3

Low Pressure Air Tests - 125 PSI Maximum

Procedure for Model LP-A4

STEP 5)

At the end of each test period, read the tube immediately and record the results. Repeat with the other tubes until all de-

sired contaminants have been sampled.

STEP 6)

Close the regulator knob (turn counterclockwise) to shut off pressure to owmeter. Open the owmeter valve to bleed

pressure from the owmeter. Disconnect regulator from air distribution manifold and store system in case.

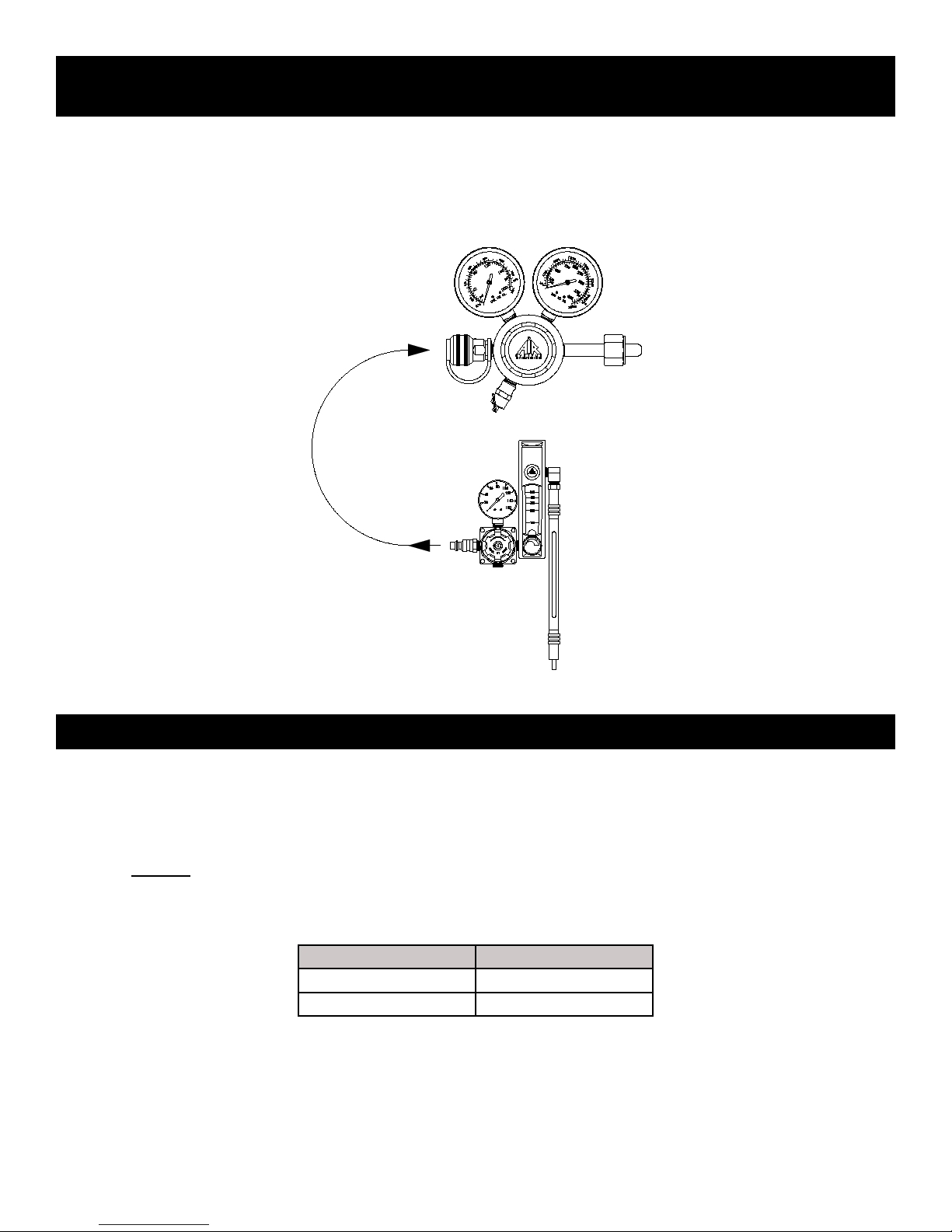

Model LP-A4 is supplied with a regulator/owmeter that must be con-

nected after the compressor’s Grade-D ltration system. The male plug,

1/4” industrial interchange, installed on the inlet of the pressure regulator

can be coupled directly into the air distribution manifold of the ltration

system. The test will determine acceptable air quality and whether or not

the ltration system is functioning properly.

STEP 1)

Attach regulator assembly to female coupling on air distribution manifold.

The owmeter should be in the vertical position for maximum accuracy.

NOTE: The 1/4” industrial interchange plug on the regulator will need to

be changed or an adapter used if the coupling on the manifold is some-

thing other than a 1/4” industrial interchange.

STEP 2)

Turn the regulator knob clockwise and set pressure between 20-30 PSI.

Do not adjust the owmeter at this time.

NOTE: The recommended tube testing sequence is as follows:

water vapor, carbon dioxide, carbon monoxide, and oil mist.

STEP 3)

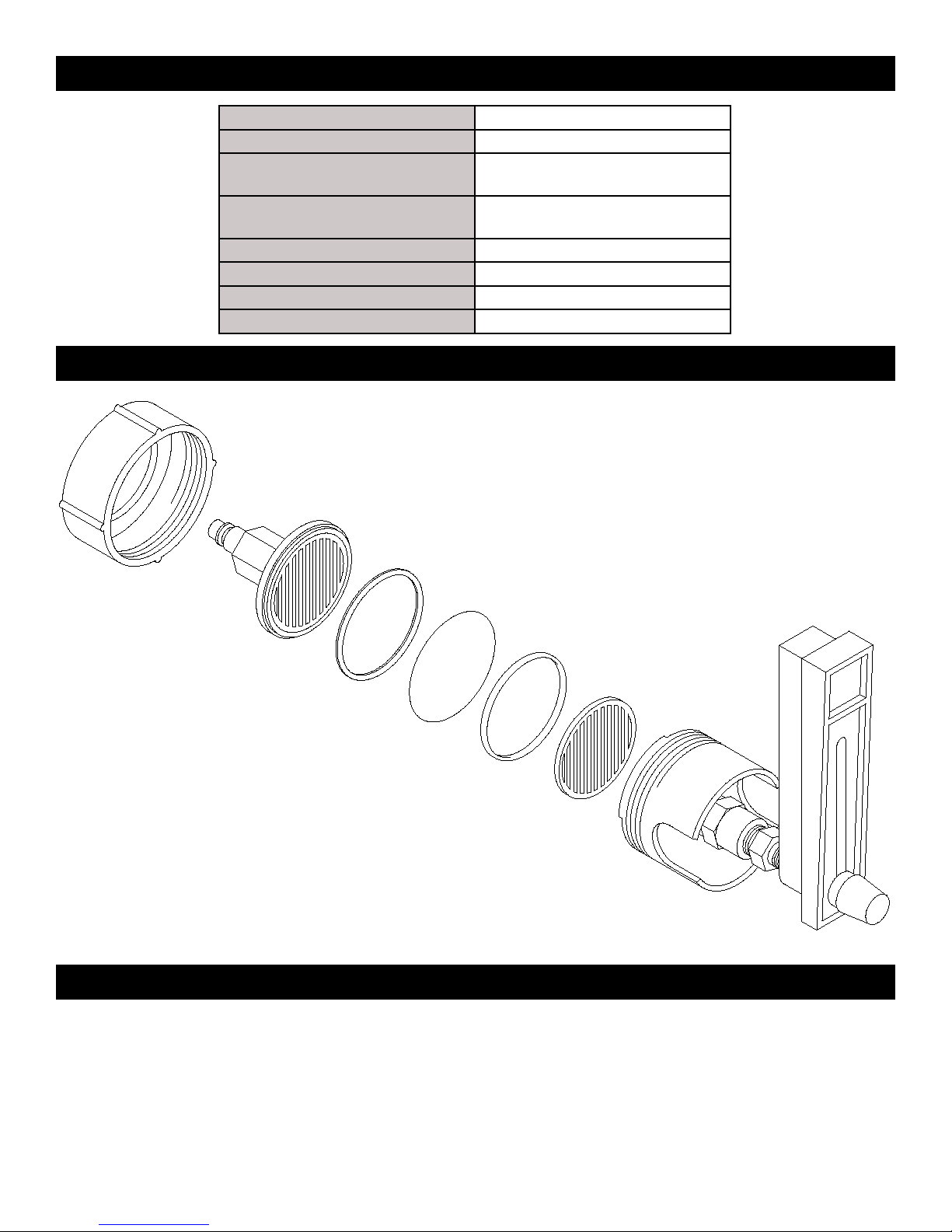

Break the ends off a fresh test tube using the small metal breaker sleeve

in the kit. Install the test tube in the rubber tube holder with the directional

arrow found on the tube pointing down. Install tube by rst inserting the

upper end into the holder then stretching the holder over the lower

STEP 4)

The rubber tube holder is then inserted into the hose barb with the test

tube arrow pointing down. Adjust the owmeter to the ow rate per the

chart on the following page and the required time. Start the test with the

water vapor test tube and work through the chart. Test Tube Breaker Sleeve

Test Tube Holder

Flowmeter

Regulator

1/4” Male Plug

Tube Contaminant Flow Rate CC/Min Test Time In Minutes

Gastec Sensidyne Gastec Sensidyne Gastec Sensidyne

6A 603SPA Water Vapor 100 500 10 1.4

2A 601SP Carbon Dioxide 100 100 5 3.5

1A 6005P Carbon Monoxide 100 175 3 2

109AD 6025P Oil Mist 500 470 40 25

WARNING!

Do not attempt to remove regulator while system is pressurized. Always test air quality after the lter system to assure

proper function. The periodic testing of CO levels does not substitute for a CO or high temperature alarm per OSHA reg-

ulations. We recommend the installation of a CO monitor in the breathing air system to continuously monitor for CO. Call

Air Systems’ customer service department to discuss a retrot for your system.