2--7 Settings

Features Settings

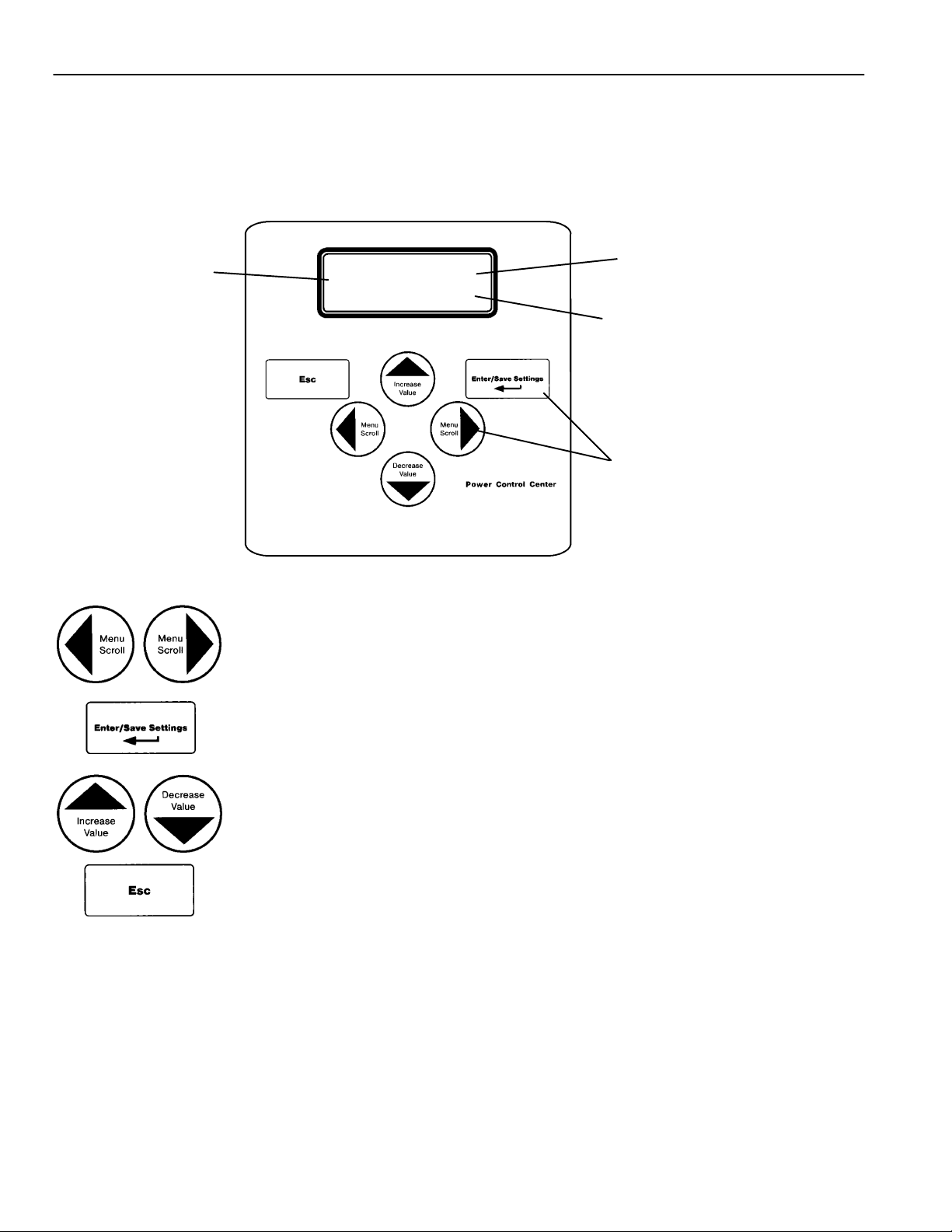

The controller (CP) Features settings can be displayed and changed from the key-

pad. Some settings may require a password (if the controller is set up for one).

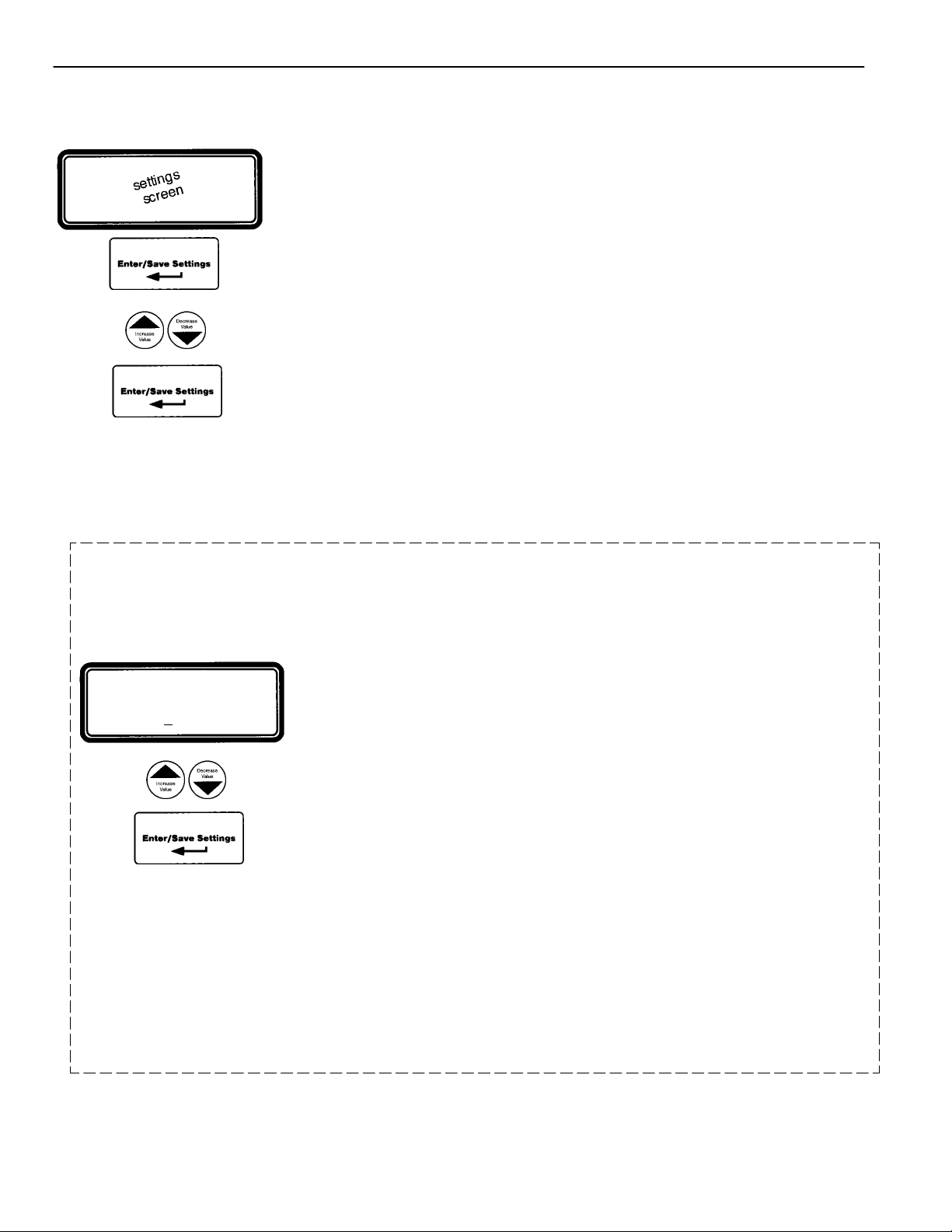

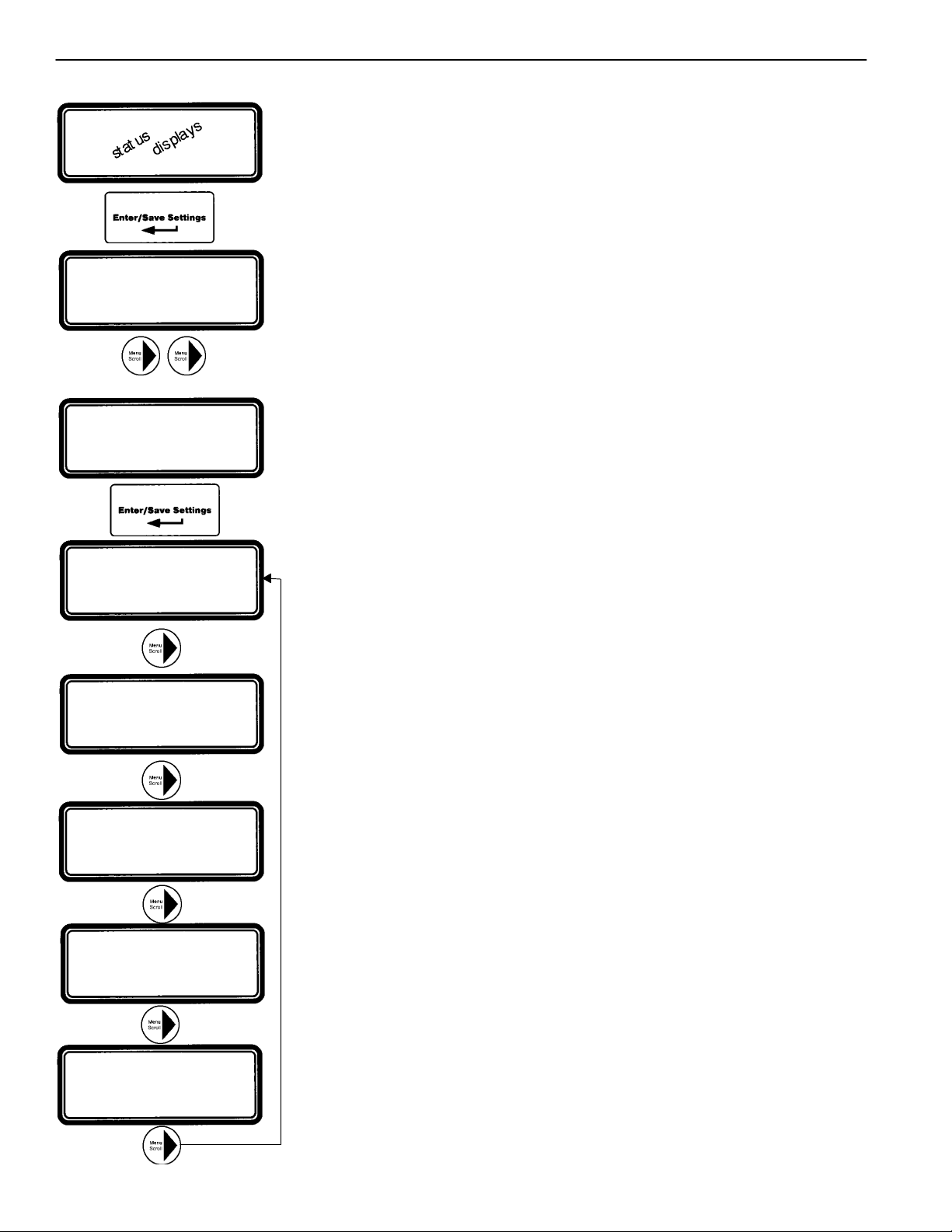

¡From any of the Status displays, press the Enter/Save Settings ¿key to move

to the Settings level of menus.

©Then press the right arrow "key to move to Setting Time Delays menu.

¢Press the right arrow "key again to move to Settings Features menu.

£Now press Enter/Save Settings ¿keytomovetothefirstFeatures display

¤You can press the right arrow "key to see the other Features menus (as shown

below). An overview explanation of each setting is listed below.

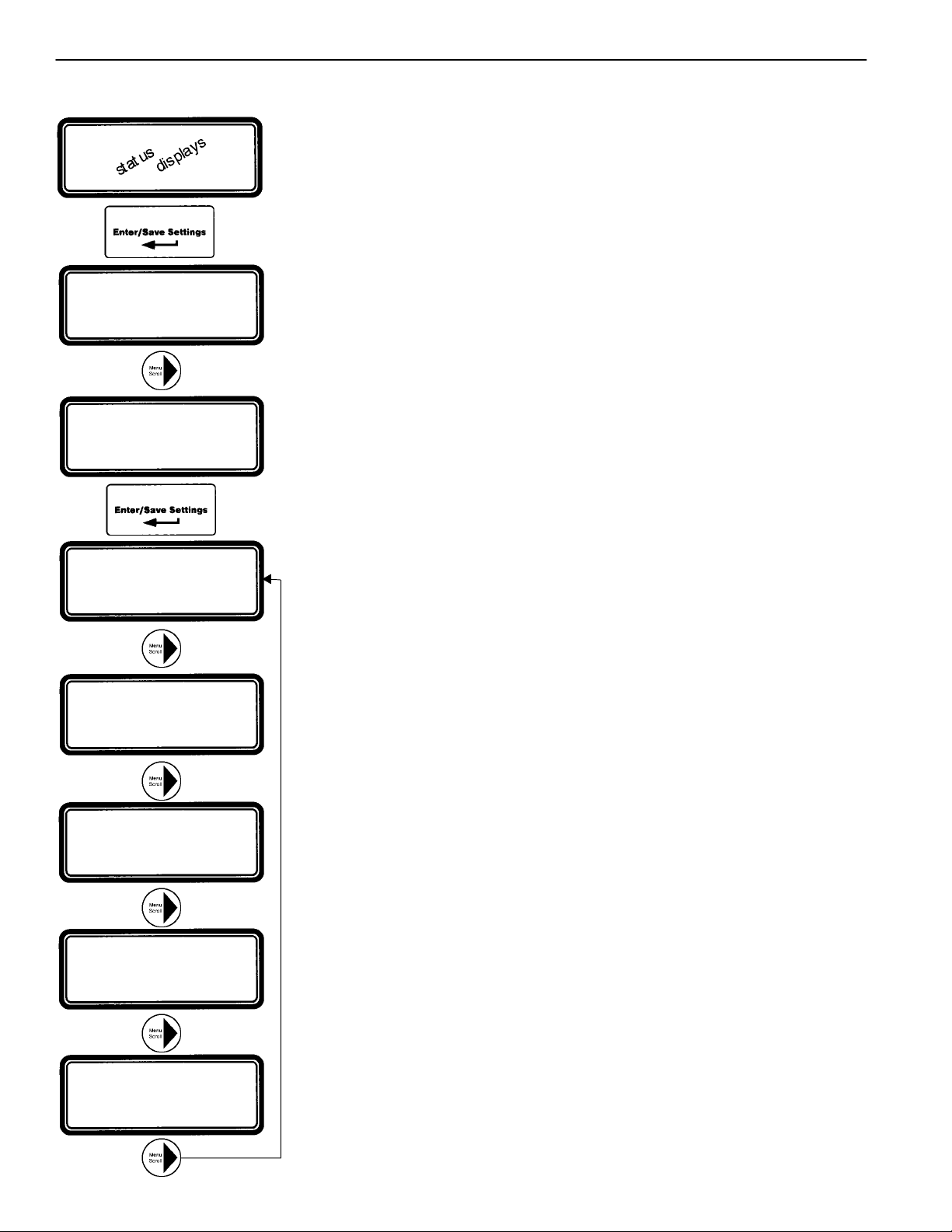

7 Features Menus (last menu loops back to first)

Commit to Xfer After TD Normal Fail seepage2–1

This display shows the commit to transfer setting. It affects the transfer

sequence as follows:

Ye s — If Normal fails, CP continues transfer sequence to emergency

even if Normal returns before Emergency becomes acceptable.

No — If Normal fails, CP cancels the transfer sequence to emergency

if Normal returns before Emergency becomes acceptable.

Shed Load seepage2–1

This display shows status of 3 load shed parameters:

Direction —from Emergency or from Normal

InPhase —yes means transfer delayed until sources are in phase

TD — 3 second default time delay

Shed Load Options seepage2–1

This display appears only for 4ACTS, 4ADTS, 7ACTS, 7ACTB, 7ADTS, or

7ADTB. It determines switch position after the shed load transfer.

IsoLoadOnSrcFail — determines switch position during a source failure.

IsoLoadOnTest17 — deterines switch position during feature 17 activation.

Ye s — Load is not connected to either source. (see wiringdiagram

No — Load is connected to the opposite source. for feature 17 desc.)

Phase Rotation Monitor seepage2–1

This display shows status of phase rotation monitor and desired reference

phase rotation. It only appears if both sources are set to 3–phase sensing.

Enabled —Ye s means phase rotation is considered as part of the

source acceptability criteria for each source. If the phase rotation of the

source does not match the reference phase rotation, that source is considered

unacceptable. If phase rotation of the two sources is different, the load will

be transferred to the source with the reference phase rotation.

Reference — phase rotation order: ABC or CBA (ABC is default)

In–Phase Monitor seepage2–1

This display appears only for 4ATS, 7ATS or 7ATB. This display shows status

of in–phase monitor and in–phase time delay (1.5 seconds is default setting).

Enabled —Ye s means in–phase transfer is initiated when any of these

conditions are met: Transfer Test (Feature 5) signal, connected source fails,

retransfer to acceptable Normal occurs and Emergency source acceptable.

CTTS Bypass / Shed Load (not shown)see page 2–1

This display shows status of the closed–transition bypass options.

FailSyncAutoBypass —Ye s means if the fail to sync alarm occurs, the controller

will bypass the closed–transition mode and will make a delayed–transiton

transfer. The load disconnect time is set by the Bypass DT Delay parameter.

Bypass InPhase —Ye s means the inphase monitor is active during load transfer.

SETTINGS

Voltage DO PU

Frequency DO PU

¡

©¢

Commit to Xfer After

TD Normal Fail: _

SHED LOAD

Direction:

InPhase: TD: s

PHASE ROTATION

MONITOR

Enable:

Reference:

£

SETTINGS

Features

¤

IN--PHASE

MONITOR

Enable:

Time Delay: s

SHED LOAD

IsoLoadOnSrcFail yes

IsoLoadOnTest17 no