TABLE OF CONTENTS

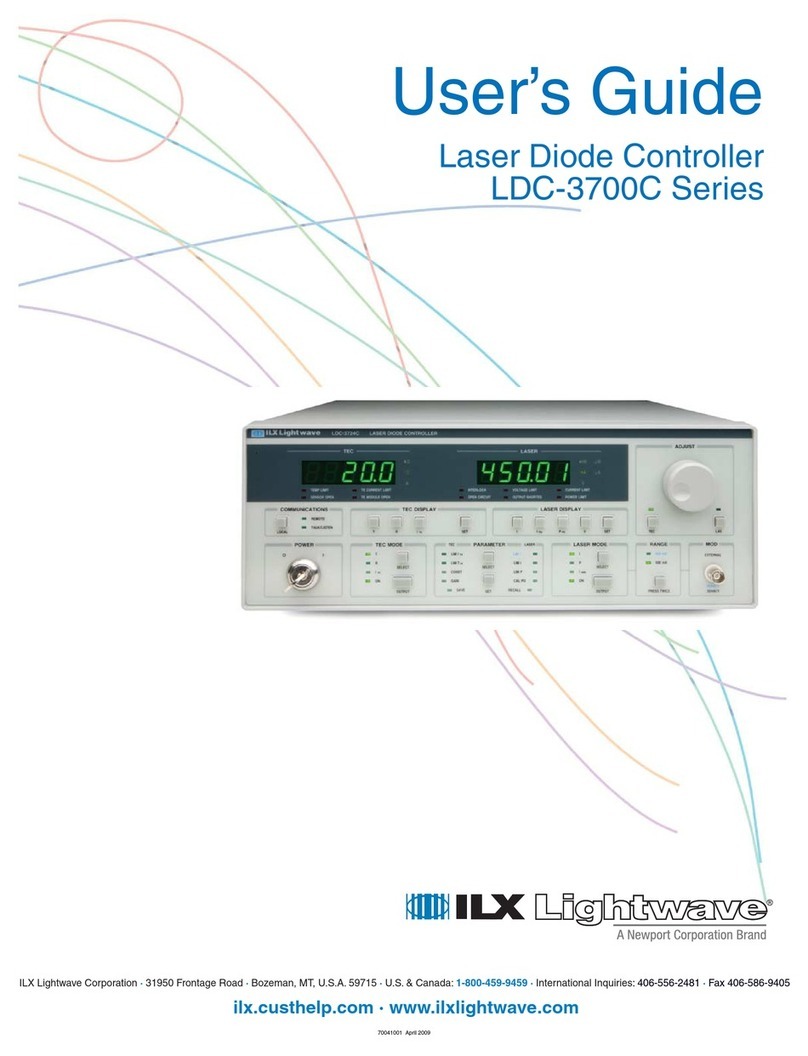

ii LDC-3700 Series

Chapter 2 Operations

Applying Power to your LD Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

The Power On Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

The Power On State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

37x4B Series Default Configuration: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Connecting to the Laser Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Connecting the Laser Current Source . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Interlock Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Photodiode Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setting the PD bias . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Grounding considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connecting to the TE Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

TEC Grounding Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operating from the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

The Laser Controller Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Operating a laser in Constant Current “I” Mode . . . . . . . . . . . . . . . . . . . . . . 16

Set Up the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Set the Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Select the Laser Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Adjusting the Set Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Set Current Source Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Automatic Shutoff Conditions for Laser Output . . . . . . . . . . . . . . . . . . . 19

Operating a Laser in Constant Power Mode, P . . . . . . . . . . . . . . . . . . . . . . . 20

Entering Photodiode Responsivity values . . . . . . . . . . . . . . . . . . . . . . . . . 20

LASER Error Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Operating the TE Controller from the Front Panel . . . . . . . . . . . . . . . . . . . . . . 24

The TEC display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Operating the Controller in Temperature Mode, T . . . . . . . . . . . . . . . . . . . . 24

Setting up the Temperature Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Temperature Controller Sensor Selection . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Setting Temperature Sensor Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Setting TE Control Loop Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Setting Temperature Controller Limits . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Adjusting the Temperature Set Point . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Automatic Shut Off Conditions for TEC Output . . . . . . . . . . . . . . . . . . . 29

TEC Error Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com