2

Table of Contents

Scale Overview.................................................................................1

Overview: Sensor Installation......................................................1

Tools Required.................................................................................2

Installing the Sensor Bracket on the Camelback Suspension...3

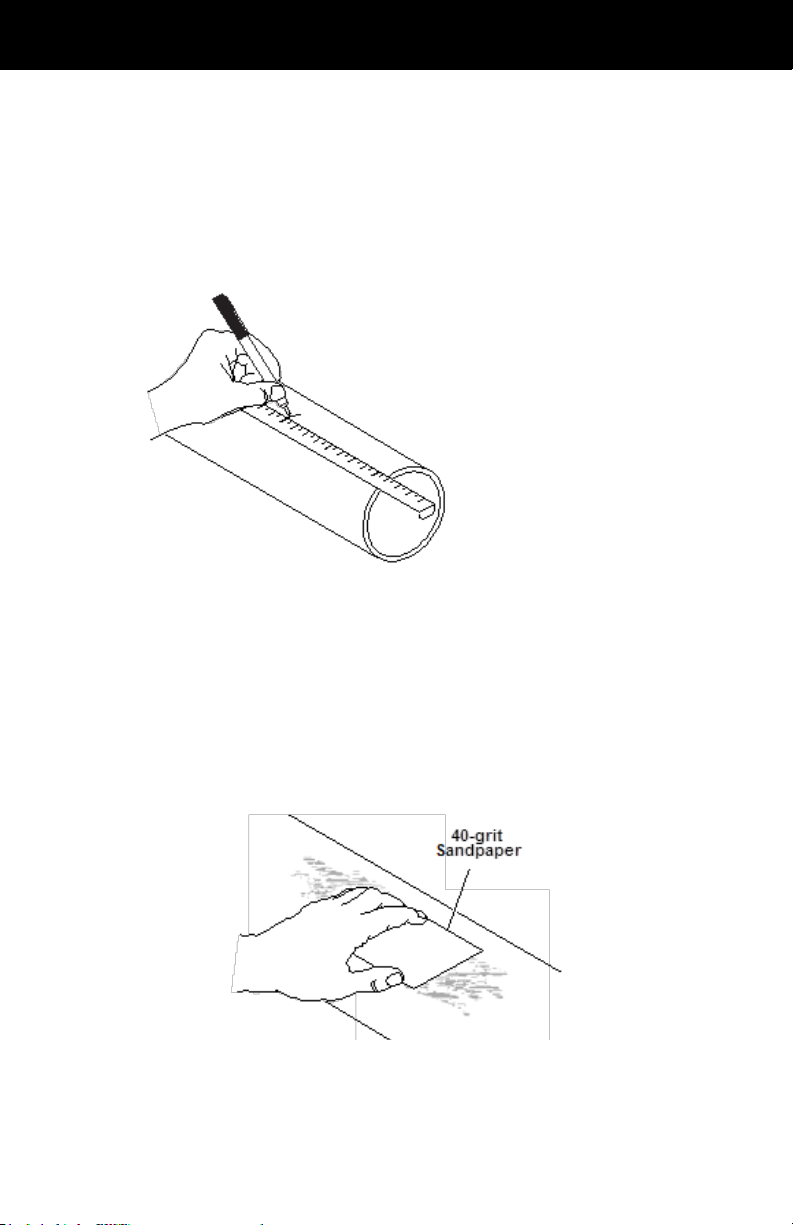

Preparing the Camelback Suspension......................................3

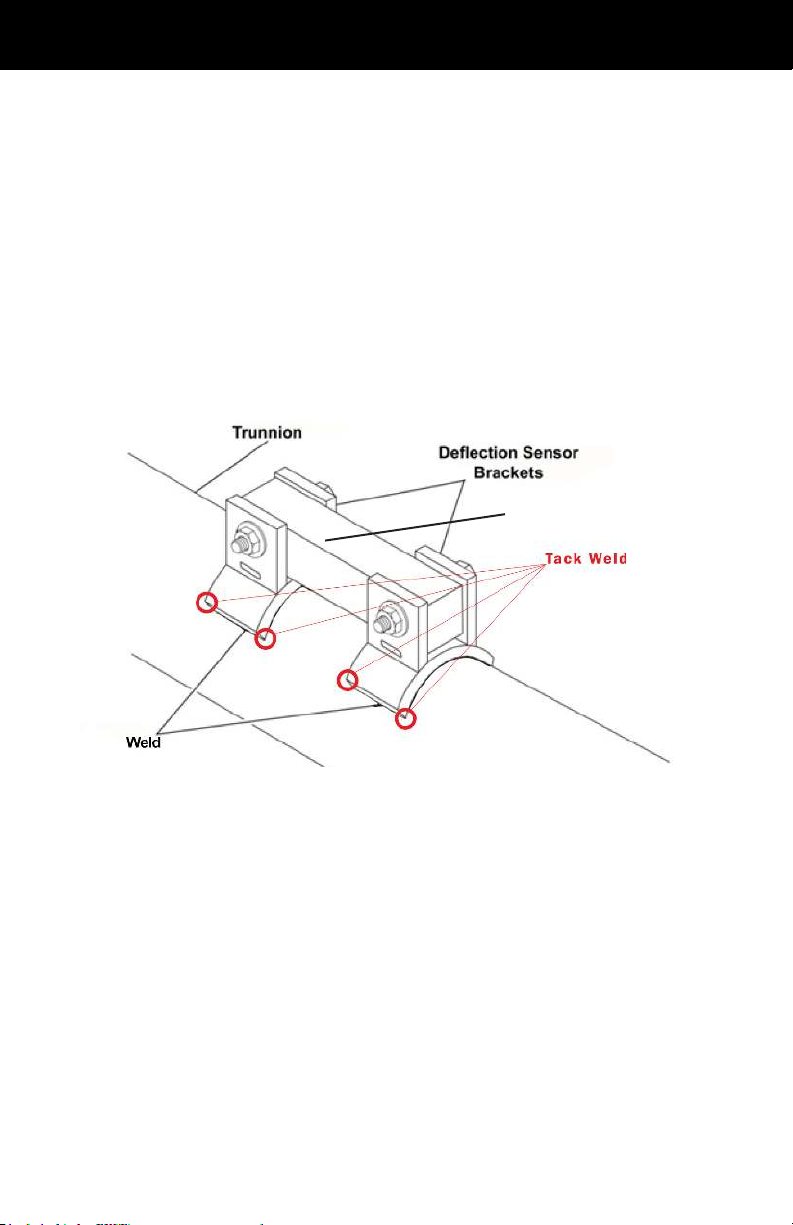

Welding the Bracket......................................................................4

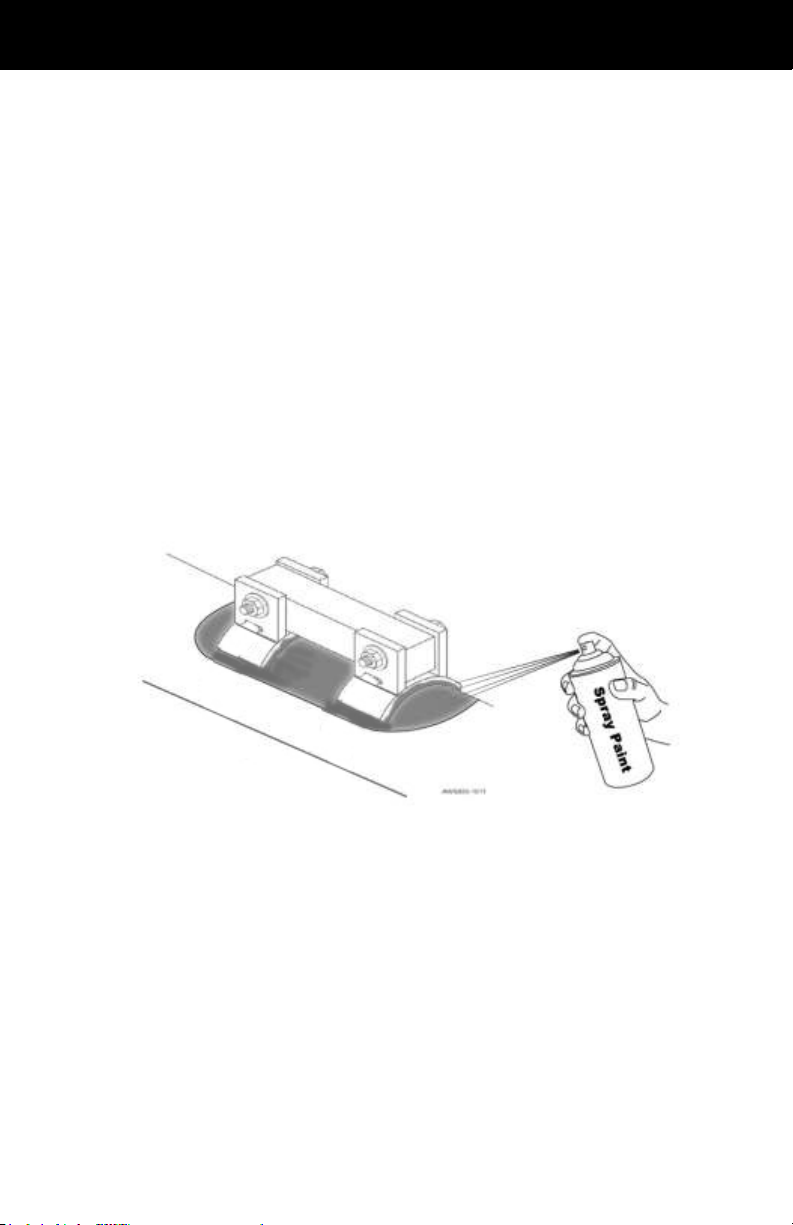

Adding a Protective Spray Paint Coating..................................5

Installing the Display and Cables..................................................6

Routing the Sensor Extension Cable.........................................6

Preparing the Cab Display for Installation.................................7

Installing the Cab Display.............................................................7

Securing Cables and Reassembling the Dash........................9

Setting the Sensor A/D Values.................................................10

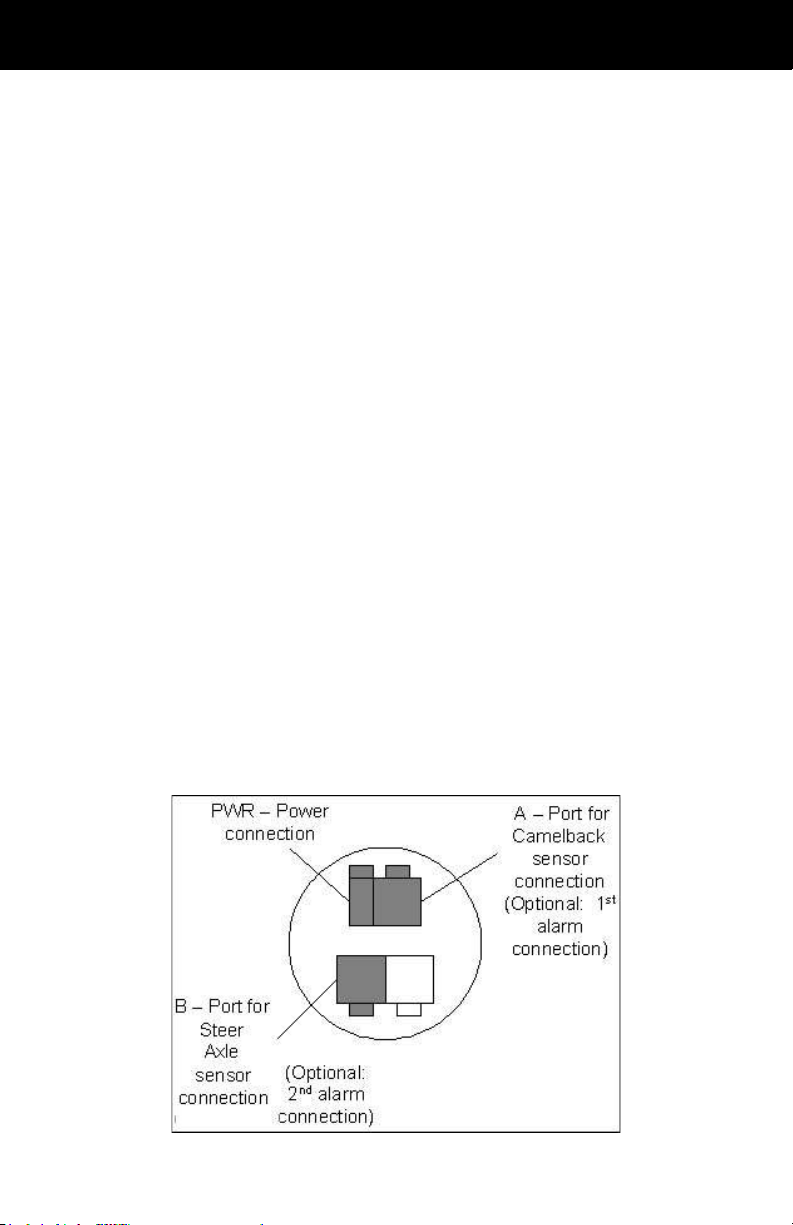

Assembling the Electrical Connector.......................................10

Adjusting the A/D Reading.........................................................11

Final Sensor Torque....................................................................12

Cover Installation...........................................................................13

Notes................................................................................................15

Limited Warranty............................................................................16

Procedure for Warranty Claims....................................................17