Megmeet MCCD Series Service manual

MCCD series display control integrated

PLC user quick reference manual

Thank you for using MCCD series PLC of Megmeet. Before using the

PLC product, please carefully read this booklet so as to better

understand it, fully use it, and ensure safety.This user manual is to offer

you a quick guide to the design, installation, connection and

maintenance of MCCD series PLC.This quick reference manual is

used for the design, installation, connection and maintenance of the

MCCD series PLC. It is convenient for users to consult the required

information on the spot, as well as the introduction of the relevant

optional accessories, FAQ, etc., for easy reference.

This manual for the following members:

MCCD-1616BMD1

MCCD-1616BMD2

MCCD-1616BMD3

MCCD-1616BMD4

MCCD-1212BMD1

MCCD-1212BMD2

MCCD-1212BMD3

MCCD-1212BMD4

Version A02

Revision date Sep 25, 2019

BOM

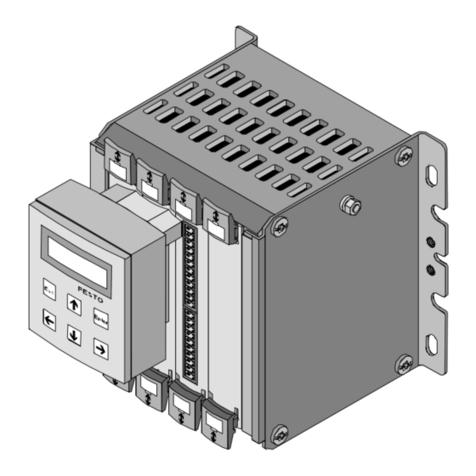

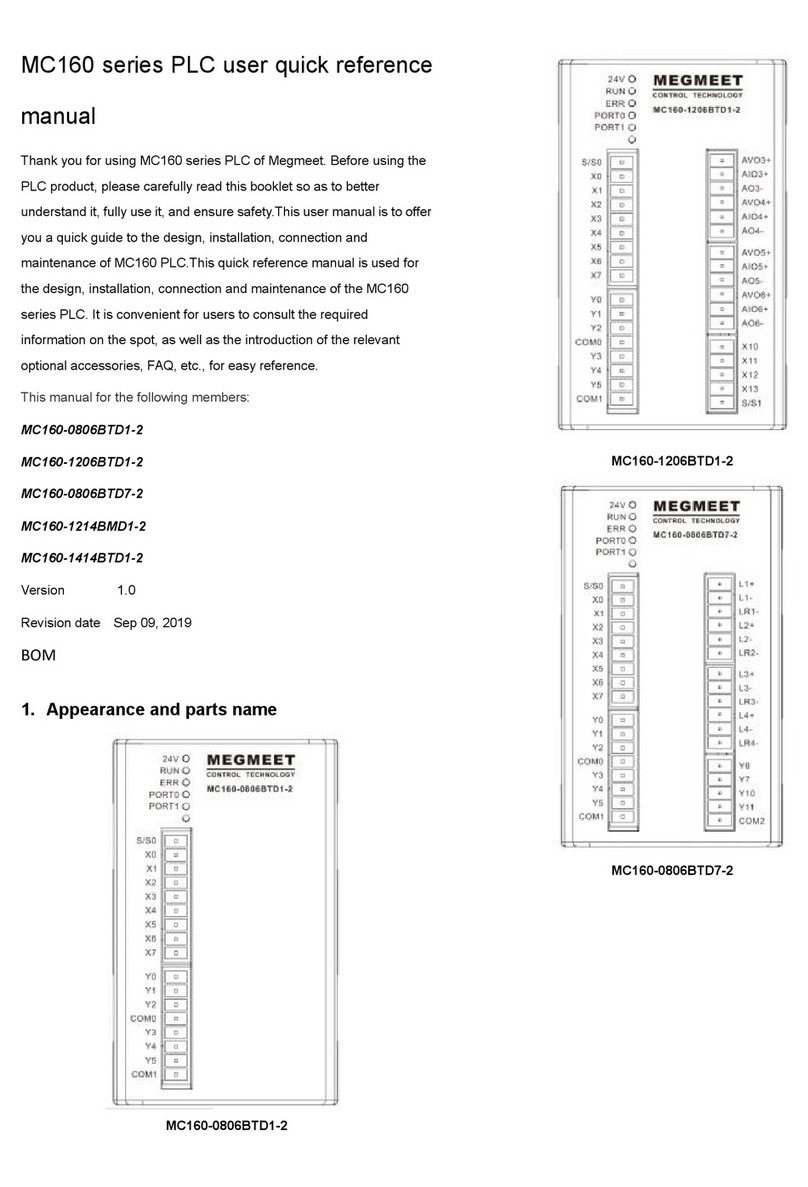

1. Appearance and parts name

Front view

Back view of MCCD-1212BMD

Back view of MCCD-1616BMD

2. Model specification

3. Installation

3.1 Environment temperature

1. Ambient temperature range: -5℃~ 55℃.

2. Humidity: <85%RH, no condensation.

3. When the ambient temperature exceeds 55℃for a long time, it is

better to choose a well-ventilated place.

3.2 Installations

Places free from corrosion, flammable and explosive gases and

liquids.

A firm, vibration-free place.

The PLC is designed for the application of installing environment

II standard and pollution level 2.

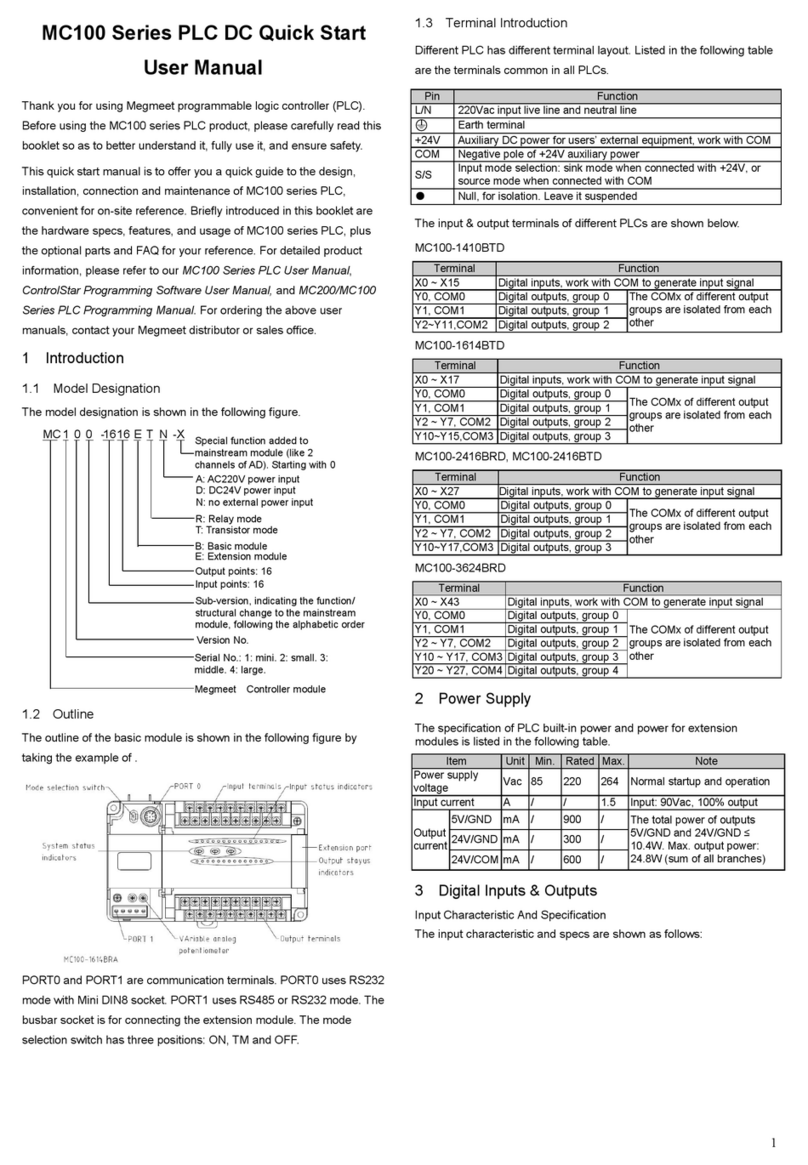

3.3 Installation dimensions

3.4 Installation method

The PLC must be installed horizontally on the back panel of the

electrical cabinet. Install it up and down and keep the distance between

the PLC and the equipment or cabinet wall above and below not less

than 20cm. Installation in other directions is not conducive to heat

dissipation of the PLC, and there should be no heating equipment

under the PLC.

Make holes in the panel according to the size of the opening. The

MCCD series display control integrated PLC is embedded from the

front of the panel, and the text display is fixed with four randomly

equipped mounting brackets. See the operation diagram below:

3.5 Cable connections and specifications

When wiring products, it is recommended to use multiple copper wires

and prefabricate insulated terminals to ensure the quality of wiring. The

sectional area and type of the recommended conductor are shown in

the table below.

Cable

Position

Allow wire

number

Recommended

stripping length

Power

terminal(3PIN)

Back

16~28AWG

6.5mm

Communication

terminal(10PIN)

Back

16~28AWG

6.5mm

DA output

terminal(6PIN)

Back

16~28AWG

6.5mm

AD input terminal

(4PIN)

Back

16~28AWG

6.5mm

TC input terminal

(8PIN)

Back

16~28AWG

6.5mm

PT100 input

terminal(4PIN)

Back

16~28AWG

6.5mm

Digital input

terminal(20PIN)

Back

16~28AWG

6.5mm

Digital output

terminal(20PIN)

Back

16~28AWG

6.5mm

For security (to prevent electric shock and fire accident), and reduce

the noise, the module of grounding terminal shall be in strict

accordance with the national electrical code requirements, grounding

resistance should be less than 0.1 Ω. When grounding multiple

modules, single point grounding should be adopted, and the ground

wire cannot form a circuit. As shown in the figure below:

Error Correct

4. Power supply

Item

Unit

Mix.

value

Type

value

Max.

value

Remark

The range of

input voltage

Vdc

20.4

24

30

Normal start-up

and working

range

Input current

A

0.45

0.5

0.55

Normal

temperature rated

full load

5. Terminal

5.1 User terminal

The terminal definition of MCCD-1212BMD1/2/3/4

Remark

Explanation

24V+,24V-

Power supply DC24V

PE

Ground

A0,B0

RS485 port 0(COM0)

A1,B1

RS485 port 1(COM1)

A2,B2

RS485 port 2(COM2)

CANH、CANL

CAN port 0

X00~X01,S/S

High-speed input port 0~1,input common

terminal

X02~X13,S/S

Switch input terminal 02~13,

input common

terminal

Y00~Y02,COM0

High-speed output port 0 ~2,output

common terminal 0

Y03~Y07,COM1

The channel of switch output3 ~7,output

common terminal 1

Y10~Y13, COM2

The channel of switch output10~13,output

common terminal 2

VI1+,VIO1-,IO1+,VI2+,

VIO2-,IO2+

The channel of analog output1 ~2

(Compatible with voltage and current)

VI1+,VI1-,VI2+,VI2-

The channel of analog output 1 and

2(voltage or current)

PT1+,PT1-,PT2+,PT2-

PT100 input channel 1 and channel 2

L1+,L1-,L2+,L2-,L3+,

L3-,L4+,L4-

TC input channel 1,channel 2,channel 3 and

channel 4

ETH

Ethernet

USB1

USB flash drive interface for program

upgrade

USB2

USB interface for program debugging and

downloading

The terminal definition of MCCD-1616BMD1/2/3/4

Remark

Explanation

24V+,24V-

Power supply DC24V

PE

Ground

A0,B0

RS485 port 0(COM0)

A1,B1

RS485 port 1(COM1)

A2,B2

RS485 port 2(COM2)

CANH、CANL

CAN terminal 0

X00~X01,S/S

High-speed input port 0~1,

input

common terminal

X02~X17,S/S

Switch input terminal 02 ~17 ,

input common terminal

Y00~Y02,COM0

The channel of high-speed

output 0 ~2,output common

terminal

Y03~Y07,COM1

The channel of switch output3~

7,output common terminal 1

Y10~Y17, COM2

The channel of switch output10~

17,output common terminal 2

VI1+,VIO1-,IO1+,VI2+,VIO2-,IO2+

The channel of analog output1~

2(Compatible with voltage and

current)

VI1+,VI1-,VI2+,VI2-

The channel of analog output 1

and 2(voltage or current)

PT1+,PT1-,PT2+,PT2-

PT100 input channel 1 and

channel 2

L1+,L1-,L2+,L2-,L3+,L3-,L4+,L4-

TC input channel 1,channel

2,channel 3 and channel 4

ETH

Ethernet

USB1

USB flash drive interface for

program upgrade

USB2

USB interface for program

debugging and downloading

5.2 Communication port

Name

Supported

protocols

Position

Physical

layer

Communication port 0

Modbus ( slave

station)

COM0

(A0 ,B0)

RS485

Communication port 1

Modbus (master

and slave station)

free port

COM1

(A1 ,B1)

RS485

Communication port 2

Modbus (master

and slave station)

COM2

(A2 ,B2)

RS485

Communication port 3

CAN free port

CAN0(H,L)

CAN

Communication port 4

Ethernet

ETH

TCP/IP

Communication port 5

USB host

USB1

USB

Communication port 6

USB slave

USB2

USB

Note: 1. Communication port 2 is HMI resource, which needs to be set

in MEGVIEW2 for use. Modbus slave station is the default.

Communication port 4, 5 and 6 are HMI resources, which need to be

set in MEGVIEW2 for use

6. Switching characteristics of input and output

6.1 Switching input characteristics and signal

specifications

The counter input port has a maximum frequency limit. If the limit is

exceeded, the count may be inaccurate or the system may not function

properly. Please arrange the input port reasonably and select the

appropriate external sensor.

The PLC provides port "S/S" for selecting whether the input signal is

source input or leak input.

6.1.1 Transistor input specifications

Item

High-speed input

Normal input

Input resistance

3.3kΩ

4.3kΩ

Input current

6.5mA (Type value)

5.3mA (Type value)

ON voltage/current

DC18V /4.5mA

DC18V /3mA (Mix.

(Mix. value)

value)

OFF voltage/current

DC4V /1mA (Max.

value)

DC4V /1mA (Max.

value)

Speed requirement

Single channel

frequency ≤50Khz,2

channels total

frequency≤80khz

≤100HZ

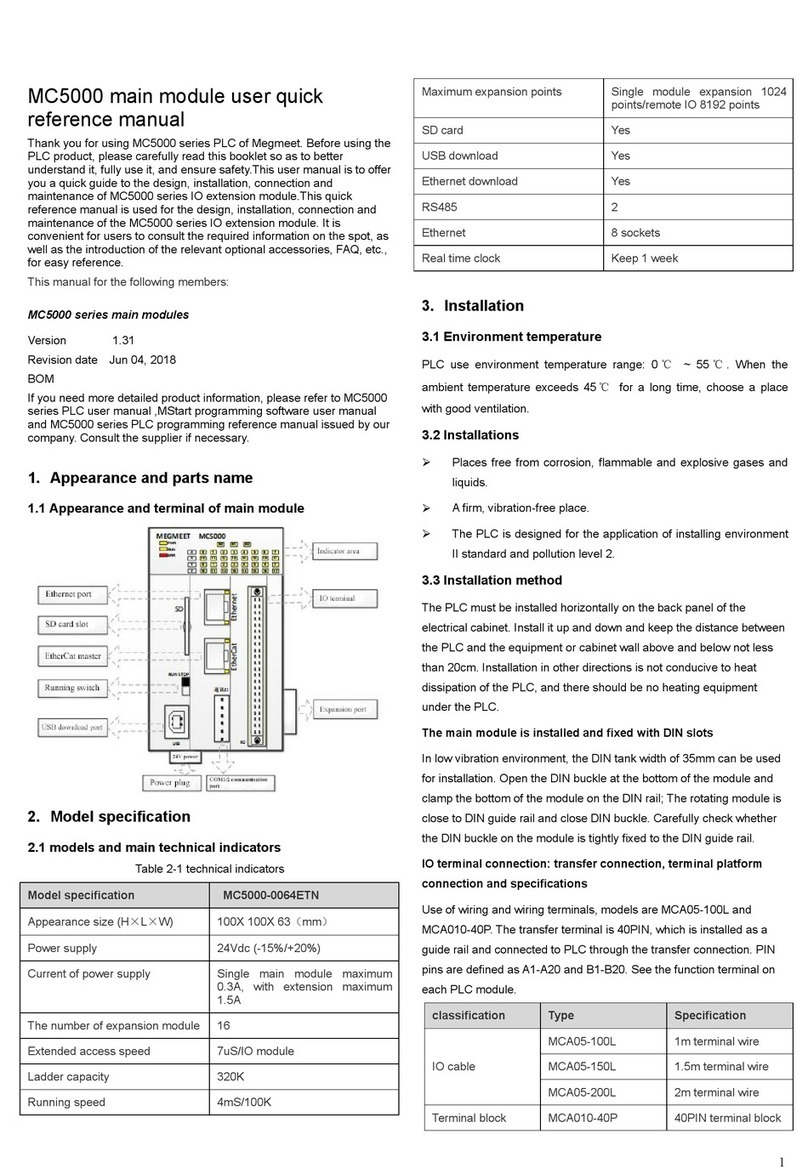

6.1.2 Wiring method

Leaky input: connect S/S terminal to +24V terminal. NPN sensors can

be connected in this way. The internal equivalent circuit and external

connection mode of leakage input mode are shown in the figure below.

Source input: Short connect S/S terminal to COM terminal. This way

can be connected to the PNP sensor. The internal equivalent circuit

and external connection mode of source input mode are shown in the

figure

Transistor input specification

6.2 Switching output characteristics and signal

specifications

The output terminals of MCCD series are divided into several groups,

each group is electrically isolated, and the output contacts of different

groups are connected to different power circuits. The output can be

divided into two types: relay and transistor. Transistor output stages

can only be used in DC 24V load circuits with attention to power

polarity. The inductive load of DC circuit should be considered to

increase the continuation diode; For the inductive load of ac circuit, the

external circuit should consider the RC instantaneous voltage

absorption circuit. As shown in the figure below.

Special function of output port

The transistor output type main module contains three high-speed

output ports Y0,Y1 and Y2. The three channels can independently

output high-speed pulse. Provides high speed I/O instructions and

location instructions to manage high speed output channels. For high

speed output, it is recommended to use double stranded shielding wire

for the corresponding input port, and to ground the shielding layer

(connected with the terminal or connected to the signal ground) to

improve disturbance immunity.

6.2.1 High-speed transistor output specifications

Item

Index

Power of loop circuit

<30Vdc

Circuit insulation

Optocoupler isolation

Min. load

5mA(5~24VDC)

Maximum output current of

resistive load

0.5A/point;

Maximum output current of

inductive load

7.2W/24VDC

ON response time

10uS

OFF response time

10uS

Response frequency

≤100kHz

6.2.2 Normal transistor output specifications

Item

Index

Power of loop circuit

<30Vdc

Circuit insulation

Optocoupler isolation

Min. load

5mA(5~24VDC)

Maximum output current of

resistive load

0.5A/point;

Maximum output current of

inductive load

7.2W/24VDC

ON response time

0.5ms

OFF response time

0.5ms

Response frequency

≤100Hz

6.2.3 Relay output specifications

Item

Index

Circuit insulation

Relay isolation

Contact load (resistive)

5A 250VAC/30VDC

Switching voltage

250VAC/30VDC

Switching current

2A

Switching power

1250VA/150W

ON response time

10ms

OFF response time

10ms

Output common terminal

Each common terminal is isolated

from each other

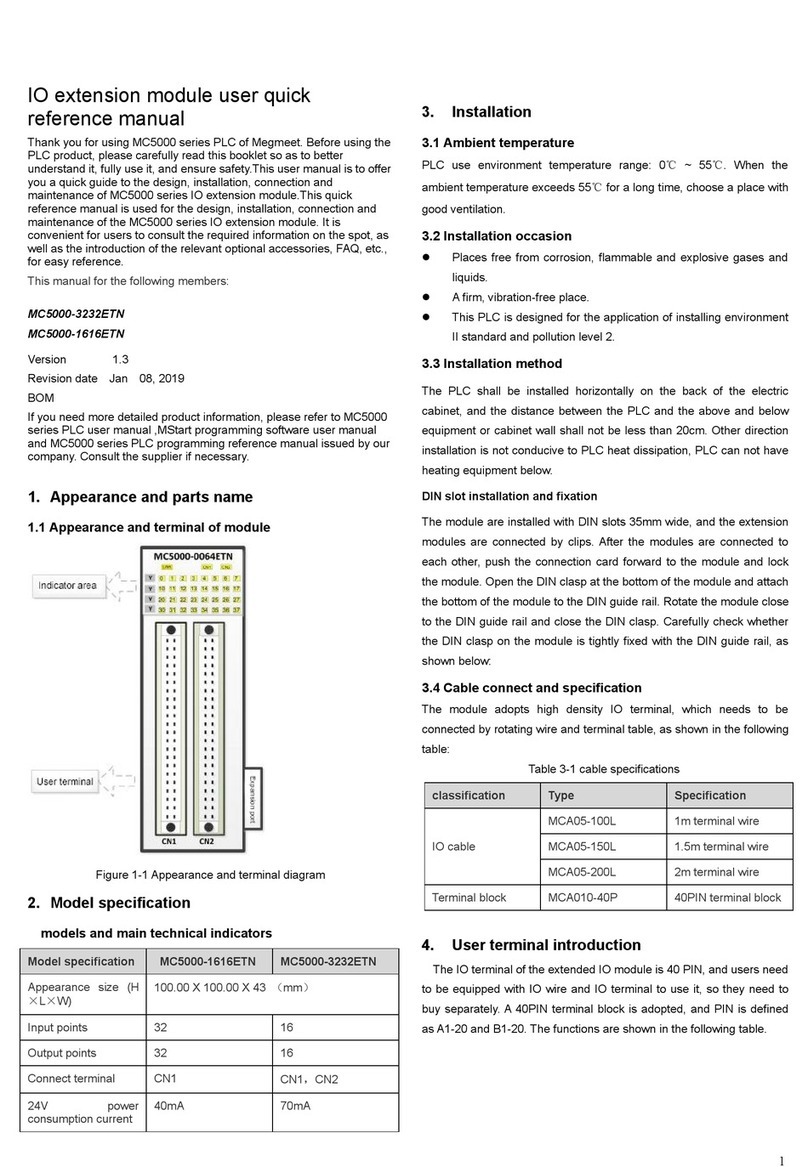

7. Analog input and output characteristics

7.1 Wiring method

The specific connection is shown in the following figure:

The wire method of analog input

The wire method of analog output

The wire method of thermal resistance input

The wire method of TC input

* Double stranded shielded cable access is recommended. Cables should be kept away

from power lines or other wires, user terminals, extension cables and interface

extension cables that may cause electrical interference.

* If the input signal fluctuates or there is electrical interference in the external wiring, it is

recommended to connect a smooth capacitor (0.1uf ~ 0.47uF/25V).

* It is recommended to use connection cables of less than 100m in length to reduce

measurement errors and noise interference.

7.2 Specifications

7.2.1 Current and voltage input channel specification

Item

Index

Conversion

speed

15ms/channel(Normal),6ms/channel(high-speed)

Analog

input

range

Voltage

input

0VDC~+10VDC,input

resistance 1MΩ

The attributes of each

channel can be set

individually through

the X-Builder

programming software

Current

input

0mA ~+20mA ,input

resistance 250Ω

Digital output

Scope:0~+2000

Resolu

tion

Voltage

input

5mV

Current

input

10uA

Accuracy

Full load ±1%

Isolation

Analog and digital circuits are not isolated

7.2.2 Analogy output channel specification

Item

Index

Conversion speed

2ms/channel

Analog

output

Voltage output

0 ~ + 10 VDC, external load

impedance ≥2 k Ω

Current output

0 ma ~ + 20 ma, external load

impedance ≤500 Ω

Digital

output

Voltage output

Default setting: 0 ~ +2000

Current output

Default setting: 0 ~ +2000

Resolution

Voltage input

5mV

Current input

10uA

Accuracy

Full load ±1%

Isolation

Analog and digital circuits are isolated,

analog channels are not isolated.

7.2.3 Thermal resistance input channel specifications

Item

Index

Thermal resistance type

Pt100、Cu100、JPt100、Cu50、Ni120

Temperature control

output

Transistors and analog output are

configurable

The sampling period

About 100ms

Temperature control cycle

1~100,unit 1s,The specific value is

determined by the characteristics of the

temperature control object

Control method

Hand control,ON/OFF control,PID

control

Sensor type

and

temperature

range

Pt100

-150℃~600℃(-238℉~1112℉)

JPt100

-150℃~500℃(-238℉~932℉)

Cu100

-30℃~120℃(-22℉~248℉)

Cu50

-30℃~120℃(-22℉~248℉)

Ni120

-80.0℃~280.0℃(-112.0℉~

536.0℉)

Thermal resistance

Input range±0.5%

7.2.4 TC input channel specifications

Item

Index

Input single

Thermocouple

type

K、J、E、N、T、R、S、B

Output

method

Transistor

output with

open gate

Loop power voltage :5V ~24V ;Max.

Power voltage of loop :30V ;Loop

current:0.3A/24Vdc;Leakage current

when open : < 0.1mA/30Vdc ;Min.

load:5mA(5Vdc~24Vdc)

The sampling period

About 100ms

Temperature control cycle

1~100,unit 1s,The specific value is

determined by the characteristics of

the temperature control object

Control method

ON/OFF control ,Hand control,single

PID control

Rate

temperature

range

K type

-100℃~1200℃(-148℉~2192℉)

J type

-100℃~1200℃(-148℉~1112℉)

E type

-100℃~850℃(-148℉~1562℉)

N type

-100℃~1200℃(-148℉~2192℉)

T type

-200℃~300℃(-328℉~572℉)

R type

0℃~1600℃(32℉~2912℉)

S type

0℃~1600℃(32℉~2912℉)

B type

400℃~1800℃(752℉~3272℉)

Accuracy

Thermocouple

Input range±0.3 % , Ambient

temperature compensation error<=2℃

Thermal

resistance

Input range±0.5%

Isolation

Channels are isolated from each

other

8. Common problems and solutions

When the module cannot work normally, please check in turn:

(1) The connection of power lines and the status of related switches

and protective appliances to ensure that the module has been reliably

supplied;

(2) Whether the connection of user terminals is firm;

If the above inspection is still unable to work, you can refer to the

following table.

phenomenon

Possible reason

Countermeasures

RUN and ERR are

OFF

Out of voltage or low

voltage

Check power supply

condition and

exclude

The power switch is

off or the fuse is

blown

Check the condition

of switches, wires or

fuses to exclude

them

Abnormal power

connection

Power plate damage

Check and confirm

whether the voltages

between 24V+ and

24V- terminals are in

normal range

RUN and ERR are

flashed intermittently

in the same time

The power supply is

unstable

The module is

damage

RUN is OFF

Shut down remotely

by upper computer

equipment

Make the upper

computer start up

remotely

System error outage

Check by assistant

ERR single light is

ON

System error outage

Check with an

assistant and consult

the errata manual

1. Warranty scope refers to the programmable controller body.

2. The warranty period is 18 months. If the product breaks down or is

damaged during normal use, our company will repair it free of charge.

3. The warranty period starts from the date the product is manufactured.

Machine code is the only basis for judging the warranty period.

Equipment without machine code shall be treated as under warranty.

4. Even within the warranty period, a maintenance fee will be charged

if:

Failure of the machine caused by failure to operate in

accordance with the user's manual.

Damage to machinery caused by fire, flood, abnormal voltage,

etc.

Damage caused when a programmable controller is used for

abnormal functions.

Self-disassemble the programmable controller.

5. The service fee shall be calculated according to the actual cost. If

there is another contract, the contract shall take precedence.

6. If you have any questions, please contact the agent or our company

directly.

SHENZHEN MEGMEET CONTROL TECHNOLOGY CO.,LTD

Add:floor 5, tower B, qinghua information port, langshan road, north

district, science and technology park, nanshan district, shenzhen

Tel:400-6662163

Fax:(+86)0755-26897197

Zip code:518067

Web:www.megmeet.com

This manual suits for next models

8

Table of contents

Other Megmeet Controllers manuals

Megmeet

Megmeet MV820 User manual

Megmeet

Megmeet MC5000 Series User manual

Megmeet

Megmeet L6 Series User manual

Megmeet

Megmeet MC160 PLC Series User manual

Megmeet

Megmeet MC100 Series User manual

Megmeet

Megmeet MC5000 Series User manual

Megmeet

Megmeet MC200E Series Manual

Megmeet

Megmeet MC5000 Series User manual

Popular Controllers manuals by other brands

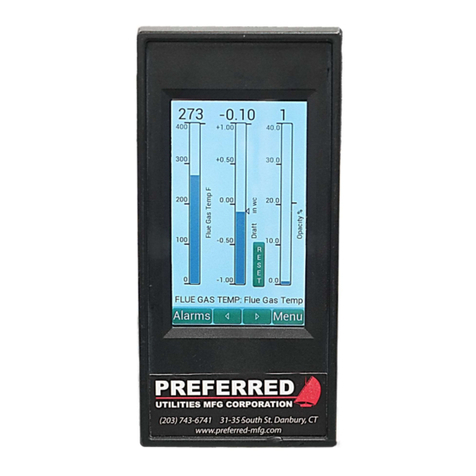

Preferred

Preferred JC-23D2 Installation & operation instructions

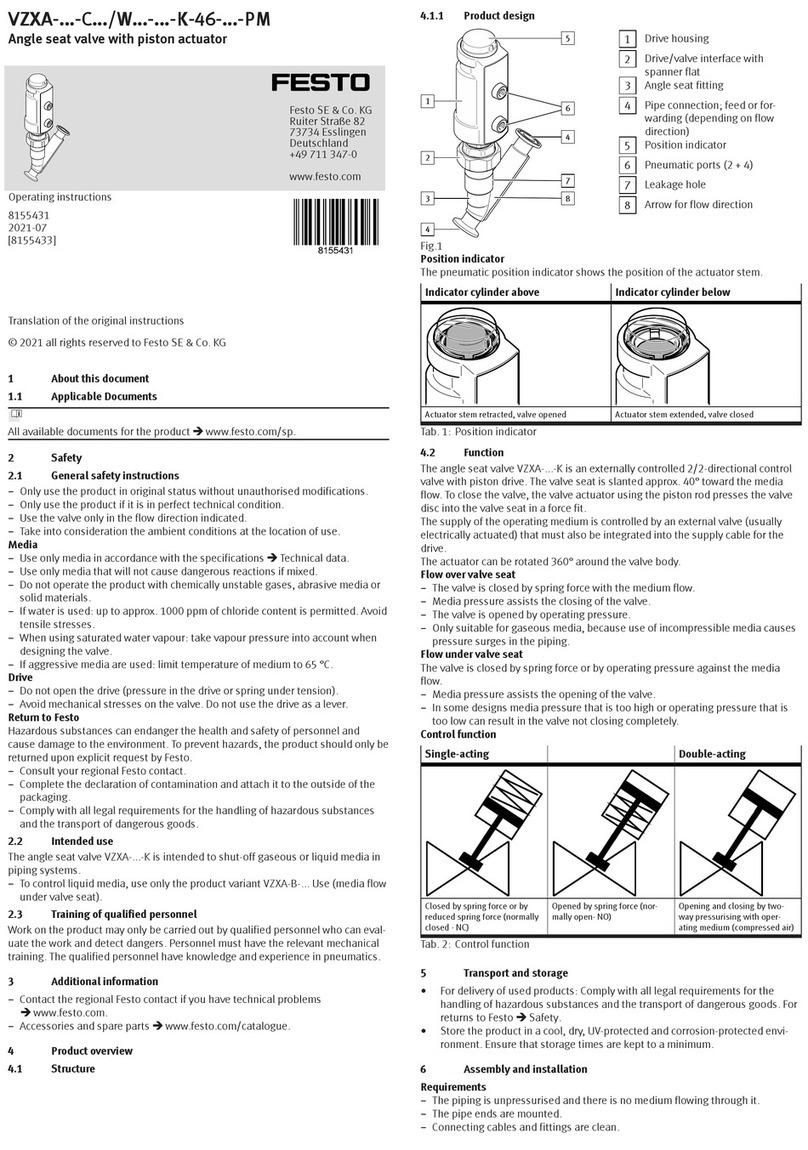

Festo

Festo VZXA Series operating instructions

tecatlantis

tecatlantis LUMINUS operating manual

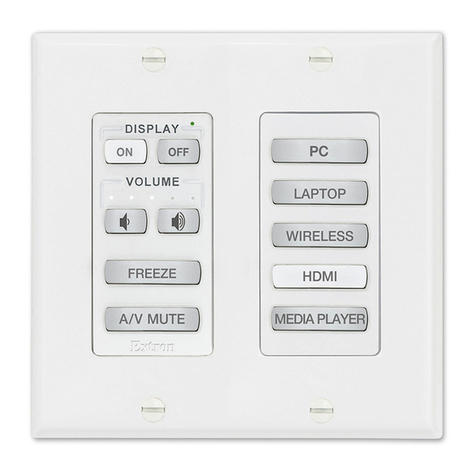

Extron electronics

Extron electronics MLC Plus 84 D Setup guide

Pixel

Pixel EM-181Mu user guide

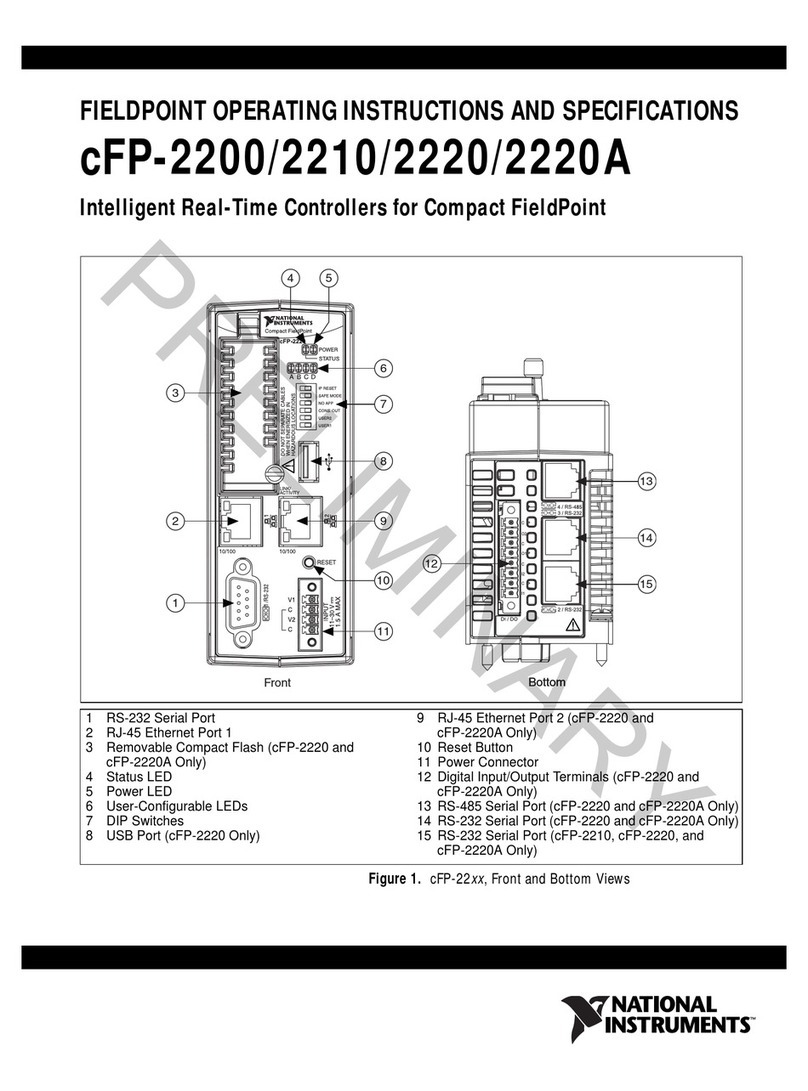

National Instruments

National Instruments cFP-22 Series manual