This product is not equipped with special dust or water proof measures, and is intended for use in

"pollution level 2" defined by IEC60664-1. For this reason, when the product is installed in the

environment requiring dust or water proof measures, the user needs to provide additional protection and

check the performance.

Vibration level of the environment in which this product is used must be 0.5G or below.

Install this product with the tilt of 5/1000 or below

Secure a work space around this product for maintenance purposes.

Comply with the safety rules required for the place of installation or equipment to be used.

Caution during Installation - Electrical:

DC power supply must be an insulation type switching power supply certified by the safety standard

(IEC60950-1 or UL90950-1) for ensuring safety. Do not use non-insulation type series power supply for

safety as well as conforming to radiation noise restriction.

Current capacity of the DC power supply should have sufficient capacity to accommodate this product.

Current capacity of the wiring material should also provide sufficient margin to the specified current value.

When the DC power supply is integrated, check if the equipment breaker and emergency stop switch

correctly operate. Test operation and any further procedure should be performed after finishing this check.

1. ON/OFF operation of the breaker reliably turns ON/OFF of the input (single phase 100V, 200V) to the

DC power supply unit.

2. ON/OFF operation of the emergency switch reliably turns ON/OFF of the input (DC24V) to this product.

Carefully check that the wiring does not contact any moving parts of this product.

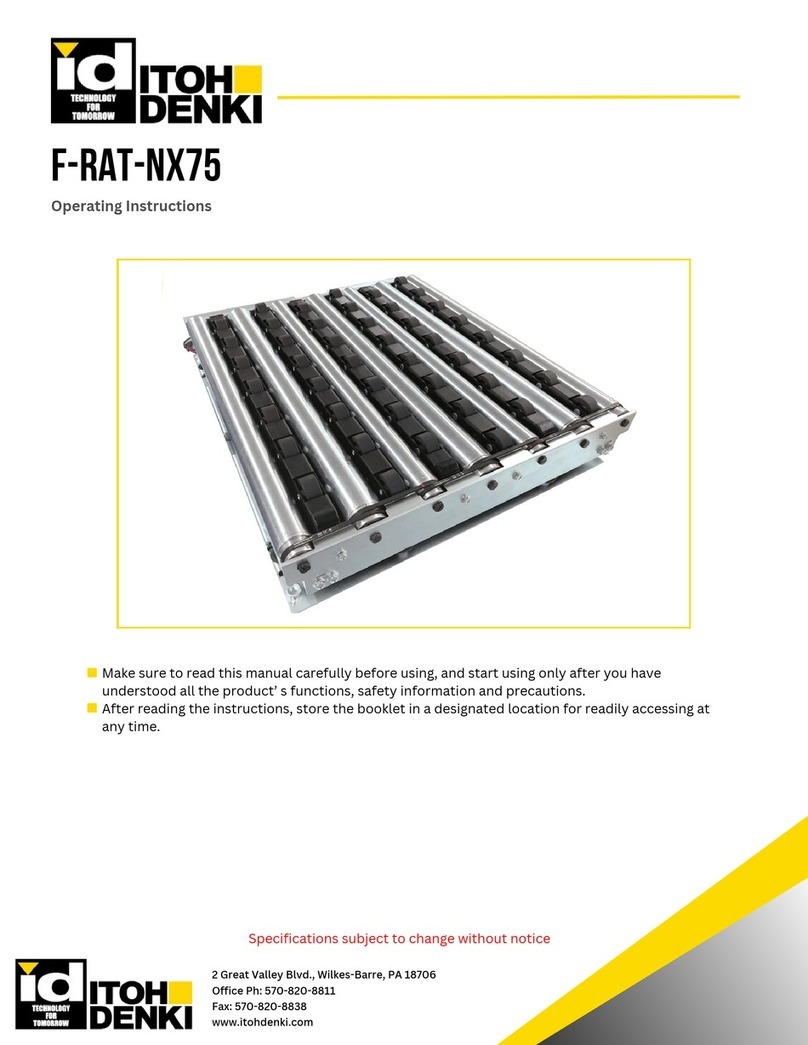

Caution during Installation - Main Unit:

Main unit installation

Checking the DC Power Supply

Checking the Wiring

Installation environment

Perform mounting operations always by 2 persons or

more.

Use caution for motor cable or sensor cable not to be

pinched by other object.

Do not attach the driver card on the F-RAT unit. It may

cause loose screws or other failure by vibration.

Securely attach the unit on the frame by considering

the product weight, tray weight, and vibration.