Installation Instructions for Accu-Drain

INTRODUCTION

The Accu-Drain line is designed for trouble-free draining of

unwanted accumulations of condensation and other

foreign matter from any collection point in a compressed air

system. As the water level in the reservoir reaches the top,

an internal oat signals the Posi-Valve (our proprietary

sliding gate valve) to open. The valve stays open until the

oat returns to the bottom.

INSTALLATION

CAUTION: COMPRESSED AIR CAN BE DANGEROUS.

Before attempting to install the drain, be certain that the

pressure vessel on which the drain will be installed is

completely depressurized. If necessary, shut down the

compressor system and vent the pressure or activate the

bypass valve in your system to redirect air away from the

vessel the drain is being installed on.

The drain should not be installed in areas that are exposed

to freezing temperatures. Be certain that the air system

pressure does not exceed the 200 PSI working pressure of

the drain.

Connecting the drain to the air system should be done by

using one of the recommended installation diagrams

shown herein. The installation of a strainer is not required

or recommended.

Install the drain as close to the source to be drained as

possible. Since the Accu-Drain uses gravity to ll the

reservoir, the entire drain must be installed below the

vessel to be drained when using the top inlet. If exible

tubing is used on the discharge, be certain it is properly

fastened to prevent it from whipping when the drain

discharges the condensation.

The Accu-Drain 2 only has a top inlet. The additional port

in the bottom is a cleaning port and is not to be used for an

inlet. An optional vent port is included in the top of the drain

which comes plugged with a Phillips head screw. We

recommend removing the screw and installing the included

1/8” Push to Connect Fitting or any needle vent with a 10-

32 thread and plumbing that port into the vessel being

drained or in the system before the vessel being drained at

an equal or lower pressure.

The Accu-Drain 3 and 5 will accept condensation from

either the top or the bottom inlet of the reservoir. Where

possible, we recommend the condensation enter through

the bottom and a vent line be installed in the top inlet port.

The other end of the vent line should be installed at a point

in the system before the vessel being drained and at a

equal or lower pressure. This will ensure that the air in the

reservoir will properly exit as the condensation lls the tank

and replaces the air.

If the top inlet is used, the bottom inlet must be plugged

with a 1/2" NPT plug (not provided). In addition, the drain

should be installed as close to the source being drained as

possible. Any reduction in pipe size is not recommended.

When using the top inlet, the Accu-Drain reservoir cannot

be higher than the bottom of the vessel that is being

drained.

Verify the voltage on label of the drain and apply power to

the drain. Push the test button on the drain and conrm

that you hear the valve clicking.

Close the By-Pass drain valve and open the Shut-O valve.

The pressure vessel can now be repressurized.

CHECKING THE DRAIN'S OPERATION

Testing the Accu-Drain can be done by pushing the TEST

button.

After installation is complete and the drain is online, a

check should be made that the condensation is properly

entering the reservoir. This can easily be done by looking

through the transparent reservoir.

If condensation is not entering the reservoir, check for the

following:

Push the test button on the control panel to see if any

condensation is drawn into the reservoir. If condensation is

drawn in, then check items 2, 3, and 4. If no condensation

is drawn in check items 1, and 5.

1. Make sure the auxiliary shut o valve is open.

2. Do not use the bottom inlet on the Accu-Drain

without installing a vent line (above the water line.)

3. If a vent line is installed, make sure that it is at or

upstream from the vessel that is being drained.

4. Be certain that the Accu-Drain reservoir is not higher

than the vessel that is being drained. This is very

important when using the top inlet on the Accu-Drain

reservoir.

5. Check to make sure that the vessel being drained has

condensation in it.

If the top inlet is being used and no condensation is

entering the Accu-Drain 3 or 5 reservoir, and all the above

items have been checked, then we recommend that the

bottom inlet be used with a vent line out of the top.

APPLICATIONS

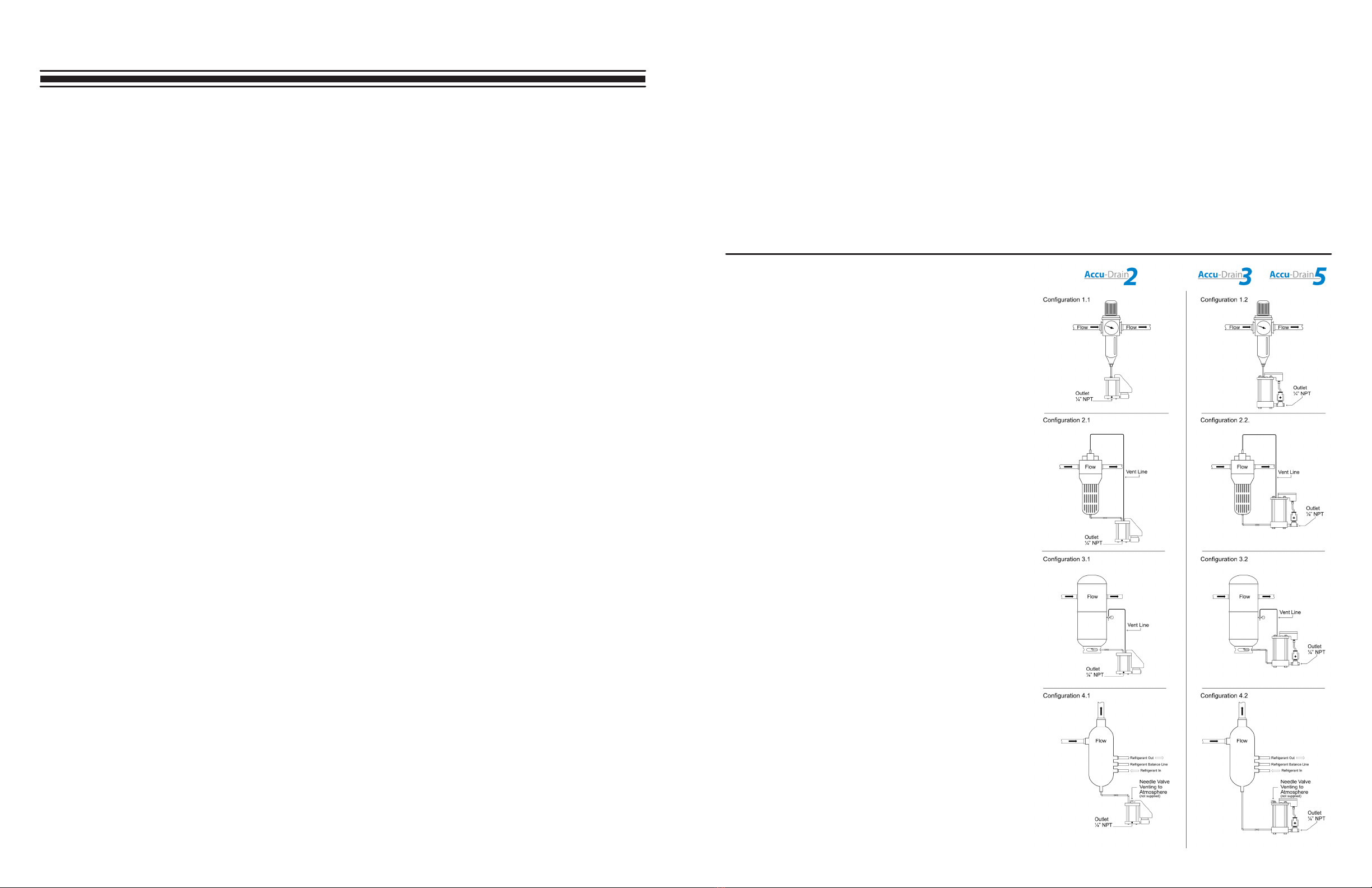

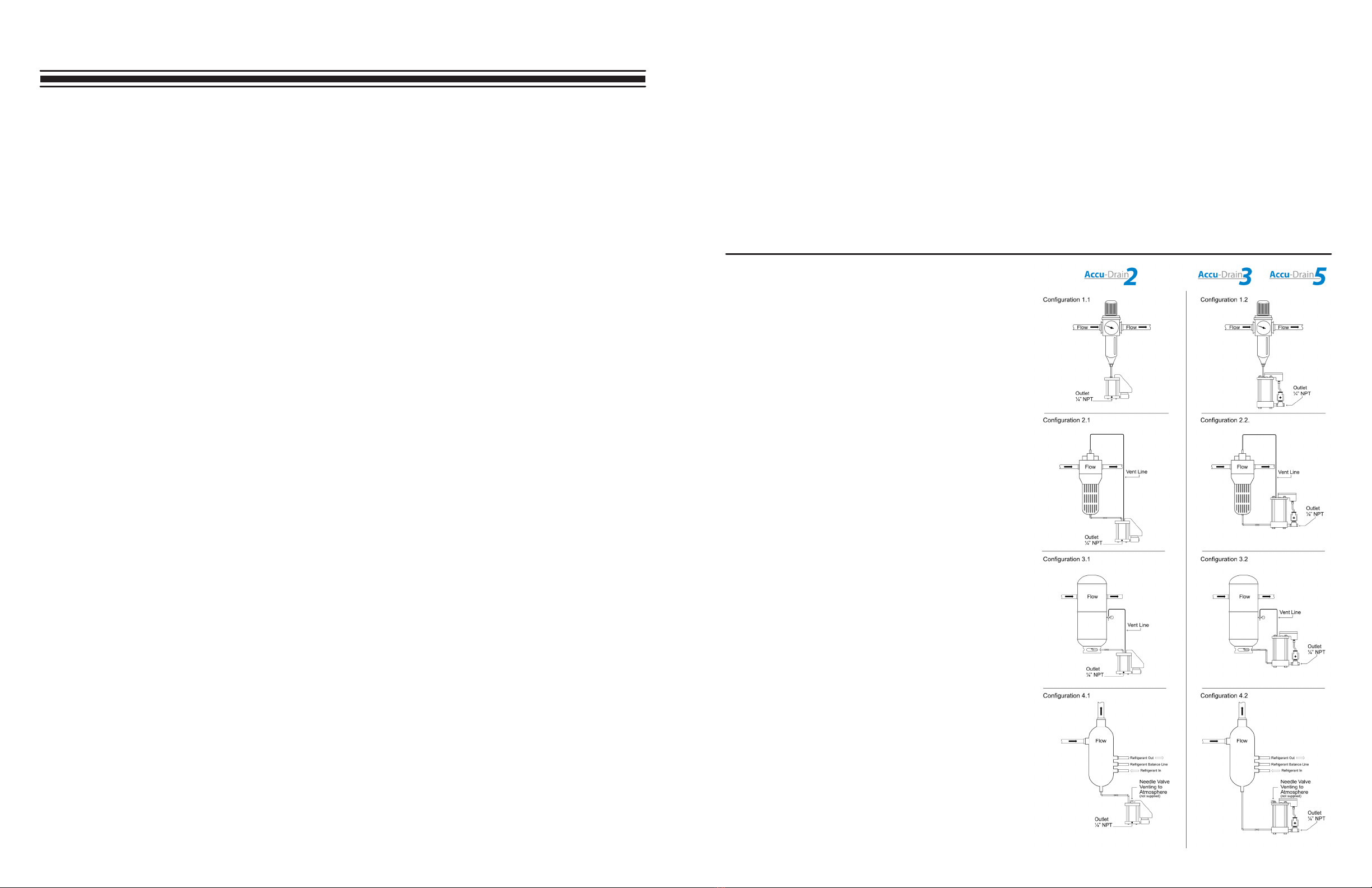

Conguration 1.1 & 1.2

Prelters, Coalescing lters, Moisture Separators, Drip

Legs.

Conguration 2.1 & 2.2

Large Prelters, Coalescing lters, Moisture Separators.

Conguration 3.1 & 3.2

Air Receiver Tanks.

Conguration 4.1 & 4.2

Refrigerated Air Dryers. This is the preferred method of

installation when it is not possible to return the vent line

back to the vessel being drained on Refrigerated Air

Dryers.

This method prevents reintroducing water vapor back into

the dried air stream which would elevate the pressure

dewpoint. (See Note below.)

NOTE:

When opting to use Alternative Installation Method #4, it is

necessary to adjust the “bleed” rate. The object here is to

allow a small amount of compressed air to bleed through

the Needle valve to atmosphere. This allows the

condensate to enter the Accu-Drain without “air-locking”

the reservoir. The following procedure applies when

adjusting the “bleed” rate for Drawing #4.

1. Close the needle valve. Then pressure Accu-Drain.

2. Slowly open needle valve until you can feel air exiting.

3. When the water level is visible, adjust the needle

valve to control the bleed rate. Slowly open or close

the needle valve until you see the water line ripple as

the air breaks through.

4. A small amount of air exiting the needle valve veries

proper adjustment.

IN GENERAL

ACCU-DRAIN relies on gravity to ll its reservoir. In order

for the condensate to properly enter the Accu-Drain

reservoir, it must be installed at a point lower than the

bottom of the vessel to be drained. Attempt to keep the

piping run short, while positioning the Accu-Drain as close

as possible to the drainage point. Run the piping in a

continuously sloping manner while avoiding any pockets

where condensate might collect. Always use non-galling

pipe sealant. The use of unions and shut-o valves are

recommended wherever possible.

VENTING / BALANCE LINE

Allowing the air to exit the Accu-Drain’s reservoir as the

condensate enters is critical for proper operation. The unit

will “air-lock” and not work properly if that exchange

cannot take place. Installing a balance line is often

necessary when it is not possible to adapt the Accu-Drain

directly to the vessel. It may also be required when sudden

surges of condensate are heavy enough to “airlock” the

Accu-Drain’s reservoir. Connecting the balance line back

to a point in the system where the pressure is “equal-to or

lesser than” the drain point will allow the condensate to ll

the reservoir while eliminating the possibility of an “air-

lock” condition.