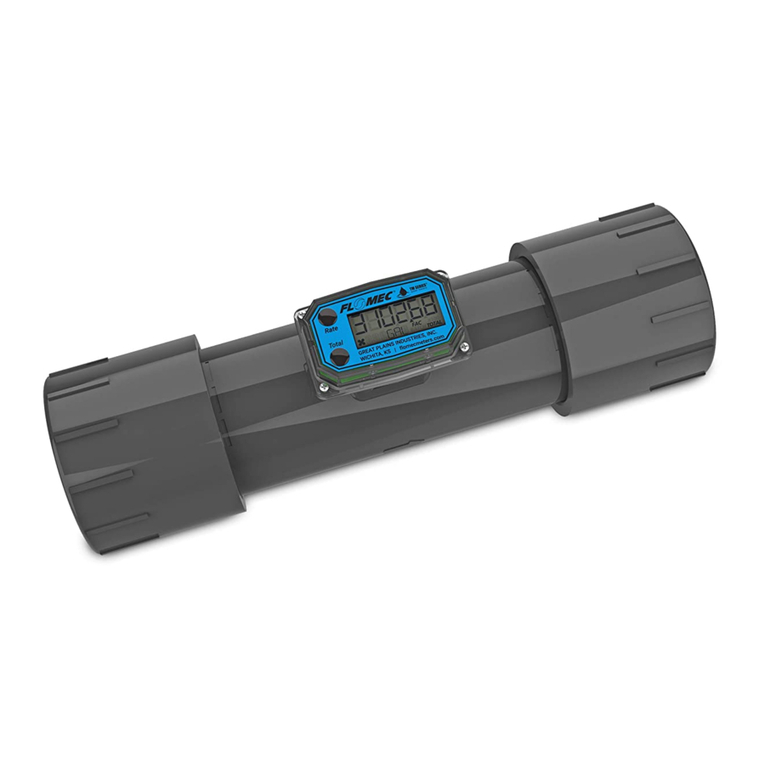

Flomec G2 User manual

Other manuals for G2

1

Table of contents

Other Flomec Measuring Instrument manuals

Flomec

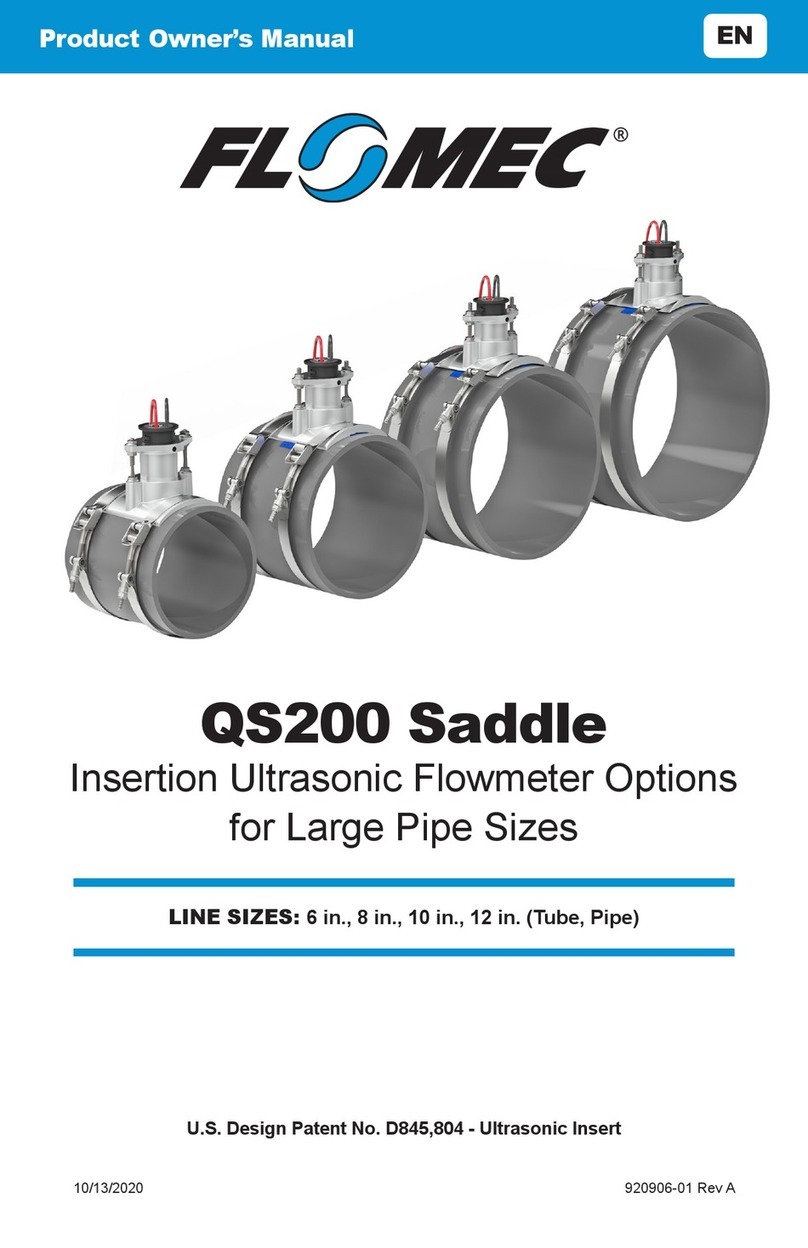

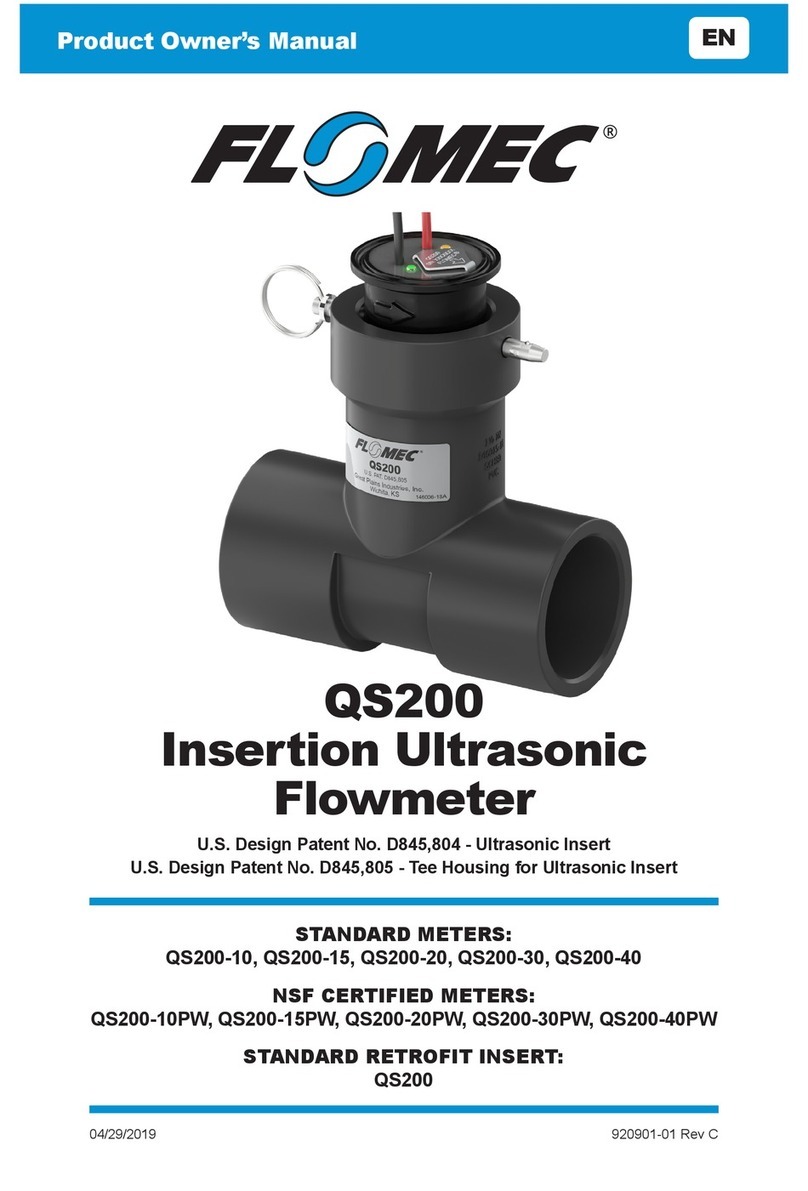

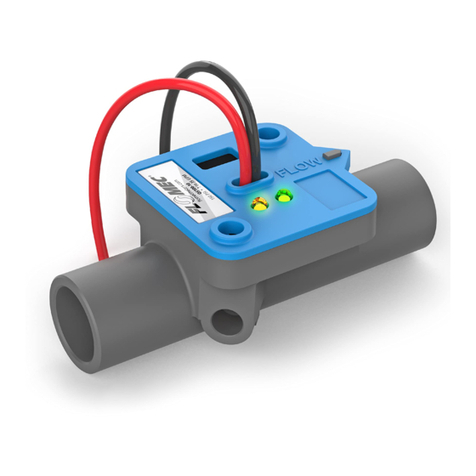

Flomec QS200 User manual

Flomec

Flomec Oval Gear User manual

Flomec

Flomec 490 User manual

Flomec

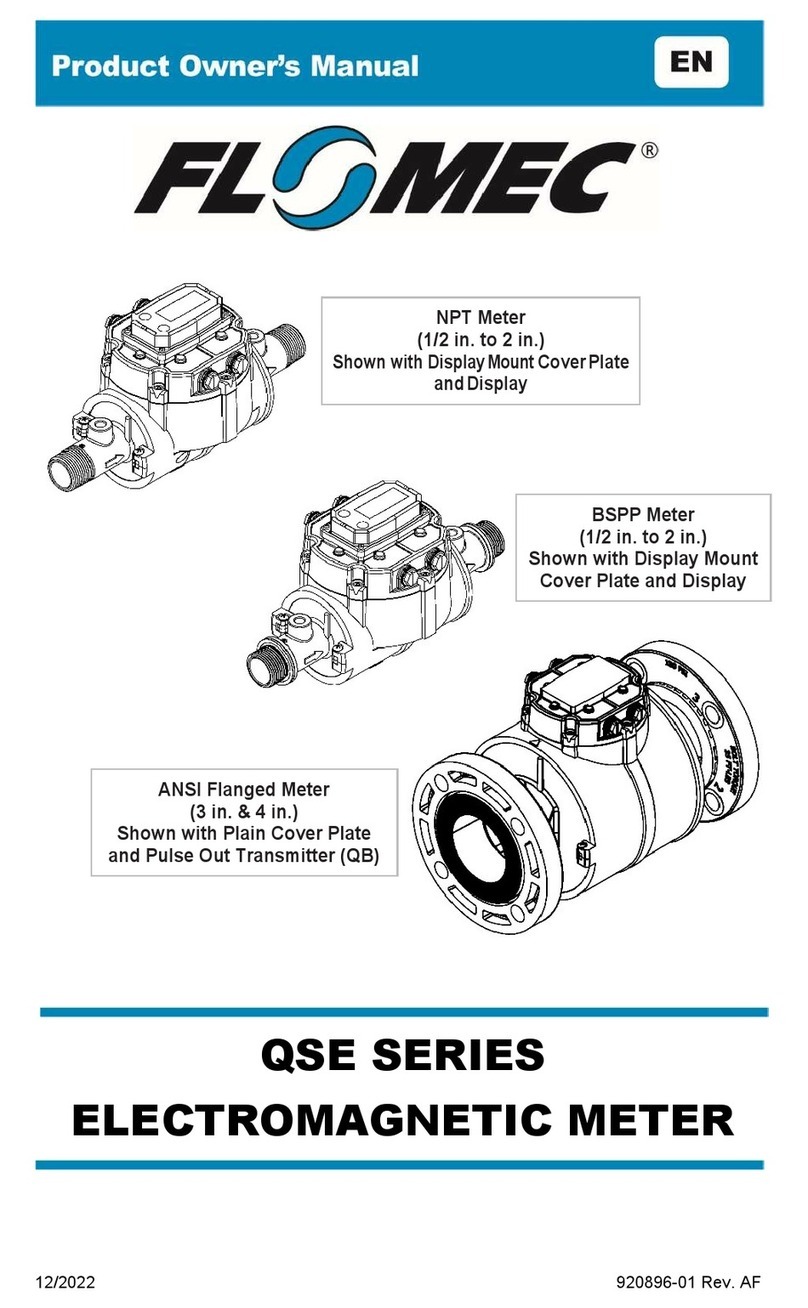

Flomec QSE Series User manual

Flomec

Flomec QSE Series User manual

Flomec

Flomec Q9 User manual

Flomec

Flomec QS200 User manual

Flomec

Flomec D-40 User manual

Flomec

Flomec G Series User manual

Flomec

Flomec TM Series User manual

Flomec

Flomec QS200 User manual

Flomec

Flomec GPRO QM Series User manual

Flomec

Flomec QSE Series User manual

Flomec

Flomec QS100-10 User manual

Flomec

Flomec QS200 User manual

Flomec

Flomec TM Series User manual

Flomec

Flomec Q9 User manual

Flomec

Flomec LM51DN User manual

Flomec

Flomec OM025 User manual

Flomec

Flomec EGM Series User manual

Popular Measuring Instrument manuals by other brands

Siemens

Siemens Sitrans F Series operating instructions

Solinst

Solinst 101 instructions

AEMC instruments

AEMC instruments Clamp-On 3705 user manual

National Instruments

National Instruments NI TB-2644 installation instructions

Sealey

Sealey AK9991 manual

PerAlert

PerAlert FW 25-50 Installation and operation manual

Agilent Technologies

Agilent Technologies PNA Series Installation note

Chauvin Arnoux

Chauvin Arnoux MEMO MD65 quick start

Cameron

Cameron Scanner 3100 EFM Hardware manual

Badger Meter

Badger Meter EPM Installation & operation manual

Hobo

Hobo RX3000 Series quick start

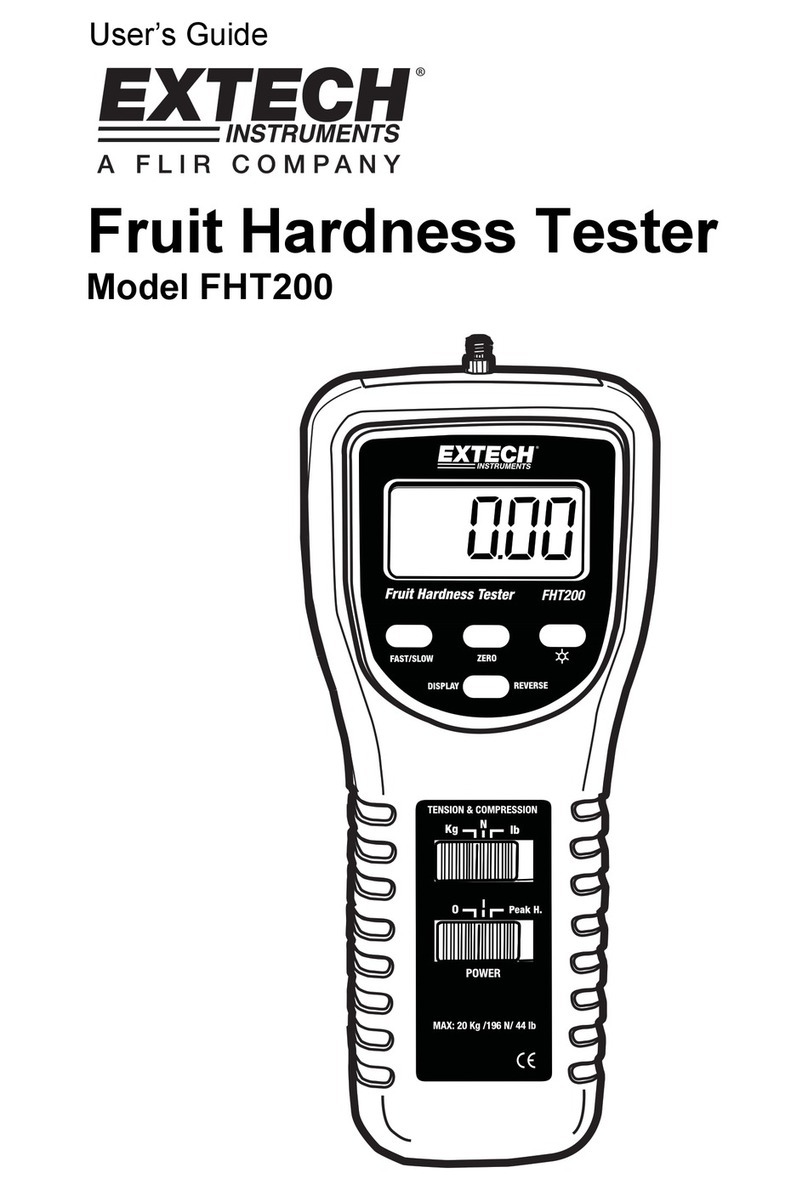

Extech Instruments

Extech Instruments FHT200 user guide