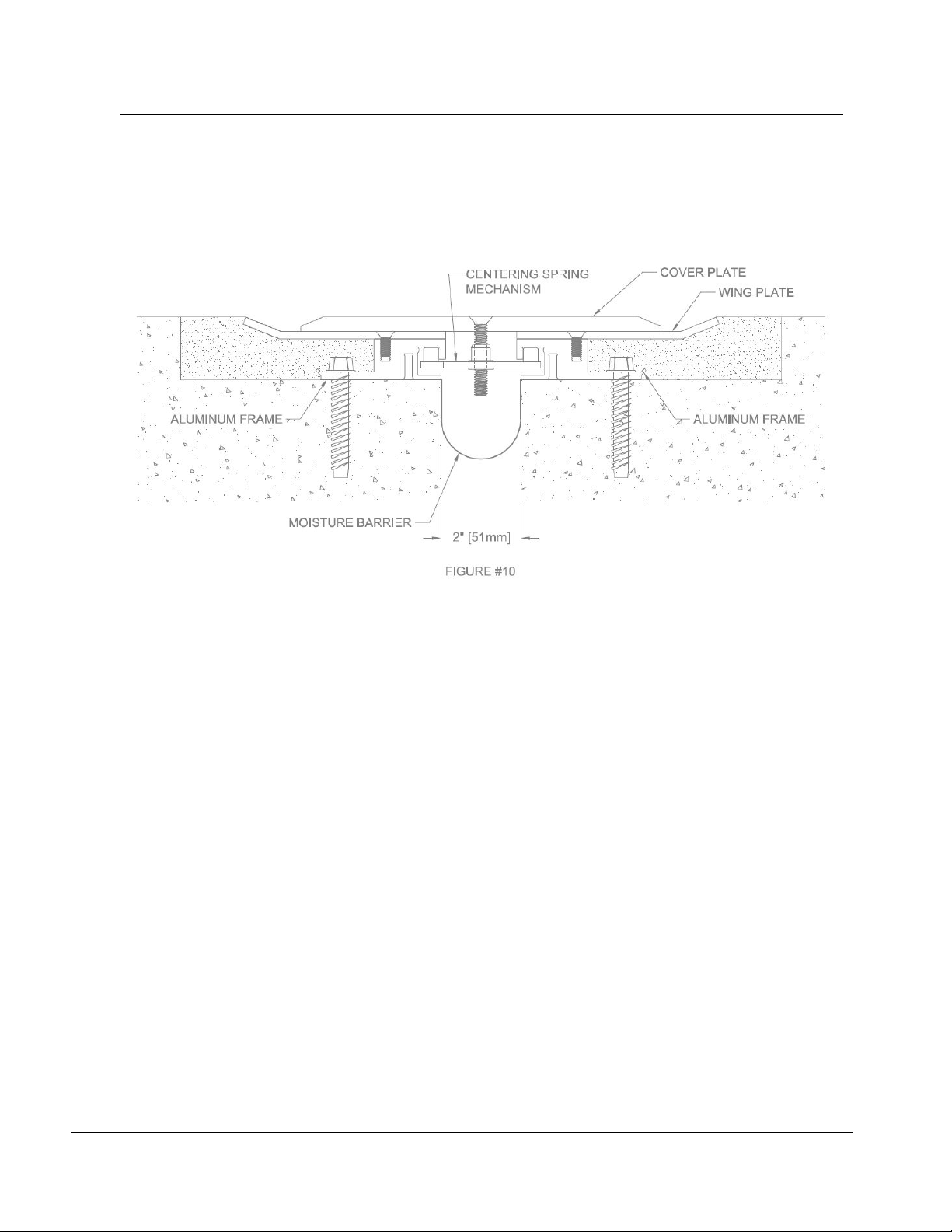

This Heavy-Duty Seismic Recessed System can

accommodate larger openings with multidirectional

movement requirements. An integral moisture

barrier keeps the weather out.

Introduction + Safety

Please read the complete instructions carefully before beginning any work. To ensure proper

installation and performance of the product, the following actions must be completed by the

installing contractor. Failure to do so will affect the product warranty.

Transportation + Storage

oInspect all shipments and materials for missing or damaged components and

hardware.

oMaterial must be stored in a clean, dry location.

Preparation

•Locate the packing slip(s) and/or shop drawings.

•Verify that all products listed on the packing slip are included in the package.

•Check the products for damage. If products are damaged, report a freight claim

immediately and leave the products in their packaging. If you sign for products

without reporting damage, you waive your right to a freight claim and will be

responsible for their replacement cost.

•Read the instructions thoroughly before beginning installation.

GENERAL SAFETY PRECAUTIONS

Improper selection, installation, or use can cause personal injury or property

damage. It is solely the responsibility of the user, through their own analysis, to select products suitable to the

specific application requirements, ensure proper maintenance and use as intended. Follow local, state, and

federal regulations for proper installation and operation requirements.