Airflow Vector Pty Ltd

4 Collins Rd, DROMANA VIC. 3936

AUSTRALIA

Ph: +61 3 5987 3733

www.airflowvector.com

SD097E (S097 Instructions booklet).doc 23 March 2011 Page 1 of 16

\\Server\d\AirflowSnorkels\Products\Snorkels\S97\SD097E (S097 Instructions booklet).doc

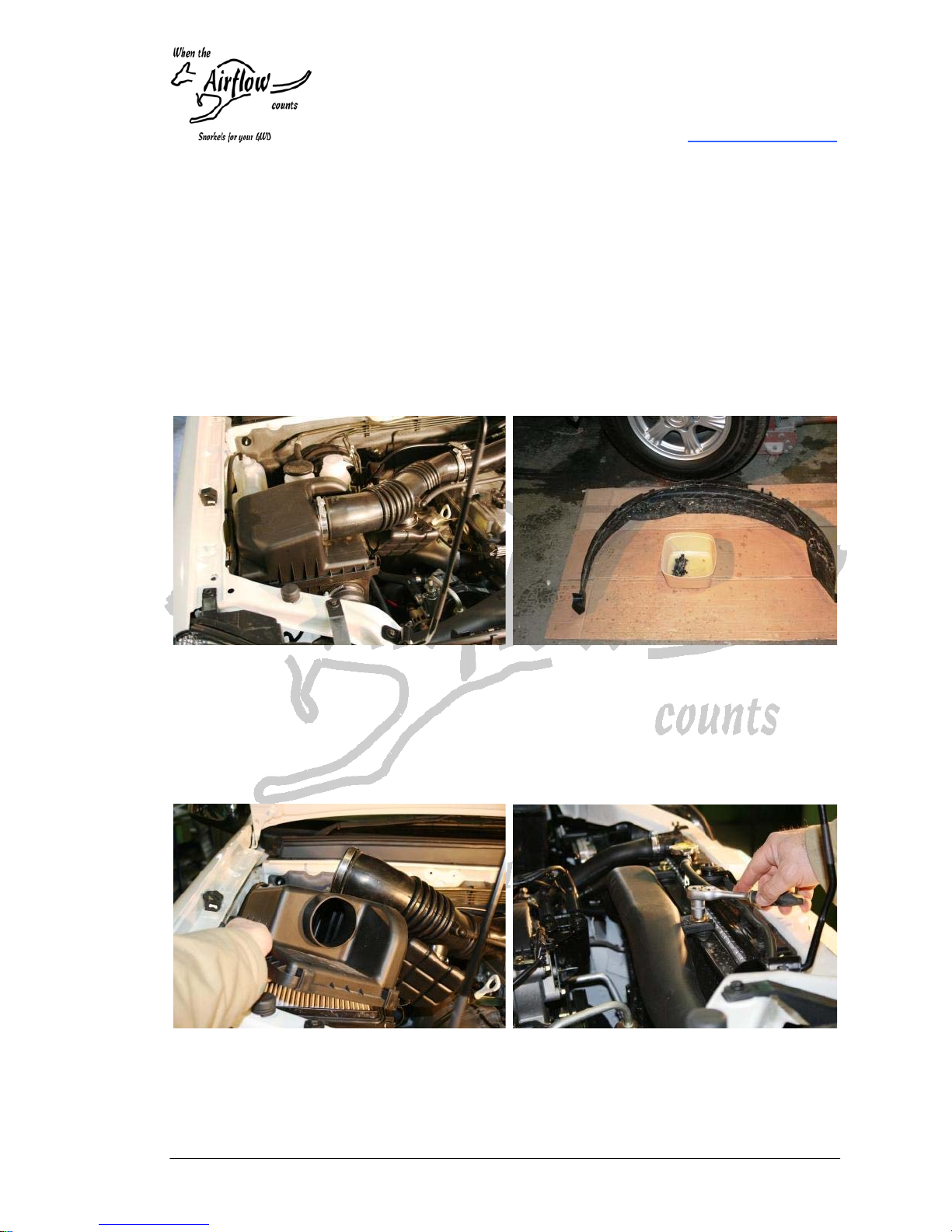

Instructions to fit the Snorkel Kit S097

for the GWC V240 4WD

1.0 Introduction

Airflow Vector Pty Ltd thanks you for your purchase and the trust you put in our

products.

We strive to supply our customers with the highest quality equipment based on

the most efficient design and best styling. We are confident that you will enjoy

using our Snorkel system.

It should improve the power of your vehicle as well as reduce its fuel

consumption.

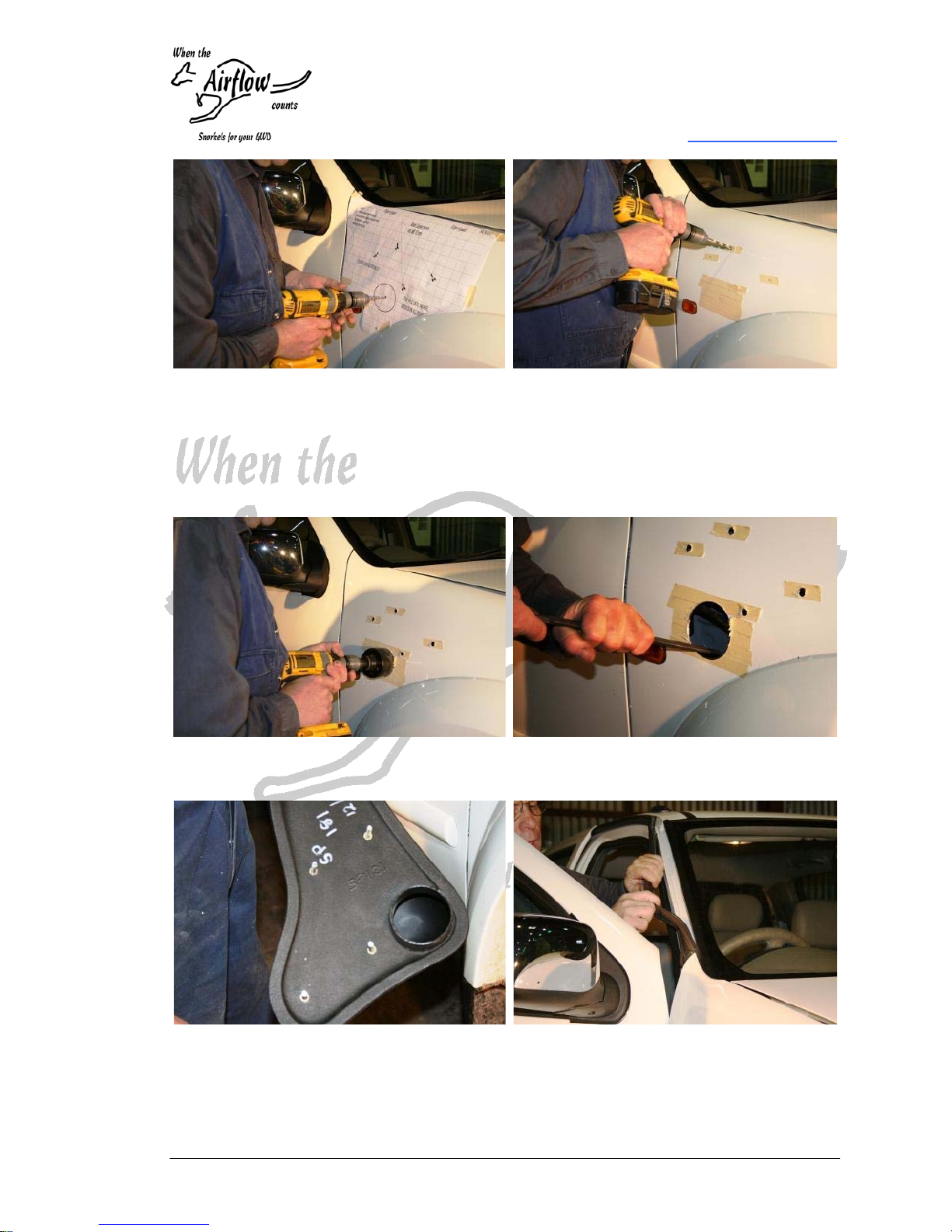

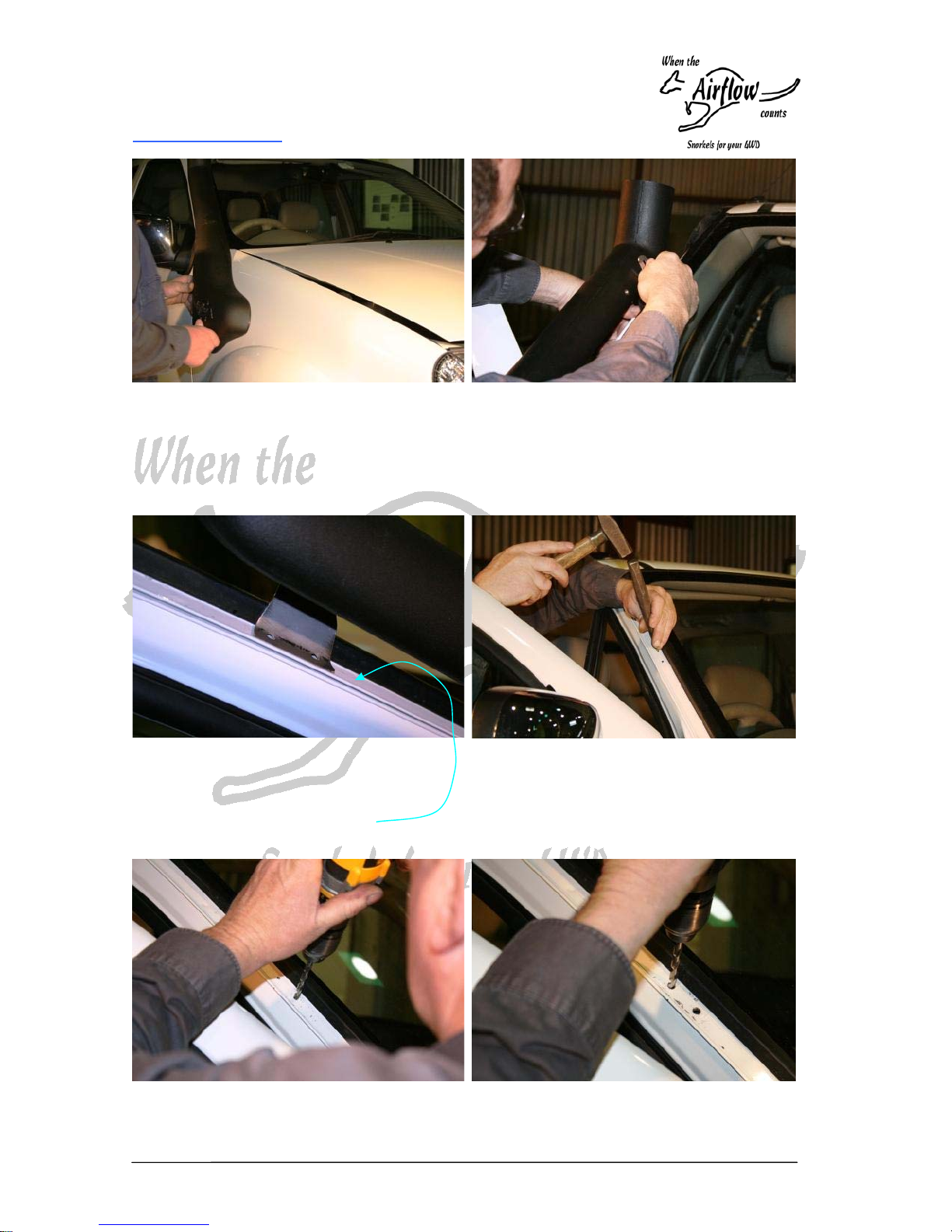

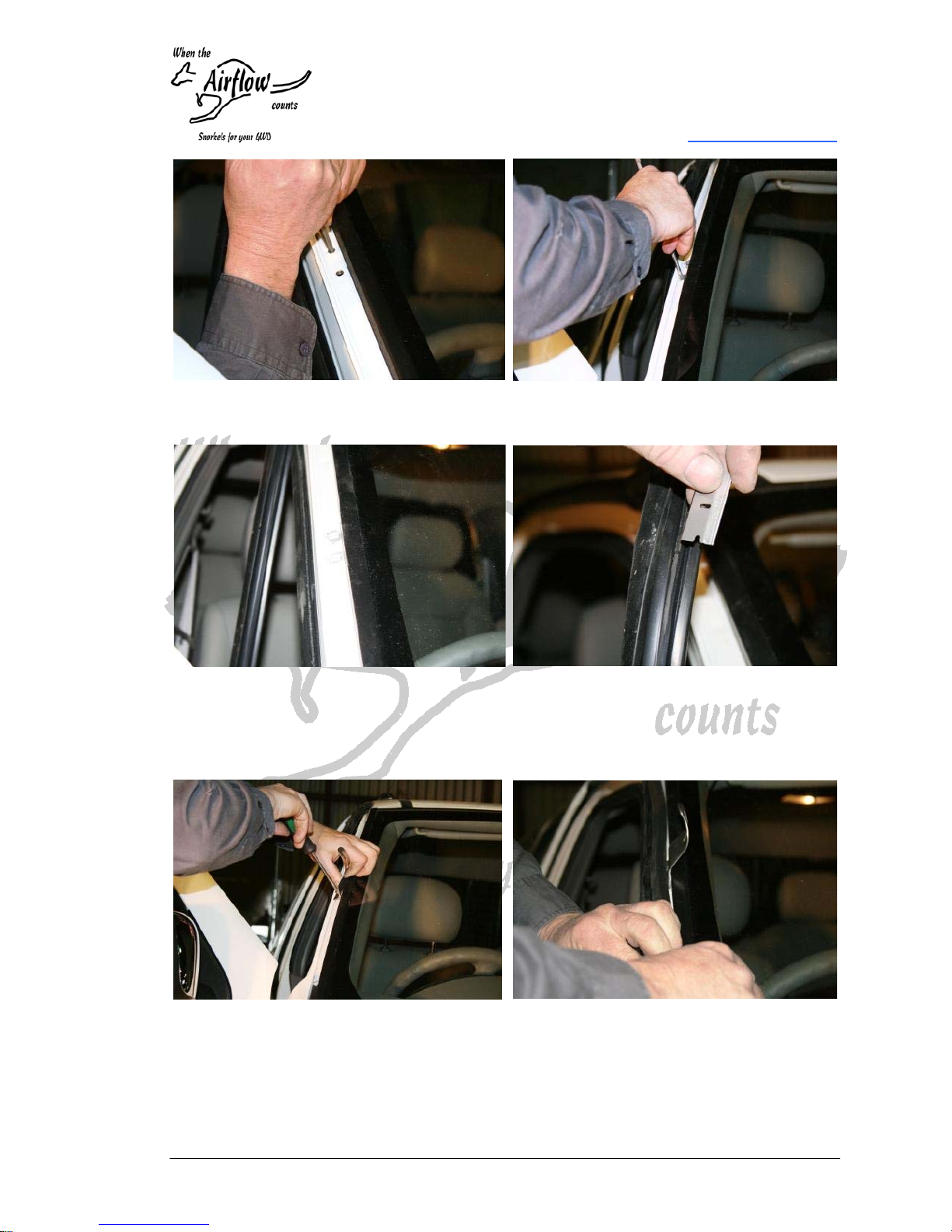

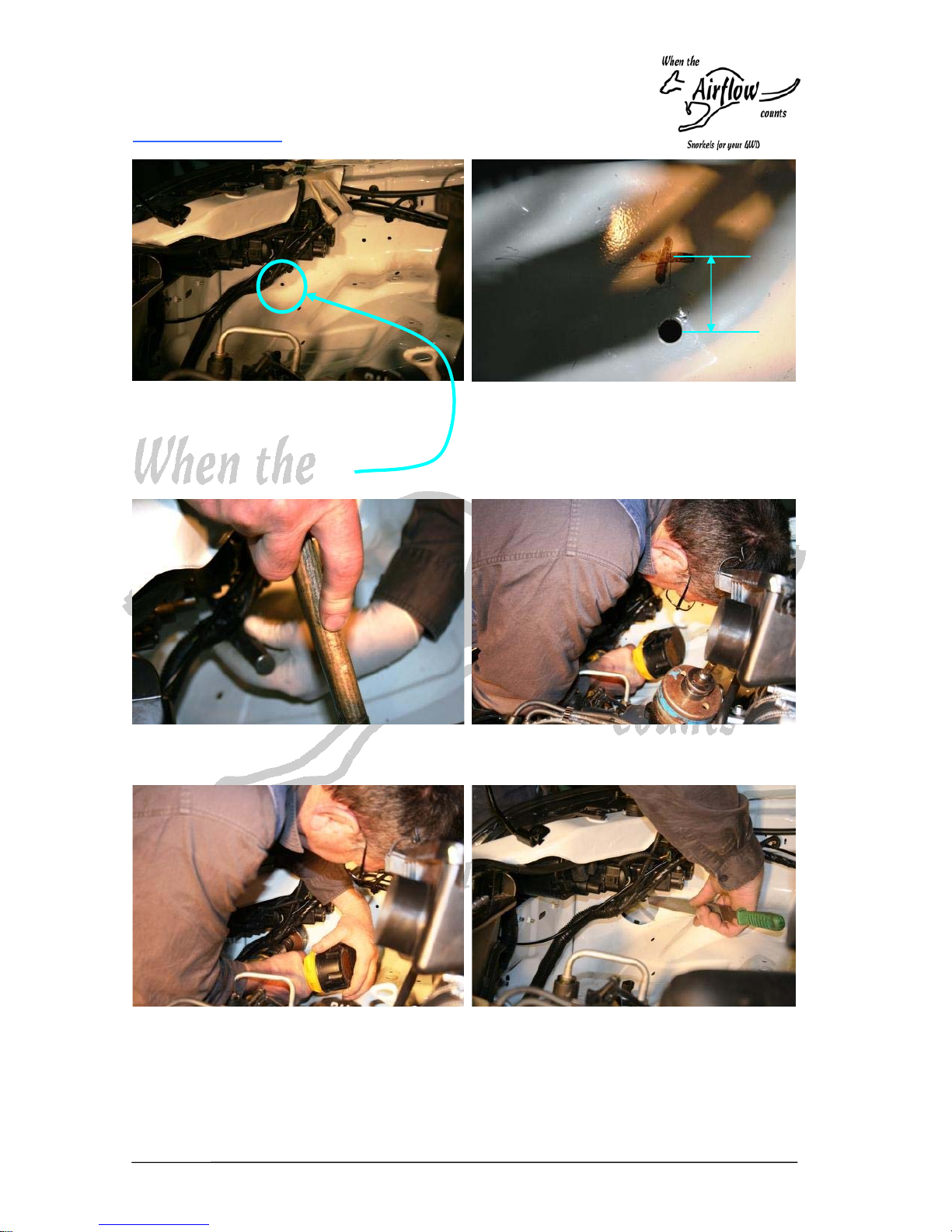

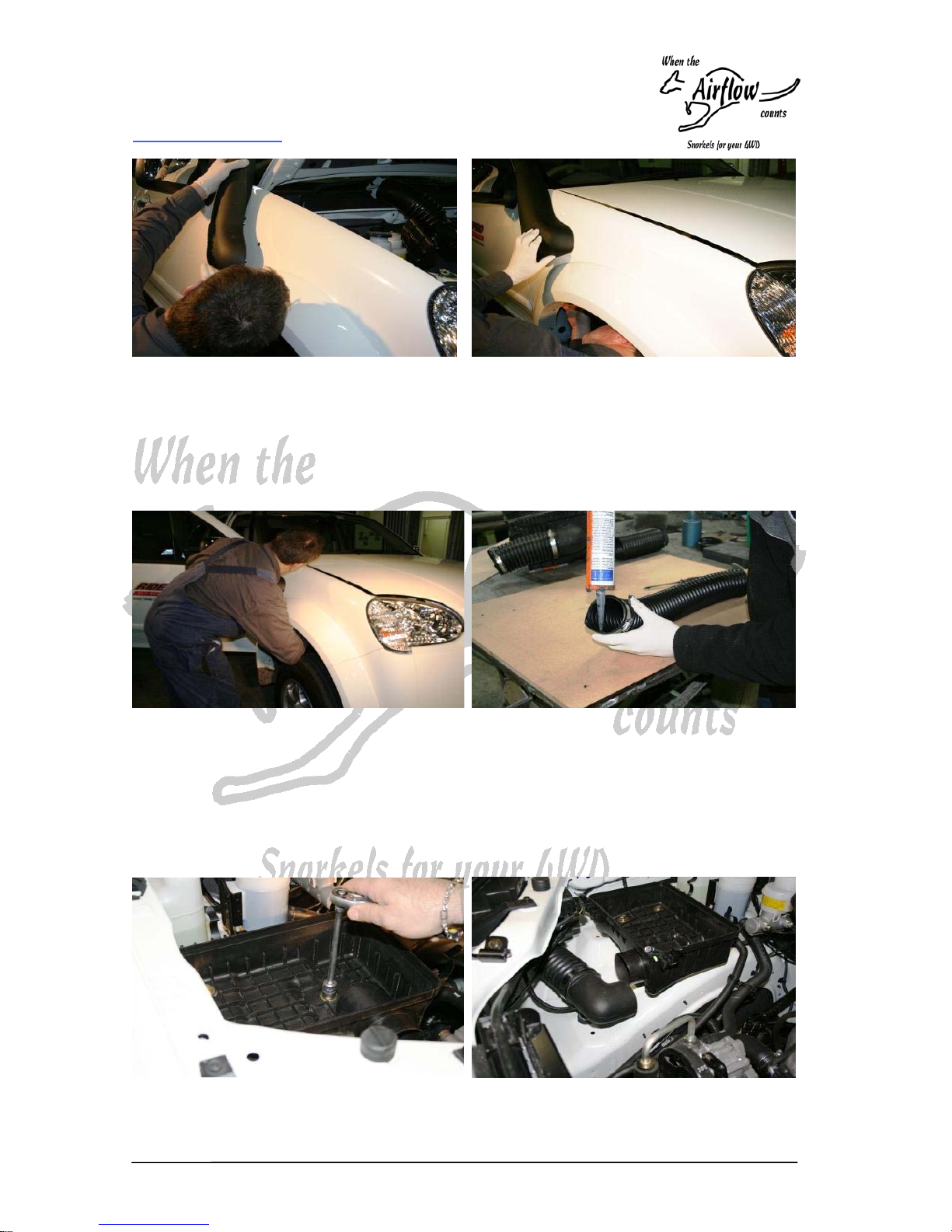

1.1 General instructions

Follow carefully the instructions listed on these pages and use the template

provided, do not over tighten bolts. Do not use silicone on any connections,

use mastic.

Ensure that safe work practices are followed when installing your Airflow

Snorkel. Protective ear and eye wear should be worn at all times when using

power tools.

1.2 Disclaimer

It is highly recommended that installation is undertaken by a qualified

mechanic or panel beater. Airflow Vector will not be held responsible for any

damage incurred through incorrect fitment of the templates and workmanship.

It is the responsibility of the fitter to ensure that particular care is taken when

assembling the Snorkel kit to the vehicle as it may cause damage to the

windscreen and or electrical components. Safe work practices must be used at

all times when undergoing installation.

We guarantee Airflow Vector’s kits against manufacturing defects as long as

proof of purchase can be established.

All models produced by Airflow Vector are verified to suit right hand drive

vehicles according to Australian specifications. Variations in vehicle

specifications may occur in other markets.

If you're in doubt about the product suitability, please forward a photograph of

the engine bay, air filter housing and of the vehicle at frontal/side position to