ELECTRA-flo Probe Arrays - Ultra

INSTALLATIONPROCEDURE

WARRANTY

AirMonitorCorporation(hereinafterreferredtoas"Seller")warrantsthatatthetimeofshipment,productssold

pursuant to this contract will be free from defects in materials and workmanship, and will conform to the

specificationsfurnishedorapprovedinwritingbySeller.Nowarrantyisgiventhatdeliveredproductswillconform

to catalog sheets, data sheets, and the like, which are subject to change without notice.

Seller will repair or replace, at its option, any products listed under this warranty which is returned freight pre-

paidtoSellerandwithintheearlierofthree(3)yearsafterstart-uporthirty-nine(39)monthsaftershipment,prove

upon test and examination by Seller to be defective within the terms of this warranty. The warranty period for

anyitemrepairedorreplacedshallbeforthetimeremainingonthewarrantyperiodfortheoriginalcomponents.

Purchaser shall notify Seller in writing of such defect within sixty (60) days of discovery of the defect.

This warranty does not extend to any product sold by Seller which has been the subject of misuse, neglect,

accident,damageormalfunctioncausedbyinterconnectionwithequipmentmanufacturedbyothers,improper

installationorstorage,orusedinviolationofinstructionsfurnishedbySeller,nordoesitextendtoanyproduct

which has been repaired or altered by persons not expressly approved by Seller.

Seller shall not be liable for any special or consequential damages or for loss of damage directly or indirectly

arising from the use of the products.

Thewarrantysetforthaboveisinlieuofallotherwarrantieseitherexpressorimpliedandconstitutesthefullextent

ofAirMonitorCorporation'sliabilitytothecustomer,oranyotherpartyforbreachofwarranty. THEREARENO

EXPRESSWARRANTIESEXCEPTASSETFORTHHEREIN. THEREARENOIMPLIEDWARRANTIESOF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE, WHICH ARE PARTICULARLY

DISCLAIMED.

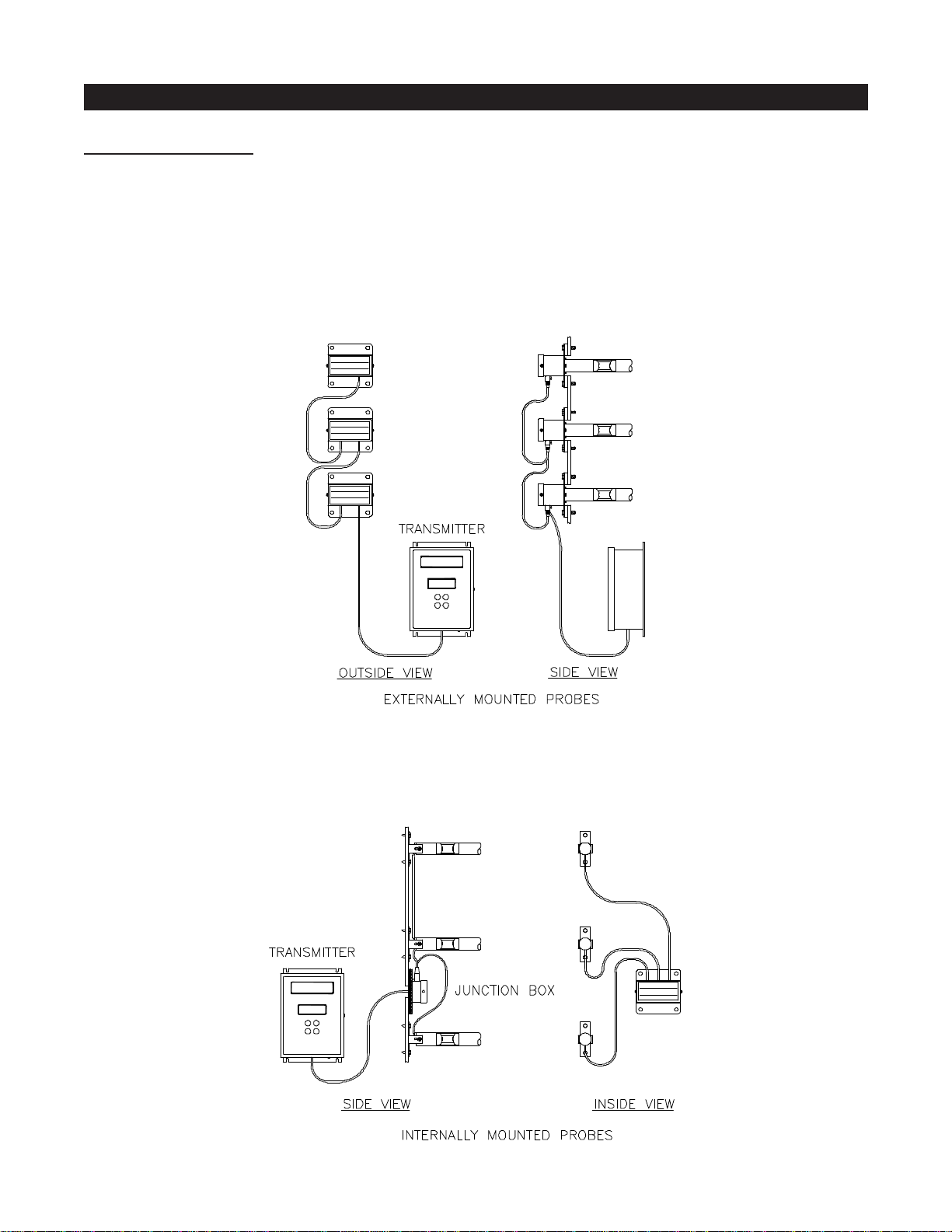

INSPECTION&HANDLING. TheELECTRA-floProbeArraysshouldbecarefullyinspectedfordamagepriortoinstallation.

Reportdamage to your FreightDepartment, orcontact deliverycarrier.

Almost any means of handling can be utilized depending on the length of the probes. Probes may be handled

while in any position; however, it is important not to drop or mishandle the probes such that damage is done to the

sensing holes, tubular members, signal connection fittings, end studs, or mounting plates.