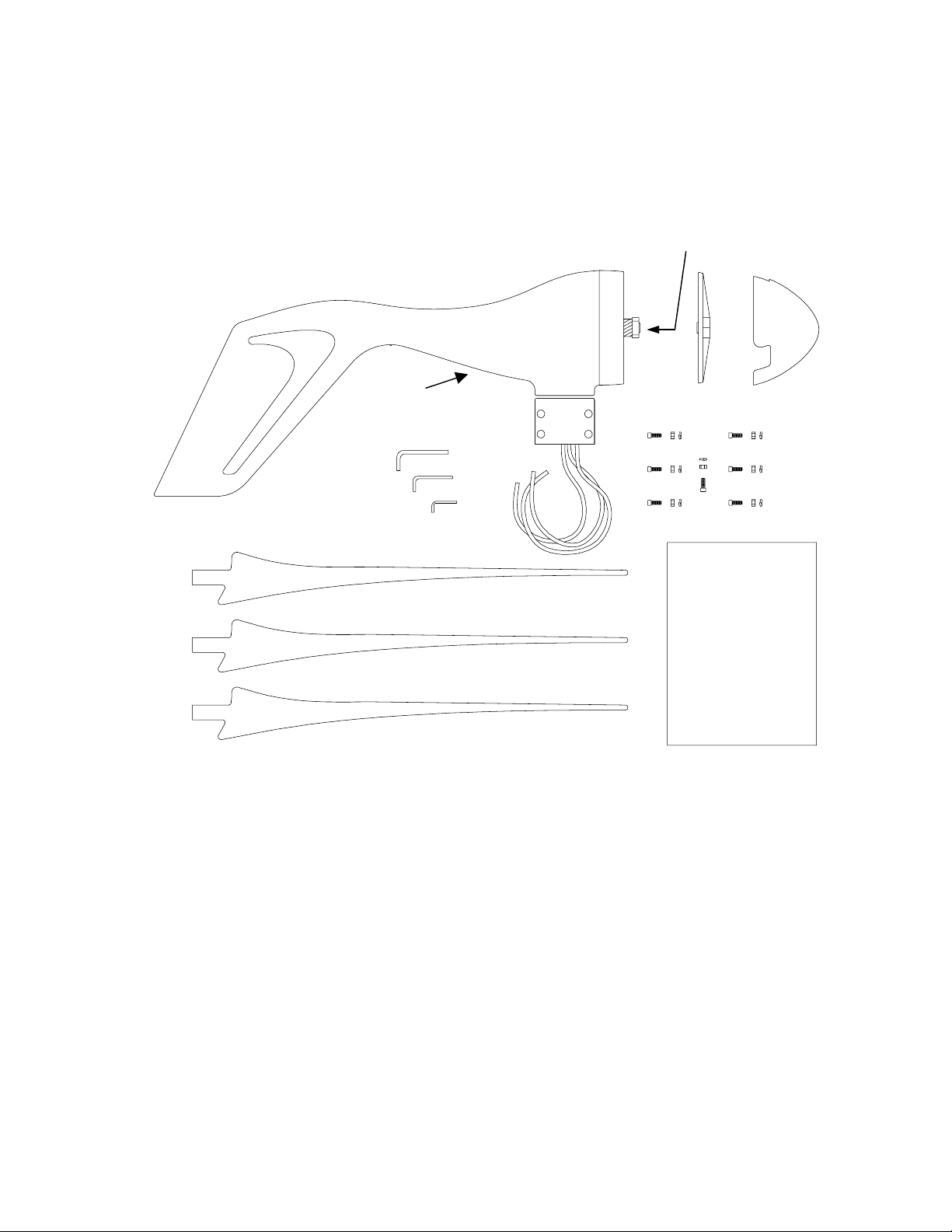

AIR-X Land Manual Document #0056 REV D

SOUTHWEST WINDPOWER 10/09/2002 4

New Features of the AIR-X

The AIR-X is the latest evolution of the AIR series of wind turbines from Southwest

Windpower. From the outside, the AIR-X looks almost identical to the AIR 303 and AIR

403. The improvements are almost all inside the turbine.

The AIR-X Features:

• New Electronics: The AIR-X incorporates an entirely new rectifier and controller. The

microprocessor based controller provides voltage regulation, peak power tracking, and

quiet, stall control in high winds. The AIR-X uses a synchronous rectifier bridge which

results in cooler, more efficient operation. The AIR-X also incorporates a voltage

boosting function which allows the turbine to reach charging voltage at a much lower

RPM.

• New Alternator: A more efficient alternator has been built into the AIR-X. The

alternator was designed to complement the peak power tracking ability of the control

electronics. The alternator uses a larger wire size than that of the AIR 403, and thus has

lower internal resistance. The result is cooler operating temperatures for improved

reliability. The strong permanent magnet rotor can be felt in rotating the rotor shaft; a

slight “catch” can be felt when spinning the shaft with your fingers. This is normal, and is

quickly overcome when the blades begin spinning.

• New Blades: The rotor blades use a highly efficient, true airfoil. They are manufactured

using a precision injection molding process that produces blades of exceptional

consistency. The result is quieter performance and minimal vibration. The AIR-X blades

differ from the AIR 403 blades in their tip angles. The AIR-X blades have an increased

tip angle which improves their ability to start rotating, and moves “flutter” to higher wind

speeds. Unlike the AIR 403 and earlier 303, the AIR-X does not rely on blade flutter for

over-speed protection. The control electronics will slow the blades before the turbine

reaches the point of flutter. Increasing the tip angle helps to ensure that the flutter noise

is not heard.

• New Yaw Shaft: The yaw shaft is the part of the turbine that mounts to the tower and

allows the turbine to rotate into the wind. The AIR-X features a new yaw shaft that allows

for stronger clamping forces to the tower, and more rigidity in the turbine.

The AIR-X also retains these features of the AIR 403:

• Hysteresis Braking: The regulation control circuitry incorporates hysteresis. This will

lock the turbine in a silent regulation mode once the batteries are fully charged. The

turbine begins producing power again when the battery voltage drops slightly below fully

charged. This means, for a factory set 12V turbine, the turbine will regulate (shut down)

when the batteries have reached 14.1V, and will resume charging when the voltage

drops to 12.75V. Minimal output is wasted, as non-charging battery voltages above

12.75V represent mostly a “surface charge” with very little energy. This feature prevents

the turbine from fluctuating in and out of regulation mode, resulting in a quieter, better-

behaved machine.

• New Body, New Hub: The AIR-X body is made from a precision casting process that

not only enhances fit and finish, but also leads to a stiffer, more durable body. The

aluminum casting also acts as a heat sink and transfers heat from the stator and the

electronics into the wind flowing past the turbine. The die cast aluminum hub design has

been engineered to be the strongest, stiffest hub we have ever produced.