Toro Groundsmaster 3320 User manual

1

All Rights Reserved

Printed in the USA

W2005 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

15 CU. FT. HOPPER Kit

Groundsmaster)3320 and 3380–D

Model No. 30356–250000001 and Up

Form No. 3353–222

Installation Instructions

Safety

Before Operating

•Read and understand the contents of this manual before

starting and operating the machine. Become familiar

with all controls and know how to stop quickly.

•Never allow children to operate the machine. Do not

allow adults to operate the machine without proper

instruction. Only trained operators, skilled in slope

operation and who have read this manual should operate

this machine.

•Never operate machine when under the influence of

drugs or alcohol.

•Remove all debris or other objects that might be picked

up and thrown by cutter blades. Keep all bystanders

away from the operating area.

•Keep all shields and safety devices in place. If a shield,

safety device, or decal is defective or damaged, repair

or replace it before operation is commenced. Also,

tighten any loose nuts, bolts, and screws to insure

machine is in safe operating condition.

•Do not wear loose–fitting clothing because it could get

caught in moving parts. Always wear long pants and

substantial shoes. Wearing safety glasses, safety shoes,

and a helmet is advisable and required by some local

ordinances and insurance regulations.

•Be sure interlock switches are adjusted correctly so

engine cannot be started unless traction pedal is

released–neutral position–and PTO switch is in

DISENGAGED position.

•Fill fuel tank before starting the engine. Avoid spilling

any fuel. Since fuel is flammable, handle it carefully.

– Use an approved fuel container.

– Do not fill fuel tank when engine is hot or running.

– Do not smoke while handling fuel.

– Fill fuel tank outdoors and only to the bottom of the

filler neck.

– Wipe up any spilled fuel.

While Operating

•Sit on the seat when starting the engine and operating

the machine.

•Before starting the engine:

– Engage parking brake.

– Make sure traction pedal is in neutral and PTO is in

DISENGAGE position.

– After engine is started, release parking brake and

keep foot off traction pedal. Machine must not

move. If movement is evident, the neutral return

mechanism is adjusted incorrectly. Shut engine off

and adjust until machine does not move when

traction pedal is released.

•Do not run the engine in a confined area without

adequate ventilation. Exhaust fumes are hazardous and

could possibly be deadly.

•Maximum seating capacity is one person. Therefore,

never carry passengers.

•Check carefully for overhead clearances before driving

under any objects.

•The grass deflector or complete blower assembly must

always be installed on cutting unit.

•To maintain machine control, 75 lb. of weight must be

mounted on left front wheel of traction unit before

using the 15 cu. ft. Hopper kit. Refer to traction Unit

Operator’s Manual for additional weight requirements.

•Operator must be skilled and trained in how to drive on

hillsides. Failure to use caution on slopes or hills may

cause loss of control and vehicle to tip or roll possibly

resulting in personal injury or death.

•Traverse slopes carefully. Do not start or stop suddenly

when traversing slopes or when traveling uphill or

downhill.

•If engine stalls or machine loses headway and cannot

make it to the top of a slope, do not turn machine

around. Always back slowly straight down the slope.

•Using the machine demands the operator’s complete

attention. To prevent loss of control:

– Operate only in daylight or when there is good

artificial light.

– Drive slowly.

2

– Avoid sudden stops and starts.

– Look behind machine before backing up.

– Watch for holes or other hidden hazards.

– Do not drive close to a sand trap, ditch, creek, or

hazard.

– Reduce speed when making sharp turns and when

turning on a hillside.

– The cutting deck must be lowered when going down

slopes for steering control.

•The grass deflector must always be installed and in

lowest position on the cutting unit when blower

assembly is removed. This product is designed to drive

objects into the ground where they lose energy quickly

in grassy areas. However. don’t take an injury risk!!

When a person or pet appears unexpectedly in or near

the mowing area, STOP MOWING. Careless operation,

combined with terrain angles, ricochets, or improperly

positioned guards, can lead to thrown object injuries.

Do not resume mowing until area is cleared.

•Never raise the cutting unit while the blades or other

parts are rotating.

•If cutting blades strike a solid object or the machine

vibrates abnormally, disengage PTO, move throttle to

SLOW, set parking brake, and shut engine off. Remove

key from switch to prevent possibility of accidental

starting. Check cutting unit, blower assembly and

traction unit for damage and defective parts. Repair any

damage before restarting the engine and operating the

cutting unit. Assure cutting unit blades are in good

condition and blade bolts are torqued to proper

specifications (See Cutting Deck Operator’s Manual).

•If the cutting unit discharge area or blower assembly

ever plugs, disengage PTO and shut engine off before

removing the obstruction.

•To stop machine, remove foot from traction pedal and

use brakes. Gradually reversing the traction pedal can

provide additional braking.

•Do not touch engine, muffler, or radiator while engine

is running or soon after it has stopped. These areas

could be hot enough to cause a burn.

•Before raising hopper:

– Make sure machine is on level ground.

– Disengage the PTO.

– Clear bystanders from area around hopper and

hopper linkage.

– Check overhead clearance.

•Do not attempt to dump clippings over an embankment.

•Hopper must be fully lowered before driving machine.

•Lower the cutting unit and hopper to their lowest

positions and remove key from switch whenever

machine is left unattended.

•Before getting off the seat:

– Move traction pedal to neutral position and remove

foot from pedal.

– Set the parking brake and disengage the PTO.

– Shut the engine off and remove key from ignition

switch. Wait for all movement to stop before getting

off the seat.

•Never operate collection system with hopper covers

open.

Maintenance

•Remove key from ignition switch to prevent accidental

starting of the engine when servicing, adjusting, or

storing the machine.

•Stay away from hopper and hopper linkage during

operation.

•Do not walk under hopper or service machine unless

hopper is fully raised and empty, with hydraulic lines

disconnected at quick couplers or fully lowered.

•Do not remove any hydraulic line unless hopper is fully

lowered or fully raised and empty.

•If major repairs are ever needed or assistance is desired,

contact an Authorized TORO Distributor.

•To reduce potential fire hazard, keep the engine free of

excessive grease, grass, leaves, and accumulations of

dirt.

•Make sure machine is in safe operating condition by

keeping nuts, bolts, and screws tight. Check all cutting

unit blade mounting bolts frequently to assure they are

torqued to proper specifications (See Cutting Deck

Operator’s Manual).

•Make sure all hydraulic line connectors are tight, and all

hydraulic hoses and lines are in good condition before

applying pressure to the system.

•Keep body and hands away from pin hole leaks or

nozzles that eject hydraulic fluid under high pressure.

Use paper or cardboard, not hands, to search for leaks.

Hydraulic fluid escaping under pressure can have

sufficient force to penetrate skin and do serious damage.

If fluid is ejected into the skin, it must be surgically

removed within a few hours by a doctor familiar with

this form of injury or gangrene may result.

•Before disconnecting or performing any work on the

hydraulic system, all pressure in system must be

relieved by stopping engine and lowering implement to

the ground.

3

•If the engine must be running to perform maintenance

or an adjustment, keep clear of PTO shaft, cutting unit

blades, and other moving parts.

•At the time of manufacture, the machine conformed to

safety standards in effect for riding mowers. To ensure

optimum performance and continued safety certification

of the machine, use genuine TORO replacement parts

and accessories. Replacement parts and accessories

made by other manufacturers may result in

non–conformance with the safety standards, and the

warranty may be voided.

Safety and Instruction Decals

107-2931

1. Warning—read the Operator’s Manual.

2. Crushing hazard—do not get under the hopper as it lowers and keep bystanders a safe distance from the machine.

108-9694

1. Warning—read the Operator’s Manual; 12 ft (3.7 m) clearance

is required for dumping.

2. Crushing hazard—do not get under the hopper as it lowers and

keep bystanders a safe distance from the machine.

3. Tipping hazard—keep the hopper lowered while moving the

machine and do not dump the hopper over a drop-off or

embankment.

4. Thrown objects hazard—do not move the machine with the

hopper open.

4

Set Up

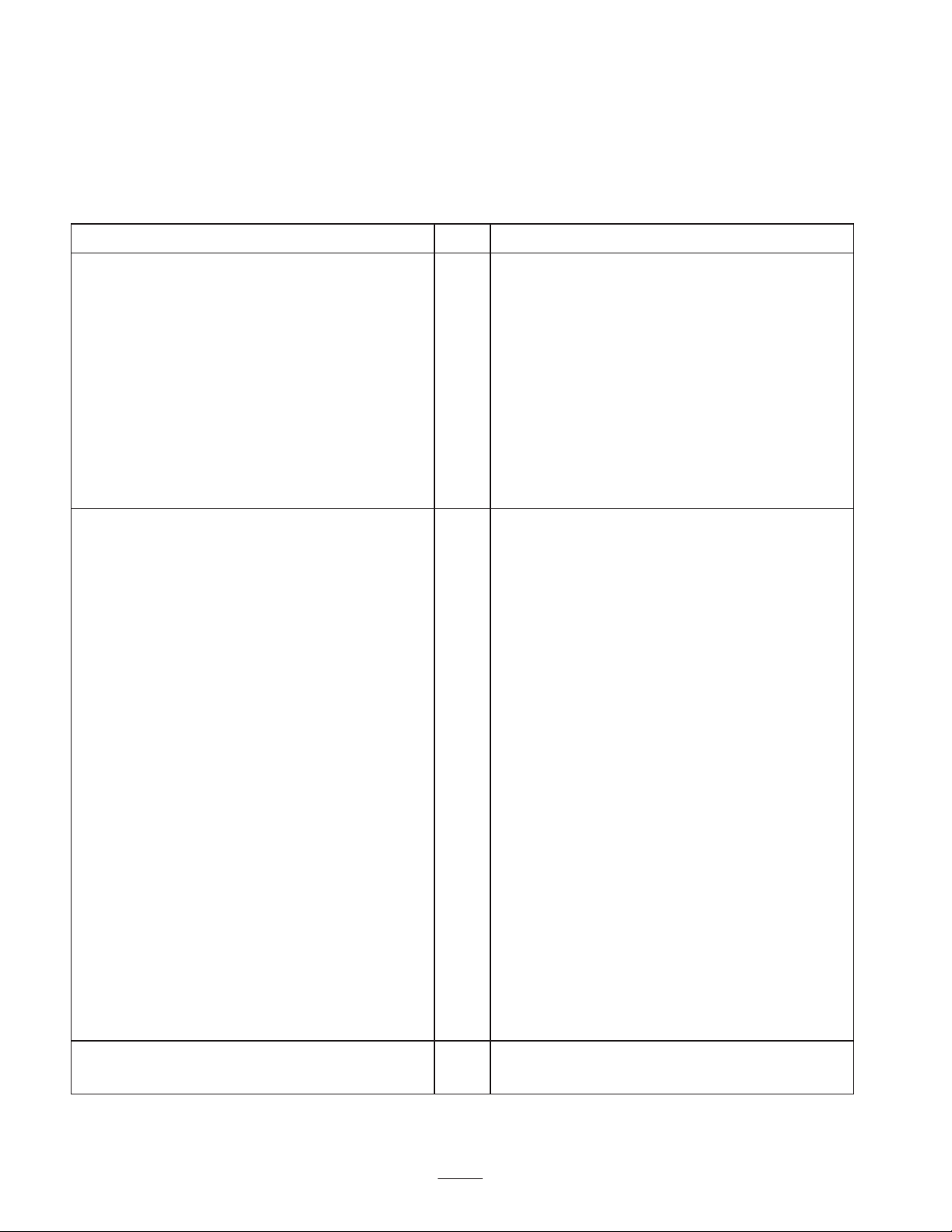

LOOSE PARTS CHART

Note: Use this chart as a checklist to assure all parts necessary for assembly have been received. Without these parts, total

set-up cannot be completed. Some parts may have already been assembled at factory.

Description Qty. Use

Control Valve Assembly

Control Valve Handle

Control Valve Pivot Lever

Socket Head Screw 10–24 x 1–1/4” lg.

Locknut #10–24

Clevis Pin

Cotter Pin

Hydraulic Hose

Capscrew 1/4 – 20 x 2–3/4” lg.

Flange Locknut 1/4–20

1

1

1

1

1

1

1

1

3

3

Mount Control Valve to Fender

Frame Assembly

Hopper Mounting Bracket – Left

Capscrew #10–24

Locknut #10–24

Capscrew 5/16 – 18 x 1–1/4” lg.

Locknut 5/16–18

Hopper Mounting Bracket – Right

Coupler Bracket

Capscrew 3/8 – 16 x 1” lg.

Lockwasher – 3/8

Locknut 3/8 – 16

Hopper Mounting Bracket – Rear

Strap

Capscrew 1/2 – 13 x 1–1/4” lg.

Capscrew 1/2 – 13 x 1–1/2” lg.

Flatwasher 1/2

Locknut 1/2–13

Disconnect Pin

Welded Mounting Pin – Long

Welded Mounting Pin – Short

Self Tapping Screw 1/4–20– x 3/4” lg.

1

1

4

4

4

4

1

1

4

2

2

1

2

2

2

2

4

1

1

1

2

Install Frame Assembly

Wire Harness

Cable Ties

1

6Connect Wire Harness

5

Description UseQty.

Hydraulic Hoses

Protective Sleeve

Retaining Ring

Retaining Ring

Dust Plug

Dust Cap

Quick Disconnect (nipple & coupler)

2

1

1

1

1

1

1

Connect Hydraulic Lines

Hopper Assembly

Welded Mounting Pin

Hair Pin Cotter – for 1/2” Shaft

Hair Pin Cotter – for 1/4” Shaft

Carriage Bolt 5/16 – 18 x 1” lg.

Flange Locknut 5/16–18

1

2

2

2

2

2

Install Hopper Assembly

Shield – Top

Shield – Wide

Shield – Narrow

Flat – Short

Flat – Long

Screw #10 – 24 x 1” lg.

Flange Nut #10 – 24

1

1

1

1

2

8

8

Install in Chute Opening of Hopper

Wheel Weight

Threaded Rod

Lockwasher

Flatwasher

Hex Nut

Installation Instructions

Parts Catalog

1

2

4

2

6

1

1

Mount to Left Wheel

Note: Refer to Traction Unit Operator’s Manual for left

side weight requirements.

Optional Equipment

Bracket Kit

Weight Kit

Part No. 92–9670

Part No. 24–5780

6

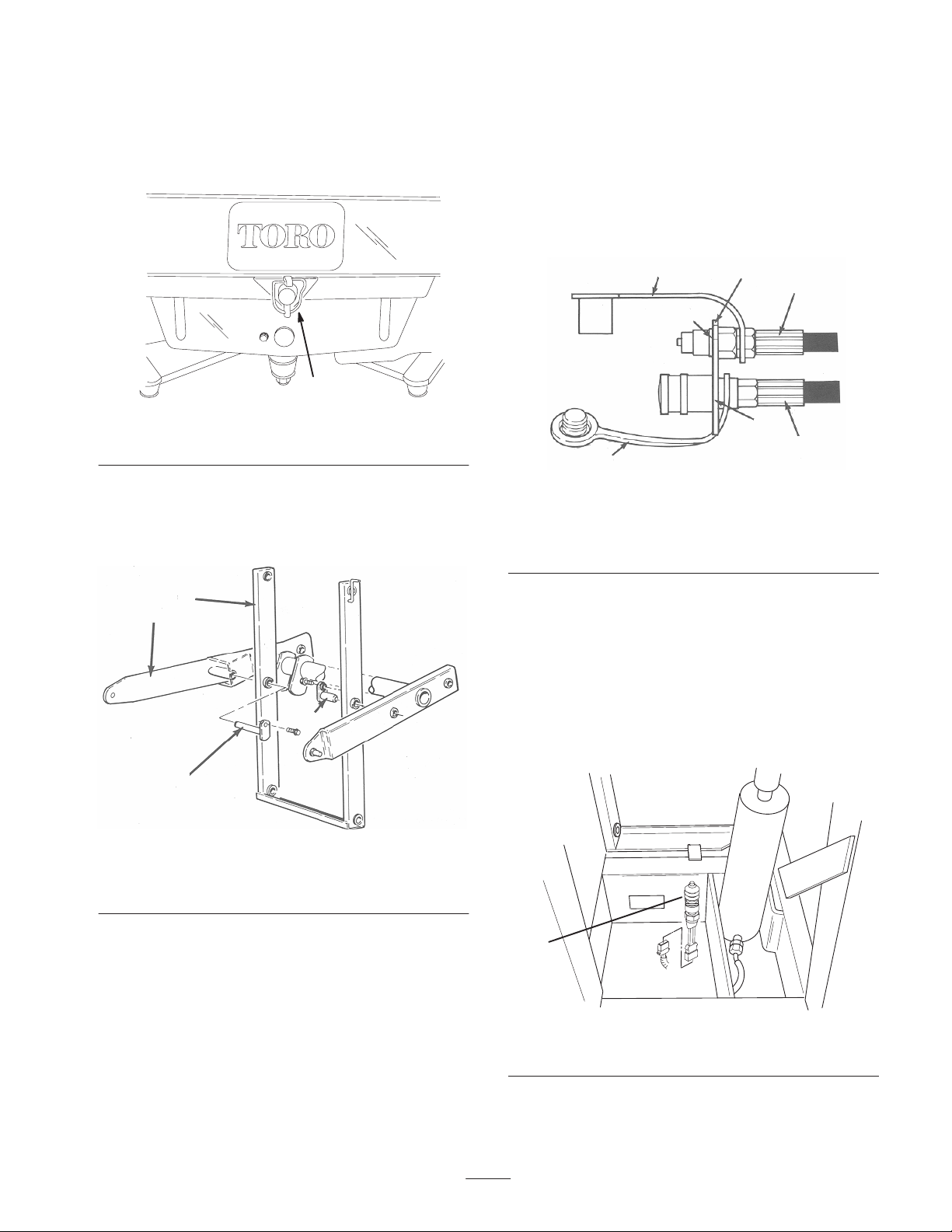

Mount the Control Valve

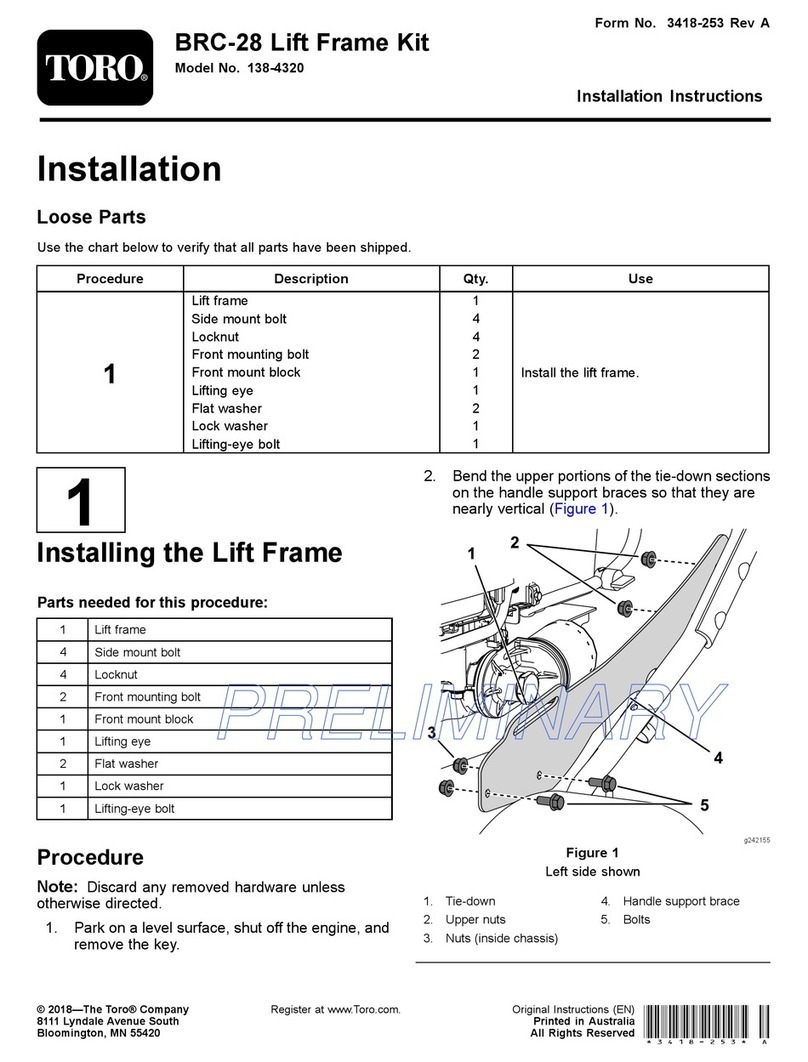

1. Remove the seat and the seat base from the machine.

2. Loosen the fuel tank mounting fasteners so the fuel tank

can be elevated enough to gain access to the right

fender.

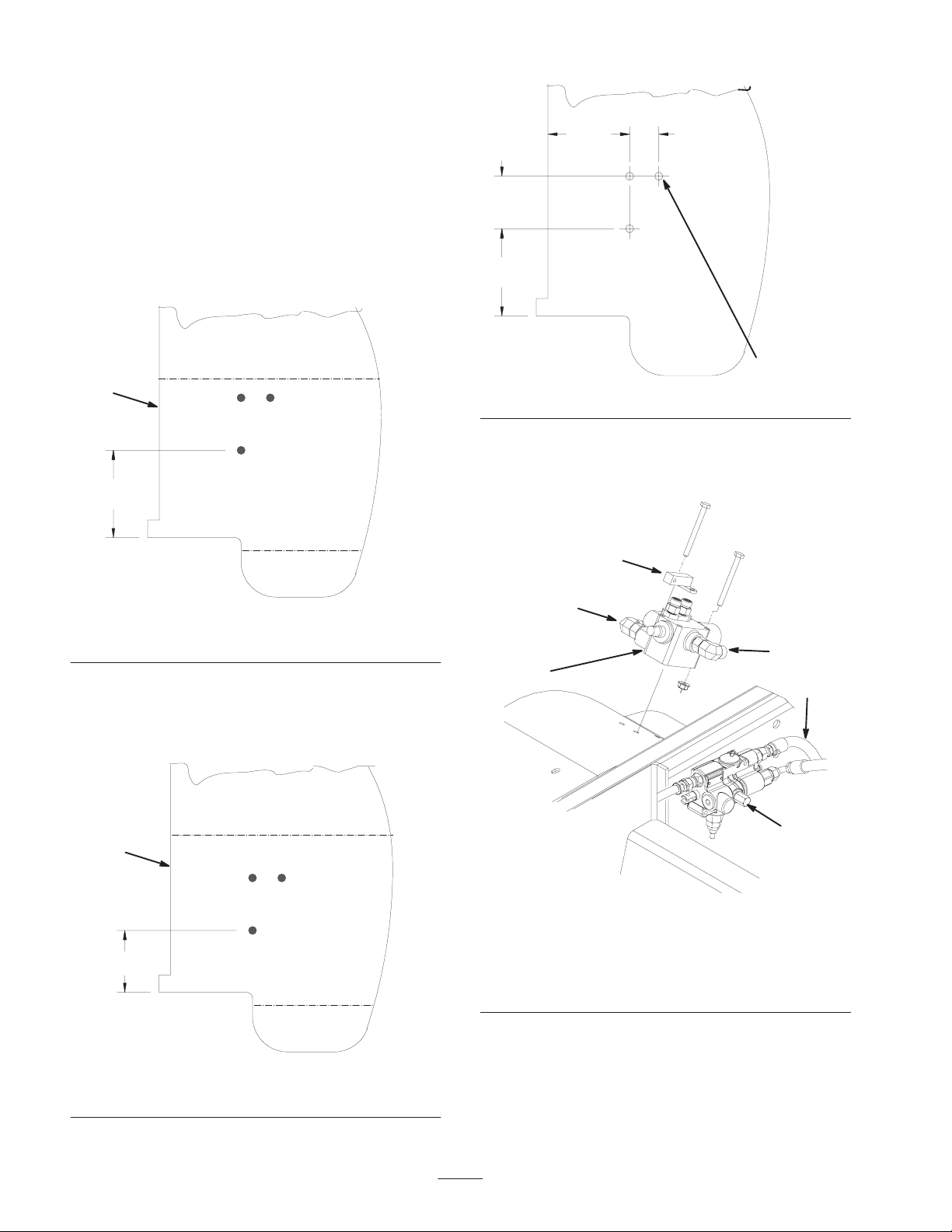

3. Locate the (3) holes in the right fender.

•If the rear hole is located 3.74 inches from the edge

of the fender as shown in figure 1, proceed to to

step 4.

3.74

1

Figure 1

1. Right fender

•If the rear hole is located 2.74 inches from the edge

of the fender as shown in figure 2, the holes must be

relocated. Use the dimensions in figure 3 to locate,

mark and drill (3) .344 in. dia. holes in the fender.

2.74

1

Figure 2

1. Right fender 2.

2.25

3.74

3.50 1.25

.344” dia. (3)

Figure 3

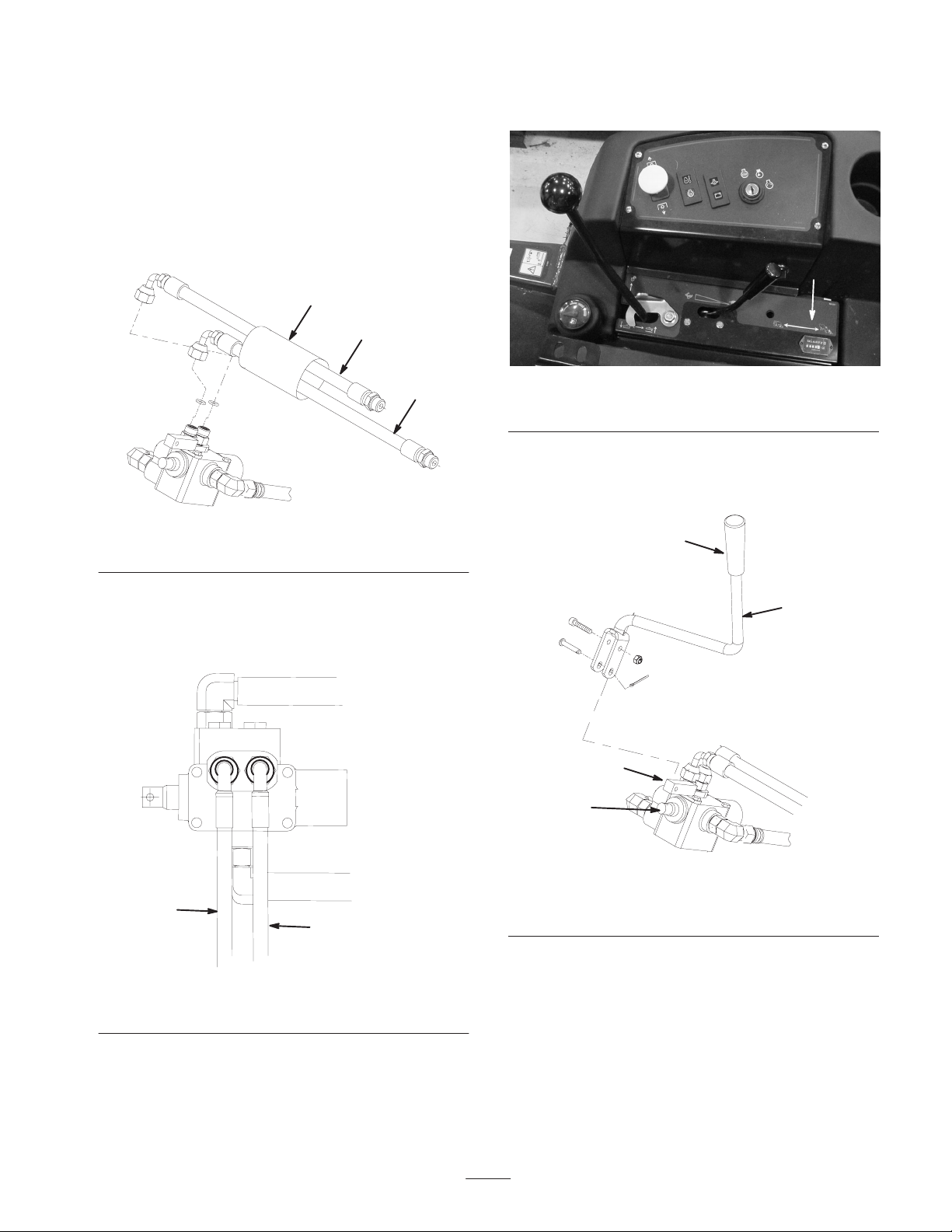

4. Mount the control valve and the pivot lever to the right

fender with (3) 1/4–20 x 2–3/4” lg. capscrews and

1/4–20 flange locknuts as shown in figure 4.

1

2

3

4

6

5

Figure 4

1. Control valve

2. Lift valve

3. Steering hose

4. Pivot lever

5. 90_fitting (operator side

of valve)

6. 90_fitting (outer side of

valve)

5. Place a drain pan under the lift valve (Fig. 4).

6. Disconnect the steering hose (Fig. 4), from the “P” port

(upper rear port) of the lift valve (hose comes from the

steering valve).

7

7. Connect the steering hose (from the lift valve “P” port)

to the 90_fitting on the operator side of the control

valve (Fig. 4).

8. Connect the hydraulic hose (included in the kit) to the

“P” port of the lift valve and to the 90_fitting on the

outer side of the control valve (Fig. 4).

9. Connect the (2) hydraulic hose assemblies to the fittings

on the top of the control valve (Fig. 5). Make sure the

O–rings are in position.

1

1

2

Figure 5

1. Hydraulic hoses 2. Protective sleeve

Note: Make sure the (2) hydraulic hoses are oriented so

they point straight out the left side of the control valve, as

shown in figure 6. This will eliminate the chance of the

hoses interfering with the fuel tank.

1

1

Figure 6

1. Hydraulic hose (2)

10. Install the protective sleeve over the hoses (Fig. 5). The

remainder of the hose installation will be completed

after the hopper frame is installed.

11. Remove the drain pan from under machine.

12. Remove the knock–out plug, under the decal, in the

lower control panel (Fig. 7).

1

Figure 7

1. Knock–out plug location

13. Mount the control valve handle to the valve spool with

a clevis pin and cotter pin. Mount the pivot lever to the

handle with a socket head screw and lock nut (Fig. 8).

2

1

3

4

Figure 8

1. Control valve handle

2. Pivot lever

3. Valve spool

4.

14. Install the control knob to the handle (Fig. 8).

15. Install the fuel tank fasteners.

16. Install the seat base and the seat.

8

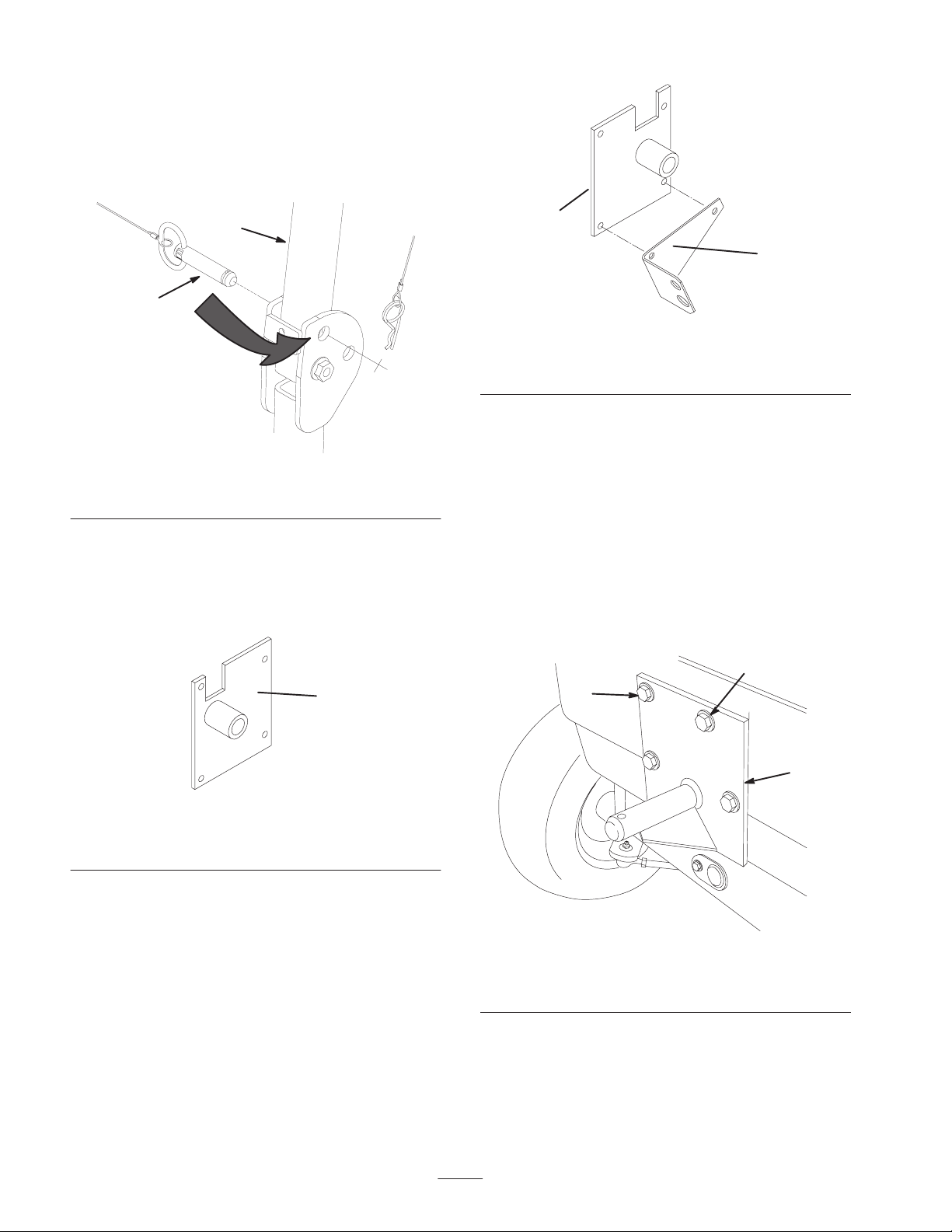

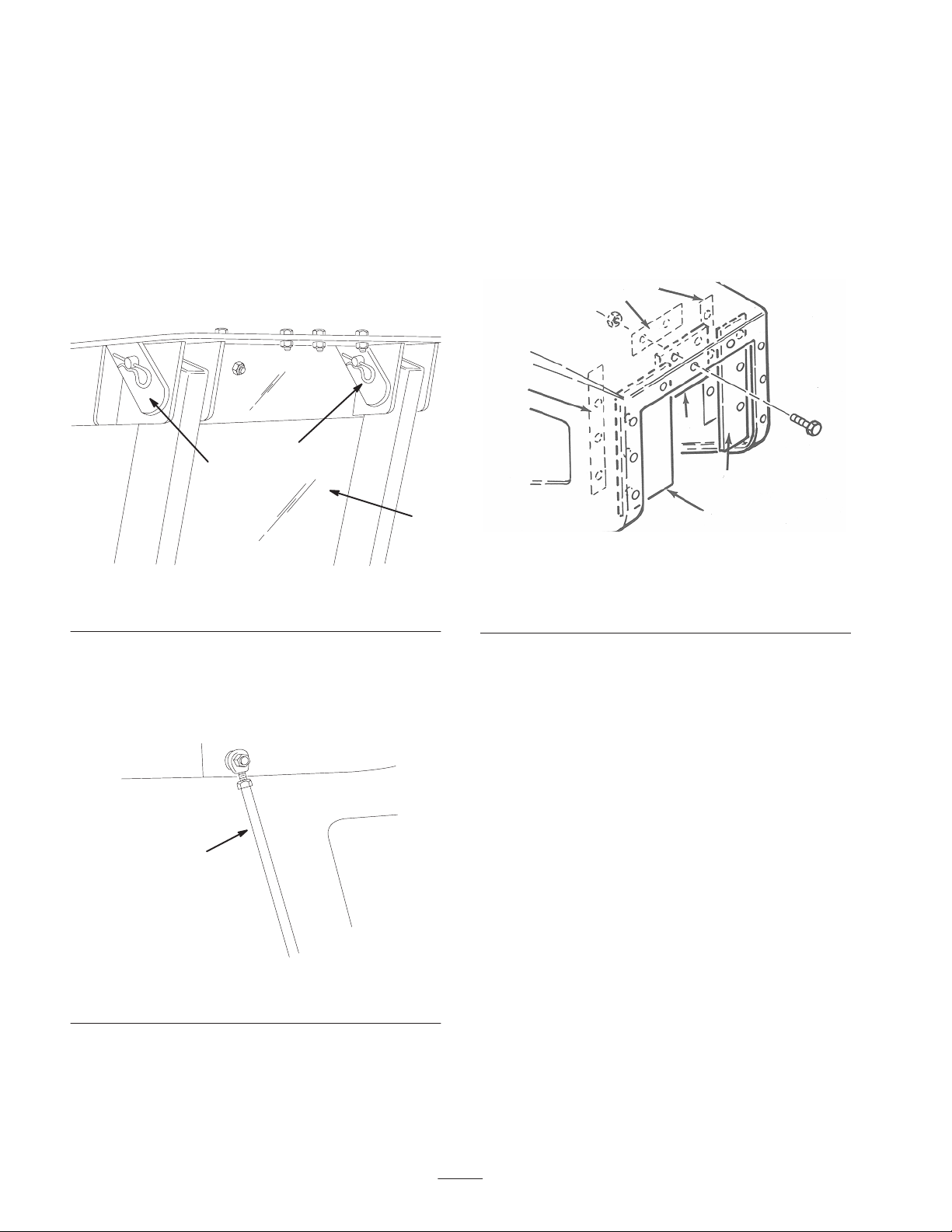

Mount the Hopper Frame

Note: Remove the hairpin cotter and pin securing the right

side of the ROPS to the pivot bracket. Re–install the pin

from the left side of the pivot bracket and secure with the

hairpin cotter.

2

1

Figure 9

1. ROPS (right side) 2. Pin

1. Using the mounting holes in the left side of the frame,

secure the left hopper mounting bracket to the frame

with (4) 5/16 – 18 x 1–1/4” capscrews and locknuts

(Fig. 10). The notch in the bracket is to fit around the

hood latch.

1

Figure 10

1. Left hopper mounting

bracket

2. Secure the top of the right hopper mounting bracket to

the right side of the machine with (2) 3/8–16 x 1” lg.

capscrews and 3/8” lockwashers (Fig. 11). The notch in

the bracket is to fit around the hood latch.

1

2

Figure 11

1. Right hopper mounting

bracket

2. Coupler bracket

3. Secure the bottom of the bracket and coupler bracket to

the frame with (2) 3/8–16 x 1” lg. capscrews and

locknuts (Fig. 11).

4. Position the rear hopper bracket on the rear frame, as

shown in figure 12, while aligning the (2) bottom

mounting holes with the holes in the frame. Using the

bracket as a guide, locate, mark and drill the remaining

(2) 9/16” dia. holes in the rear frame.

5. Mount the top of the rear hopper bracket to the frame

using (2) 1/2–13 x 1–1/4” lg. capscrews, mounting strap

and (2) 1/2 – 13 locknuts (Fig. 12). The strap is to be

positioned between the frame and the bracket.

1

2

2

Figure 12

1. Rear hopper mounting

bracket

2. Drill the holes for these

capscrews

6. Mount the bottom of the bracket to the frame with (2)

1/2–13 x 1–1/2” lg. capscrews, mounting strap, 1/2

flatwashers and locknuts. The strap is to be positioned

between the frame and the bracket.

9

7. From the rear of the machine, slide the front of the

hopper frame onto the side mounting bracket pins and

the rear of the frame over the rear bracket pin.

8. Secure the rear of the frame to the bracket pin with the

disconnect pin (Fig. 13).

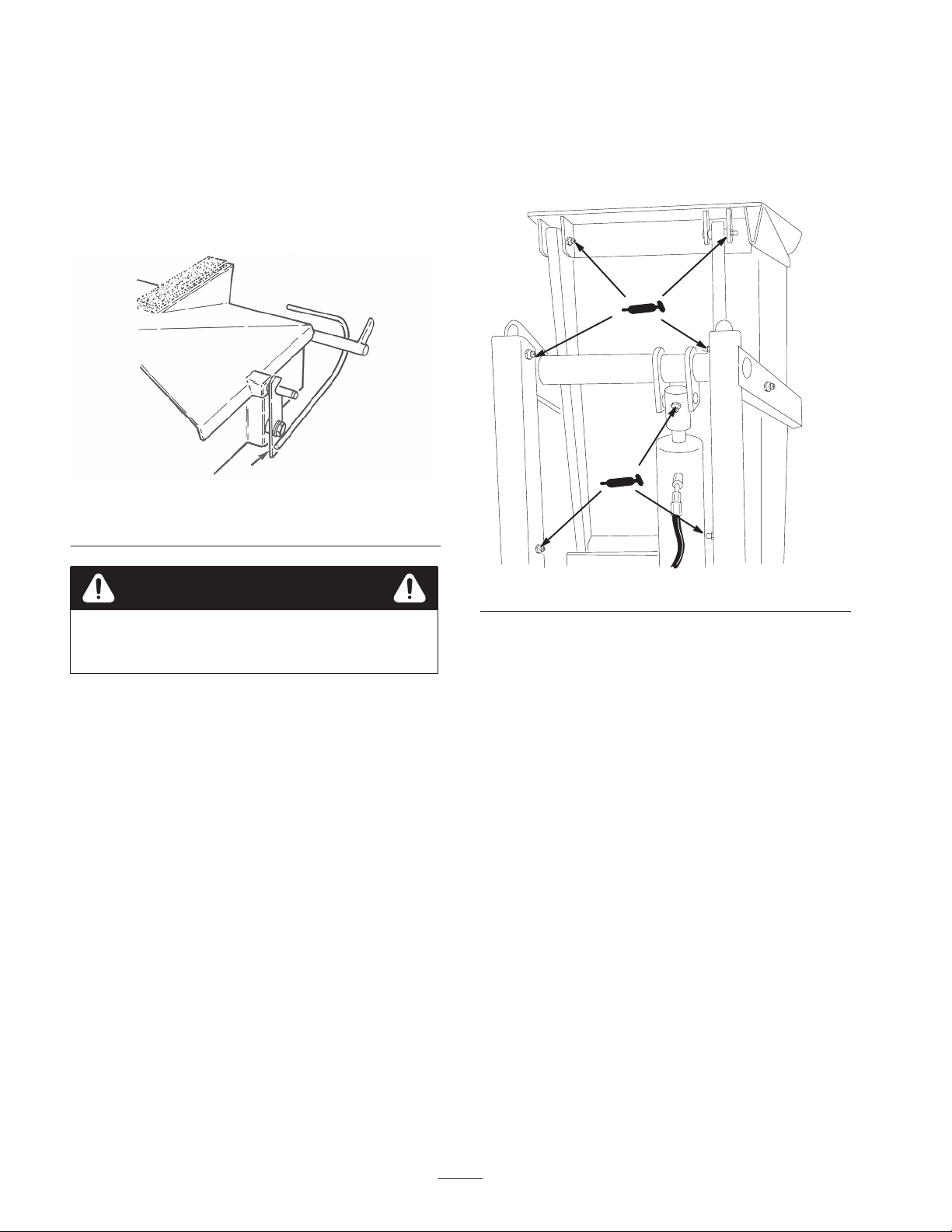

1

Figure 13

1. Disconnect pin

9. Install the short and the long welded mounting pins

through the arm assembly and the main lift arm

assembly (Fig. 14). Secure with 1/4–20 x 3/4” lg. self

tapping screws.

2

1

3

4

Figure 14

1. Arm assembly

2. Main lift arm assembly

3. Short pin (on left side)

4. Long pin (on right side)

Connect the Hydraulic Hoses

1. Slide the loop end of the dust plug over the end of

hydraulic hose from front valve fitting. Insert the

female coupler thru the bottom hole in the coupler

bracket and secure with a retaining ring.

2. Secure the hose assembly to the female coupler

(Fig. 15).

3. Slide the loop end of the dust cap (Fig. 15) over the end

of the hydraulic hose coming from the rear valve fitting.

Install the male nipple to the hose end.

4. Insert the end of the hose thru the top hole in the

coupler bracket (Fig. 15). Secure the hose assembly to

the bracket with a retaining ring.

5. Connect the appropriate hydraulic hose from the hopper

assembly to the hoses installed to the coupler bracket.

21

3

4

6

5

3

Figure 15

1. Top hydraulic hose

2. Coupler bracket

3. Retaining ring

4. Dust cap

5. Bottom hydraulic hose

6. Dust plug

Connect the Wire Harness

1. Unplug the wire harness connector from the seat switch.

2. Plug the tee end of the hopper switch harness into the

seat switch and the seat switch harness.

3. Route the harness to the hopper switch mounted to the

frame tube (Fig. 16). Plug the harness into the switch.

1

Figure 16

1. Hopper switch

10

4. Secure the harness to stationary frame components with

cable ties.

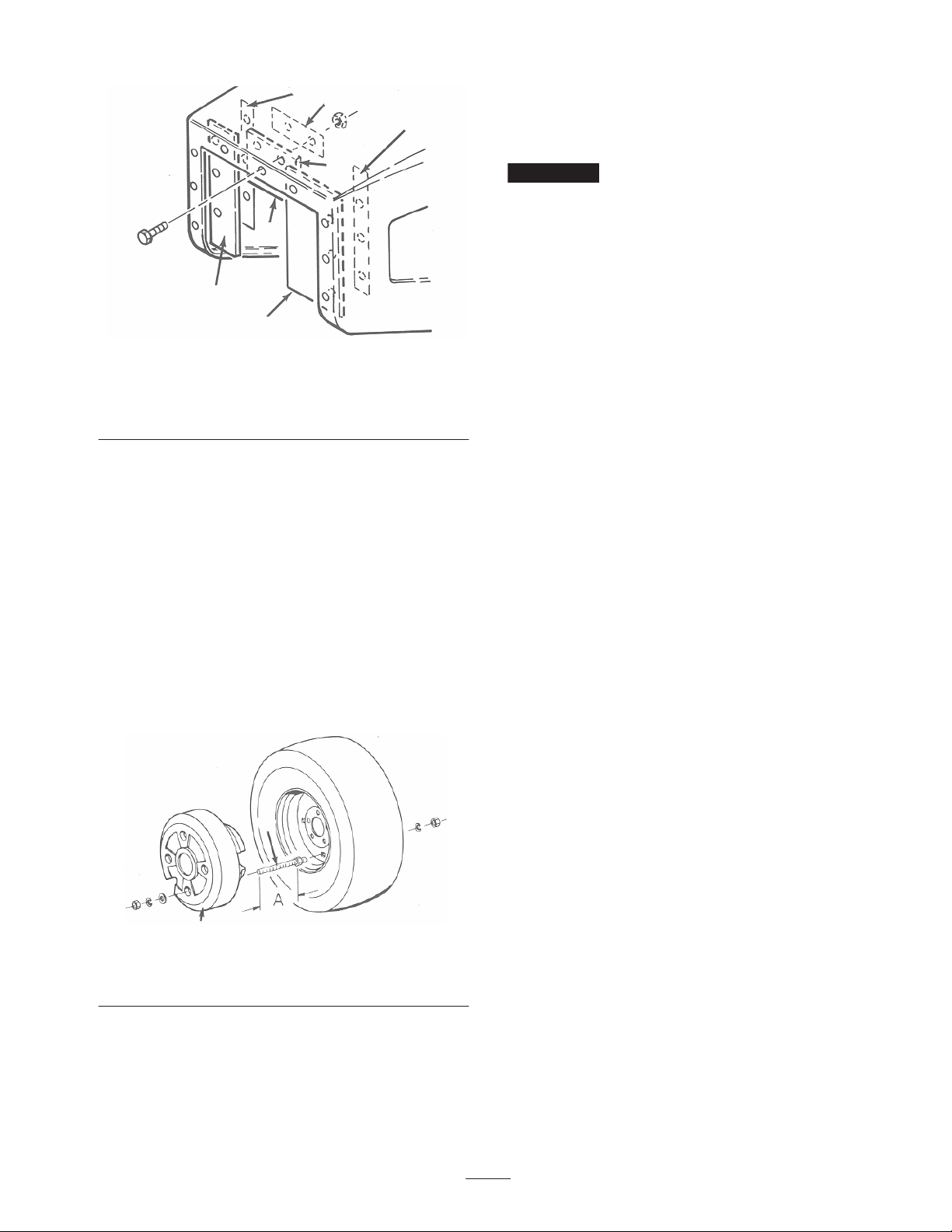

Mount Hopper Assembly

1. Remove the tie straps securing the tie rods to the hopper

arms. Install (2) 5/16 – 18 x 1” lg. carriage bolts and

flange nuts in hopper arm holes where tie straps

previously were.

2. Slide the hopper assembly (hopper cover to rear) into

the side frame while aligning the mounting holes in

hopper with the holes in frame (Fig. 17).

2

2

1

Figure 17

1. Hopper assembly 2. Mounting pins

3. Secure the hopper to the frame with (2) welded

mounting pins and hair pin cotters (Fig. 17).

4. Secure the hopper tie rods to the frame with hair pin

cotters (Fig. 18).

1

Figure 18

1. Hopper tie rod

5. Adjust the tie rods up or down to make sure the hopper

is level with the machine and it does not contact the

machine during operation.

Install Front Blowout Shields

Note: The following instructions are as viewed from the

front of the machine.

When hopper is used with a 52” Deck

1. Secure the wide shield to the left inside lip of the

hopper opening with a long flat, (3) #10 – 24 X 1” lg.

screws and #10 – 24 flange nuts (Fig. 19).

1

2

4

52

3

Figure 19

1. Wide shield

2. Long flat

3. Narrow shield

4. Narrow shield

5. Short flat

2. Secure the narrow shield to the right inside lip of the

hopper opening with a long flat, (3) #10 – 24 X 1” lg.

screws and #10 – 24 flange nuts (Fig. 19).

3. Secure the top shield to the upper inside lip of the

hopper opening with a short flat, (2) #10 – 24 X 1” lg.

screws and #10 – 24 flange nuts (Fig. 19). Use the (2)

mounting holes on the right side of the opening only.

When hopper is used with a 60” Deck

1. Secure the wide shield to the right inside lip of the

hopper opening with a long flat, (3) #10 – 24 X 1” lg.

screws and #10 – 24 flange nuts (Fig. 20).

2. Secure the narrow shield to the left inside lip of the

hopper opening with a long flat, (3) #10 – 24 X 1” lg.

screws and #10 – 24 flange nuts (Fig. 20).

3. Cut 1–1/2” of material off the bottom edge of the top

shield. Secure the top shield to the upper inside lip of

hopper opening with a short flat, (2) #10 – 24 X 1”. lg.

screws and #10–24 flange nuts (Fig. 20). Use the (2)

mounting holes on the left side of the opening only.

11

1

2

4

5

2

6

3

Figure 20

1. Wide shield

2. Long flat

3. Narrow shield

4. Narrow shield

5. Short flat

6. Cut off 1–1/2”

Mount Wheel Weight

1. Measure the depth of the wheel rim. This is achieved by

measuring the distance from the hole to the outside edge

of the rim.

2. Add 3–7/8” to the measurement attained. This becomes

dimension ”A” in figure 21.

3. Thread a hex nut onto each threaded rod to the ”A”

dimension.

4. Insert the threaded rods through two opposite holes in

the rim and secure them in place with 1/2” lockwashers

and hex nuts (Fig. 21).

1

2

Figure 21

1. Wheel weight 2. Threaded rod

5. Place the wheel weight over the ends of the threaded

rods and secure in place with flatwashers, lockwashers

and hex nuts (Fig. 21). Do not overtighten the hex nuts

or damage to the plastic housing of the weight may

occur.

Note: If there is excess thread protruding from the nuts or

inside of wheel, cut it off with a hacksaw. The threaded rod

must not contact any parts of the machine when the wheel

is rotating.

Important Refer to the weight chart in the Traction

Unit Operator’s Manual for additional weight requirements.

12

Operation

Note: Determine the left and right sides of the machine

from the normal operating position.

Before Operating Hopper

1. Start the engine. Raise and lower the hopper several

times. Move the control valve lever forward to lower

the hopper and in reverse direction to raise the hopper)

2. Check the interlock switch operation as follows:

•Raise the hopper and engage the PTO switch while the

engine is running. The engine should stop within 2

seconds. If the engine stops, the switch is operating

correctly; thus, proceed to next step. If the engine does

not stop, there is a malfunction in the interlock system.

•Raise the hopper and depress the traction pedal while

the engine is running and the PTO lever is disengaged.

The engine should stop within 2 seconds. If the engine

stops, the switch is operating correctly; thus, continue

operation. If the engine does not stop, there is a

malfunction in the interlock system.

3. Stop the engine. Check for hydraulic leaks. Check the

hydraulic fluid level in the front axle and replenish it as

necessary. (Refer to the Traction Unit Operator’s

Manual for specifications).

Hopper Operation

(When used with a 52” or 60” Blower Kit)

1. Move the control valve lever forward to lower the

hopper and in the reverse direction to raise the hopper.

Operating Characteristics

When the grass collector is removed, NEVER

operate without the deflector in place.

Caution

For the best performance, regulate the traction pedal to

keep engine rpm high and somewhat constant. A good rule

to follow is: decrease the ground speed as the load on the

cutting blade increases; and increase the ground speed as

the load on the blade decreases. This allows the engine,

working with the transmission, to sense the proper ground

speed while maintaining high blade tip speed necessary for

good quality–of–cut, vacuuming action, and to throw grass

into the hopper. If the blower speed drops too low, plugging

may result. Refer to the Cutting Unit and Traction Unit

Operator’s Manual for operation of each.

Use care to avoid a collision between the

hopper and any stationary objects. Always

trim with the left side of the cutting unit.

Caution

1. Inflate all the tires on the traction unit to 18–20 psi.

2. This grass collector is designed for use in wet or dry

conditions. Do not collect extremely long grass as the

hopper will fill too quickly.

3. When collecting wet, heavy grass, some clippings may

not be thrown completely through the chute. The hole in

the bottom of the chute allows these clippings to drop

out without plugging the chute. When this happens,

reduce ground speed.

Never place hands or feet in chute, blower, or

cutting unit.

Caution

4. The bumper which protects the blower housing doesn’t

extend far enough to eliminate the chance of the hopper

or hopper frame striking a stationary object. Stay far

enough away from obstructions to avoid collisions.

Trim with the left side of the cutting unit only.

5. While operating, check frequently for excessive

clippings left on the turf or uncut grass. If those

conditions occur, the blower or cutting unit may be

plugged. Stop the unit, disengage the PTO, set the brake

and shut off the ignition. Check for obstructions in the

chute, blower or cutting unit. Clear any obstruction

using a stick or similar tool. Check blower belt tension.

If slipping, readjust.

6. The grass collector hopper is designed to exhaust air

beside the chute. This allows the hopper to fill

completely without decreasing performance. Grass will

fall through the opening in the front of the hopper when

hopper is full. Immediately disengage the power take

off and empty the hopper.

7. Cut the grass often, especially when the turf growth is

rapid. If shorter turf is desired, cut the grass again.

Overlap the swaths to produce an even cutting pattern.

Important When transporting, hopper must be in down

position with rear cover latched over large cover.

13

Hopper & Frame Removal

1. Stop the unit, disengage the PTO, set the brake and shut

off the ignition.

2. Move the hopper control valve lever forward and

reverse a few times to release the pressure in the

hydraulic system.

3. Disconnect the hydraulic line quick couplers.

4. Remove the (2) hair pin cotters securing the tie rods to

the frame.

5. Remove the (2) welded mounting pins and hair pin

cotters securing the hopper to the frame. Remove the

hopper from the frame.

6. Disconnect the wire harness from the switch on the

hopper frame or seat and remove from the traction unit.

Keep harness with hopper.

Note: The hopper frame is heavy. Support the frame when

removing it or have a helper assist you.

7. Remove the disconnect pin securing the rear of the

frame to the machine. Slide the frame off the machine.

8. To prevent the contamination of the hydraulic lines,

connect the hopper lines together.

9. Insert the dust caps over the hydraulic fittings on the

machine.

14

Maintenance

Adjusting the Rear Cover Latch

1. Adjust the latch assembly (Fig. 22) up or down if the

cover does not seal properly or if the cover does not

latch when operating.

1

Figure 22

1. Latch assembly

Never work on hopper unless it is in the

lowered position.

Caution

General Practices

1. Keep the unit clean, checking that engine is free of dirt

and chaff. Make sure all fasteners are tight. Check the

deflectors, baffles and shields for wear and replace as

needed.

2. Clean grass clippings from the hopper, chute, blower

and cutting unit after each use. Wash the underside of

the cutting unit daily with a hose. An excessive buildup

of clippings will impair the collection system

performance.

3. Refer to Cutting Unit and Traction Unit Operator’s

Manuals for service requirements of each.

Lubrication

After every 25 hours of operation, grease the cylinder and

all pivot points with No. 2 multi–purpose lithium base

grease. There are (8) grease fittings at various pivot points

and (1) fitting on each end of cylinder (Fig. 23).

Figure 23

15

The Toro General Commercial Products Warranty

A Two-Year Limited Warranty

Conditions and Products Covered

The Toro Company and its affiliate, Toro Warranty Company,

pursuant to an agreement between them, jointly warrant your Toro

Commercial Product (“Product”) to be free from defects in

materials or workmanship for two years or 1500 operational

hours*, whichever occurs first. Where a warrantable condition

exists, we will repair the Product at no cost to you including

diagnosis, labor, parts, and transportation. This warranty begins

on the date the Product is delivered to the original retail purchaser.

* Product equipped with hour meter

Instructions for Obtaining Warranty Service

You are responsible for notifying the Commercial Products

Distributor or Authorized Commercial Products Dealer from whom

you purchased the Product as soon as you believe a warrantable

condition exists.

If you need help locating a Commercial Products Distributor or

Authorized Dealer, or if you have questions regarding your

warranty rights or responsibilities, you may contact us at:

Toro Commercial Products Service Department

Toro Warranty Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

952-888-8801 or 800-982-2740

E-mail: [email protected]

Owner Responsibilities

As the Product owner, you are responsible for required mainte-

nance and adjustments stated in your operator’s manual. Failure

to perform required maintenance and adjustments can be grounds

for disallowing a warranty claim.

Items and Conditions Not Covered

Not all product failures or malfunctions that occur during the

warranty period are defects in materials or workmanship. This

express warranty does not cover the following:

•Product failures which result from the use of non-Toro

replacement parts, or from installation and use of add-on,

modified, or unapproved accessories

•Product failures which result from failure to perform required

maintenance and/or adjustments

•Product failures which result from operating the Product in an

abusive, negligent or reckless manner

•Parts subject to consumption through use unless found to be

defective. Examples of parts which are consumed, or used up,

during normal Product operation include, but are not limited to,

blades, reels, bedknives, tines, spark plugs, castor wheels,

tires, filters, belts, and certain sprayer components such as

diaphragms, nozzles, and check valves, etc.

•Failures caused by outside influence. Items considered to be

outside influence include, but are not limited to, weather,

storage practices, contamination, use of unapproved coolants,

lubricants, additives, or chemicals, etc.

•Normal “wear and tear” items. Normal “wear and tear” includes,

but is not limited to, damage to seats due to wear or abrasion,

worn painted surfaces, scratched decals or windows, etc.

Parts

Parts scheduled for replacement as required maintenance are

warranted for the period of time up to the scheduled replacement

time for that part.

Parts replaced under this warranty become the property of Toro.

Toro will make the final decision whether to repair any existing part

or assembly or replace it. Toro may use factory remanufactured

parts rather than new parts for some warranty repairs.

General Conditions

Repair by an Authorized Toro Distributor or Dealer is your sole

remedy under this warranty.

Neither The Toro Company nor Toro Warranty Company is

liable for indirect, incidental or consequential damages in

connection with the use of the Toro Products covered by this

warranty, including any cost or expense of providing substi-

tute equipment or service during reasonable periods of

malfunction or non-use pending completion of repairs under

this warranty. Except for the Emissions warranty referenced

below, if applicable, there is no other express warranty. All

implied warranties of merchantability and fitness for use are

limited to the duration of this express warranty.

Some states do not allow exclusions of incidental or consequential

damages, or limitations on how long an implied warranty lasts, so

the above exclusions and limitations may not apply to you.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Note regarding engine warranty: The Emissions Control System

on your Product may be covered by a separate warranty meeting

requirements established by the U.S. Environmental Protection

Agency (EPA) and/or the California Air Resources Board (CARB).

The hour limitations set forth above do not apply to the Emissions

Control System Warranty. Refer to the Engine Emission Control

Warranty Statement printed in your operator’s manual or con-

tained in the engine manufacturer’s documentation for details.

Countries Other than the United States or Canada

Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer)

to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfied with your Distributor’s service or

have difficulty obtaining guarantee information, contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty

Company.

Part No. 374-0031 Rev. C

This manual suits for next models

2

Table of contents

Other Toro Industrial Equipment manuals

Toro

Toro MH-400SH2 User manual

Toro

Toro FM 330 User manual

Toro

Toro Ultra Buggy e2500 User manual

Toro

Toro 301 High Lift User manual

Toro

Toro MB TX 2500 User manual

Toro

Toro MH-400SH2 User manual

Toro

Toro LAC TM User manual

Toro

Toro TX 1300 User manual

Toro

Toro Workman 07224-90001 Instruction Manual

Toro

Toro 22340 User manual