3 Starting operation

The sequence must be strictly

respected!

Explosion hazard! All parts such as tools

and hands that come into contact with

oxygen must be kept free from oil and

grease.

3.1 Before starting work, the instructions in

this operating manual must be read and

followed during the work!

3.2 Check if the pressure regulator is suitable

for the intended gas type and pressure

(see symbol Point 3).

3.3 Check if the cylinder valve connector and

the seal are clean and undamaged. In

case of any damage, the pressure regula-

tor must not be connected.

Before screwing on the pressure

regulator, open the cylinder valve once

briefly and close it again in order to blow

out any possible dirt. Do not stand in

front of the valve when doing this or hold

your hand in front of the valve. (except

for hydrogen and hydrogen mixtures,

propane, corrosive, toxic and irritant

gases, and flammable test gases). Ensure

good ventilation.

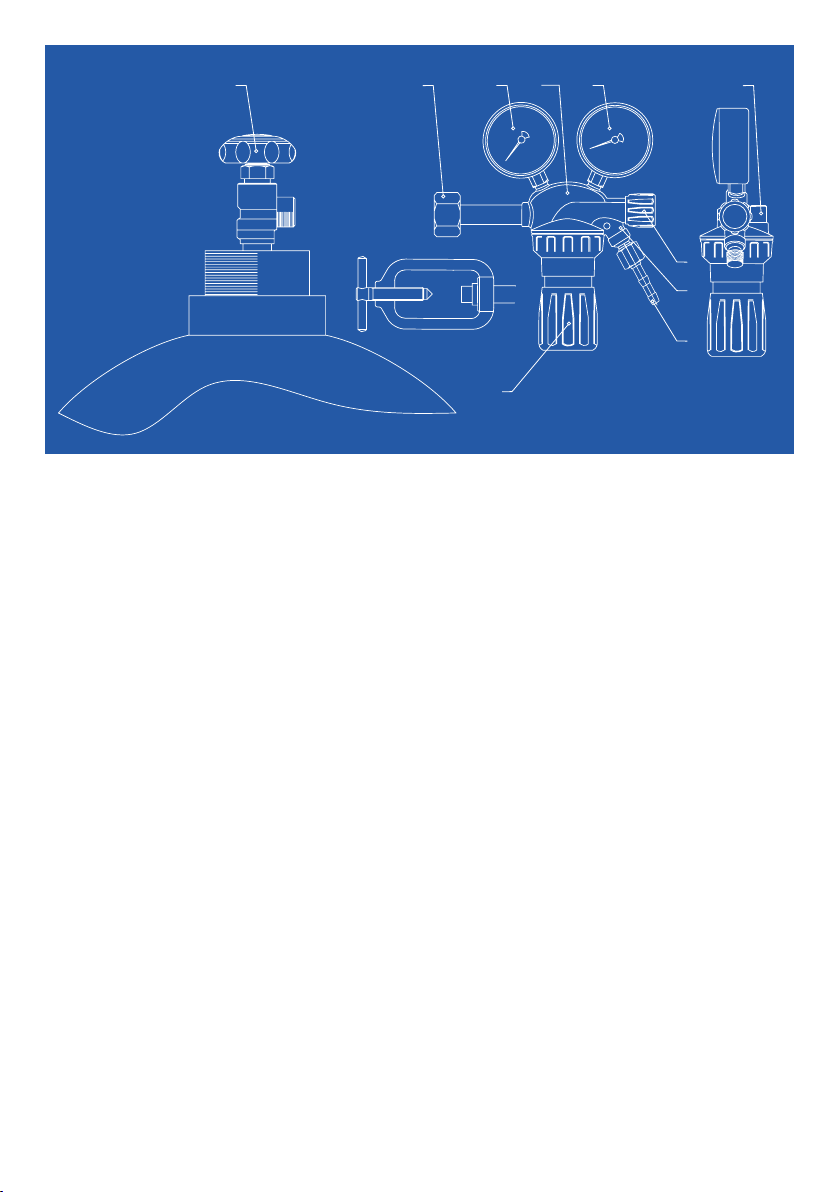

3.4 Connect the regulator with screw con-

nection to the bottle valve (1) using a

suitable spanner or connection bracket

(2) in a gas-tight manner. For regulators

with manual connection (O-ring seal), this

screw connection must be tightened by

hand. No tools must be used for manual

connection. The mounting position of the

regulator must always be vertical in rela-

tion to the pressure gauges.

3.5 Connect the hose to the hose connector

on the outlet stud (7) and to the consum-

er device. Hoses and hose connections

(hose nozzles) shall be used according to

actual and related standard. Secure the

hoses with suitable hose clips.

3.6 Adjusting the pressure

Before releasing the gas into the system, check

the following:

1. Correct version of the cylinder pressure

regulator

2. All indicators at zero

3. Pressure fully turned off on the pressure

adjustment screw (5) (anticlockwise)

4. Re-adjustment valves are closed.

Then close the shut-off valve (6) and release

pressure and pressure regulator by unscrewing

the pressure adjustment screw (5). Open the

cylinder valve slowly, the high-pressure gauge

(3) indicates the cylinder pressure. Open the

shut-off valve (6) and slightly open the corre-

sponding shut-off valve of the consumer device.

Then screw down the pressure adjustment

screw (5) to set the desired outlet pressure

(operating pressure) and check it on the low

pressure gauge (4). Correct the pressure set-

ting if the pressure dips.

Carry out leak test with Air Liquide leak

detection spray!

4 Stopping operation

• For short shutdown periods: close the

shut-off valve on the pressure regulator.

• For longer shutdown periods: Close the

cylinder valve, release pressure, pres-

sure regulator has zero pressure, loosen

pressure adjustment screw (5). Close the

shut-off valves on the pressure regulator

and the consumer device. Never tighten

or loosen screw connectors while they

are under pressure!